文章编号:1004-0609(2013)S1-s0198-04

TC4钛合金的真空扩散焊连接

熊进辉,高福洋,陈 斌,郭立栋

(中国船舶重工集团公司 第七二五研究所,洛阳 471039)

摘 要:在不施加中间层的情况下,采用不同工艺参数对TC4钛合金进行真空扩散焊连接。利用光学显微镜分析接头的显微组织结构,利用拉伸试验检测接头力学性能,研究工艺参数对显微组织结构和接头力学性能的影响。结果表明:采用适当的工艺参数可以实现TC4钛合金的真空扩散连接。连接过程中,扩散焊界面经历了紧密接触、塑性变形、元素扩散与反应以及体积扩散微孔消除的过程,焊后形成无明显界面的扩散连接接头,接头的最大室温拉伸强度为958 MPa。

关键词:钛合金;真空扩散焊;显微组织;力学性能;工艺参数

中图分类号:TG 407 文献标志码:A

Vacuum diffusion bonding of TC4 titanium alloy

XIONG Jin-hui, GAO Fu-yang, CHEN Bin, GUO Li-dong

(Luoyang Ship Material Research Institute, Luoyang 471039, China)

Abstract: TC4 titanium alloy was joined by vacuum diffusion bonding without any middle layers at different parameters. The microstructures of the diffusion bonding joints were investigated by optical microscopy (OM). The mechanical properties of the diffusion bonding joints were measured by mechanical testing machine. The effect of processing parameters on the microstructures and mechanical properties were investigated. The results show that TC4 titanium alloy is joined by vacuum diffusion bonding using appropriate bonding temperature and holding time. The diffusion bonding process can be divided into four stages. The maximum tensile strength of the diffusion bonding joints at room temperature is 958 MPa.

Key words: titanium alloy; diffusion bonding; microstructures; mechanical property; processing parameter

钛合金具有优异的综合性能和良好的加工特性,如比强度高、耐蚀性好、密度小、韧性和焊接性较好等,在航空航天、船舶和石油化工等行业都获得了广泛的应用[1-5]。

钛合金常用的熔化焊方法包括TIG、MIG、激光焊和电子束焊等[6-9],但是对于一些连接面积大的特殊接头形式,上述焊接方法并不适用,特别是钛合金在高温条件下易吸收气体,焊接过程中的保护尤为重要。真空扩散焊[10-11]是在真空、高温和施加一定压力的条件下,被焊材料表面原子经过较长时间相互扩散、相互渗透,最终实现材料永久连接的方法。与熔化焊相比,真空扩散焊具有焊接过程与空气隔绝,焊接变形小甚至无变形、节省材料、耐腐蚀性和母材的相当等优点。适用于连接某些特殊接头形式,而且整个连接过程在真空条件下完成,能够有效避免钛合金在高温状态下氧化,成为钛合金某些特殊接头形式连接的优选方法。

本文作者针对TC4 钛合金,开展真空扩散焊工艺试验研究,焊后利用光学显微镜分析接头的显微组织结构,利用拉伸试验检测接头力学性能,研究工艺参数对显微组织结构和接头力学性能的影响。

1 实验

1.1 试验材料

被焊材料采用TC4钛合金,TC4钛合金的组分为Ti-6AI-4V(质量分数,%),名义化学成分如表1所列。

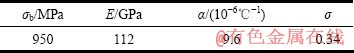

TC4钛合金初始状态为退火态,原始组织为a+b相结构,TC4钛合金具有较好的力学性能,其主要室温力学性能参数如表2所列。

表1 TC4合金化学成分

Table 1 Chemical composition of TC4 (mass fraction, %)

