文章编号: 1004-0609(2005)12-2060-06

分解过程氢氧化铝产品粒度变化机理及规律

吴玉胜1, 毕诗文1, 李文成2, 杨志华2

(1. 东北大学 材料与冶金学院, 沈阳 110004; 2. 中国铝业公司 山东分公司研究院, 淄博 255052)

摘 要: 在拜耳法氧化铝生产中粒度依然存在着周期性细化现象, 严重影响到拜耳法系统的正常运行。 为了解决周期性爆发性细化问题, 模拟工业条件对种分过程产品的周期性细化进行研究。 结果表明: 产品氢氧化铝粒度变化的周期随温度的升高而缩短, 随晶种量的增加而延长; 粒度波动的振幅随温度的升高而减小, 随晶种加入量的增加而增大; 在其它条件基本不变的情况下, 用于分解的晶种粒度分布出现断层造成其分布不平衡, 特别是细粒子减少, 粗粒子增多, 导致种子的比表面积变小, 以至于分解后期种子的比表面积小于某一临界值, 从而导致产品粒度的爆发性细化。 在此基础上对产品粒度周期性细化的机理做了进一步的探讨。

关键词: 氢氧化铝; 周期性细化; 粒度分布; 比表面积; 晶种分解 中图分类号: TF803.22

文献标识码: A

Mechanism and rule of Al(OH)3 particles variation in seed precipitation

WU Yu-sheng1, BI Shi-wen1, LI Wen-cheng2, YANG Zhi-hua2

(1. School of Materials and Metallurgy,

Northeastern University, Shenyang 110004, China;

2. Research Institute of Shandong Aluminum Co. Ltd.,

China Aluminum Co. Ltd., Zibo 255052, China)

Abstract: Periodical attenuation of particles, which interferes seriously with the normal alumina production of Bayer method, exists in the alumina production process of Bayer method. In order to solve this problem, the reasons of the periodical attenuation of particle size were analyzed by simulating the real production. The results show that the period of Al(OH)3 particle size variation shortens with rising of temperature and lengthens with increasing of solid content, and that the amplitude of the particle size fluctuation reduces with rising of temperature and enhances with increasing of solid content. Unbalance of particle size distribution, that the particles become gradually bigger, induces the specific surface area of seeds smaller, which is the major factor causing explosive attenuation of seed precipitation. The mechanism of particles periodically explosive attenuating was also studied.

Key words: aluminate hydroxide; periodically attenuating; particle distribution; specific surface area; seed precipitation

随着对环保要求的日益严格以及大型预焙电解槽的广泛应用, 具有颗粒均匀粗大、 较好的流动性、 良好的熔盐溶解性能、 优越的干法吸附性等诸多优点的砂状氧化铝更加受到青睐。 近年来, 氧化铝界的科研单位和企业做了大量的工作。 目前, 氧化铝的粒度和强度等均有了很大的改善, 但我国拜耳法氧化铝的粒度控制, 仍然没有摆脱周期性细化的干扰[1-3]。 在粒度细化期间, 立盘及平盘过滤机状况恶化, 产能大幅度下降, 焙烧炉电收尘负荷加大, 出口含尘升高, 事故频繁, 严重影响到拜耳法系统的正常运行。 由于粒度变化的微观性, 人们对产品氢氧化铝粒度的变化过程和控制过程众说不一。 本文作者针对这一问题, 在实验室模拟工业条件考查了温度、 晶种数量、 种子粒度及种子比表面积对周期性细化的影响。

1 实验

1.1 实验条件

分解用铝酸钠精液取自某拜耳法生产现场, 氧化铝质量浓度为150~165g/L, 铝酸钠溶液的分子比αK=1.43~1.6, 分解时间为40h。 实验采用循环分解: 每次实验所用溶液均为工业铝酸钠溶液, 实验结束取后部分产品氢氧化铝作为下一轮分解的晶种。 分解用分解槽为威海自控反应釜有限公司生产的容积为7.5L的程控搅拌式分解槽, 搅拌转速为150r/min。

