DOI: 10.11817/j.issn.1672-7207.2016.10.010

超声空化对大规格高强铝合金热顶铸造凝固组织的影响及作用机理

李瑞卿,李晓谦,陈平虎,郭兴,张敏

(中南大学 机电工程学院,高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:在直径为650 mm的高强铝合金热顶半连续铸造中施加多源超声波振动系统,考察多源超声场的施加对铸锭宏微观组织的影响,并分析热顶铸造过程中超声空化作用对熔体凝固的作用机理。研究结果表明:铸锭截面组织整体均匀细化,晶粒形状由发达的枝晶变为等轴枝晶,晶粒平均粒度减小了107 μm,在超声辐射杆附近区域,细化效果最明显;在热顶铸造过程中,铝液中的超声空化范围主要在辐射杆附近有限区域内,故空化效应主要作用于液态金属中的异质颗粒,空化泡崩溃产生的冲击波增大了异质颗粒与液态金属的接触角,降低了形核所需自由能,促使异质形核发生,增大了形核率,细化了凝固组织。

关键词:超声空化;高强铝合金;热顶铸造

中图分类号:TG148; TB559 文献标志码:A 文章编号:1672-7207(2016)10-3354-07

Effect rules and function mechanism of ultrasonic cavitation on solidification microstructure of large size high-strength aluminum alloy with hot top casting

LI Ruiqing, LI Xiaoqian, CHEN Pinghu, GUO Xing, ZHANG Min

(State Key Laboratory of High Performance Complex Manufacturing,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Multi-source ultrasonic vibration system was imposed on high-strength aluminum alloy melt which was in diameter 650 mm hot top semi-continuous casting to explore the effect and mechanism of multi-source ultrasonic field on ingot macrostructure and microstructure. The results show that the ingot organization overall refines, grain shape changes from developed dendrite into equiaxed dendrite, the average grain size decreases by 107 μm, refining effect is most obvious on region around the ultrasonic radiation. In hot top casting process, the region of cavitation mainly lies in a limited area near radiation rod in aluminum liquid. Cavitation activates the heterogeneous particles in the liquid metal, the shock wave generated by collapse of cavitation bubbles increases the contact angle of heterogeneous particles and liquid metal, reduces the nucleation free energy, promotes heterogeneous nucleation occurs, increases the nucleation rate and refines solidification structure.

Key words: ultrasonic cavitation; high-strength aluminum alloy; hot top casting

Al-Cu-Mn系合金属于可热处理强化的加工铝合金,具有良好的工艺性能,广泛应用于航空航天领域。其中,2219铝合金不但耐热性好,易于焊接,而且低温性能良好,在-270~300 ℃力学性能和抗应力腐蚀性能优良,故常应用于火箭燃料箱与助燃剂箱,例如美国雷神δ(Thor-Delta)、土星Ⅱ(Saturn S-Ⅱ)号及日本H-1型火箭的燃料与助燃剂箱[1]。随着我国航天事业的快速发展,急需研制重推力的运载火箭。然而,对于大型高强度铝合金的铸造,由于空间尺度效应和铸造环境非均匀、凝固区域的温度场与流场分布不均匀等往往会造成铸锭凝固组织、成分在空间分布严重不均匀,甚至导致内部应力超限产生裂纹,因此,发展先进的熔炼铸造技术以获得均质、细晶、无裂纹的大规格铸锭是大规格高性能构件成形的前提条件[2-4]。超声波辅助铸造技术是一种绿色无污染的先进铸造技术。近年来,国内外研究者针对施加单源超声场(1个超声波源)对熔体凝固行为及组织的影响进行了研究,取得了一定的理论与实验研究成果。例如JIAN等[5-6]对A356铝合金凝固过程中施加超声振动,发现经超声处理的铝合金铸锭组织由树枝状晶粒转变为等轴晶状晶粒,内部气孔含量降低。IRSID等[7]将超声波振动施加于连铸过程中,用超声波处理Al-Si合金,也取得了良好的效果。赵君文等[8]研究了不同温度下导入超声波对ZL101铝合金半固态浆料凝固的影响,发现当导入温度为610 ℃时,初生晶粒逐渐由枝晶向非枝晶转化,120 s后初生晶粒粒状化。乔翔等[9]研究了超声处理的7050铝合金在变形和热处理后组织的平均晶粒粒度比常规合金的晶粒粒度小50 μm左右,而屈服强度和抗拉强度均比常规铸造合金高60 MPa。上述关于超声波铸造技术的研究多局限于小规格铸锭,施加的超声均为单个超声源。但对于工业大规格铝锭的铸造如厚度大于500 mm的扁锭、直径大于550 mm的圆锭,施加1个超声源作用熔体往往难以取得理想的作用效果,这时需要对熔体同时施加多个超声波振动源。目前人们对这种条件下超声的作用效果及机理研究较少,为此,本文作者在直径为650 mm热顶半连续铸造生产中施加多源超声波辅助铸造2219铝合金圆锭,考察多源超声的施加对铸锭宏微观组织的影响,并针对大规格热顶铸造过程中液位高、液穴深等特征,探讨超声空化作用对铝熔体凝固过程的作用机理。

