DOI:10.11817/j.ysxb.1004.0609.2020-36349

温轧高强韧镍铝青铜合金的组织与力学性能

马 硕1, 2,龚安华3,付立铭1, 2,单爱党1, 3

(1. 上海交通大学 材料科学与工程学院,上海 200240;

2. 上海交通大学 高新船舶与深海开发装备协同创新中心,上海 200240;

3. 上海似德精密机械制造有限公司,上海 201611)

摘 要:通过形变量为75%的温轧形变热处理,制备了一种超细组织的QAl10-4-4镍铝青铜合金,研究其微观组织与力学性能。结果表明:经大变形温轧后,温轧后的镍铝青铜材料由超细层状(α+β′)双相组织以及细小的k相组成(其中α相为铜基固溶体、β′相为共析相变受阻产生的Cu3Al基马氏体及NiAl析出相、k相为Fe3Al、NiAl等金属间化合物),合金的屈服强度由318 MPa提升至1020 MPa,抗拉强度由784 MPa提升至1104 MPa,具有7.8%的均匀伸长率并呈现良好的应变硬化能力。温轧镍铝青铜合金的高强度主要归因于位错强化、细晶强化以及温轧过程中诱发的纳米析出强化,而良好的塑韧性主要与超细的片层α相和β′相的应力应变协调有关。温轧形变热处理是制备高强韧镍铝青铜合金的一种有效方法。

关键词:镍铝青铜;高强韧;温轧;组织;力学性能;超细层状结构

文章编号:1004-0609(2020)-01-0069-09 中图分类号:TG146.1+1 文献标志码:A

镍铝青铜合金具有良好的铸造性能、力学性能和耐腐蚀性能,是一种在工业领域广泛应用的重要结构材料[1-2]。相比二元铝青铜合金,由于镍、铁、锰等元素的添加,镍铝青铜合金的强度、硬度和耐磨性能都获得了大幅度提高[3-4]。随着工业的快速发展,对结构材料的性能提出了更高的要求[3]。研究表明,不同处理工艺下镍铝青铜合金可以呈现α、β′及k相等不同的组织形式[5-7],通过对各相的形态、分布及相组成的调控,可以实现合金性能的大幅调整[8-9]。近年来,在不改变成分的基础上,通过工艺设计优化和组织状态调控的方式获得高强高韧的镍铝青铜合金成为研究的热点内容之一[3, 5, 10-14]。

晶粒(组织)细化是提高材料强度和韧性的有效手段。传统的强烈塑性变形(Severe plastic deformation,SPD)方式,可以获得纳米晶或者超细晶组织,进而显著提高材料的强度。通过等通道转角挤压(Equal channel angular pressing)制备铜合金[15-16],可大幅提高材料的强度、硬度,但加工硬化能力较弱。然而由于模具和样品尺寸的限制,SPD制备技术很难实现大规模工业化应用。轧制是工业生产大型板材最常用也是最理想的方法。通常采用大变形轧制并结合一定的热处理工艺可以实现晶粒细化[17]。NESTOROVIC等[18]研究表明,强度及硬度随着冷轧变形量的增加而增大,经70%冷轧和约250 ℃时效后铜合金的硬度达到最大值,其强化机制以细晶强化和析出强化为主。热轧铝青铜合金的研究表明,850 ℃下轧制变形量小于80%时,晶粒细化和强化效果与压下量呈正相关,压下量大于80%时,细化效果不明显,尽管位错强化和纳米孪晶等提高了强度,但是韧塑性显著降低[10]。中温变形及热处理工艺是一种实现材料组织细化的有效手段,在制备高强韧钢铁[19]、铝合金[20]、钛合金[21]、镁合金[22]等领域已被广泛采用,但在高强高韧铜合金领域的相关研究鲜有报道。

最近有研究发现,具有片层状组织或结构的材料会呈现强度和韧性同时提升的特性,相关研究受到广泛关注[23-27]。本文依托QAl10-4-4镍铝青铜合金,采用温轧形变热处理方式,制备了一种具有超细(α+β′)片层组织的高强韧铝青铜合金,研究了大变形温轧及时效处理后对组织与性能影响,并探讨了其强韧化机制。

