文章编号:1004-0609(2007)12-1922-06

固溶后预析出对7A55铝合金力学及腐蚀性能的影响

张新明,游江海,张小艳,刘胜胆,刘 瑛

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用硬度测试、电导率测试及透射电镜观察,研究固溶后降温至440 ℃预析出处理时间对7A55铝合金板材力学和腐蚀性能的影响。结果表明:随预析出处理时间的延长,基体析出相逐渐增多且长大,导致合金时效后硬度和强度先提高而后降低;晶界析出相逐渐长大,晶界无沉淀析出带宽化,晶界相不连续性先提高而后降低,导致合金抗晶间腐蚀和剥落腐蚀性能也先升高而后降低。

关键词:7A55铝合金;预析出;晶间腐蚀;剥落腐蚀

中图分类号:TG 146.1 文献标识码:A

Effect of pre-precipitation after solution on mechanical properties

and corrosion resistance of aluminium alloy 7A55

ZHANG Xin-ming, YOU Jiang-hai, ZHANG Xiao-yan, LIU Sheng-dan, LIU Ying

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The influence of pre-precipitation at 440 ℃ after solution on the mechanical properties and corrosion resistance of aluminium alloy 7A55 was investigated by hardness tests, conductivity tests and transmission electron microscopy (TEM). The results show that with increasing the pre-precipitation time, the density of the precipitates in the matrix becomes higher and then the size becomes larger. As a result the hardness and strength increase first and then decrease. At the same time, the particles at the grain boundaries become larger with wider precipitate free zone, and the discontinuity of these particles increases first and then decreases with increasing pre-precipitation time. Consequently, intergranular corrosion and exfoliation corrosion resistance increase first and then decrease.

Key words: 7A55 aluminium alloy; pre-precipitation; intergranular corrosion; exfoliation corrosion

Al-Zn-Mg-Cu合金是热处理可强化合金,其比强度高,广泛用于航空航天工业中的结构材料,如何提高该系合金的抗腐蚀性能而不降低其力学性能一直是研究的热点[1]。高强铝合金的腐蚀一般沿晶界扩展,因此晶界的化学性质对合金抗腐蚀性能的提高起着十分重要的作用。为获得抗腐蚀性能良好的7×××铝合金,国内外研究人员对该合金的时效制度进行了大量的研究[2-8],使晶界析出相由连续状态变为不连续状态,阻断合金的腐蚀通道,从而提高合金的抗腐蚀性能。近年来,人们采用先高温后低温的两步固溶处理来改善合金的抗应力腐蚀性能[9-10],但主要是研究温度变化对合金性能的影响,而对时间变化的影响研究很少。并且这种合金的应用,需提供某温度处理条件下的时间窗口。然而,有关这方面的研究相当缺乏。对于7A55合金,前期研究表明440 ℃降温预析出处理后,合金的强度降低不多,而抗腐蚀性能明显提 高[9]。为此,本文作者研究了固溶后440 ℃降温预析出处理时间对7A55铝合金板材力学性能及抗晶间腐蚀和剥落腐蚀性能的影响,并结合组织观察对其机理进行分析。

1 实验

1.1 样品制备

实验合金名义成分为(质量分数,%):Zn 8.0, Mg 2.0,Cu 2.3,Zr 0.15,余量为Al。合金在780 ℃下进行熔炼,除气静置一段时间后于720 ℃下浇入铜模,获得厚度为20 mm的铸锭。铸锭在箱式电阻炉中经465 ℃,24 h均匀化处理后空冷,铣面后在420 ℃下保温2 h,然后轧成厚度为1.7 mm的板材,轧制变形量为91.5%。取板材样品在SX-4-10型箱式电阻炉中进行450 ℃, 0.5 h+480 ℃, 0.5 h固溶,然后随炉降温至440 ℃进行预析出处理,保温时间分别为0.5、1.0、1.5、2.0、2.5、3.0、4.0、5.0和10 h,水淬,并立即在101A-3型恒温干燥箱中进行121 ℃,24 h人工时效。

1.2 性能测试及组织观察

采用HV-10B硬度计测试样品硬度,载荷为29.4 N;用7501涡流电导仪测试样品的电导率。每个样品测试3次取其平均值。

晶间腐蚀实验按照GB7998—87标准进行。试样工作面积为25 mm×15 mm,平行试样为3个。腐蚀液为NaCl 30 g/L+HCl 10 mL/L,加蒸馏水至1 L。实验时溶液体积与试样实验面积之比小于2 dm2/L,温度为(35±2)℃,浸泡时间为24 h。腐蚀产物用HNO3去除。实验结束后将悬挂端切去5 mm进行金相组织观察,并进行IGC (intergranular corrosion)等级评定。