1 实验材料与方法

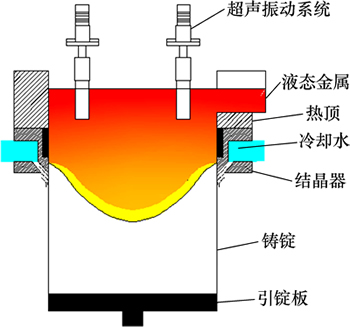

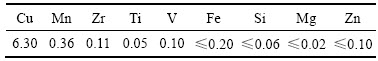

铸造的2219铝合金成分如表1所示。采用工业纯铝、Al-Cu合金、Al-Zr合金、Mn剂、Ti剂和V剂进行配比,细化剂采用Al-Ti-B丝在线添加。结晶器直径为650 mm。当铸造到一定长度时,在结晶器中加入3套近似对称分布的超声振动系统,见图1和图2。从铝熔炉倾倒出液体金属,通过导流槽平稳地流入结晶器上部的热顶内,热顶可有效保温及防止熔体二次污染。随着超声对热顶及结晶器内的液态金属的不断振动,铸锭从底部不断拉出直到熔炉完全清空。

图1 超声辅助热顶铸造示意图

Fig. 1 Schematic diagram of hot top casting with ultrasonic treatment

表1 2219铝合金成分(质量分数,%)

Table 1 Alloy composition of 2219 Aluminum alloy %

超声波辅助铸造的具体过程为:当铸造长度为750 mm时,在热顶结晶器中加入3套超声波振动系统,超声辐射杆插入铝液深度为70 mm左右,近似对称分布(视具体实验条件,可能有误差),如图2所示。打开超声波电源开始施振,直至铸造结束。最终铸锭长度为3 000 mm。

取样时分别距铸锭底部650 mm和1 700 mm处锯切厚度为50 mm的截面进行检测分析。取样图见图2。在2片对比试片上分别取1/4进行低倍组织检验,另外沿不同方向取20 mm厚的样条作为高倍组织检测试样,剩余试片留作备用。图2中黑色圆形表示3支超声辐射杆,图形正上方为浇注口的位置。

低倍检测试样检查前需要进行铣削加工,使其粗糙度不大于3.2 μm,在室温下用高浓度混合酸侵蚀适当时间后立即用清水清洗,观察试样表面,若晶粒显示不清则重复上述过程,直至晶粒显示清晰为止。参考GB/T 3246.2—2012对铸锭的晶粒度等级进行划分并计算平均晶粒度。在金相试样样条上等间隔的切取6个为20 mm×20 mm的试样,经研磨、抛光、腐蚀、烘干后采用Leica台式金相显微镜观察其显微组织,利用TESCAN扫描电镜观察结晶相的形状与粒度,并用OXFORD能谱仪对不同形貌的结晶相进行打点分析。利用截线法及图形处理软件计算不同位置的晶粒粒度。显微组织检验参考GB/T 3246.1—2012。在进行微观组织与晶粒粒度分析时,定义晶粒细化率rgf作为晶粒细化程度的评估指标,

