文章编号:1004-0609(2009)03-0570-06

采用熔融碱法从红土镍矿中提取硅

牟文宁,翟玉春,刘 岩

(东北大学 材料与冶金学院,沈阳 110004)

摘 要:通过正交试验,研究红土镍矿熔融碱法提硅过程中反应温度、反应时间、碱矿质量比及搅拌速度对SiO2提取率的影响。结果表明:试验过程中各因素对SiO2提取率的影响由大到小的顺序为反应温度>反应时间>碱矿质量比>搅拌速度;最佳的试验条件为反应温度550 ℃,反应时间20 min,碱矿质量比4?1,搅拌速度400 r/min;按照最佳条件进行实验,SiO2的提取率可达93%以上,镍、铁和镁等元素富集于渣中,氧化镍的质量含量达到2.92%。

关键词:红土镍矿;熔融碱;二氧化硅

中图分类号:TD 982;TF 111.313;O 613.72 文献标识码:A

Extraction of silicon from laterite-nickel ore by molten alkali

MU Wen-ning, ZHAI Yu-chun, LIU Yan

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: The effects of reaction temperature, reaction time, mass ratio of alkali to ore, and agitation speed on the extracting ratio of SiO2 during the process of extracting silicon from laterite-nickel ore by molten alkali were investigated through orthogonal experiments. The results show that the sequence of each factor affecting the extracting ratio of SiO2 is reaction temperature>reaction time>mass ratio of alkali to ore>agitation speed. The optimum technological conditions are obtained as reaction temperature of 550 ℃, reaction time of 20 min, mass ratio of alkali to ore of 4?1 and agitation speed of 400 r/min. The extracting ratio of SiO2 is over 93% under the optimum conditions, the elements of iron, magnesium and nickel are enriched in the residue, and the mass content of NiO is as high as 2.92%.

Key words: laterite-nickel ore; molten alkali; silicon dioxide

世界陆基镍储量约为4.7亿吨,其中28%以硫化矿形式存在,72%以氧化矿形式存在[1]。目前,世界上约60%的镍是从硫化镍矿中提取的,但随着镍需求的不断增加和可经济利用硫化镍矿资源的逐渐减少,红土镍矿的经济开发成了当今镍冶金的研究热点[2?6]。

红土镍矿是含镍的岩石经长期风化淋滤变质而形成的,由铁、铝、硅等含水氧化物组成的疏松的粘土状氧化矿石[7?8]。矿石中镍含量较低,且与其他矿物相互镶嵌,结合紧密,分离异常困难[9?11]。典型的冶金处理工艺有火法和湿法两种[12?15]。火法工艺包括电炉还原炼镍铁合金和硫化熔炼产出镍锍;湿法工艺包括加压酸浸和还原-氨浸。上述工艺均以提取矿石中含量较少的镍为目标,其冶炼过程存在投资大,生产成本高等缺点,且产生大量含硅废渣,给环境带来极大的负担。因此,探索处理红土镍矿的新工艺和新技术具有重要的实际意义。

本文作者建立以红土镍矿为原料,熔融碱为反应介质,通过水浸提取矿石中二氧化硅的工艺,富集镍、铁、镁等有价组元,为后续镍、铁、镁的提取创造条件,是实现红土镍矿高附加值综合利用的第一步。

1 实验

1.1 实验原料

红土镍矿经破碎、研磨后用于实验,主要化学组成如表1所列。矿石的主要成分为SiO2,其含量为49.3%,极具利用价值。

表1 红土镍矿的主要化学组成

Table 1 Chemical compositions of laterite-nickel ore (mass fraction, %)

红土镍矿的XRD谱如图1所示。由图1可知,红土镍矿中的主要物相组成是蛇纹石(Mg3Si2O5(OH)4)、游离的二氧化硅(SiO2)和赤铁矿(Fe2O3)。

图1 红土镍矿的XRD谱

Fig. 1 XRD pattern of laterite-nickel ore

实验所用碱为工业级NaOH,纯度≥96%;水为去离子水。

1.2 实验原理

红土镍矿中的硅主要以蛇纹石和游离二氧化硅的形式存在,碱熔过程发生的主要化学反应如下:

红土镍矿碱熔提硅过程,SiO2提取率的高低取决于含硅矿物的溶解反应与铝硅酸钠的析出反应的竞争。当含硅矿物的溶解速率大于铝硅酸钠的析出速率时,SiO2的提取率升高;当铝硅酸钠的析出速率大于含硅矿物的溶解速率时,SiO2的提取率呈现下降的趋势。