剥落腐蚀实验按照ASTM G34—79标准进行。试样工作面积为30 mm×15 mm,非工作面用松香密封,平行试样为3个。腐蚀液为NaCl 4.0 mol/L+KNO3 0.5 mol/L+HNO3 0.1 mol/L,加蒸馏水至1 L。实验溶液体积与试样实验面积之比为20 mL/cm2,溶液温度控制在(25±3)℃,浸泡时间为48 h。浸泡过程中,根据ASTM G34—79标准判断同一样品浸泡不同时间的剥蚀情况,并采用数码相机记录样品整体形貌。实验结束后立即取出试样,作下述处理:记录形貌并拍照→按ASTM G34—79标准评定剥蚀等级→水洗→HNO3去除腐蚀产物→记录形貌并拍照。

采用XJP-6A型金相显微镜和TECNAI G2 20型透射电镜观察样品的组织。TEM观察样品先预减薄为约0.1 mm厚的薄片,并冲成d3 mm的圆片,然后在MTP-1A双喷减薄仪上进行双喷减薄。双喷液采用 30%HNO3+70%CH3OH(体积比),温度控制在-20 ℃以下。表1所示为腐蚀实验和透射样品编号。

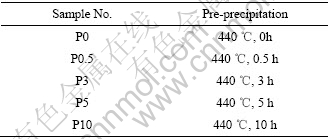

表1 实验样品编号

Table 1 Sample number of aluminium alloy 7A55

2 结果

2.1 合金的硬度及电导率

图1所示为440 ℃预析出处理时间对7A55铝合金时效后性能的影响。由图1(a)可知,随着预析出时间的延长,合金的电导率变化不大,而合金的硬度先明显提高,但1 h后提高程度不大。由此可知预析出处理时间的改变对合金的电导率影响不大,而硬度改变较明显。由图1(a)中可看出0.5、3.0、5.0和10 h这4个时间点变化比较明显,因此选取0.5、3.0、5.0及10 h分别作力学性能测试和腐蚀性能测试。图1(b)所示为合金经440 ℃预析出处理0.5、3、5及10 h且时效后的强度和伸长率曲线,由图可知随着预析出时间的延长,合金的强度和伸长率先升高而后降低,在5 h时达到最高。

图1 440 ℃预析出处理时间对时效7A55铝合金性能的影响

Fig.1 Effect of pre-precipitation time on properties of aluminium alloy 7A55 aged at 440 ℃: (a) Hardness and conductivity; (b) Strength and elongation

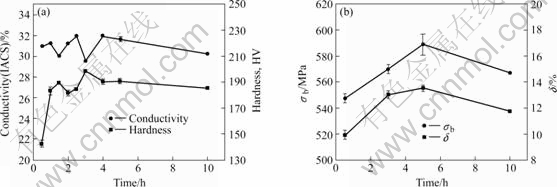

2.2 晶间腐蚀

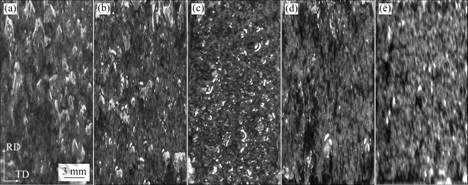

所有样品放入晶间腐蚀液后立即有气泡产生,16 h后样品P0的溶液颜色已明显变为红褐色,样品P3也有轻微改变,溶液颜色从P0.5到P3、P5逐渐加深。在腐蚀液中浸泡24 h后各个样品都发生了不同程度的晶间腐蚀。样品从溶液中取出时,可看到随预析出处理时间的延长样品表面颜色逐渐变浅。样品经硝酸清洗后,样品表面有很明显的沿轧向的腐蚀沟,而随着预析出处理时间的延长,蚀沟逐渐不明显。图2所示为预析出处理时间对合金的晶间腐蚀形貌的影响。从金相组织分析可得到各状态样品的最大腐蚀深度分别为140 μm(P0)、130 μm(P0.5)、110 μm(P3)、100 μm(P5)和110 μm(P10),等级均为3级。因此,随着预析出处理时间的延长,合金的抗晶间腐蚀性能提高,且3 h后抗晶间腐蚀性能变化不大;但时间过长时,抗晶间腐蚀性能又有轻微的下降。