表2 TC4合金力学性能

Table 2 Mechanical Properties of TC4

1.2 试验设备

真空扩散焊工艺试验设备为ZC-ZK/YL40型多功能真空扩散焊系统,如图1所示。其主要技术指标如下:形式为单室,立式,水平进出料;有效加热区尺寸为d 600 mm×600 mm;最高温度为1 300 ℃;额定工作温度为1 200 ℃;控制精度为±1 ℃;有效热区温差≤±5 ℃;极限真空度≤5×10-4Pa(冷态条件,不装工件);工作真空度≤1×10-2Pa(空炉,500~1 000 ℃);冷却方式为负压充气快速冷却和真空冷却;真空降温速率:在真空环境下通过循环水冷从900 ℃降至200 ℃需要9 h;快速降温速率:保证设备能够在180 min内由900 ℃降至200 ℃;冷却气体为氩气(纯度≥99.99%)。

图1 真空扩散焊系统

Fig.1 System of diffusion bonding

1.3 焊接工艺

钛合金待焊面采用精车处理,除去表面杂物,使待焊面达到光滑平整,表面粗糙度可达1.6 μm,用丙酮清洗风干后备用。为了满足力学性能测试的要求,待焊母材尺寸为d 35 mm×45 mm。

对于TC4钛合金,扩散焊温度应该低于相变温度,即不宜超过950 ℃,焊接温度愈低,对钛合金性能影响愈小。对于α+β钛合金而言,焊接温度一般选低于β转变温度40~50 ℃,TC4合金β转变温度为996 ℃,扩散焊温度可选950 ℃左右。因此,在本研究中,选用的连接温度为910~950 ℃,保温时间30~60 min,连接压力3 MPa。

准备好的待焊件放入ZC-ZK/YL40型多功能真空扩散焊炉的恒温区,先用旋片泵抽低真空,然后再用分子泵继续抽高真空,当真空度达到2.5×10-2 Pa以上时开始加热。采用逐步阶段升温保温,使得炉内温度较快较均衡的达到加热温度,之后经过一段时间的保温,开始降温,降温速度约为2 ℃/min,降到200 ℃时关掉分子泵,旋片泵继续工作,当炉温冷却到接近室温时,取出连接好的工件。

1.3 微观组织分析与性能测试

根据国家标准GB/T 5168—2008制备金相试样,利用光学显微镜对接头进行微观组织观察和分析。根据国家标准GB/T 228—2002和GB/T 2651—2008制备力学性能检测试样,在电子万能实验机上进行焊接接头拉伸试验,拉伸试样尺寸如图2所示。

图2 接头拉伸试样示意图

Fig.2 Schematic diagram of tensile sample of joint (Unit: mm)

2 结果与讨论

2.1 接头微观组织结构

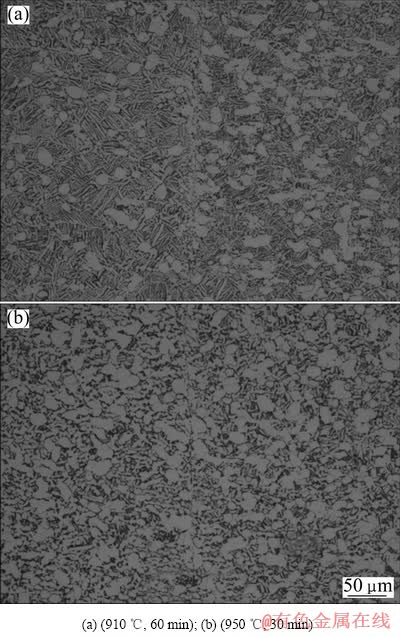

图3所示为扩散焊后接头低倍组织,连接工艺分别为910 ℃、60 min和950 ℃、30 min,连接压力3 MPa。

由图3可知,钛合金真空扩散焊可以形成完整的连接接头,接头界面无明显的气孔、裂纹和夹杂等缺陷。当连接温度较低时(910 ℃),即使保温时间较长(60 min),焊后还是存在较为明显的连接界面,如图3(a)所示。当连接温度较高时(950 ℃),即使保温时间较短(30 min),焊后连接界面基本消失,几乎分辨不出来。