1 实验

1.1 材料成分与样品制备

研究用材料为QAl10-4-4镍铝青铜合金,化学成分如表1所列。8 mm厚度的样品在880 ℃保温1 h后,空冷至780 °C后进行轧制。轧制工艺采用少道次大变形温轧方式,在70 t轧机上经三道次连续轧制,单道次压下量分别为3 mm,2 mm和1 mm,将板材最终轧制到2 mm,累积变形量为75%,水冷至室温。温轧后的板材线切割成小块样品,在350 °C进行时效处理,保温时间为2 h,空冷。

表1 研究用合金QAl10-4-4铝青铜合金的化学成分

Table 1 Chemical composition of experimental QAl10-4-4 aluminum bronze (mass fraction, %)

1.2 实验方法

温轧及时效处理后的样品经切割、镶嵌、研磨、抛光和腐蚀后,制备成金相样品。所用腐蚀液为氯化铁盐酸酒精溶液,配比为6 g FeCl3+20 mL 70%盐酸(体积分数)+100 mL分析纯酒精。对所制备的样品在MEF4A型光学显微镜(OM)进行金相组织观察,采用配有能谱仪(Inca energy-dispersive spectrometer, EDS)的JSM-7600F场发射扫描电镜(Scanning electron microscopy, SEM)进行微观组织形貌观察和典型相的成分分析。TEM透射薄膜样品制样在MTP-1A型电解双喷仪上进行,电解液为7%高氯酸酒精溶液,工作温度为-35~-25 ℃,工作电压和电流分别为50 V和30 mA。采用JEOL 2100F型场发射高分辨透射电子显微镜(TEM)进行精细组织分析,并使用所配能谱仪(EDS)进行成分分析,透射电镜工作电压为200 kV。X射线衍射(XRD)分析在Shimadzu XRD-6000 X射线衍射仪上进行,测试采用Cu靶、Kα射线,扫描范围是20°~100°,扫描速度为2 (°)/min,扫描电流电压为40 V/40 mA。利用ZEISS-Observe.D1M维氏显微硬度计对样品进行硬度测试,载荷为500 g,保载时间为15 s,取8点平均值为最终测试结果。拉伸实验在Zwick/ Roell-Z100型拉伸实验机上进行,拉伸样品沿板材的轧制方向取样,拉伸样品的标距为12 mm,拉伸速率为5×10-4 s-1。

2 实验结果

2.1 显微组织

根据相图[28],QAl10-4-4镍铝青铜合金在880 ℃时的平衡组织为(α+β+k)相。图1所示为镍铝青铜合金在温轧变形前后的光学显微组织对比图。轧制前的样品经(880 ℃,1 h)保温淬火后,组织主要由α和β′相组成,α相呈等轴状,晶粒尺寸在15 μm左右,均匀分布在β′相上(见图1(a)),组织中还均匀弥散分布有一些细小k析出相(见图1(a)中箭头所示)。经70%温轧后,α和β′相由变形前的等轴状转变成超细片层状,组织显著细化,如图1(b)所示。

图1 经70%温轧前后的QAl10-4-4铝青铜光学组织

Fig. 1 Microstructures of experimental alloy

图2 大变形温后样品的SEM像

Fig. 2 SEM images of experimental alloy

图2所示为温轧及时效后样品的SEM显微组织观察结果。由图2(a)和2(b)可以发现,温轧变形处理后铝青铜合金的组织主要呈现双相片层状结构,由相对较宽的α相片层和超细的β′相片层组成,α相片层的宽度在6 μm以下,超细β′相片层宽度小于1 μm。温轧后的样品中存在两种不同状态的k析出相,一种是尺寸为1~2 μm的粒状k相,均匀分布在α和β′片层中(见图2(b)),这种尺寸相对较大的析出是温轧变形前所形成的初生k相,温轧变形后依然稳定存在;另一种为大量的纳米尺度的k析出相,均匀分布在超细β′相片层中(见图2(c)),这种析出是温轧过程中发生共析相变产生的k相[12, 29]。温轧并经350 ℃时效后的组织如图2(d)所示,由于时效过程中组织发生回复,超细β′相片层之间界面变得模糊和不连续,但是整体的组织依然保持(α+β′)双相片层结构。