1.2 实验方法

采用MASTERSIZER 2000激光粒度分析仪(英国MARVERN公司制造)分析颗粒的分布。 粒度的平均粒径定义为: 随粒度的增大, 其对应粒度的质量百分含量增加, 当累计百分含量增至50%时, 其对应的粒度即为平均粒径。 采用岛津 SSX-550 型扫描电镜分析产品的结晶形貌。

2 结果与分析

2.1 分解温度对周期性细化的影响

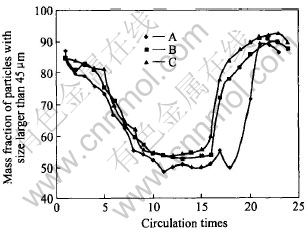

本实验所用降温制度如表1所示, 晶种加入量为600g/L。 不同分解温度制度对周期性细化的影响如图1所示。

从图1看到, 升高初始分解温度可以延缓产生爆发性细化的时间, 减弱周期性波动的振幅, 但并不能从根本上消除粒度的周期性细化现象。 另一方面, 升高温度却降低了溶液分解率, 分解率的平均值从52%降到46%。 这是因为温度对分解的影响具有两重性。 温度低可以提高分解率, 但温度低铝酸钠溶液的过饱和度增大, 分解速度快, 如果没有足够的用于分解的种子表面积, 容易发生二次成核(二次成核是相对于溶液中自发生成新晶核的一次成核过程而言, 它是在原始溶液过饱和度高而晶种表面积小的条件下产生新晶核的过程, 所形成的晶核称为二次晶核[4-6]), 从而造成产物粒度细化。 分解温度高能抑制二次成核, 促进附聚的进行(所谓附聚, 就是在范德华力、 自粘力、 附着力等力的作用下, 微粒物质自发和定向地连接在一起的现象[7, 8]), 但提高温度使溶液的过饱和度降低, 减缓分解的速度, 降低分解率。 因此, 单纯的升高温度来抑制粒度的周期性细化是不可取的。

表1 晶种分解过程的降温制度

Table 1 Scheme of temperature dropping during seed precipitation

图1 不同温度制度对周期性细化的影响

Fig.1 Effect of different schemes of temperature on periodical attenuation

2.2 晶种加入量对周期性细化的影响

降温制度采用表1中的方式B。

图2所示为分解产品氢氧化铝的粒度变化。 从图2可以看到, 随着晶种加入量的增加, 粒度波动的周期延长。 晶种加入量大, 不但细化的时间长,细化的程度也较大。 晶种加入量少, 产生细化后粒度恢复较快。 这是由于在本次实验的分解工艺制度下, 3个试样中氢氧化铝的析出速度基本一致, 晶种量大, 种子的总表面积由于附聚、 长大而降低的速度慢, 达到产生爆发性细化临界条件的时间就长, 产生细化后, 溶液中细粒子的量较大, 大量的细粒子转变为大颗粒所需沉积在其上的氢氧化铝的量也较多, 而此时溶液不能完全提供所需要的氢氧化铝, 所以细粒子转变为大颗粒的时间长, 从而使粒度波动的周期延长; 晶种加入少的情况与此相反。

图2 不同晶种数量对周期性细化的影响

Fig.2 Effect of different amounts of Al(OH)3 on periodical attenuation

2.3 种子粒度及种子比表面积对周期性细化的影响

本次实验的晶种加入量为600g/L, 分解温度制度为表1中的方式B, 实验结果如表2所示。

上面在分析温度、 晶种加入量对周期的影响时所用的数据为粒度仪分析的质量分数, 采用质量分数从宏观上分析产品氢氧化铝粒度的变化比较合适, 但不能对粒度变化的微观现象给予很好的解释。 为了对氢氧化铝粒度的变化规律认识更加准确, 下面的粒度分析采用个数分数。 由表2可知, 在分解的过程中, 粒度分布出现严重的不平衡现象。 在实验开始的第二轮, 产生的粒径小于5μm的颗粒的个数百分含量就高达79.89%, 粒径小于15μm的颗粒的个数百分含量也在96%左右, 从粒度的个数百分含量反映出生成一茬次生晶核的数量很多。 在附聚、 长大等作用下, 实验进行到第4轮结束时, 颗粒粒径小于5μm的个数百分数已减少为零, 但此时5~15μm粒径之间的粒子的个数百分含量竟高达80%, 这说明在周期性变化的过程中, 晶体的长大属于群体式生长。 随着分解的进行, 由于没有更细一级的粒子补充进来, 晶种的整体粒度变得越来越大, 当粒径小于25μm颗粒的个数百分含量不到0.1%, 粒径小于30μm颗粒的个数百分含量不到10%时, 很快就产生了第二次的爆发性细化。