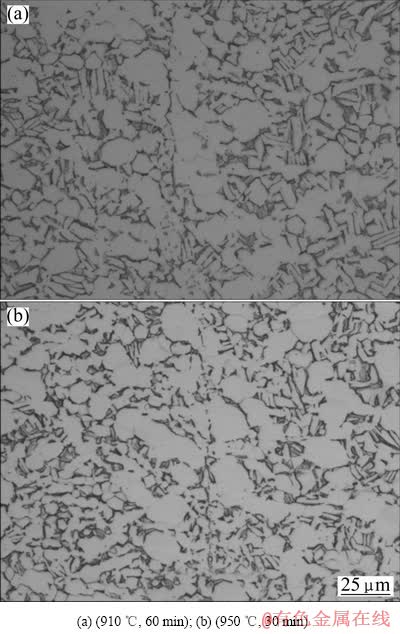

图4所示为扩散焊后接头高倍组织,图5所示为接头连接界面的高倍组织,连接工艺分别为910 ℃、60 min和950 ℃、30 min,连接压力3 MPa。

图3 扩散焊接头低倍组织

Fig.3 Optical microstructures of diffusion bonding joint

图4 扩散焊接头高倍组织

Fig.4 Optical microstructures of diffusion bonding joint

图5 扩散焊接头界面高倍组织

Fig.5 Optical microstructures of interface in diffusion bonding joint

由图4和5可知,扩散焊过程没有改变母材组织,连接界面处组织比母材的细小,这是由于在扩散焊过程中连接界面发生再结晶现象,使得组织得到细化,界面逐步闭合。当连接温度较小时(910 ℃),连接界面再结晶不够充分,界面晶粒尺寸不均匀,如图4和5(a)所示。当连接温度较高时(950 ℃),连接界面再结晶充分,界面两端材料晶粒完全融合,连接界面充分闭合,如图4和5(b)所示。

2.2 接头力学性能

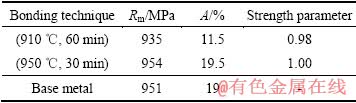

钛合金真空扩散焊接头拉伸性能如表3所列。

表3 扩散焊接头力学性能

Table 3 Mechanical properties of diffusion bonding joint

由表3可知,采用适当的扩散焊工艺参数(950 ℃,30 min),钛合金真空扩散焊接头强度和伸长率均与母材的相当;采用其他扩散焊工艺参数时(910 ℃,60 min),扩散焊接头强度和伸长率略低于母材的,强度系数在0.98~1.00之间,这表明钛合金真空扩散焊焊接性能优良。采用适当的扩散焊工艺参数(950 ℃、30 min),焊接接头的拉伸试验断裂在母材区域,断口有明显的缩颈现象,如图6所示。

图6 扩散焊接头拉伸断裂试样照片

Fig.6 Photo of tensile failure sample of joint

由图3~5可知,当采用适当的扩散焊工艺参数时(950 ℃,30 min),扩散焊连接界面基本闭合,界面形成完整的晶粒,组织细小,因此,扩散焊接头强度与伸长率与母材的相当;当采用其他扩散焊工艺参数时(910 ℃,60 min),扩散焊连接界面较为明显,再结晶不充分,界面晶粒不完整,连接界面没有完全闭合,因此,扩散焊接头强度与伸长率低于母材的,拉伸试验断口可在连接界面处。

2.3 钛合金真空扩散焊连接机理

钛合金扩散焊接接头的形成过程分为3个阶段。第一阶段为物理接触阶段,高温下微观不平的表面,在外加压力作用下,局部接触点首先达到塑性变形,在持续压力的作用下接触面积逐渐扩大,最终使整个接合面达到可靠接触;第二阶段是相互扩散和反应阶段,在温度和压力的作用下,紧密接触的界面发生元素扩散、晶界迁移和化学反应,使微孔消除和形成新的反应相,并在界面形成牢固的结合层;第三阶段是接合层的成长阶段,主要是结合层逐渐向体积方向发展,气孔消除并形成可靠的连接接头。上述过程相互交叉进行,最终在连接界面处由于扩散、再结晶等生成固溶体及共晶体。