(1)

(1)

式中: 为常规铸造条件下第i个试样测得的平均晶粒粒度,i取1~6;

为常规铸造条件下第i个试样测得的平均晶粒粒度,i取1~6; 为非常规条件下第i个试样测得的平均晶粒粒度。rgf越大,则晶粒细化效果越好,反之越差。

为非常规条件下第i个试样测得的平均晶粒粒度。rgf越大,则晶粒细化效果越好,反之越差。

图2 检测试样位置

Fig. 2 Location of test sample

2 实验结果

图3所示为铸锭低倍组织检验结果。从图3可看出:超声铸锭组织全断面显著细化;沿铸锭半径方向上同一位置处,超声铸锭的组织均有不同程度的细化,具体为边部晶粒度等级为1.0级,较普通铸锭的1.5级降低0.5级,而心部为2.5级较普通铸锭的3.5级降低了1.0级。从边部到心部均匀性提高,经计算,超声铸锭的平均晶粒度约为2.0级,而未加超声铸锭平均晶粒度约为3级,平均晶粒度等级降低1.0级。对比图3(a)和图3(b)可发现超声铸锭的边部细晶区域范围增大。

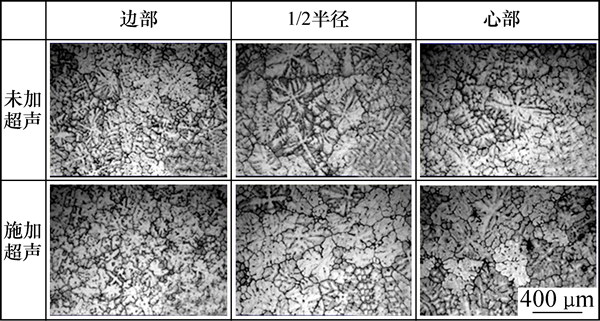

图4所示为显微组织对比图。在边部细晶区,普通铸锭有部分等轴枝晶,但粒度较大,晶粒粒度约为290 μm,超声铸锭组织多为细小等轴晶,分布更加弥散、均匀,平均晶粒粒度约为219 μm;在1/2半径附近处,普通铸锭晶粒组织为二次枝晶臂比较发达的枝晶,晶粒粒度约为410 μm,而施加超声后晶粒的形貌比较圆整,晶粒粒度约为300 μm;在心部粗晶区域,普通铸锭晶粒组织为发达的柱状枝晶,二次枝晶较发达,晶粒粒度为460 μm左右,超声铸锭晶粒虽然也进一步增大,但多为圆整的等轴状枝晶,晶粒粒度约为367 μm。

图3 铸锭低倍组织图

Fig. 3 Diagrams for macrostructures of casting

图4 铸锭显微组织图

Fig. 4 Diagrams for microstructures of casting

从边部到心部所取6个试样的晶粒平均粒度见表2(其中,编号1对应边部,编号6对应心部)。从表2可发现细化率最大的位置在边部到1/2半径这一区域,从1/2半径到铸锭心部细化率逐渐减小。

进一步分析表2可发现:在边部超声铸锭晶粒粒度分布较平缓,说明晶粒粒度普遍较小,比较均匀,边部细晶区范围扩大;越往心部,组织越粗大,但晶粒最粗大区域并不在心部而在其附近,尤其是施加超声铸锭组织曲线在心部明显地向下倾斜,说明铸锭心部组织并没有继续长大反而有所减小。未加超声和施加超声的晶粒平均粒度变化趋势大致相同,边部较小,心部较大;超声虽然对全断面具有细化作用,但细化率并不一致,在1/2半径到边部这一区域比较大。

