DOI: 10.11817/j.issn.1672-7207.2020.02.002

自结炉衬电熔窑调质过程数值模拟

宋锐,苏福永,温治

(北京科技大学 能源与环境工程学院,北京,100083)

摘要:建立电炉窑内炉渣调质过程的电磁场和温度场数学模型,利用ANSYS有限元软件分析自结炉壁结渣过程,考虑电极柱插入深度对系统电流密度、磁感应强度、焦耳热、温度和熔池深度的影响,并分析不同电极插入深度下熔池形状。研究结果表明:随着电极柱插入深度增加,电流在渣池中流经区域增加,系统的等效电阻增加,电流减小,系统温度极值减小,实际熔融区域增加,有利于调质过程的进行;由于熔池中焦耳热减小,自结炉衬厚度逐渐增大,且最大自结炉衬厚度与最小自结炉衬厚度差值逐渐增大;熔池形状同时受电极柱产生的焦耳热以及水冷壁温度的影响,由于底端离电极较远,电极柱影响较小,温度梯度较大,熔池深度较深;随着电极柱插入深度增加,结渣高度和凝固区高度逐渐减小。

关键词:电熔窑;调质过程;自结炉壁;数值模拟

中图分类号:TF806 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)02-0287-07

Numerical simulation on qualification process of self-jointing wall electric furnace

SONG Rui, SU Fuyong, WEN Zhi

(School of Energy and Environmental Engineering, University of Science and Technology Beijing,Beijing 100083, China)

Abstract: The mathematical model of electromagnetic field and temperature field of slag tempering process in electric furnace was established. Slagging process of the self-jointing furnace wall was analyzed by ANSYS finite element software. The effects of insertion depth of electrode column on current density, magnetic induction intensity, Joule heat, temperature and bath depth were considered, and the shape of molten pool at different insertion depths of electrode was also analyzed. The results show that with the increase of the insertion depth of the electrode column, the current flowing through the slag pool increases, and the equivalent resistance of the system increases. With the increase of slag layer thickness, the system extreme temperature decreases and the actual melting area increases, which is conducive to the quenching and tempering process. The thickness of the self-made furnace lining increases gradually due to the reduction of Joule heat in the molten pool, and the difference between the maximum and the minimum self-jointing furnace lining thicknesses increases gradually. The shape of the molten pool is affected by the Joule heat produced by the electrode column and the temperature of the water-cooled wall at the same time. Because the bottom is far away from the electrode, the influence of the electrode column is small, the temperature gradient is large, and the depth of the molten pool is deep. With the increase of electrode column insertion depth, the slagging height and the height of the solidification area decrease gradually.

Key words: electric furnace; qualification process; self-jointing furnace wall; numerical simulation

随着我国钢铁产业的发展,固体废弃物排放越来越多,对于其资源化利用的需求也日益迫切。将炼钢产生的高炉渣作为炼制微晶玻璃的原材料,既能充分利用炼钢产生的余热,也能实现废物资源化利用,减少环境污染[1-3]。但传统的电熔窑调质方式存在一定缺陷:传统电熔窑内壁材料为耐火砖,在高温下会改变熔渣成分,降低微晶玻璃质量。因此,本文创新性地提出用熔渣自结炉衬的形式代替耐火砖,保护外侧金属炉壳。在电熔窑研究方面,因为炉渣熔化过程的高温特性,对其进行实验研究非常困难,所以,国内外学者大多采用数值模拟进行研究。KHARICHA等[4]运用VOF模型描述了渣/池界面,在电流随时间变化情况下构建了炉渣和金属分布的动态模型。王子坤[5]以非稳态方式模拟了双电极串联、三相三电极以及三相六电极下电磁场、焦耳热场和温度场。苗志奇等[6]通过计算得到了电渣重熔过程中不同电极插入深度、渣量以及炉渣电导率所对应的电阻,建立了工业电渣重熔过程数学模型。WANG等[7]采用多相耦合的MHD方法研究了炉渣在交流电流作用下的熔融及运动过程。YU等[8]通过动态网格技术描述了熔渣流动过程,研究了电渣重熔过程中热流分布及渣层的动态形成过程。KELKAR等[9-11]建立了柱形锭瞬态电渣重熔过程数学模型,分析了炉渣在电极柱附近熔融及结晶壁附近凝固过程。REN等[12-15]探究了三电极系统的电渣重熔过程,发现与单电极系统相比,三电极的渣池中的热源更加分散。前人对于多电极系统的研究集中在多物理场耦合下各场量分布[16-19],但未进一步研究电熔窑工艺参数对各场量影响。为此,本文基于电磁场和传热学的基本理论,建立自结炉衬电炉窑内炉渣熔化过程的电磁场和温度场的数学模型,利用ANSYS有限元软件分析系统的电磁场,得到炉渣熔化过程中的电流密度和焦耳热分布,利用有限元耦合计算得到系统的温度分布及自结炉衬自结炉衬厚度变化规律;此外,还讨论电极柱插入深度对系统电流密度、磁感应强度、焦耳热、温度和自结炉衬厚度的影响。