另外, 从表2中还可看出, 晶种的比表面积在产生爆发性细化后开始增大, 增大到最大值后又开始减小, 到产生第二次爆发性细化的前一轮, 其比表面积已减小到最小值, 而在分解的其它时间, 晶种的比表面积都比细化前要大, 说明用于分解的晶种的比表面积小于某一临界数值是产生爆发性细化的重要原因。 其原因可能是: 在用于分解的晶种量不变的情况下, 当晶种的比表面积较小时, 用于分解的种子的总的表面积就会很小, 而此时溶液的过饱和度很大, 这样从溶液中析出的Al(OH)3很容易在晶种的表面形成大量的枝晶和吸附层[9-11]。 这些枝晶和吸附层在随后的分解过程中会在碰撞、 磨损等因素的影响下突然破碎和脱落, 从而产生大量的二次晶核。

综上分析, 在其它条件基本不变的情况下, 由于分解的晶种粒度分布发生断层造成其分布不平衡, 特别是细粒子减少, 粗粒子增多, 导致种子的比表面积减小, 在分解后期氢氧化铝颗粒的比表面积小于某一临界值时, 就将产生爆发性细化。

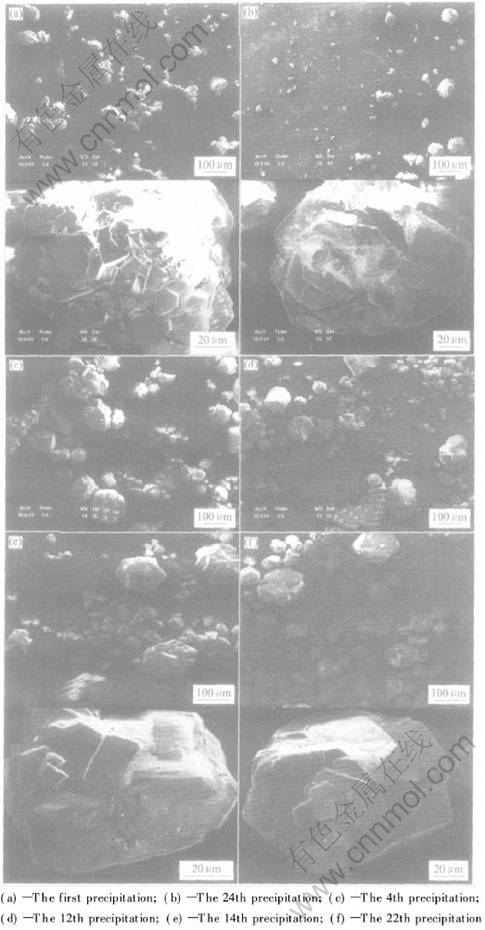

2.4 晶体形貌在分解过程中的变化

为了对颗粒在整个周期中的变化过程有更进一步的认识, 我们对分解过程中不同阶段产品氢氧化铝的结晶形貌进行了观察(分析用样品为2.3节中的产品), 颗粒的电镜照片如图3所示。 从图3可以看到, 分解第2轮和第24轮(两极分化期)的产品粒度呈两极分化, 细粒子大多为片状或柱状结构, 粗颗粒表面结晶完整, 形状浑圆, 仔细观察, 在大颗粒的表面上粘有很多微细粒子, 尤其在晶面的台阶交界处, 微细颗粒的数量更多, 说明此时二次成核还没结束。 分解进行到第4轮(细化初期), 大颗粒表面光滑, 微细颗粒的数量已大大减少, 这和前面分析的在分解到第4轮二次成核结束, 微细颗粒开始快速附聚相吻合。 颗粒的群体式生长方式在第12轮(细化加剧期)和第14轮(粗化初期)的图片中得到进一步的体现, 此时的颗粒粒径主要在15~25μm之间, 且颗粒多为以附聚体为基体的镶嵌式结构, 晶体表面凹凸不平, 有很多的棱角和表面缺陷。 从第22轮的图片(细化前)中发现经过长时间的长大, 颗粒又变得很粗大, 晶体的结构也由原来的镶嵌式结构转变为径向和单晶体结构, 晶体表面光滑, 结晶完整, 原来的台阶面、 棱角、 晶面缺陷也几乎被新析出的氢氧化铝填平, 从扫描电镜下很难发现微细粒子的存在。