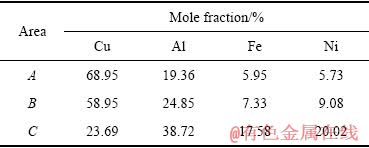

本研究采用的QAl10-4-4铝青铜合金中主要存在3种不同类型的k相(k2、k3和k4)[30],通常k3为NiAl型的BCC金属间化合物,空间结构为B2。k2在相对较高温度下析出,相尺寸为几微米,而k4是在相对较低温度下析出的纳米尺度析出相,二者均为Fe3Al型的BCC结构的金属间化合物[1-2, 30],空间结构为DO3。图3所示为本研究中能谱仪(EDS)线扫描成分分析结果,可以判断图3(a)中的α相片层中较大的粒状析出相为富Fe的k2相(Fe3Al型),如图3(b)所示。从图3(c)中成分线扫描结果可以判定β′相片层中存在有富Al、Ni的析出相,说明温轧变形处理后获得超细片层β′相中的纳米析出相(见图2(c))为k3相(NiAl型)。

图4所示为温轧及时效处理后的TEM像。温轧样品的TEM微区观察到的β′相仍呈现明显的片层状组织,片层宽度在500 nm到1 μm之间(见图4(a))。从图4(b)的微观双相片层组织的TEM像中发现,在片层β′相中存在尺寸约50 nm左右的析出相,通过EDS成分分析结果判断为k3相(见表2),这种弥散分布的析出相会有利于材料的强化。图4(c)所示为时效后样品的TEM观察结果,衍射斑点呈不连续环状,呈现多晶材料的典型特征,析出相尺寸大多在100 nm左右,说明时效过程中的k相有长大趋势。图4(d)所示为图4(c)中所示微区局部放大图,可观察到少量的超细再结晶晶粒生成。

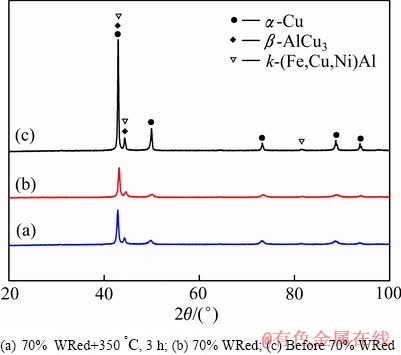

2.2 XRD分析

图5所示为XRD测试结果,温轧前、温轧后以及温轧时效后的QAl10-4-4铝青铜样品组织均由α相、β′相及少量k相组成。与变形前材料相比,温轧及温轧时效后的的衍射峰明显宽化,这与轧制导致的高密度位错和组织细化有直接关系[31]。此外,从XRD衍射分析结果来看,温轧态与时效态的各衍射峰并没有发生明显变化,说明时效处理对温轧铝青铜合金的组织影响不大。

图3 温轧样品的SEM像和成分线扫描EDS谱

Fig. 3 EDS line scanning of composition analysis for warm-rolling sample

图4 温轧及时效态样品的TEM像

Fig. 4 TEM images of warm-rolled and aged samples

表2 图4(b)中各点的能谱测试结果

Table 2 EDS analysis of experimental points in Fig. 4(b)

图5 不同状态铝青铜合金的XRD谱

Fig. 5 XRD patterns of samples for different states

2.3 力学性能

图6所示为温轧前后及时效后的样品的拉伸性能测试及相应的应变硬化速率( )曲线,拉伸性能具体值列于表3中,表中同时给出三种状态的硬度测试结果。QAl10-4-4铝青铜经过温轧变后,硬度显著提升。相对温轧前,温轧后的拉伸样品的屈服强度由318 MPa提升至1020 MPa,抗拉强度由784 MPa提高至1104 MPa,并具有7.8%的均匀伸长率(εu),温轧工艺处理后铝青铜合金的性能明显提升。温轧经350 ℃时效处理后,镍铝青铜合金的硬度、强度都有所下降,断后伸长率(εt)略有增加,但均匀伸长率显著下降。从拉伸曲线和应变硬化速率曲线也可发现,温轧镍铝青铜合金呈现很高的应变硬化速率,明显优于时效处理后的样品的。