1 数学模型的建立

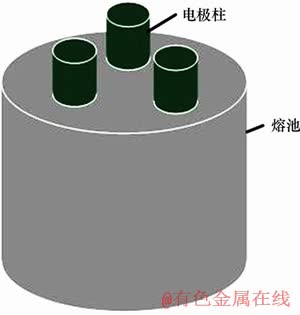

高炉渣作为制备微晶玻璃原料前,需要在自结炉衬电熔窑中熔融,同时在液态炉渣中加入硅砂、纯碱等物质进行调质。自结炉衬电熔窑金属炉壳外壁采用循环水冷却,金属炉壳内壁通过炉渣的凝固形成保护炉衬。熔融过程使用交流电,电极插入熔渣中,并通过短网与结晶器底部相连,此时,电极、液态熔渣、凝固区、固态熔渣、结晶器、短网和变压器构成完整回路。外加电流流过渣池产生大量的焦耳热熔化炉渣,整个流程包含熔化、精炼和凝固过程,还伴随着电磁场、温度场和流场等物理场的综合作用。自结炉衬电熔窑物理模型如图1所示。

炉渣调质过程中电磁场、温度场和流场相互作用,对渣池内熔渣换热过程影响较复杂。为了简化计算,本研究进行如下假设:1) 熔渣和金属热物性参数视为常数且各向同性;2) 由于加入调质用溶质量较少,忽略其对电磁场及温度场影响;3) 电极和炉渣导磁率等同于真空导磁率;4) 炉渣调质过程处于准稳态,忽略熔池流动对电磁场的影响。

图1 自结炉衬电熔窑物理模型

Fig. 1 Physical model of self-jionting furnace lining electric furnace

1.1 电磁场模型

描述电磁场的基本方程为Maxwell方程组:

(1)

(1)

式中: 为磁场强度矢量,A/m;

为磁场强度矢量,A/m; 为总电流密度矢量,A/m2;

为总电流密度矢量,A/m2; 为电通密度矢量,A/m2;t为时间,s;

为电通密度矢量,A/m2;t为时间,s; 为洛伦兹力,N;

为洛伦兹力,N; 为磁通密度矢量,T;

为磁通密度矢量,T; 为电场强度矢量,V;

为电场强度矢量,V; 为发热密度,W/m3。

为发热密度,W/m3。

1.2 温度场模型

电熔炉系统主要由钼电极、渣池和结晶壁组成,各部分之间相互传热,可用热传导控制方程表示

(2)

(2)

式中:ρ为材料密度,kg/m3;cp为材料比热容,J/(kg·K);T为温度,℃;λ为热导率,W/(m·K);ξ为等效比热容,J/(kg·K);r为半径方向距离,m;φ为熔池周向弧度,rad;Z为熔池高度方向距离,m;q为内热源,J/m3。

炉渣结晶壁上凝固传热控制方程为

(3)

(3)

式中:keff为有效导热系数,W/(m·K)。

渣池表面辐射边界条件为

(4)