3 结论

1) 真空扩散焊可以实现TC4钛合金无明显界面缺陷的优质连接。

2) 采用适当的扩散焊工艺参数,扩散焊接头界面再结晶充分,可实现完全闭合。

3) 采用适当的扩散焊工艺参数,扩散焊接头抗拉强度达到954 MPa,伸长率为19.5%,与母材的相当。

REFERENCES

[1] LEYENS C, PETERS M, EDITORS. Titanium and titanium alloys (Fundamentals and applications)[M]. Weinheim: Wiley-VCH Verlag Gmb-H & Co. KGaA; 2003: 53–86.

[2] 古 一, 戚延龄, 夏长清, 李学雄, 王志辉. 热暴露对 TC11 钛合金组织和力学性能的影响[J]. 中国有色金属学报, 2013, 23(4): 997-1004.

GU Yi, QI Yan-ling, XIA Chang-qing, LI Xue-xiong, WANG Zhi-hui. Effects of thermal exposure on microstructure and mechanical properties of TC11 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 997-1004.

[3] 李赛毅, 文 浩, 雷力明, 张慧儒. TC11 合金两相区退火对微观组织与微观织构的影响[J]. 中国有色金属学报, 2012, 22(11): 3022-3028.

LI Sai-yi, WEN Hao, LEI Li-ming, ZHANG Hui-ru. Effect of annealing in two phase field on microstructure and microtexture of TC11 alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3022-3028.

[4] 文志刚, 王韦琪, 王小翔. 热处理温度对Ti-6Al-3Nb-2Zr-1Mo 合金板材显微组织和性能的影响[J]. 中国有色金属学报, 2010, 20(S1): s647-s649.

WEN Zhi-gang, WANG Wei-qi, WANG Xiao-xiang. Effects of heat treatment temperature on microstructure and mechanical properties of Ti-6Al-3Nb-2Zr-1Mo alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s647-s649.

[5] 张尧武, 曾卫东, 史春玲, 康 超, 彭雯雯. 真空去应力退火对TC18钛合金残余应力及组织性能的影响[J]. 中国有色金属学报, 2011, 21(11): 2780-2785.

ZHANG Yao-wu, ZENG Wei-dong, SHI Chun-1ing, KANG Chao, PENG Wen-wen. Influence of vacuum stress relieving annealing on residual stress and microstructure properties of TC18 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2780-2785.

[6] QI Yun-lian, DENG Ju, HONG Quan, ZENG Li-ying. Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet[J]. Mater Sci Eng A, 2000, 280: 177-181.

[7] SARESH N, GOPALAKRISHNA P M, MATHEW J. Investigations into the effects of electron beam welding on thick Ti-6Al-4V titanium alloy[J]. J Mater Process Technol, 2007, 192/193: 83-88.

[8] BALASUBRAMANIAN M, JAYABALAN V, BALASUBRAMANIAN V. A mathematical model to predict impact toughness of pulsed-current gas tungsten arc-welded titanium alloy[J]. Int J Adv Manuf Technol, 2008, 35: 852-855.

[9] NOOLUA N J, KERRA H W, ZHOUA Y, XIEB J. Laser weldability of Pt and Ti alloys[J]. Mater Sci Eng A, 2005, 397: 8-15.

[10] BALASUBRAMANIAN M, JAYABALAN V, BALASUBRAMANIAN V. Prediction and optimization of pulsed current gas tungsten arc welding process parameters to obtain sound weld pool geometry in titanium alloy using lexicographic method[J]. ASM Int, JMEPEG, 2009, 18: 871-877.

[11] KATO H, SHIBATA M, YOSHIKAWA K. Diffusion welding of Ti/Ti and Ti/stainless steel roads under phase transformation in air[J]. Materials Science and Technology, 1986, 4(2): 405-409.

(编辑 龙怀中)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:熊进辉,高级工程师,博士; 电话: 0379-67256041; E-mail: xiongjinhui@126.com