图2 440 ℃预析出处理时间对7A55铝合金晶间腐蚀形貌的影响

Fig.2 Effect of pre-precipitation time on intergranular corrosion of aluminium alloy 7A55 aged at 440 ℃: (a) Sample P0; (b) Sample P0.5; (c) Sample P3; (d) Sample P5; (d) Sample P10

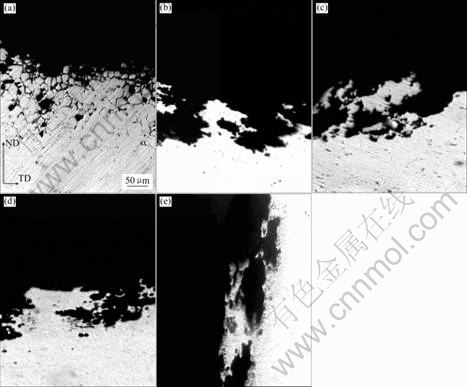

2.3 剥落腐蚀

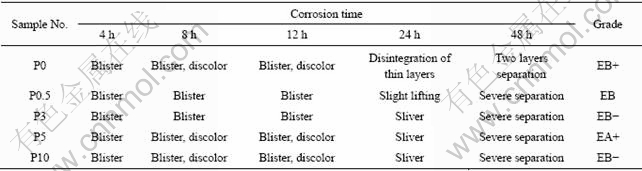

所有样品放入剥落腐蚀液后,都有气泡产生。随着时间的延长,各样品发生不同的变化。表2所示为不同时间预析出处理样品腐蚀不同时间后表面形态的比较。腐蚀大约9 h时,样品P0和P5表面都已开始变色,但样品P0.5和P3表面还没什么变化,也没有产生剥起现象。到24 h时,除样品P5外,其他样品都已有剥起,且样品P0表面已成片地剥起。32 h时样品P0、P0.5、P3和P10均已剥掉一层,已有少部分的新金属表面裸露出来。到48 h时,除P5外其他样品均有大量剥落产物,且P0已开始第三层剥落。

表2 不同时间预析出处理对样品抗剥落腐蚀的影响

Table 2 Effect of pre-precipitation time on exfoliation corrosion

从合金剥落腐蚀等级评定结果看,随着预析出处理时间的延长,合金抗剥落腐蚀性能由EB+变为EB、EB-直至EA+级,明显提高。而预析出时间从5 h延长至10 h时又由EA+变至EB-,有轻微的降低。图3所示为合金在剥落腐蚀液中浸泡48 h后的腐蚀形貌。

图3 样品表面剥落腐蚀形貌

Fig.3 Surface morphologies of samples after exfoliation corrosion: (a) Sample P0; (b) Sample P0.5; (c) Sample P3; (d) Sample P5; (d) Sample P10

2.4 组织观察

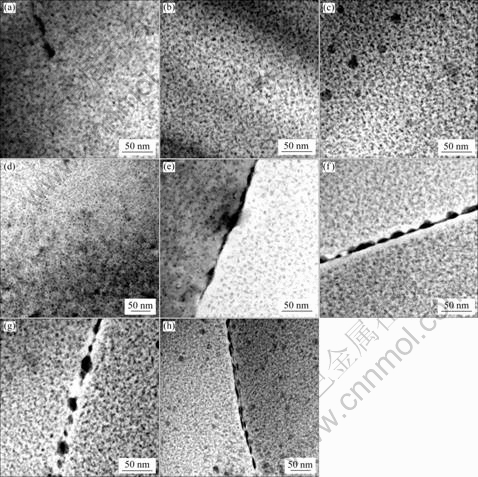

图4所示为样品P0.5、P3、P5和P10时效后晶内和晶界的透射组织照片。

图4 7A55铝合金时效后的TEM形貌

Fig.4 TEM images of aged aluminium alloy 7A55 in matrix and at grain boundaries: (a) Sample P0.5; (b) Sample P3; (c) Sample P5; (d) Sample P10; (e) Sample P0.5; (f) Sample P3; (g) Sample P5; (h) Sample P 10

由图4(a)、(b)、(c)和(d)可知,样品P3和P5与P0.5相比,基体析出相数量增多,而P10和P5相比基体析出相略有长大。由图4(e)、(f)、(g)和(h)可知,从P0.5到P3和P5,随着预析出处理的时间延长,晶界析出相明显长大,分布更加不连续,晶界无沉淀析出带宽度也逐渐变大;而P10与P5相比,随着预析出时间从5 h延长到10 h时,晶界析出相和晶界无沉淀析出带变化不大。