1.3 实验过程

将一定量的固体氢氧化钠加入不锈钢反应器中,通过电阻丝炉加热至实验所需温度,按一定的碱矿比(NaOH与红土镍矿的质量比)称取红土镍矿,在搅拌条件下加入熔融碱中,反应一段时间后,停止加热,体系降温至150 ℃以下时,加水浸出生成的硅酸钠。离心分离得到碱熔渣和硅酸钠溶液,镍、镁和铁等元素富集于渣中,溶液中硅的含量采用氟化钠滴定法测 定,并按式(1)计算SiO2的提取率:

1.4 分析测试

采用德国Xep03 std Vakuum X-荧光分析仪分析粉体样品中各元素含量;采用日本理学Rigaku X射线自动射仪对样品进行物相分析;采用SSX?550型扫描电子显微镜对样品的形貌进行表征。

2 结果与讨论

2.1 正交实验结果与分析

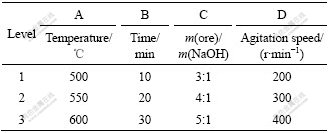

在探索性试验研究的基础上,采用正交表L9(34)设计实验,各因素和水平列于表2。

表2 因素水平表

Table 2 Factors and levels

以SiO2提取率为评价指标进行正交试验,试验结果如表3所列。采取极差法对正交试验结果进行统计分析,由极差R的大小可知:1) 在各因素选定的范围内,影响SiO2提取率各因素的主次关系为:A>B>C>D,即反应温度的影响最为显著,其次是反应时间,碱矿质量比和搅拌速度的影响较小;2) 红土镍矿熔融碱法提硅的最佳实验条件为:反应温度550 ℃,反应时间20 min,碱矿质量比4?1,搅拌速度为400 r/min。按照最佳条件进行验证实验,SiO2的提取率可达93%以上。

表3 正交试验结果与分析

Table 3 Results and analysis of orthogonal test

2.2 反应温度对SiO2提取率的影响

在反应时间为20 min、碱矿质量比为4?1、搅拌速度为400 r/min的条件下,考察了反应温度对SiO2提取率的影响,结果如图2所示。

由图2可知,随着温度的升高,SiO2的提取率显著增加,在550 ℃时出现最高点,而后曲线呈现降低趋势。这是因为温度升高,不仅加快了SiO2与碱的反应速率,使得一定时间内矿石中溶出的SiO2相应地增多;而且也增大了水合铝硅酸钠生成速率,已经溶解的SiO2又返回到矿石中,一定程度上降低了SiO2的提取率。另外,当温度大于573 ℃时,矿石中SiO2的晶型将转变为稳定的α-SiO2[18],常压下难以与碱反应,导致SiO2提取率降低。

图2 反应温度对SiO2提取率的影响

Fig.2 Effect of reaction temperature on extracting ratio of SiO2

2.3 反应时间对SiO2提取率的影响

在反应温度为550 ℃、碱矿质量比为4?1、搅拌速度为400 r/min的条件下,反应时间与SiO2提取率的关系如图3所示。

由图3可知,随着反应时间的延长,SiO2的提取率逐渐增大,当时间超过20 min后,SiO2的提取率随时间的增加而逐渐降低。这是因为随着时间的增加,红土镍矿碱熔过程的二氧化硅的溶解反应与铝硅酸钠的析出反应不断进行,当时间超过20 min后,与硅酸钠的生成速率相比,铝硅酸钠析出的速率更大,致使体系中SiO2的含量减少,SiO2的提取率降低。

图3 反应时间对SiO2提取率的影响

Fig.3 Effect of reaction time on extracting ratio of SiO2

图4所示为不同反应时间得到的碱熔渣的XRD谱。由图4可知,反应时间为10 min时,碱熔渣中存在较小的蛇纹石衍射峰,此反应时间下仍有部分蛇纹石未反应;当反应时间进行至20 min时,碱熔渣的含硅矿物衍射峰全部消失,此时含硅矿物已趋于反应完全;继续延长反应时间至30 min时,碱熔渣出现了较为明显的铝硅酸钠衍射峰,说明此条件下,水合铝硅酸钠的生成速率大于含硅矿物的溶解速率,继续延长时间会导致SiO2提取率的降低。

