文章编号:1004-0609(2007)07-1129-06

润滑剂含量不同时W-Ni-Fe合金的温压行为

彭元东,易健宏,刘 宁,叶途明,李丽娅,罗述东,冉俊铭

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:研究90W-7Ni-3Fe合金的温压成形工艺,探讨润滑剂含量不同时温压行为对硬粉的作用,并比较温压工艺与常温压制工艺的不同。结果表明:在相同单位压制压力下,温压压坯密度明显高于常温压制的;润滑剂含量为0.6%(质量分数)时压坯密度达到最大值,温压压制与常压压制相比,压坯密度增加0.26 g/cm3;润滑剂含量超过0.6%后,压坯密度又逐渐下降;添加润滑剂后合金的脱模力明显降低,其温压脱模力较常压脱模力小;试样的抗拉强度、伸长率在润滑剂含量为0.6%时达最大值,这与烧结体的密度随润滑剂含量的变化一致;同时温压烧结坯的密度与常压试样的区别不明显,但抗拉强度和伸长率都高于同批的常压试样。

关键词:W-Ni-Fe合金;润滑剂;粉末冶金;温压成形;力学性能

中图分类号:TF 124.3; TG 146.4 文献标识码:A

Warm compacting behavior of W-Ni-Fe alloy with

different lubricant contents

PENG Yuan-dong, YI Jian-hong, LIU Ning, YE Tu-ming, LI Li-ya, LUO Shu-dong, RAN Jun-ming

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract:The warm compacting process of 90W-7Ni-3Fe alloys was discussed. The warm compacting behavior of hard powders with different lubricant contents, and the difference between room-temperature (RT) compaction and warm compaction was investigated. The results indicate that the relative density of greens via warm compaction is clearly higher than that of greens via RT compaction under the same compacting pressure. The highest green density is obtained in the sample via warm compaction with 0.6% lubricant, 0.26 g/cm3 higher than that of samples compacted at RT. When the lubricant addition is more than 0.6%, the green density decreases. The greens containing lubricant obviously have a decrease in ejecting force, and also the ejection force in warm compaction is lower than that in RT compaction. Both the tensile strength and elongation reach the highest values in the sample with 0.6% lubricant, which is in agreement with the change of sintered density as a function of lubricant content. Although little difference exists between the densities obtained by RT compaction and warm compaction, the warm compaction leads to higher tensile strength and elongation.

Key words: W-Ni-Fe alloy; lubricant; powder metallurgy; warm compaction; mechanics properties

温压技术是20世纪90年代中期发展起来的一种粉末冶金新工艺。该技术采用特殊的粉末加温、粉末输送和模具加热系统,将加有特殊润滑剂的预合金粉末和模具等加热至130~150 ℃,并将温度变化控制在±2.5 ℃以内,然后和传统粉末冶金工艺一样进行压制、烧结而制得粉末冶金零件的技术[1-4]。温压工艺具有自身的独特技术优点[5-8]:压坯密度和烧结密度高,压坯强度高,脱模压力低,弹性后效小,压坯密度分布均匀;特别当零件密度材质相同时,采用温压工艺制得材料的极限抗拉强度比复压复烧工艺所制得材料的提高了10%左右,而且疲劳强度也提高了10%~ 40%。正是由于这些特点,在国际粉末冶金学界,人们称温压工艺是导致粉末冶金革命的一项新技术。

长期以来,温压工艺的主要研究与应用对象是铁基P/M零件。由于温压可提高粉末压坯的密度,降低压坯脱模压力和弹性后效,以及在烧结过程中对尺寸的一致性保持良好的特点,于是人们便探讨并研究了以下问题:能否将温压应用于其它塑性粉末、甚至在脆性粉末的压制过程中,温压的温度效应对这些粉末压制密度的影响趋势是否与对铁粉的影响趋势相似。实验结果表明[9-12],温压无论对塑性粉末还是脆性粉末均有效果,这为非铁基金属粉末的温压工艺提供了实验室依据。