3 分析与讨论

3.1 预析出处理时间对合金力学性能的影响

Al-Zn-Mg-Cu合金的强化机制主要是沉淀强化,高温固溶后淬火形成过饱和固溶体,在时效过程中分解产生的析出相阻碍位错运动,因而得到很高的强度。显然,过饱和程度降低,时效析出相的数量将减少,从而降低强化效果。而在固溶后降温至440 ℃预析出处理0.5 h时,晶界处已有少量析出,导致淬火后固溶体的过饱和度降低,时效阶段析出相的密度变小,体积分数降低,而强度不高。随着预析出处理时间的延长,晶界析出相长大,晶界和晶内的电位差变小,导致在时效时晶内析出更加均匀、弥散。由图4(a)、(b)和(c)也可知,样品P3、P5和P0.5相比,晶内析出相数量变多,因而强化效果逐渐增强,硬度提高,强度也变大。而当440 ℃预析出处理从5 h延长至10 h时,晶内析出相数量已没有变化,只有析出相粒子的长大,从而导致合金的强度又略有降低。

3.2 预析出处理时间对合金抗腐蚀性能的影响

晶间腐蚀和剥落腐蚀是Al-Zn-Mg-Cu合金的主要腐蚀形式,并且本质都是晶界上优先发生腐蚀。当晶粒呈平行于材料表面、宽而长的扁平状时,由于腐蚀产物体积膨胀产生楔入力使晶间腐蚀沿着与表面平行的方向发展并逐步演变成剥落腐蚀。对7×××铝合金来说,在腐蚀环境中,晶界上的η相和无沉淀析出带与铝基体相比都可能作为阳极相[11],两者都可优先溶解,但η相作为阳极溶解的趋势更为严重,从而造成腐蚀沿晶界的扩展。因此合金的腐蚀性能主要由晶界析出相的尺寸和分布决定[12-13]。当晶界析出相连续时,在腐蚀环境中,很容易造成沿着晶界的连续溶解,从而导致合金的抗腐蚀性能急速下降。而当晶界析出相不连续,为一个个粗大的粒子时,切断了连续的腐蚀通路,腐蚀时也只是一个个单个粒子的溶解,提高了合金的抗腐蚀性能。当合金固溶后随炉降温至440 ℃保温时,随着保温时间延长,晶界上开始有少量的η相析出,且逐渐长大。在随后的时效过程中,晶界上的粒子长大,晶界析出状态逐渐变得不连续,使得合金的抗腐蚀性能提高。从图4(e)、(f)和(g)可看出,在440 ℃降温预析出处理0.5 h后,晶界的析出相分布已变为不连续状态。由于η相在高能晶界上析出时,吸收了附近的溶质和空位原子,从而形成了溶质原子和空位浓度贫乏区,而随着预析出处理时间延长,晶界析出相长大,同时造成晶界附近的固溶原子贫化更加严重,晶界无沉淀析出带宽度变大。从图4(g)可看出在440 ℃预析出处理5 h后晶界的析出相已经相当粗大,而无析出带也已很宽。粗大且不连续的晶界析出相阻断了合金的连续腐蚀通道,但较宽的无沉淀析出带在腐蚀环境中也可能充当阳极,可使合金的腐蚀性能降低[14-15],所以这两者实际上是相互制约的关系。但对7×××铝合金来说,一般晶界的不连续析出占主导地位,导致合金的抗腐蚀性能提高。当440 ℃预析出处理从5 h延长至10 h时,晶界析出相继续长大,从而导致晶界析出相的不连续性变差,而Mg、Zn原子的扩散也更加充分,导致无沉淀析出带宽度又变小,但晶界析出相的状态改变又使得合金的抗腐蚀性能略有降低。

4 结论

1) 固溶后440 ℃预析出处理时,随着预析出时间的延长,7A55铝合金的硬度和强度先升高后降低;而抗晶间腐蚀和剥落腐蚀性能也是先略提高后而略降低。

2) 对7A55铝合金,随着预析出处理时间的延长,首先基体析出相增多,密度增大,合金的硬度和强度提高。当时间延长至10 h时,析出相长大,合金的硬度和强度降低,而晶界平衡相尺寸变大,分布不连续,且晶界无沉淀析出带宽化,合金的抗晶间腐蚀和剥落腐蚀性能提高。当预析出时间为10 h时,晶界平衡相分布不连续性降低,从而导致抗晶间腐蚀和剥落腐蚀性能降低。

3) 440 ℃预析出处理5 h时,合金具有良好的力学性能和耐蚀性能。

REFERENCES

[1] Liu J, Kulak M. A new paradigm in the design of aluminum alloys for aerospace applications[J]. Materials Science Forum, 2000, 331/337: 127-140.