图4 不同反应时间得到的碱熔渣的XRD谱

Fig.4 XRD patterns of residue at different reaction times

2.4 碱矿质量比对SiO2提取率的影响

图5所示为反应温度550 ℃、反应时间20 min、搅拌速度400 r/min时,不同碱矿质量比与SiO2提取率的关系曲线。

图5 碱矿质量比对SiO2提取率的影响

Fig.5 Effect of mass ratio of alkali to ore on extracting ratio of SiO2

由图5可知,随着碱矿质量比的增大,SiO2的提取率均逐渐增大,当碱矿质量比大于4?1时,SiO2的提取率曲线趋于平缓。碱矿质量比较低时,反应体系粘度较大,流动性较差,传质困难,不利于反应的进行;随着碱矿质量比的增大,体系粘度逐渐降低,液固界面间的传质阻力减小,物质间的扩散速度增大,使反应能够更好地进行;但碱矿比过大会导致碱循环量的增大和操作困难。

2.5 搅拌速度对SiO2提取率的影响

在反应温度为550 ℃、反应时间为20 min、碱矿质量比为4?1的条件下,考察搅拌速度对SiO2提取率的影响,结果如图6所示。

由图6可知,随着搅拌速度的增加,SiO2的提取率逐渐增大,当搅拌速度大于400 r/min后,SiO2的提取率的增加不明显。增大搅拌速度可以加快扩散速度,强化传质过程,使固体颗粒之间的碰撞加剧,有利于破坏矿石表面的沉积物,加快反应的进行。搅拌速度达到400 r/min时,即已达到碱液与矿石的充分接触,再增加搅拌速度SiO2的提取率无明显提高。

图6 搅拌速度对SiO2提取率的影响

Fig. 6 Effect of agitation speed on extracting ratio of SiO2

2.6 碱熔渣的成分分析

碱熔渣经洗涤至中性,取样进行成分分析,结果如表4所列。由表4可知,碱熔渣中二氧化硅的含量较低,大部分已经被浸出,而镍、铁、镁等元素均得到富集,氧化镍含量可达2.92%。

表4 渣的主要化学组成

Table 4 Chemical compositions of residue (mass fraction, %)

碱熔渣的X射线衍射分析如图7所示。结果显示,碱熔渣的主要物相为Mg(OH)2和Fe2O3,含硅矿物峰消失。这说明红土镍矿经熔融碱法处理后,含硅矿物反应完全,而赤铁矿不参加反应。

图7 碱熔渣的XRD谱

Fig.7 XRD pattern of residue

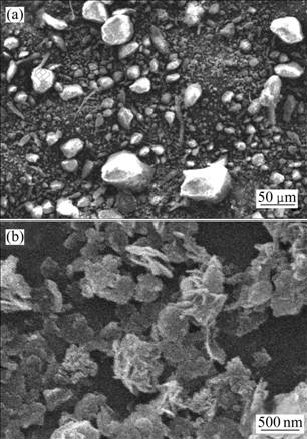

图8所示为红土镍矿和碱熔渣经喷金处理后的SEM像。由图8(a)可以看出,红土镍矿表面粗糙,形状不规则,尺寸不一,粒度分布范围较广,在10~80 ?m之间。由图8(b)可知,碱熔渣呈片状,颗粒尺寸较小,平均粒径小于1 ?m。红土镍矿经熔融碱处理后,原矿的形貌被瓦解,形成了结晶良好的Mg(OH)2,这为后续镁的提取奠定了基础。

图8 红土镍矿及碱熔渣的SEM像

Fig.8 Typical SEM images of laterite-nickel ore(a) and residues(b)

3 结论

1) 通过正交试验得到红土镍矿熔融碱法提硅的最佳实验条件为:反应温度550 ℃,反应时间20 min,碱矿质量比4?1,搅拌速度400 r/min;各因素对SiO2提取率影响由大到小的顺序为:反应温度>反应时间>碱矿质量比>搅拌速度。

2) 按照最佳条件进行红土镍矿碱熔融实验,SiO2的提取率可达93%以上,镍、铁、镁等元素在渣中得到了富集,氧化镍含量达到2.92%。

3) 红土镍矿熔融碱法提硅的工艺技术上可行,为红土镍矿的高附加值综合利用开辟了一条新的途径。

REFERENCES

[1] MCDONALD R G, WHITTINGTON B I. Atmospheric acid leaching of nickel laterites review Part Ⅰ: Sulphuric acid technologies[J]. Hydrometallurgy, 2008, 91: 35?55.

[2] XU Yan-bin, XIE Yan-ting, YAN Lan, YANG Ru-dong. A new method for recovering valuable metals from low-grade nickeliferous oxide ores[J]. Hydrometallurgy, 2005, 80: 280?285.

[3] DEEPATANA A, TANG J A, VALIX M. Comparative study of chelating ion exchange resins for metal recovery from bioleaching of nickel laterite ores[J]. Minerals Engineering, 2006, 19: 1280?1289.

[4] PICKLES C A. Microwave heating behaviour of nickeliferous limonitic laterite ores[J]. Minerals Engineering, 2004, 17: 775?784.