(4)

式中:σ为渣池表面黑度,取0.8;Tamb为环境温度,℃;ε为辐射角系数。

渣池与结晶壁对流传热边界条件,

(5)

(5)

式中:h为换热系数,W/(m2·K);Tw为冷却水温度,℃。

1.3 模型计算参数

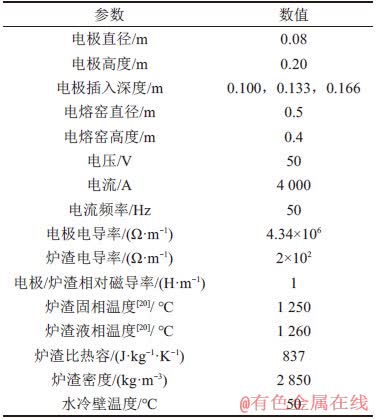

自结炉衬电熔炉系统的具体操作参数如表1所示。热力学边界条件为设定电极柱温度为300 ℃,渣池表面发射率为0.8,环境温度为20 ℃,设定初始熔渣状态为液态且温度为1 300 ℃。

表1 模型所用参数

Table 1 Parameters used in the model

2 模拟结果

2.1 电磁场及温度场

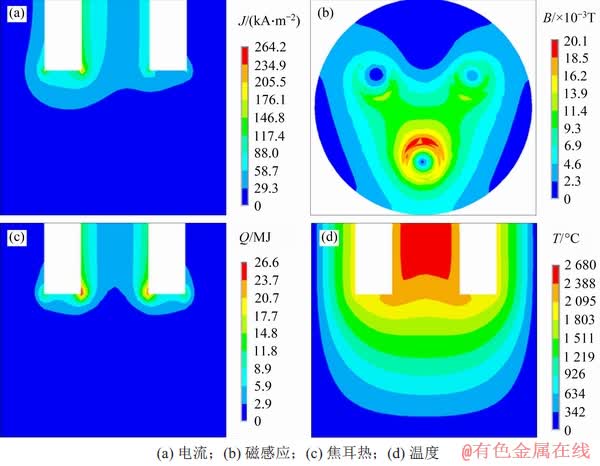

在电极柱插入深度为0.133 m时,渣池中电流、磁感应、焦耳热和温度场分布如图2所示。由图2可知:电极柱之间电流较大,最大电流出现在底端尖头处,磁感应强度分布与电流强度分布对应,电极内侧磁感应强度较大,且下方电极柱由于电流密度更大,其磁感应强度更强;渣池中焦耳热主要集中与3根电极之间,且最大焦耳热位于电极柱下端尖头处;虽然焦耳热是温度场产生的基础,但两者云图存在一定差异,在焦耳热分布云图中,最大焦耳热值在电极柱下端尖头处,但在温度场分布中最大温度值出现在渣池中心,这是由于液态炉渣的流动性较好,电极柱附近产生的热量能够很快传递出去,因此,最大焦耳热值产生于渣池中心3根电极柱之间。