本文作者以W-Ni-Fe为原料粉末,研究润滑剂含量不同时硬脆性金属粉末的常压与温压行为,为进一步探索温压的致密化机理提供实验依据。

1 实验

1.1 原料

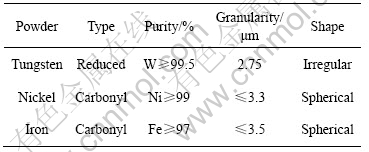

本实验所用原料粉末的特性见表1,润滑剂采用德国赫司特公司生产的ME-106润滑剂。

表1 原料粉末特性

Table 1 Characteristics of powders

1.2 实验过程

先将称好的粉末原料W、Ni、Fe以质量比为90?7?3的比例倒入不锈钢球磨筒中,球料比为5?1,采用无水酒精为介质。然后将球磨筒放入XQM变频行星式球磨机混料,转速为120 r/min。最后将混合好的粉末料,滤去酒精后,取出硬质合金球,放入100 ℃干燥箱干燥,至粉末不结团后,取出粉末装好放在干燥皿中备用。

将样品分为6份,分别加入质量分数为0%、0.2%、0.4%、0.6%、0.8%和1.0%的润滑剂,混合均匀。

成形过程分为常温压制(简称常压)成形和温压成形(简称温压),压制压力均为600 MPa,常温为20 ℃,温压的温度为150 ℃,所用设备为Gleeble1500热模拟实验机。

将所得的压坯在900 ℃进行预烧,以除去压坯中的润滑剂;随后进行烧结,烧结温度为1 460 ℃,保温1 h。整个过程在卧式电阻炉中进行,以氢气为保护气氛。接着将烧结后的试样在真空炉中于1 200 ℃保温2 h进行热处理,最后风冷至室温即得试样。

1.3 组织与性能检测

分别对生坯的密度、烧结坯的密度、抗拉强度、硬度和伸长率进行测量,同时也对产品的致密度进行计算。最后在日本产的JSM-6360LV扫描电子显微镜观察试样的表面和拉伸断口形貌。

2 结果及分析

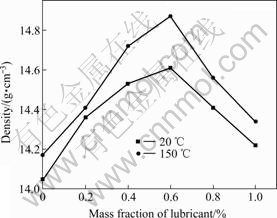

2.1 润滑剂含量不同时W-Ni-Fe粉末的压坯密度

图1所示为W-Ni-Fe混合粉末在润滑剂含量不同时常压和温压所得的压坯密度。由图1可见,在相同单位压制压力下压制W-Ni-Fe混合粉末时,温压压坯密度明显高于常压所得的压坯密度。这与铁基粉末温压成形的工艺特点是一致的[9]。随着润滑剂含量的升高,压坯密度在润滑剂含量为0.6%时达到最高点,常压和温压的密度分别达到理论密度的85.19%和86.17%,温压与常压相比,压坯密度增加0.26 g/cm3。润滑剂含量超过0.6%后,压坯密度又逐渐下降。

图1 润滑剂不同含量和温度下W-Ni-Fe粉末的压坯密度

Fig.1 Dependence of W-Ni-Fe green densities with lubricant content and temperature

在压坯的压制过程中,致密化机制主要为颗粒重排与塑性变形。一方面,温压改进粉末颗粒的重排,促使小粉末填充到大粉末颗粒的间隙中,同时还增强粉末颗粒的塑性变形,从而提高生坯密度[13-14]。因此,要获得较高的压制密度,就要求粉末颗粒有适当的塑性变形能力及粉末的粒度组成。在本实验所用的90W-7Ni-3Fe混合粉末中,由于钨颗粒的塑性变形能力有限,镍、铁颗粒对致密化的作用便显得尤为突出。另一方面,润滑剂的加入改变粉末的表面性能,使其在温压时处于粘流态,从而提高压制过程中粉末颗粒之间的润滑效果,减少摩擦阻力,使压制时粉末颗粒能更好地传递压力,粉末颗粒充填性好,而有利于密度的明显提高[15-16]。因此,适量的润滑剂含量有利于压制成形,提高压坯密度;而润滑剂添加过量,润滑剂相对质量和体积增加,密度反而下降。