表2 沿半径方向晶粒粒度

Table 2 Grain size along radius direction

图5所示为普通铸锭与超声铸锭背散射图,可见普通铸锭组织的结晶相比较发达,且有很多结晶相的粒度粗大。而超声铸锭的结晶相呈现等轴状,形状比较圆整,结晶相的分布比较分散,粗大结晶相也很少。经能谱分析发现这2种铸锭的结晶相种类主要是α(Al)+θ(Al2Cu) 二元共晶,其次为α(Al)+θ(Al2Cu)+ T(Al20Cu2Mn3) 三元共晶及杂质相Al7Cu2(FeMn),超声的施加并未改变结晶相的种类,但改变了结晶相的形貌,同时减少了杂质相Al7Cu2(FeMn)的含量。如图5所示放大方框内普通铸锭内含有较多的粗大结晶相,其中呈骨骼状、块状的结晶相,经能谱分析该相为Al7Cu2(FeMn),因为该杂质相常常存在于粗大的二元共晶或三元共晶相内,而超声铸锭的共晶相形貌变得细小,分布也更加均匀,故含Fe杂质相也相应地减少。

图5 加超声与无超声铸锭背散射图

Fig. 5 Back scattering diagrams of two ingots

3 分析与讨论

对于超声作用于金属熔体凝固组织的机理,有多种学说,目前认为超声细晶的主要作用是空化效应和声流效应[10-12],但金属凝固过程的高温、不可观察等原因缺乏最直接的实验证据,而且对于小型实验室模铸和大型工业化铸造等不同铸造条件,超声的作用机理也有所不同。本文铸造采用热顶铸造,其特点是高液位,液面到凝固前沿的距离很大,在实验过程中经实际测量,中心部位凝固前沿的深度达到395 mm,边部的深度为230 mm(液穴分布模拟图见图6(a))。本文将直径为650 mm的超声热顶铸造超声辐射杆插入铝液中的深度为70 mm,施加位置靠近边部(见图2)。这里着重探讨在高液位的熔池中超声的空化效应在铝熔体凝固过程中所起的作用。首先对超声在铝熔体中声压场的分布进行计算仿真,得到超声空化区域,然后进一步分析热顶铸造中超声空化作用的内在机理。

3.1 铝熔体中超声空化场的模拟仿真

建立超声振动系统的有限元模型,进行结构动力学和流固耦合仿真,并计算超声振动系统在流体介质中的声压场。结构动力学分析基于下列基本方程:

(2)

(2)

其中:[M],[C]和[K]分别为系统的质量矩阵、阻尼矩阵和刚度矩阵;{F}为载荷力向量;{u}, 和

和 分别为位移矢量、位移对时间的一阶导数、位移对时间的二阶导数。在有限元模型的几何粒度与材料物性确定的情况下,模型就会确定一个唯一的[M],[C]和[K]。

分别为位移矢量、位移对时间的一阶导数、位移对时间的二阶导数。在有限元模型的几何粒度与材料物性确定的情况下,模型就会确定一个唯一的[M],[C]和[K]。

在计算声场前先假设流体为均质、非黏性、无不规则流动,流体密度是关于压力P的函数并随之变化,则声压分布服从Helmholtz方程[13]:

(3)

(3)

式中:ω=2πf;f为声波的振动频率,Hz;c为声波在流体中的传播速度,m/s。

该偏微分方程的解仅与边界条件和ω和c有关,只要确定某计算域的声压边界条件和声波在该区域介质中的振动频率、传播速度,便可确定该区域的声场分布。当涉及流固耦合问题分析时,在结构方程中考虑流体界面处的声压,从而得到

(4)

(4)

式中: ,

, ;

;

N为声压的形函数;S为声源边界面积;n为边界的法向余弦向量。

对声压积分并将声压的形函数矩阵式代入得到结构动态有限元方程:

(5)

(5)

据该方程与界面能量耗损声波离散方程,得到流固耦合问题的有限单元法离散方程:

(6)

(6)

其中: 。在进行流固耦合分析时,采用直接耦合方式将广义位移向量取作结构位移向量{u}与流体总节点声压向量。通过以上声 场-流固耦合方程进行有限元模拟仿真,结果见图6。