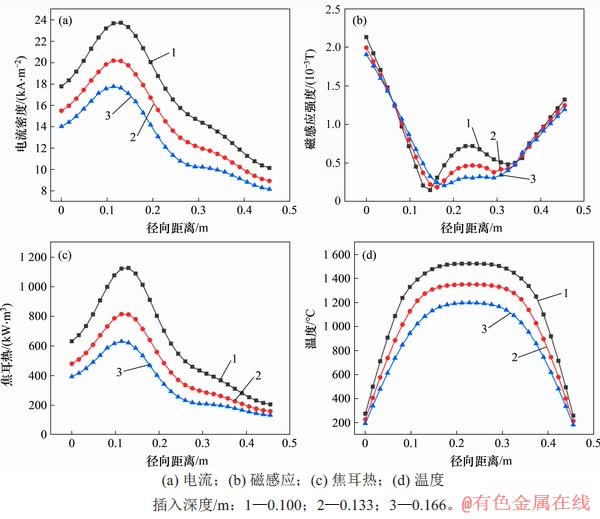

在电极柱插入深度为分别为0.100,0.133和0.166 m时,渣池中的最大电流分别为321.7,264.2和193.7 kA/m2,最大磁感应强度分别为2.16×10-2,2.01×10-2和0.189×10-2 T,渣池中的最大焦耳热分别为3.92×107,3.66×107和1.9×107 J,渣池中最高温度分别为3 260,2 680和2 312 ℃。随着电极柱插入深度增加,渣池中电流逐渐减小,相应的焦耳热分布也减小,高温区域增加,渣池中温度极值降低。这是由于系统中电流路径分别为通过电极柱侧面达到渣池及通过电极柱底端到达渣池,系统等效电阻为这2种路径电阻并联值,随着电极柱插入深度增加,通过电极侧面电流经区域增加电阻增加,通过电极柱底端流经区不变,电阻不变,因此,其电阻串联值增加,系统电流分布减小。虽然局部焦耳热减小且温度极值降低,但产热区域增加,熔池中温度更加均匀,有利于调质过程的进行。因此,在实际生产中,在保证加热效果的情况下,可增加电极柱插入深度从而增大高温区域,提高调质效果。

不同电极柱插入深度下渣池中距电极柱底端0.08 m处主要场量分布图如图3所示。由图3可见:由于渣池电阻较小,不存在趋肤效应,渣池中电流分布主要受到电极柱的影响。由于左侧电极柱输入电流较大,其电流分布呈现左侧高于右侧,且电极柱正下方出现电流陡增的趋势,磁感应强度分布呈两端高中间低的趋势,且由于电极柱的影响在电极柱其下方出现陡降,焦耳热分布呈现左侧高于右侧且在电极柱下方出现陡增的趋势,温度分布两端低中间高的趋势;随着插入深度增加,渣池的等效电阻增加,渣池中电流分布逐渐减小,渣池中磁感应强度降低,且电极柱下方磁感应强度陡增趋势减弱,电极柱下方焦耳热陡增趋势减小,温度随之降低;电极柱插入深度每增加0.033 m,电流、磁感应强度、焦耳热和温度分别降低16.5%,6.8%,31.3%和10.3%。

图2 主要场量分布云图

Fig. 2 Distribution nephograms of main field quantities

2.2 自结炉衬厚度

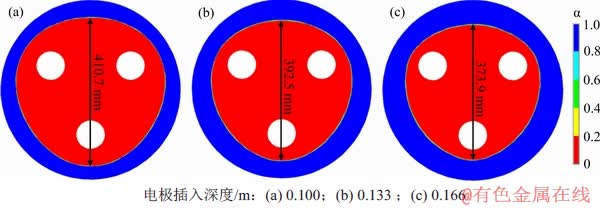

不同电极插入深度下熔池形状横截面云图如图4所示,不同电极柱插入深度下最大及最小自结炉衬厚度如表2所示。由图4和表2可见:随着电极插入深度增加,由于熔池中焦耳热减小,自结炉衬厚度逐渐增大,且最大自结炉衬厚度与最小自结炉衬厚度差值逐渐增大。

图3 主要场量分布云曲线

Fig. 3 Cloud curves of main field distribution

图4 不同电极插入深度下熔池形状横截面云图

Fig. 4 Shapes of molten pool (cross section) at different electrode insertion depths