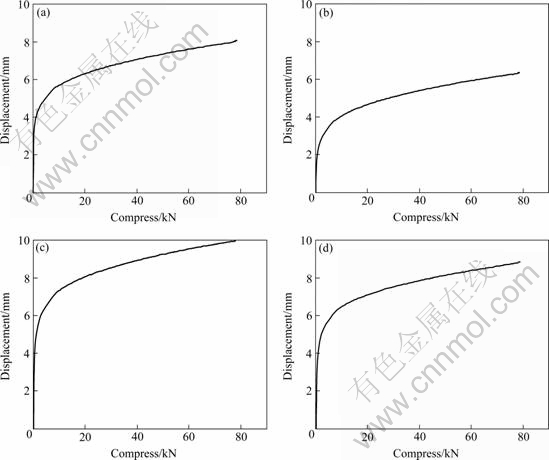

2.2 润滑剂含量不同时W-Ni-Fe粉末的温压压制过程

压制过程W-Ni-Fe粉末的载荷—位移曲线如图2所示。从图2中可看出,随着压制压力的增加,位移逐渐增大。在位移增大的过程中,随着压下量的增大,压坯的抵抗力也随着增大,压下速度相应地减慢,曲线由陡变缓。

一般认为,温压工艺能获得高密度材料的主要原因是粉末颗粒的塑性变形得以松弛的结果。然而,在温压时,粉末颗粒的屈服强度降低并不明显,不可能造成粉末压坯密度的显著提高。因而,在温压过程中,粉末压坯致密化由多种因素控制。从粉末原料的特性来看,在温压时,由于粉末硬度下降而使有限塑性变形得以较充分进行,即产生协调性变形,有利于克服粉末之间的相互牵制,导致颗粒移动阻力下降,从而为粉末颗粒间的相互填充创造了条件。这就是压制过程中的颗粒重排现象[17]。

2.3 润滑剂含量对W-Ni-Fe压坯脱模过程及脱模力的影响

图3所示是W-Ni-Fe压坯脱模过程的脱模力—位移曲线。从图3可以看出,不含润滑剂时常压与温压时的脱模力都较大,大约为12~18 kN,远高于添加润滑剂以后的脱模力(大约5~7 kN),说明添加润滑剂有助于压坯从阴模中脱出。这种较低的脱模力可提高工业生产中模具的使用寿命。此外,润滑剂含量相同时,温压的脱模力比常压的脱模力低。这也是因为温度升

图2 W-Ni-Fe粉末的位移—载荷曲线

Fig.2 Displacement—compress curves of W-Ni-Fe powders in compaction: (a) Warm compaction sample without lubricant; (b) Room-temperature compaction sample without lubricant; (c) Warm compaction sample with 0.6% lubricant; (d) Room- temperature compaction sample with 0.6% lubricant

图3 W-Ni-Fe压坯的脱模力—位移曲线

Fig.3 Force—displacement curves of W-Ni-Fe green in ejection course: (a) Warm compaction sample without lubricant; (b) Room-temperature compaction sample with lubricant; (c) Warm compaction sample with 0.6% lubricant; (d) Room-temperature compaction sample with 0.6% lubricant

高改善了润滑剂的润滑效果,从而使得温压脱模力低于常压。

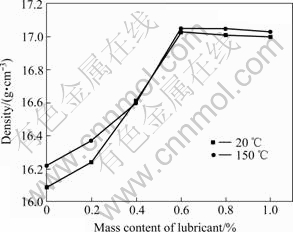

2.4 W-Ni-Fe合金烧结体密度分析

由图4可见,W-Ni-Fe合金烧结体在润滑剂含量为0.6%时密度可达17.05 g/cm3,相对密度为99%以上;温压烧结坯密度较之常温压坯密度要略高。这表明温压压制不仅对生坯密度有明显的提高,而且对于烧结坯的密度也略有提高。