[5] 尹 飞, 阮书锋, 江培海, 王成彦, 陈永强. 低品位红土镍矿还原焙砂氨浸试验研究[J]. 矿冶, 2007, 16(3): 29?32.

YIN Fei, RUAN Shu-feng, JIANG Pei-hai, WANG Cheng-yan, CHEN Yong-qiang. Experimental study on roasted ore of poor nickeliferrous laterite ore with ammonia leaching technology[J]. Mining and Metallurgy, 2007, 16(3): 29?32.

[6] 刘 瑶, 丛自范, 王德全. 对低品位镍红土矿常压浸出的初步探讨[J]. 有色矿冶, 2007, 23(5): 28?30.

LIU Yao, CONG Zi-fan, WANG De-quan. Primary probe into normal atmospheric leaching of low-nickel laterites[J]. Non-ferrous Mining and Metallurgy, 2007, 23(5): 28?30.

[7] PICKLES C A. Drying kinetics of nickeliferous limonitic laterite ores[J]. Minerals Engineering, 2003, 16: 1327?1338.

[8] 李建华, 程 威, 肖志海. 红土镍矿处理工艺综述[J]. 湿法冶金, 2004, 23(4): 191?194.

LI Jian-hua, CHEN Wei, XIAO Zhi-hai. Review on process technologies of laterite-nickel ore[J]. Hydrometallurgy of China, 2004, 23(4): 191?194.

[9] BRAND N W, BUTT C R M, ELIAS M. Nickel laterites: classification and features[J]. AGSO Journal of Australian Geology and Geophysics, 1998, 17: 81?88.

[10] SOLER J M, CAMA J, GAL? S, MEL?NDEZ W, RAM?REZ A, ESTANG A J. Composition and dissolution kinetics of garierite from the Loma de Hierro Ni-laterite deposit, Venezuela[J]. Chemical Geology, 2008, 249: 191?202.

[11] GLEESON S A, BUTT C R M, ELIAS M. Nickel laterites: A review[J]. SEG Newsletter, 2003, 54: 11?18.

[12] LEE H Y, KIM S G, OH J K. Electrochemical leaching of nickel from low-grade laterites[J]. Hydrometallurgy, 2005, 77: 263?268.

[13] 李小明, 唐 琳, 刘仕良. 红土镍矿处理工艺探讨[J]. 铁合金, 2007(4): 24?28.

LI Xiao-ming, TANG Lin, LIU Shi-liang. Technology of treating nickel-bearing laterite[J]. Ferro-alloys, 2007(4): 24?28.

[14] 何焕华. 氧化镍矿处理工艺述评[J]. 中国有色冶金, 2006(6): 12?15.

HE Huan-hua. Review on nickel oxide ore treating processes[J]. China Nonferrous Metallurgy, 2006(6): 12?15.

[15] HERN?ANDEZ C M F, BANZA A N, GOCKB E. Recovery of metals from Cuban nickel tailings by leaching with organic acids followed by precipitation and magnetic separation[J]. Journal of Hazardous Materials, 2007, 139: 25?30.

[16] 杨 波, 王京刚, 张亦飞, 张 懿. 常压下高浓度NaOH浸取铝土矿预脱硅[J]. 过程工程学报, 2007, 7(5): 922?927.

YANG Bo, WANG Jing-gang, ZHANG Yi-fei, ZHANG Yi. Pre-desiliconization of a bauxite ore through leaching by high concentration NaOH solution under atmospheric pressure[J]. The Chinese Journal of Process Engineering, 2007, 7(5): 922?927.

[17] 李光辉, 姜 涛, 范晓慧, 黄柱成, 邱冠周. 一水硬铝石型焙烧—碱浸脱硅新工艺(Ⅲ)[J]. 中国有色金属学报, 2000, 10(6): 899?904.

LI Guang-hui, JIANG Tao, FAN Xiao-hui, HUANG Zhu-cheng, QIU Guan-zhou. Technology of desilication from diasporic bauxite by roasting-alkali leaching process (Ⅲ)[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 899?904.

[18] 饶东生. 硅酸盐物理化学[M]. 北京: 冶金工业出版社, 1980: 32?37.

RAO Dong-sheng. Physicochemistry of silicate[M]. Beijing: Metallurgical Industry Press, 1980: 32?37.

基金项目:国家重点基础研究发展计划资助项目(2007CB613603)

收稿日期:2008-09-02;修订日期:2008-12-31

通讯作者:翟玉春,教授,博士;电话:024-83687731;传真:024-83687731;E-mail: danae2007@yahoo.cn

(编辑 龙怀中)