。在进行流固耦合分析时,采用直接耦合方式将广义位移向量取作结构位移向量{u}与流体总节点声压向量。通过以上声 场-流固耦合方程进行有限元模拟仿真,结果见图6。

图6 铝熔体内超声声压模拟

Fig. 6 Acoustic pressure simulations in molten aluminum

图6(b)所示为铝熔体中超声声压幅值分布。由图6(b)可见辐射杆端面附近为声压较强,沿端面法向方向声压幅值迅速衰减。辐射杆侧面也存在1个声辐射区域,该辐射区域声压幅值比端面区域声压幅值低,面积也较小。

液体中产生空化需要达到相应的空化阈值,该空化阈值与液体的温度、含气量、静压力等因素密切相关[14]。经研究[15-16],在700 ℃时,高强铝合金的空化阈值约为1.1 MPa。对近场中声压幅值高于1.1 MPa区域进行重新表示,所得结果如图6(c)所示。当施振深度为70 mm时,超声辐射杆空化区域主要有2部分:辐射杆端面正下方空化区为端面至端面以下70 mm处;侧面空化区则位于辐射杆浸入部分中心部位,其径向距离达到30 mm。故热顶铸造过程中结晶器内超声空化效应的主要作用在辐射杆附近,自液面至液面以下140 mm区域内,离凝固前沿仍有一段距离,因此,空化作用并没有直接参与凝固形核,而是间接影响到凝固过程。

3.2 超声对异质颗粒的润湿活化作用

金属熔体中往往存在许多亚微观不溶性固体异质颗粒物(如氧化物、碳化物、氮化物等),在实际生产中,晶核优先依附于这些异质颗粒表面形成,即以异质形核方式生长。但在通常情况下,由于异质颗粒表面存在一些窄裂缝、凹槽、凸台、裂纹等表面缺陷使得大部分异质颗粒处于惰性状态,并未成为有效异质核心参与形核,因此,在工业生产中,往往需要向熔体中添加细化剂,如向铝合金添加铝钛硼、铝钛碳等。施加超声场对这些异质颗粒具有强烈的活化作用,能够把它们转变为有效晶核参与到凝固形核过程。

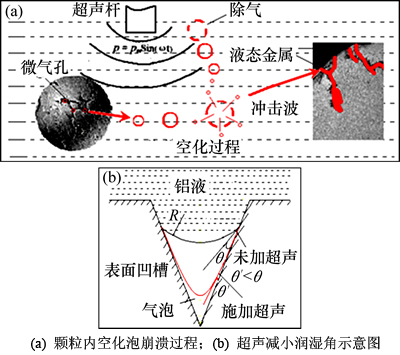

由超声空化作用机理可知在靠近声源较近的区域,空化气泡在极短时间内出现膨胀、收缩和崩溃运动。由于空化时间很短,将气泡的压缩过程认为是绝热过程,则空化作用在铝熔体中产生局部的高温高压,当固液界面上存在局部压力或压力作用在整个系统上时,液相和固相的自由能随着压力和温度的变化而变化。通过试验及文献[17]可以推导出空化泡崩溃、爆裂时的最大压力Pmax为

(7)

(7)

式中:P为空化泡内的蒸汽压;Pm为气泡闭合时的外部压力;γ为蒸汽的比热比。通过计算,在超声频率为19 kHz,超声声强为88.1967 W/cm2时,空化气泡破灭能产生的最大压强为1.6 GPa,如此大的瞬时压强产生的冲击将异质颗粒表面的污物层击溃并使其脱落,而当液态金属中游移的空化泡不断产生、膨胀、收缩和崩溃时,空泡溃灭的冲击压力连续不断地冲击颗粒表面,起到清洗异质颗粒表面的作用。空化泡在振荡过程中将伴随着一系列二阶现象发生, 如使液体本身产生环流,它可使振动气泡表面处存在很高的速度梯度和黏滞应力,促使清洗件表面污物破坏和脱落。同时,超声空化在固体和液体截面上所产生的高速微射流能够除去或削弱边界污层,深入颗粒表面的空穴、凹槽、狭缝和微孔中,提高异质颗粒的润湿性。此外,超声振动也能引起金属液中异质颗粒的强烈振动,也能增大其在液态金属中的润湿性。上述作用使在辐射杆附近的空化区域内异质颗粒不断被冲击、活化,当它们传到液穴中时,就为液穴增加了大量的活性晶核。