)曲线,拉伸性能具体值列于表3中,表中同时给出三种状态的硬度测试结果。QAl10-4-4铝青铜经过温轧变后,硬度显著提升。相对温轧前,温轧后的拉伸样品的屈服强度由318 MPa提升至1020 MPa,抗拉强度由784 MPa提高至1104 MPa,并具有7.8%的均匀伸长率(εu),温轧工艺处理后铝青铜合金的性能明显提升。温轧经350 ℃时效处理后,镍铝青铜合金的硬度、强度都有所下降,断后伸长率(εt)略有增加,但均匀伸长率显著下降。从拉伸曲线和应变硬化速率曲线也可发现,温轧镍铝青铜合金呈现很高的应变硬化速率,明显优于时效处理后的样品的。

图6 不同状态下样品的拉伸及应变硬化速率曲线

Fig. 6 Tensile properties of samples for different process

表3 不同处理状态合金样品的力学性能

Table 3 Mechanical properties of alloy for different states

3 讨论

经880 °C固溶处理后,QAl10-4-4镍铝青铜合金主要由基体β相、等轴状的α相以及两相中分布的约几微米大小的k相组成。经大变形温轧后,过冷的α和β相被轧扁拉长,同时组织发生动态回复再结晶,并在温轧过程中相变产生大量的纳米尺度k析出相。因此,温轧合金经淬火处理后,获得了一种由细小α相、超细β′相(含共析相变产物)以及均匀弥散分布其中的细小k相的片层状组织。经温轧形变热处理后的合金组织显著细化,尤其是形成的超细β′相片层组织以及内部诱发生成的纳米k相,对铝青铜的综合性能提升起到了重要的作用。典型变形后的QAl10-4-4镍铝青铜合金的屈服强度通常仅为550~600 MPa[32],在870 °C以上热轧及处理后调控后,其屈服强度可以超过700 MPa[33];在850 °C的相对较低温度进行95%热轧后,屈服强度可达到842 MPa,但是断裂伸长率仅5%左右[10]。而本研究通过温轧形变热处理制备的QAl10-4-4镍铝青铜合金的屈服强度达到了1020 MPa和7.8%的均匀伸长率,说明温轧形变热处理是制备高强韧镍铝青铜合金的一种有效方法。

本研究采用少道次、70%大压下中温轧制热处理的制备方法,一方面,在相对较低的中温变形,可以有效地抑制高温轧制过程的变形组织的动态再结晶长大;另一方面,相对冷轧变形,中温轧制下材料的流变应力相对较低,可以显著降低合金轧制的变形抗力,更易于实现大变形量轧制,有助于高密度缺陷组织发生动态回复再结晶,从而实现了材料组织细化[19-22]。本文中,相对固溶处理态,温轧形变热处理后的α和β′两相组织显著细化(见图1和图2),晶粒细化是温轧高强韧铝青铜合金的重要强化机制。首先,强变形温轧制(少道次、大压下量)过程中会形成大量高密度位错、位错胞等缺陷,为扩散型的亚稳材料中的动态析出提供良好动力学基础[21-22]。其次,温轧变形过程中在超细片层β′相的诱发生成了大量的纳米尺度的k析出相(见图2(c)、图4(b)),析出强化是温轧镍铝青铜合金具有高强度的另外一个重要因素。此外,温轧变形过程中在材料内部形成的高密度的位错,会在随后淬火处理中部分保留,从而进一步提高合金的强度。因此,温轧铝青铜合金的高强度主要归因于细晶强化、第二相析出强化和位错强化三种综合作用的结果。