表2 自结炉衬厚度

Table 2 Thickness of self-jointing wall

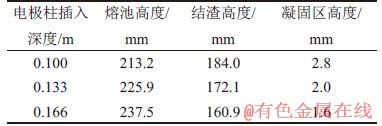

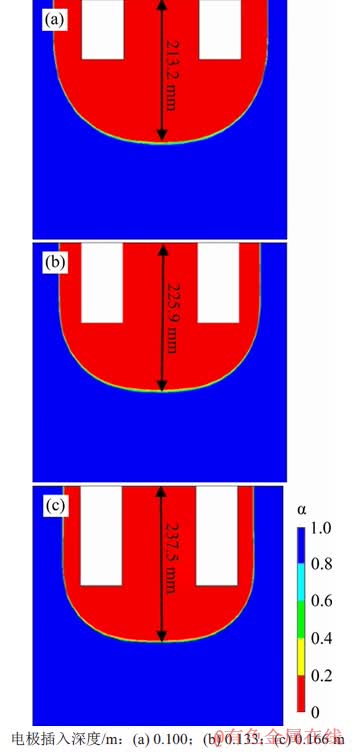

不同电极插入深度下熔池形状纵截面云图如图5所示,由图5可见:熔池形状与温度场云图对应,由于固相温度线为1 250 ℃,液相温度线为1 260 ℃,温度相差较小,凝固区范围较小。表3所示为电极柱插入深度对熔池、结渣层及凝固区高度的影响,由表3可见:熔池高度随电极插入深度增加而增加,结渣高度随电极插入深度增加而减小,凝固区高度随电极插入深度增加而减小。熔池形状同时受电极柱产生的焦耳热以及水冷壁温度的影响,由于底端离电极较远,电极柱影响较小,温度梯度较大。由图5可见熔池深度较深,这是由于主要产热区域为电极柱底端尖头处。随着电极柱插入深度增加,结渣高度和凝固区高度逐渐减小。

表3 电极柱插入深度对熔池、结渣层及凝固区高度的影响

Table 3 Influence of insertion depth of electrode column on height of molten pool, slag and solidification zone

图5 不同电极插入深度下熔池形状纵截面云图

Fig. 5 Shapes of molten pool (longitudinal section) at different electrode insertion depths

3 结论

1) 渣池电阻较大,不存在趋肤效应。渣池中电流的流动路径为电极柱侧表面及电极柱底端,其中底端流出的电流大于侧表面流出的电流。受电极柱影响,在电极柱下方会出现电流陡增现象。渣池中磁感应强度与电流对应,随着距圆心距离增大而增大,且随深度增加而减小。

2) 渣池中温度呈现两端低中间高的趋势,且随渣池深度降低而减小。渣池中焦耳热位于电极柱内侧底端尖头处,但最大温度位于渣池中心。这是由于液态炉渣的流动性较好,换热效果较强,在电极柱尖头处产生的热量被很快带走。

3) 随着电极柱插入深度增加,电流在渣池中流经区域增加,系统的等效电阻增加,系统温度极值减小,实际熔融区域增加,有利于调质过程的进行。

参考文献:

[1] KANG Junfeng, CHENG Jinshu, WANG Jing, et al. Preparation and properties of CaO-MgO-Al2O3-SiO2 glass-ceramics from granite wastes[J]. Materials Science Forum, 2017, 890: 312-316.

[2] FRANCIS A, VILMINOT S. Crystallisation kinetics of mullite glass-ceramics obtained from alumina–silica wastes[J]. International Journal of Sustainable Engineering, 2013, 6(1): 74-81.

[3] QIN Shouwan, SHEN Jianjun, WANG Huifen, et al. Utilization of blast furnace slag, steel slag in the production of clinker[J]. Materials Science Forum, 2013, 743/744: 334-338.

[4] KHARICHA A, SCHUTZENHOFER W, LUDWIG A, et al. Influence of the slag/pool interface on the solidification in an electro-slag remelting process[J]. Materials Science Forum, 2010, 649: 229-236.

[5] 王子坤. 非稳态电渣重熔过程电磁场与温度场的研究[D]. 沈阳: 东北大学材料与冶金学院, 2014: 19-26.

WANG Zikun. Transient study of electromagnetic and temperature field in ESR system[D]. Shenyang: Northeastern University. School of Materials and Metallurgy, 2014: 19-26.

[6] 苗志奇, 成国光, 李世健, 等. 工业电渣重熔过程电极插入深度数学模型及应用[J]. 钢铁, 2018,53(9): 25-29.

MIAO Zhi-qi CHENG Guo-guang LI Shijian, et al. Mathematical model of electrode immersing depth in industrial electroslag remelting process and application[J]. Iron & Steel, 2018,53(9): 25-29.