超声空化作用对异质颗粒的润湿活化示意图如图7所示。超声空化泡崩溃时产生的高强脉冲不断地将液态金属挤入异质表面缺陷中,降低固-液界面润湿角θ,提高异质表面的润湿性。假定在固态颗粒表面形成的是球形晶核,则均质形核功[18]为

(8)

(8)

图7 超声空化作用对异质颗粒的润湿活化示意图

Fig. 7 Schematic diagram of ultrasonic cavitation effect on heterogeneous particles

异质形核形核功为:

(9)

(9)

(10)

(10)

式中: 和

和 分别为液相与基底、液相与晶核的界面张力;Tm为金属的熔点;△Hm为结晶潜热;△T为过冷度。

分别为液相与基底、液相与晶核的界面张力;Tm为金属的熔点;△Hm为结晶潜热;△T为过冷度。

经对比发现,异质形核功 与

与 之间只差1个因子f(θ)。对于0°≤θ<180°,非均质形核所需的能量普遍比均质形核的小。在不同润湿角下,异质形核与均质形核过程中所需克服的自由能势垒比值如图8所示。从图8可见:θ越小,异质形核所需的能量比均质形核的能量越低,即越容易形核。

之间只差1个因子f(θ)。对于0°≤θ<180°,非均质形核所需的能量普遍比均质形核的小。在不同润湿角下,异质形核与均质形核过程中所需克服的自由能势垒比值如图8所示。从图8可见:θ越小,异质形核所需的能量比均质形核的能量越低,即越容易形核。

图8 异质形核所克服的自由能势垒与接触角的关系

Fig. 8 Relationship between heterogeneous nucleation free energy barrier and contact angle

超声的空化作用对熔池上部的金属液体内异质颗粒起到活化作用,增加其润湿性,降低了θ,促进其在凝固结晶时增加形核核心。在边部,由于超声的施加位置更接近凝固前沿,超声的作用效果更加明显,所以,超声铸锭边部组织细晶区域范围明显增大,细化效果也显著增强(如图5所示)。在心部,超声施加位置远离凝固前沿,因此,对凝固过程作用较小,如表2中心部附近细化率最低。

4 结论

1) 在大规格圆锭热顶半连续铸造过程中,施加多源超声能场,有效地细化了凝固组织,晶粒平均粒度降低107 μm,尤其在铸锭边部到1/2半径附近位置,细化效果最强;铸锭的结晶相粒度变小,呈等轴状,含Fe杂质相也相应减少。

2) 在液穴较深的热顶铸造过程中,超声空化作用对凝固形核过程的影响主要为空化泡的膨胀、收缩、崩溃对液态金属中的异质颗粒不断冲击,增大了其与金属液的接触角,活化了异质颗粒,促使其在凝固过程中形成有效的形核核心,从而细化了凝固组织。

参考文献:

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2005: 931-933.

WANG Zhutang, TIAN Rongzhang. Handbook of aluminum alloy and processing[M]. Changsha: Central South University Press, 2005: 931-933.

[2] 覃锡伯. 铝合金圆铸锭工艺问题及对策[J]. 技术与市场, 2013, 20(6): 140-141.

TAN Xibo. Aluminum alloy round ingot process problems and countermeasures[J]. Technology and Market, 2013, 20(6): 140-141.

[3] 樊富友, 陈明, 于晓艳, 等. 大型薄壁铝合金舱体铸件裂纹分析及试验研究[J]. 铸造技术, 2013, 34(2): 196-199.

FAN Fuyou, CHEN Ming, YU Xiaoyan, et al. Crack analysis and research of large-scale thin-wall cabin body casting of aluminum alloy[J]. Foundry Technology, 2013, 34(2): 196-199.

[4] 崔长齐, 闫绍国, 林晨华, 等. 采用连铸连锻的技术防治合金铸件缺陷[J]. 精密成形工程, 2013, 5(4): 69-73.