表2 氢氧化铝粒度分布(个数)和比表面积变化

Table 2 Particle size distribution and specific surface area of Al(OH)3

总之, 从整个周期中不同阶段的产品氢氧化铝的结晶形貌图片可以看到, 在粒度的细化加剧期和粗化前期, 晶体颗粒小, 主要为镶嵌式结构, 晶体表面凹凸不平, 棱角、 褶皱、 台阶面和表面缺陷很多。 在这种情况下几乎没有微细晶粒存在, 晶体表面也很难发现粘附的微细晶粒, 此时的晶种活性很大, 这一点从溶液的分解率可以得到验证(分解率高于其它时间的分解率)。 而在粒度的两极分化期和细化前的照片中, 粗颗粒大都外形浑圆, 多为径向和单晶体结构, 晶体表面光滑, 缺陷少。 由此进一步说明由结晶长大而形成的大颗粒表面结晶完整, 致使其比表面积小于某一临界值是产生大量二次成核的主要原因。

2.5 周期性爆发性细化的机理分析

铝酸钠溶液与氢氧化铝晶体之间的界面张力高达1.25N·m[12], 因而在分解过程中氢氧化铝晶核难于自发生成, 必须从外界加入现成的晶种, 给分解反应提供足够的表面积才能促进氢氧化铝结晶析出。 由于铝酸钠溶液晶种分解是从晶种表面开始的, 所以晶种的粒度分布、 表面结构决定着分解的进行, 但并不是所有的表面积都起作用, 只有晶种表面上的微观缺陷、 晶体的棱和角是活性点。

为了更好地模拟工业生产, 实验中用于分解的种子为上一轮分解的产品, 未采取分级措施。 在这种条件下进行分解, 溶液中产生的大量微细粒子生长缓慢。 从前面的分析看到, 溶液中一次性产生细颗粒的数量很多, 小于5μm粒子的个数百分含量高达80%, 这些细颗粒在粒径小于15μm时发生显著的附聚, 在粒径大于15μm时附聚就变得很弱, 主要以长大为主。 在分解过程中, 由于长大很慢, 每天仅1μm左右, 所以这些大量的细颗粒向较大颗粒转变的过程中, 就会导致粒径大于45μm(筛分)颗粒在分解的过程中呈现弦波式变化。

图3 分解不同阶段氢氧化铝颗粒的SEM照片

Fig.3 SEM photographs of Al(OH)3 in various periods of seed precipitation

随着分解的进行, 开始产生的细颗粒越长越大, 晶体的结晶也越来越完善, 这些结构比较完善的粗颗粒表面上的活性点很少, 但粗颗粒占有的比例很大。 活性中心具有较高的能量, 铝酸阴离子首先被吸附在这些活性点上, 此时吸附活化能最小, 这样就可能出现两种现象: 1) 晶体表面的活性点少, 在溶液过饱和度大, 晶种较粗且数量较少的情况下, 从溶液中析出的Al(OH)3易在较少的活性点上产生枝晶, 这些枝晶会在磨蚀、 碰撞等条件下脱落, 从而产生大量二次晶核; 2) 在溶液过饱和度大, 温度低, 晶种较粗而且数量较少的条件下, 铝酸阴离子吸附到晶种表面要比它们循序的重新排列成晶格要快, 因而在结晶表面上形成只经过重排的溶质群, 过量的溶质在这些地方继续析出而形成二次晶核(即吸附层的脱落)。