[2] 郑子樵, 李红英, 莫志民. 一种7055型铝合金的RRA处理[J]. 中国有色金属学报, 2001, 11(5): 771-776.

ZHENG Zi-qiao, LI Hong-ying, MO Zhi-min. Retrogression and reaging treatment of 7055 type aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 771-776.

[3] Andreatta F, Terryn H. Corrosion behaviour of different tempers of AA7075 aluminium alloy[J]. Electrochimica Acta, 2004, 49: 2851-2862.

[4] Puiggali M, Zielinski A. Effect of microstructure on stress corrosion cracking of an Al-Zn-Mg-Cu alloy[J]. Corrosion Science, 1998, 40(4): 805-819.

[5] Polmear I J, Ringer S P. Evolution and control of microstructure in aged aluminum alloy[J]. Journal of Japan Institute of Light Metals, 2000, 50(12): 633-642.

[6] Murakami Y. Recent investigations on precipitation phenomena of aluminum alloys[J]. Sumitomo Light Metals Technology, 1988, 29(1): 3-17.

[7] Lenclvai J. Precipitation and strengthening in aluminum alloys[J]. Materials Science Forum, 1996, 217/222: 43-56.

[8] 李 海, 郑子樵, 王芝秀. 过时效-重固溶-再时效处理对7055铝合金组织与性能的影响[J]. 材料热处理学报, 2004, 25(3): 57-61.

LI Hai, ZHENG Zi-qiao, WANG Zhi-xiu. Effect of over-aging and re-solution and re-ageing treatment on microstructure and properties of 7055 Al alloy[J]. Transactions of Materials and Heat Treatment, 2004, 25(3): 57-61.

[9] 黄振宝. 双级固溶对7A55铝合金组织与力学性能的影响[D]. 长沙: 中南大学, 2006: 53-61.

HUANG Zhen-bao. Effect of two-step solution heat treatment on the microstructure and mechanical properties of aluminum alloy 7A55[D]. Changsha: Central South University, 2006: 53-61.

[10] 陈康华, 黄兰萍, 郑 强, 胡化文. 高温预析出对7A52合金应力腐蚀性能的影响[J]. 中国有色金属学报, 2005, 15(3): 441-445.

CHEN Kang-hua, HUANG Lan-ping, ZHENG Qiang, HU Hua-wen. Effect of high-temperature pre-precipitation on stress corrosion cracking of 7A52 alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 441-445.

[11] Ramgopal T, Gouma P I, Frankel G S. Role of grain-boundary precipitates and solute-depleted zone on the intergranular corrosion of aluminum alloy 7150[J]. Corrosion, 2002, 58(8): 687-697.

[12] 王 月, 吴庭翱. 含钪Al-Mg合金的抗应力腐蚀和剥落腐蚀性能研究[J]. 中国腐蚀与防护学报, 2005, 25(8): 218-221.

WANG Yue, WU Ting-ao. Stress corrosion cracking and exfoliation corrosion resistance of Al-Mg alloy with addition of scandium[J]. Journal of Chinese Society for Corrosion and Protection, 2005, 25(8): 218-221.

[13] Najjar D, Magnin T, Warner T J. Influence of critical surface defects and localized competition between anodic dissolution and hydrogen effects during stress corrosion cracking of a 7050 aluminum alloy[J]. Material Science and Engineering A, 1997, 238(2): 293-302.

[14] 张新明, 刘胜胆, 刘 瑛, 张小艳. 淬火速率和锆含量对7055型铝合金晶间腐蚀的影响[J]. 中南大学学报(自然科学版), 2007, 38(2): 181-185.

ZHANG Xin-ming, LIU Sheng-dan, LIU Ying, ZHANG Xiao-yan. Influence of quench rate and zirconium content on intergranular corrosion of 7055 type aluminum alloy[J]. Journal of Central South University (Science and Technology), 2007, 38(2): 181-185.

[15] 张 琦, 李 荻, 丁学谊. LC4铝合金晶间腐蚀电化学机理[J]. 材料保护, 1996, 29(8): 6-7.

ZHANG Qi, LI Di, DING Xue-yi. Electrochemical mechanism of intergranular corrosion in LC4 aluminum alloy[J]. Materials Protection, 1996, 29(8): 6-7.

基金项目:国家重点基础研究发展计划资助项目(2005CB623700)

收稿日期:2007-03-09;修订日期:2007-06-26

通讯作者:张新明,教授;电话:0731-8830265;E-mail: xmzhang@mail.csu.edu.cn

(编辑 李向群)