CUI Changqi, YAN Shaoguo, LIN Chenhua, et al. Solution to the defect of aluminium alloy foundry goods by continuous castingand forging process[J]. Journal of Netshape Forming Engineering, 2013, 5(4): 69-73.

[5] JIAN Xiaoli, XU Hanbing, MEEK T T. Effect of power ultrasound on solidification of aluminum A356 alloy[J]. Materials Letters, 2005, 59(2/3): 190-193.

[6] XU Hanbing, HAN Qingyou, MEEK T T. Effects of ultrasonic vibration on degassing of aluminum alloys[J]. Materials Science and Engineering A, 2008, 473(1/2): 96-104.

[7] IRSID. Ultrasonic can replace mould oscillation during billet casting[J]. Steel Times Int, 1989, 10(5): 45.

[8] 赵君文, 吴树森, 万里, 等. 超声场中金属半固态浆料组织的演化[J]. 金属学报, 2009, 45(3): 314-319.

ZHAO Junwen, WU Shusen, WAN Li, et al. Evolution of microstructure of semisolid metal slurry in ultrasonic field[J]. Acta Metallurgica Sinica, 2009, 45(3): 314-319.

[9] 乔翔, 张志高, 李建涛, 等. 铸造过程中超声处理对7050铝合金变形及热处理的影响[J]. 金属热处理, 2011, 36(12): 62-65.

QIAO Xiang, ZHANG Zhigao, LI Jiantao, et al. Effect of ultrasonic treatment during casting on deformation and heat treatment of 7050 aluminum alloy[J]. Heat Treatment of Metals, 2011, 36(12): 62-65.

[10] ESKIN G I. Effect of ultrasonic (cavitation) treatment of the melt on the microstructure evolution during solidification of aluminum alloy ingots[J]. Zeitschrift Für Metallkunde, 2002, 93(6): 502-507.

[11] HUNT J D, JACKSON K A. Nucleation of solid in an undercooled liquid by cavitation[J]. Journal of Applied Physics, 1966, 37(1): 254-257.

[12] YASUDA K, SAIKI Y, KUBO T, et al. Influence of high-power ultrasonic irradiation on primary nucleation process during solidification[J]. Japanese Journal of Applied Physics, 2007, 46(7B): 4939.

[13] HUMPHREY V F. Ultrasonic review[J]. Progress in Biophysics and Molecular Biology, 2007, 93(1/2/3): 195-211.

[14] 冯若. 超声手册[M]. 南京: 南京大学出版社, 1999: 28.

FENG Ruo. Ultrasonics handbook[M]. Nanjing: Nanjing University Press, 1999: 28.

[15] ESKIN G I. Principles of ultrasonic treatment application for light alloys Melts[J]. Advanced Performance Materials, 1997, 4(2): 223-232.

[16] 张敏, 李晓谦, 蒋日鹏, 等. 超声振动系统振幅分布与空化腐蚀区域研究[J]. 振动与冲击, 2014, 33(13): 59-62.

ZHANG Min, LI Xiaoqian, JIANG Ripeng, et al. Amplitude distribution and cavitation corrosion field of ultrasonic transducer system[J]. Journal of Vibration and Shock, 2014, 33(13): 59-62.

[17] MONDOLFO L F. Structure and properties of aluminum alloys[M]. London: Butterworths Press, 1976: 232-260.

[18] 范晓明. 金属凝固理论与技术[M]. 武汉: 武汉理工大学出版社, 2012: 211-213.

FAN Xiaoming. Metal solidification theory and technology[M]. Wuhan: Wuhan University of Technology Press, 2012: 211-213.

(编辑 陈灿华)

收稿日期:2015-11-20;修回日期:2016-01-24

基金项目(Foundation item):国家重点基础研究发展计划(973计划)项目(2012CB619504);国家自然科学基金资助项目(51475480,51575539)(Project(2012CB619504) supported by the National Key Basic Research Program (973 Program) of China; Projects(51475480, 51575539) supported by the National Natural Science Foundation of China)

通信作者:李瑞卿,博士研究生,从事金属凝固成形、超声波辅助铸造等研究;E-mail:lll87430@126.com