以上两种主要机理的发生使得分解过程中出现了周期性爆发性细化现象。

3 结论

1) 分解温度和晶种数量只能影响粒度周期性变化的周期和粒度波动的振幅, 但并不是粒度产生周期性爆发性细化的主要原因。

2) 在分解过程中, 在其它条件基本不变的情况下, 用于分解的晶种粒度分布出现断层。 晶种的整体粒度由于不断地长大变粗, 致使分解一定时间后晶种的比表面积小于某一临界值, 是导致产生爆发性细化的主要原因。

3) 产生周期性细化的原因是分解后期处于同一粒级上的大颗粒比较多, 且大颗粒晶体表面光滑, 结晶比较完善, 活性点少, 致使一次性产生二次晶核的数量较多, 产生大量的细粒子。 而晶体的生长缓慢, 在没有采取有效措施的情况下, 粒子的群体式长大在宏观上出现弦波式变化。

REFERENCES

[1]张存兵, 赵萍. 拜耳法种分氢氧化铝粒度“两极分化”的探讨[J]. 轻金属, 1999(9): 17-19.

ZHANG Cun-bing, ZHAO Ping. Study on polarizing particle size of aluminate hydroxide in Bayer process[J]. Light Metals, 1999(9): 17-19.

[2]张广, 杨金妮. 拜耳法种分分解过程中物料粒度变化研究[J]. 轻金属, 2002(9): 9-12.

ZHANG Guang, YANG Jin-ni. Study on particle size fluctuating of aluminate hydroxide in Bayer process[J]. Light Metals, 2002(9): 9-12.

[3]胡玉波, 甘国耀. 砂状氧化铝的粒度控制及其分析方法[J]. 有色金属(冶炼部分), 1999(6): 19-22.

HU Yu-bo, GAN Guo-yao. Controlling particles and analyzing technique of sand alumina[J]. Nonferrous Metals (Smelting), 1999(6): 19-22.

[4]Halfon A, Kaliaguine C. Alumina trihydrate crystallization. Part Ⅰ. Secondary nucleation and nucleation and growth rate kinetics[J]. The Candian Journal of Chemical Engineering, 1976, 54(3): 160-167.

[5]Rossiter D S, Fawell P D, Ilievski D, et al. Investigation of the unseeded nucleation of gibbsite Al(OH)3 from synthetic Bayer liquid[J]. Journal of Crystal Growth, 1998, 191(3): 525-536.

[6]Brown N. A quantitative study of new crystal formation in seeded causitic aluminate solutions[J]. Journal of Crystal Growth, 1975, 29(3): 309-412.

[7]Seyssiecq I, Veesler S, Mangin D, et al. Modelling gibbsite agglomeration in a constant supersaturation crystallizer[J]. Chemical Engineering Science, 200, 55(23): 5565-5778.

[8]Halfon A. Alumina trihydrate crystallization. Part 2. A model of agglomeration[J]. The Canadian Journal of Chemical Engineering, 1976, 54(6): 168-172.

[9]Randolph A D. Theory of Particulate Processes[M]. 2nd ed. New York: Academic Press, 1988.

[10]Brown N. The production of coarse mosaic aluminum trihydroxide from ball-milled seed[J]. Light Metals, 1990, 40: 73-78.

[11]Brown N. Secondary nucleation of aluminium trihydrate-kinetics and mechanism[J]. Journal of Crystal Growth, 1970, 16(1): 1-14.

[12]陈国辉, 陈启元, 尹周澜, 等. 超声强化和温度对铝酸钠溶液种分过程的影响[J]. 中国有色金属学报, 2002, 12(3): 607-610.

CHEN Guo-hui, CHEN Qi-yuan, YIN Zhou-lan, et al. Effect of ultrasound and temperature on seed precipitation of sodium aluminate liquor[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 607-610.

基金项目: 国家重点基础研究发展规划资助项目(G1999064902)

收稿日期: 2005-06-08; 修订日期: 2005-09-16

作者简介: 吴玉胜(1978-), 男, 博士研究生

通讯作者: 毕诗文, 教授; 电话: 024-83686460; E-mail: henanwys@sohu.com

(编辑袁赛前)