[7] WANG Qiang, HE Zhu, LI Baokuan. Modeling of magnetohydrodynamic, thermal and solidified behavior in electroslag remelting process[M]//EPD Congress 2014. Hoboken, NJ, USA: John Wiley & Sons Inc, 2014: 409-415.

[8] YU Jia, LIU Fubin, JIANG Zhouhua, et al. Numerical simulation of the dynamic formation of slag skin and heat flow distribution during the electroslag remelting process[J]. Steel Research International, 2018, 89(5): 1700481.

[9] KELKAR K M, PATANKAR S V, SRIVATSA S K, et al. Computational modeling of electroslag remelting (ESR) process used for the production of high-performance alloys[M]//Proceedings of the 2013 International Symposium on Liquid Metal Processing & Casting. Cham: Springer International Publishing, 2013: 3-12.

[10] SCHOLER A, LOTHENBACH B, WINNEFELD F, et al. Hydration of quaternary Portland cement blends containing blast-furnace slag, siliceous fly ash and limestone powder[J]. Cement and Concrete Composites, 2015, 55: 374-382.

[11] NGUYEN T C, LOGANATHAN P, NGUYEN T V, et al. Adsorptive removal of five heavy metals from water using blast furnace slag and fly ash[J]. Environmental Science and Pollution Research, 2018, 25(21): 20430-20438.

[12] REN N, LI B K, LI L M, et al. Numerical investigation on the fluid flow and heat transfer in electroslag remelting furnace with triple-electrode[J]. Ironmaking & Steelmaking, 2018, 45(2): 125-134.

[13] KARIMI-SIBAKI E, KHARICHA A, BOHACEK J, et al. On validity of axisymmetric assumption for modeling an industrial scale electroslag remelting process[J]. Advanced Engineering Materials, 2016, 18(2): 224-230.

[14] WANG Qiang, CAI Hui, PAN Liping, et al. Numerical investigation of influence of electrode immersion depth on heat transfer and fluid flow in electroslag remelting process[J]. The Journal of Minerals, Metals & Materials Society, 2016, 68(12): 3143-3149.

[15] HUANG Xuechi, LI Baokuan, LIU Zhongqiu, et al. Numerical investigation and experimental validation of motion and distribution of nonmetallic inclusions in argon protection electroslag remelting process[J]. Metals, 2018, 8(6): 392.

[16] KELKAR K M, O’CONNELL C J. A computational model of the electroslag remelting (ESR) process and its application to an industrial process for a large diameter superalloy ingot[C]//Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications. Cham: Springer International Publishing, 2018: 243-261.

[17] WANG Zhen, FU You, WANG Ninghui, et al. 3D numerical simulation of electrical arc furnaces for the MgO production[J]. Journal of Materials Processing Technology, 2014, 214(11): 2284-2291.

[18] KARALIS K T, KARKALOS N, CHEIMARIOS N, et al. A CFD analysis of slag properties, electrode shape and immersion depth effects on electric submerged arc furnace heating in ferronickel processing[J]. Applied Mathematical Modelling, 2016, 40(21/22): 9052-9066.

[19] GENG Xin, JIANG Zhouhua, LI Wanming, et al. Numerical simulation of thermal characteristics in the process of electroslag remelting for production of large slab ingots[J]. Journal of Iron and Steel Research(International), 2012, 19(S1): 149-152.

[20] XIE Dongsheng, Jahanshahi S, Norgate T. Dry granulation to provide a sustainable option for slag treatment[C]//Sustainable Mining Conference, Kalgoorlie, Australia. 2010: 22-28.

(编辑 秦明阳)

收稿日期: 2019 -09 -06; 修回日期: 2019 -11 -11

基金项目(Foundation item):国家重点研发计划项目(2018YFB0605900) (Project(2018YFB0605900) supported by National Key Research & Development Program of China)

通信作者:苏福永,副教授,从事冶金化工炉窑模型及优化控制研究;E-mail:sfyong@ustb.edu.cn