经温轧后的合金呈现较好的塑韧性和良好应变硬化能力。镍铝青铜中各相的微观硬度相差很大,其中α相硬度为HV200~270,β′相为HV290~407,k相为HV420~700[29],对强度影响较大的是β′相和k相,而对塑韧性影响较大的主要取决于α相的含量、分布及形态[6]。研究发现,相对于等轴状和球状组织,沿加载方向拉长的层状组织具有更高的加工硬化能力[23, 34]。WU等[24, 26]认为具有片层及非均匀性微观组织和结构的材料具有更加优异的强韧性,背应力硬化(Back-stress hardening)和软硬(或不同尺度)相之间有效地微观应变协调是片层结构材料的主要强韧化机制。分析表明[35],双相合金在拉伸变形过程中,由于各组成相力学性质的不同,根据宏应力应变的变化,各相会通过微观应力应变分配及相互协调来完成整个变形过程,各相形态、尺寸和体积分数会对合金的宏观变形行为产生重要的影响。本研究中,通过温轧变形过程的动态回复再结晶,组织显著细化,晶界、亚晶界和诱发的大量纳米k相析出能够有效地阻碍位错的运动,从而提高合金的塑韧性和应变硬化能力。温轧变形热处理后的合金组织呈现典型的(α+β′)双相片层状结构,尺寸相对较大(几微米)且相对较软α相片层,具有良好的微观塑性变形与容纳位错的能力,而纳米k相析出强化的相对较硬的超细β′相片层(小于1 μm),起到承担较大外加应力的作用,在宏观拉伸变形过程中,交替排列的软硬片层组织相互协调,提升了镍铝青铜合金的整体的应变硬化能力。

通常,镍铝青铜合金经时效处理后,强度和硬度会因时效过程的析出强化而增加[6, 36],但是,本研究中的温轧铝青铜合金在(350 °C,2 h)时效处理之后,硬度、强度都有所下降,总伸长率虽略有增加,但均匀伸长率和应变硬化能力显著下降,拉伸曲线呈现典型超细晶/纳米晶合金的塑性失稳特征[15-17, 27],材料软化主要是由于时效期间硬相β′相马氏体发生分解,而分解后生成的(α+k)相超细组织导致的组织细化是均匀伸长率下降的主要原因。此外由于大变形温轧过程中纳米尺度k相析出基本完成(见图4(c)),时效过程中进一步发生长大(见图3(c)),这显著降低了温轧镍铝青铜合金进一步时效析出的强化效果,同时部分变形组织在时效过程发生回复,位错密度也进一步降低,材料强度相应减弱。

4 结论

1) 采用70% 温轧方法制备了一种(α+β′)双相片层结构的高强韧镍铝青铜合金,该合金 由1~6 μm的α相片层、小于1 μm的超细β′相片层组织以及均匀弥散分布在双相片层中的细小的k析出相组成。

2) 与温轧前相比,温轧后的片层结构的镍铝青铜合金的屈服强度由318 MPa提升至1020 MPa,抗拉强度由784 MPa提高至1104 MPa,并具有7.8%的伸长率和良好的应变硬化能力。

3) 温轧(α+β′)双相片层镍铝青铜合金的高强度主要归因于位错强化、细晶强化以及温轧过程中诱发的纳米析出强化,而良好的塑韧性主要与超细的片层α相和β′相的应力应变协调有直接关系。

4) 温轧形变热处理是制备高强韧镍铝青铜合金的一种有效方法。

REFERENCES

[1] JAHANAFROOZ A, HASAN F, LORIMER G W, RIDLEY N. Microstructural development in complex nickel- aluminum bronzes[J]. Metallurgical Transactions A, 1983, 14(10): 1951-1956.

[2] NELSON E A. Microstructural effects of multiple passes during friction stir processing of nickel aluminum bronze[R]. Monterey: Naval Postgraduate School, 2009.

[3] 袁庆龙, 管红艳, 张宝庆. 铝青铜合金研究进展[J]. 材料导报, 2011, 25(23): 127-132.

YUAN Qing-long, GUAN Hong-yan, ZHANG Bao-qing. Development of aluminum bronze alloy[J]. Materials Review, 2011, 25(23): 127-132.

[4] HIGASHI K, OHNISHI T, NAKATANI Y. Superplastic behavior of commercial aluminum bronze[J]. Scripta Metallurgica, 1985, 19(7): 821-823.