90W-7Ni-3Fe的理论密度为17.15 g/cm3,因此,烧结体中的孔隙大约只占总体积的约1%,烧结体基本致密。这是由于高密度合金是由混合粉末经液相烧结而成,烧结温度高于1 465 ℃时就形成共晶液相,高于此温度烧结15 min,合金就可获得致密度达99%以上的烧结体。同样是因为高密度烧结属于典型的液相烧结,所以虽然常压与温压压坯密度有较大差别,

图4 W-Ni-Fe合金烧结体密度与润滑剂含量和温度的关系曲线

Fig.4 Dependence of W-Ni-Fe sintered composition density on lubricant content and temperature

但是两者烧结密度差别却不是很大。

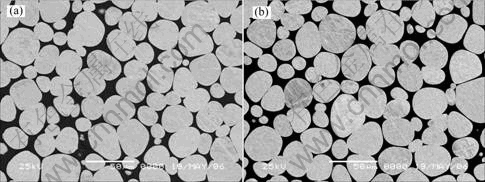

2.5 W-Ni-Fe合金力学性能与显微组织分析

表2所列为常压与温压W-Ni-Fe合金试样的力学性能。从表2可以看出,试样的抗拉强度、伸长率随润滑剂含量增加而增大,润滑剂含量为0.6%时达最大值,随后又下降。这与烧结体的密度随润滑剂含量的变化一致。同时温压烧结坯的抗拉强度、伸长率都高于同批的常压试样。如图5所示,由于密度相差很小;温压和常压烧结体的微观组织并没有明显的差别,晶粒大小、分布均差不多。因此,出现抗拉强度不同的原因可能是温压较常压的试样密度均匀性好的缘故,这有待于进一步实验证实。由表2可见,各组烧结体硬度大致相当,总体偏低,这说明润滑剂的含量变化对烧结体硬度的改变没有明显影响。

图6所示为含0.6%润滑剂温压成形试样的拉伸断口形貌照片。从图6可以看出,合金拉伸断口性质主要为W晶粒的沿晶断裂和粘结相的延性撕裂,粘结相撕裂呈韧窝状;图中白色集中的部分是Ni-Fe富集区,钨颗粒少数表现为解理断裂,与此相对应的合金力学性能也不是很高。

表2 润滑剂不同含量时W-Ni-Fe合金烧结体的力学性能

Table 2 Mechanical properties of W-Ni-Fe alloy samples by room-temperature compaction and warm compaction

图5 含0.6%润滑剂W-Ni-Fe烧结体的表面SEM照片

Fig.5 SEM images of W-Ni-Fe sintered compacts with 0.6% lubricant: (a) Warm compaction; (b) Room-temperature compaction

图6 含0.6%润滑剂温压W-Ni-Fe烧结试样的断口形貌照片

Fig.6 Tensile fracture images of warm compaction W-Ni-Fe sintered samples with 0.6% lubricant content

3 结论

1) 在相同压制压力下,W-Ni-Fe粉末温压压坯密度明显高于常压压坯密度。压坯密度随着润滑剂含量的升高而升高,在润滑剂含量为0.6%时达到最大值,温压和常压的压坯密度分别达到理论密度的86.17%和85.19%;温压与常压相比,其压坯密度增加0.26 g/cm3;润滑剂含量超过0.6%后,压坯密度又逐渐下降。

2) 不含润滑剂时烧结体的脱模力大约为12~ 18 kN,大大高于添加润滑剂以后的脱模力(大约5~ 7 kN);温压脱模力较常压脱模力小。

3) 试样的抗拉强度、伸长率先随润滑剂含量增加而增大,润滑剂含量为0.6%时达到最大值,随后又下降;这与烧结体密度随润滑剂含量的变化一致。同时温压烧结坯密度同常压烧结坯密度的差别不是很明显,但温压试样的抗拉强度、伸长率都高于同批的常压试样。

REFERENCES

[1] Capus J, Pickering S, Weaver A. Hoeganaes offers higher density at lower cost[J]. Metal Powder Report, 1994, 49(7/8): 22-24.

[2] Rutz H G, Hanejko F G. High density processing of high performance ferrous materials[J]. The International of Powder Metallurgy, 1995, 31(1): 9-17.

[3] 韩凤麟. ANCODENSE TM温压工艺特性[J]. 粉末冶金技术, 1995, 13(4): 294-302.