[5] 龚 习. QA110-5-5铝青铜合金组织与性能研究[D]. 长沙: 中南大学, 2011.

GONG Xi. Study of microstructure and properties of QAl10-5-5 aluminum bronze[D]. Changsha: Central South University, 2011: 3-4.

[6] 张卫文, 谭 伟, 罗宗强, 李元元. 镍铝青铜合金中组织与布氏硬度关系的定量金相分析[J]. 金属热处理, 2012, 37(9): 43-47.

ZHANG Wei-wen, TAN Wei, LUO Zong-qiang, LI Yuan-yuan. Relationship between microstructure and Brinell hardness of nickel-aluminum bronze by quantitative metallography analysis[J]. Heat Tratement of Metals, 2012, 37(9): 43-47.

[7] 王智祥, 潘少彬, 叶艳君, 刘 峰, 刘建辉. 固溶时效对热轧态QAl10.9-5-5合金组织及性能的影响[J]. 材料导报, 2016, 30(16): 82-85.

WANG Zhi-xiang, PAN Shao-bin, YE Yan-jun, LIU Feng, LIU Jian-hui. Influence of solid solution and aging treatment on microstructure and properties of hot rolled QAl10.9-5-5 alloy[J]. Materials Review, 2016, 30(16): 82-85.

[8] KAPLAN M, YILDIZ A K. The effects of production methods on the microstructures and mechanical properties of an aluminum bronze[J]. Materials Letters, 2003, 57(28): 4402-4411.

[9] CHEN R P, LIANG Z Q, ZHANG W W, ZHANG D T, LUO Z Q, LI Yuan-yuan. Effect of heat treatment on microstructure and properties of hot-extruded nickel- aluminum bronze[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(6): 1254-1258.

[10] Lü Y, WANG L, HAN Y, XU X, LU W. Investigation of microstructure and mechanical properties of hot worked NiAl bronze alloy with different deformation degree[J]. Materials Science & Engineering A, 2015, 643: 17-24.

[11] GUPTA R K, GHOSH B P, SINHA P P. Design of heat treatment cycle for hardness improvement of Cu-9Al-6Ni-5Fe alloy[J]. Canadian Metallurgical Quarterly, 2013, 45(3): 353-358.

[12] WHARTON J A, STOKES K R. The influence of nickel-aluminium bronze microstructure and crevice solution on the initiation of crevice corrosion[J]. Electrochimica Acta, 2008, 53(5): 2463-2473.

[13] SU J, SWAMINATHAN S, MENON S K, MCNELLEY T R. The effect of concurrent straining on phase transformations in NiAl bronze during the friction stir processing thermomechanical cycle[J]. Metallurgical & Materials Transactions A, 2011, 42(8): 2420-2430.

[14] Lü Y, YANG D, HAN Y, ZHANG L C, WANG L, LU W. Strengthening mechanism of friction stir processed and post heat treated NiAl bronze alloy: Effect of rotation rates[J]. Materials Science & Engineering A, 2017, 685: 439-446.

[15] BARR C J, XIA K. Significantly enhanced tensile strength and ductility in nickel aluminium bronze by equal channel angular pressing and subsequent heat treatment[J]. Journal of Materials Science, 2013, 48(13): 4749-4757.

[16] VINOGRADOV A, PATLAN V, SUZUKI Y, KITAGAWA K, KOPYLOV V I. Structure and properties of ultra-fine grain Cu-Cr-Zr alloy produced by equal-channel angular pressing[J]. Acta Materialia, 2002, 50(7): 1639-1651.

[17] 赵 欣, 单爱党. 大变形轧制制备超细晶镍基合金的显微组织与拉伸性能[J]. 机械工程材料, 2017, 41(7): 76-79.

ZHAO Xin, SHAN Ai-dang. Microstructure and tensile properties of ultrafine-grained Ni-based alloy prepared by severe deformation rolling[J]. Materials for Mechanical Engineering, 2017, 41(7): 76-79.

[18] NESTOROVIC S, MARKOVIC D, IVANIC L. Influence of degree of deformation in rolling on anneal hardening effect of a cast copper alloy[J]. Bulletin of Materials Science, 2003, 26(6): 601-604.

[19] Lü L, FU L, AHMAD S, SHAN A. Effect of heavy warm rolling on microstructures and mechanical properties of AISI 4140 steel[J]. Materials Science & Engineering A, 2017, 704: 469-479.

[20] RAO P N, JAYAGANTHAN R. Effects of warm rolling and ageing after cryogenic rolling on mechanical properties and microstructure of Al 6061 alloy[J]. Materials & Design, 2012, 39: 226-233.

[21] HUANG C, HAWBOLT E B, CHEN X, MEADOWCROFT T R, MATLOCK D K. Flow stress modeling and warm rolling simulation behavior of two Ti-Nb interstitial-free steels in the ferrite region[J]. Acta Materialia, 2001, 49(8): 1445-1452.

[22] WANG Y, KANG S B, CHO J. Microstructural evolution of twin-roll cast Mg-3Al-0.5Mn-0.2Mm alloys during warm rolling and subsequent annealing[J]. Journal of Materials Processing Technology, 2010, 210(10): 1270-1275.

[23] 曹文全, 徐海峰, 张明达, 董 瀚, 翁宇庆. 新型低密度高强高韧热轧层状钢研发[J]. 钢铁, 2016, 51(9): 1-10.

CAO Wen-quan, XU Hai-feng, ZHANG Ming-da, DONG Han, WENG Han, WENG Yu-qing. Research and development of a new hot rolled laminated structure[J]. Iron and Steel, 2016, 51(9): 1-10.

[24] YANG M X, YUAN F P, XIE Q G, WANG Y D, MA E, WU X L. Strain hardening in Fe-16Mn-10Al-0.86C-5Ni high specific strength steel[J]. Acta Materialia, 2016, 109: 213-222.

[25] YANG M, YAN D, YUAN F, JIANG P, MA E, WU X. Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength[J]. Proceedings of the National Academy of Sciences of the United States of America, 2018, 115(28): 7224-7229.

[26] WU X L, JIANG P, CHEN L, ZHANG J F, YUAN F P, ZHU Y T. Synergetic strengthening by gradient structure[J]. Materials Research Letters, 2014, 2(4): 185-191.

[27] WU X, YANG M, YUAN F, WU G, WEI Y, HUANG X, ZHU Y. Heterogeneous lamella structure unites ultrafine- grain strength with coarse-grain ductility[J]. Proceedings of the National Academy of Sciences of the United States of America, 2015, 112(47): 14501-14505.

[28] 龚安华, 付立铭, 索忠源, 王孝忠, 单爱党. 振动研磨工艺对QAl10-4-4合金的表面组织及性能的影响[J]. 有色金属材料与工程, 2016, 37(6): 249-254.

GONG An-hua, FU Li-ming, SUO Zhong-yuan, WANG Xiao-zhong, SHAN Ai-dang. Effect on the microstructure and surface properties of the QAl10-4-4 alloy by the mechanical vibration polishing treatment[J]. Nonferrous Metals Materials and Engineering, 2016, 37(6): 249-254.

[29] 王智平, 李海兰, 徐建林, 路 阳, 刘明朗. 固溶时效对高铝青铜组织与性能的影响[J]. 铸造, 2004, 53(6): 439-442.

WANG Zhi-ping, LI Hai-lan, XU Jian-lin, LU Yang, LIU Ming-lang. Effect of solid solution and aging treatment on microstructure and properties of high-aluminum bronze[J]. Foundry, 2004, 53(6): 439-442.

[30] HASAN F, JAHANAFROOZ A, LORIMER G W, RIDLEY N. The morphology, crystallography, and chemistry of phases in as-cast nickel-aluminum bronze[J]. Metallurgical and Materials Transactions A, 1982, 13(8): 1337-1345.

[31] BIRKS L S, FRIEDMAN H. Particle size determination from X-ray line broadening[J]. Journal of Applied Physics, 1946, 17(8): 687-692.

[32] 刘培兴, 刘晓瑭. 铜与铜合金加工手册[M]. 北京: 化学工业出版社, 2008.

LIU Pei-xin, LIU Xiao-tang. Copper and copper based alloys processing handbook[M]. Beijing: Chemical Industry Press, 2008.

[33] MENON S K, PIERCE F A, ROSEMARK B P, OH-ISHI K, SWAMINATHAN S, MCNELLEY T R. Strengthening mechanisms in NiAl bronze: Hot deformation by rolling and friction-stir processing[J]. Metallurgical & Materials Transactions A, 2012, 43(10): 3687-3702.

[34] TANAKA K, MORI T. The hardening of crystals by non-deforming particles and fibres[J]. Acta Metallurgica, 1970, 18(8): 931-941.

[35] 魏 兴, 付立铭, 刘世昌, 王 巍, 单爱党. 双相钢组成相的变形行为及其影响因素[J]. 材料研究学报, 2013, 27(6): 665-672.

WEI Xing, FU Li-ming, LIU Shi-chang, WANG Wei, SHAN Ai-dang. Deformation behavior of constituent phases and the affected factors in dual-phase steel[J]. Chinese Journal of Materials Research, 2013, 27(6): 665-672.

[36] 李振亚, 杨丽景, 许 赪, 冒守栋, 宋振纶. 时效温度对镍铝青铜合金的硬质相演变的影响[J]. 中国有色金属学报, 2016, 26(4): 766-772.

LI Zhen-ya, YANG Li-jing, XU Cheng, MAO Shou-dong, SONG Zhen-lun. Effect of aging temperature on hard phase evolution of nickel aluminum bronze[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 766-772.

Microstructure and mechanical properties of high strength-ductility aluminum bronze alloy produced by warm rolling

MA Shuo1, 2, GONG An-hua3, FU Li-ming1, 2, SHAN Ai-dang1, 3

(1. School of Materials Science and Engineering, Shanghai Jiao Tong University, Shanghai 200240, China;

2. Shanghai Jiaotong University, Collaborative Innovation Center for Advanced Ship and Deep-Sea Exploration (CISSE), Shanghai 200240, China;

3. Shanghai Seed Machinery Co., Ltd., Shanghai 201611, China)

Abstract: An ultra-fine lamellar-structured QAl10-4-4 aluminum bronze alloy was produced by 70% warm-rolling (WR) and quenching method. The microstructure evolution and mechanical properties of the WRed alloy were investigated. The results show that the microstructures of the produced alloy mainly comprise ultrafine α+β′ lamellar structure and uniformly distributed ultrafine-grained k precipitations. The WRed alloy exhibits excellent comprehensive mechanical properties. The yield strength, ultimate tensile strength of the WRed alloy are dramatically improved from 318 MPa and 784 MPa to 1020 MPa and 1104 MPa, respectively. Furthermore, the alloy still remains uniform elongation of 7.8% and processes very good strain hardening ability. The high strength of the WRed alloy is primarily attributed to the strengthening of dislocation, grain-refinement and nano-sized precipitation induced by warm-rolling processing, and the excellent ductility is mainly associated with the strain coordinating and partitioning between ultrafine lamellar α and β′ phases. It is believed that the warm-rolling and subsequently heat-treating is an effective method to prepare high strength and toughness nickel aluminum bronze alloy.

Key words: nickel aluminum bronze alloy; high strength-ductility; warm-rolling; microstructure; mechanical property; ultrafine lamellar structure

Foundation item: Project(2014ZX07214-002) supported by the National Basic Research Development Program of China

Received date: 2019-02-22; Accepted date: 2019-09-02

Corresponding author: FU Li-ming; Tel: +86-21-54747489; E-mail: lmfu@sjtu.edu.cn;

SHAN Ai-dang; Tel: +86-21-54747489; E-mail: adshan@sjtu.edu.cn

(编辑 王 超)

基金项目:国家重点研发计划资助项目(2014ZX07214-002)

收稿日期:2019-02-22;修订日期:2019-09-02

通信作者:付立铭,助理研究员,博士;电话:021-54747489;E-mail:lmfu@sjtu.edu.cn;

单爱党,教授,博士;电话:021-54747489;E-mail:adshan@sjtu.edu.cn