HAN Feng-lin. Characteristic of ANCODENSE TM warm compaction[J]. Powder Metallurgy Technology, 1995, 13(4): 294-302.

[4] 肖志瑜, 张菊红, 吴苑标, 等. 烧结参数对温压Fe-2Ni-2Cu- 1Mo-1C材料抗拉强度的影响[J]. 中国有色金属学报, 2006, 16(8): 1326-1330.

XIAO Zhi-yu, ZHANG Ju-hong, WU Yuan-biao, et al. Influence of sintering parameters on tensile strength of warm compacted Fe-2Ni-2Cu-1Mo-1C material[J]. Journal of China Nonferrous Metals, 2006, 16(8): 1326-1330.

[5] 彭元东, 易健宏, 叶途明, 等. 温压工艺的研究进展[J]. 粉末冶金材料科学与工程, 2006, 11(3): 133-139.

PENG Yuan-dong, YI Jian-hong, YE Tu-ming, et al. Researching progress on warm compaction [J]. Materials Science and Engineering of Powder Metallurgy, 2006, 11(3): 133-139.

[6] 曹顺华, 易建宏, 曲选辉, 等. 温压技术的发展、特点及其问题分析[J]. 材料科学与工程, 1999, 17(1): 58-61.

CAO Shun-hua, YI Jian-hong, QU Xuan-hui, et al. Development and characteristics of warm compaction and its technological problem analysis[J]. Materials Science and Engineering, 1999, 17(1): 58-61.

[7] 易健宏, 叶途明, 彭元东. 粉末冶金温压工艺的研究进展及展望[J]. 粉末冶金技术, 2005, 23(2): 140-144.

YI Jian-hong, YE Tu-ming, PENG Yuan-dong. Research progress and prospect of the process in warm compaction in powder metallurgy[J]. Powder Metallurgy Technology, 2005, 23(2): 140-144.

[8] 李元元, 肖志瑜, 倪东惠, 等. 温压成形技术的研究进展[J]. 华南理工大学学报, 2002, 30(11): 15-20.

LI Yuan-yuan, XIAO Zhi-yu, NGAI Tungwai, et al. Research progress in warm compaction forming technology[J]. Journal of South China University of Technology, 2002, 30(11): 15-20.

[9] 亓家钟. 铁基材料高密度温压工艺[J]. 粉末冶金工业, 1996, 6(2): 14-16.

QI Jia-zhong. Warm compaction process of ferrous materials offers high density[J]. Powder Metallurgy Industry, 1996, 6(2): 14-16.

[10] 李明怡. 金属粉末温压工艺的研究现状和进展[J]. 世界有色金属, 1999(12): 40-42.

LI Ming-yi. Researching status and progress of metal powder warm compaction[J]. World Nonferrous Metals, 1999(12): 40-42.

[11] 李明怡, 果世驹, 康志君, 等. 不同类型金属粉末的温压行为[J]. 粉末冶金技术, 2000, 18(4): 261-264.

LI Ming-yi, GUO Shi-ju, KANG Zhi-jun, et al. Warm compaction behavior of various metal powders[J]. Powder Metallurgy Technology, 2000, 18(4): 261-264.

[12] 罗述东, 唐新文, 易健宏, 等. 钨基高密度合金粉末的温压成形行为研究[J]. 粉末冶金工业, 2003, 13(3): 31-35.

LUO Shu-dong, TANG Xin-wen, YI Jian-hong, et al. Study on warm compacting behavior of high-density tungsten alloy powders[J]. Powder Metallurgy Industry, 2003, 13(3): 31-35.

[13] Capus J. Warm compacted turbine hub leads new PM thrust[J]. Metal Powder Report, 1997, 52(9): 19.

[14] Capus J. PM2TEC’97, Chicago[J]. Powder Metallurgy, 1997, 40(3): 181-185.

[15] Degoix C N, Griffo A, German R M. Effect of lubrication mode and compaction temperature on the properties of Fe-Ni-Cu-Mo-C [J]. The International Journal of powder Metallurgy, 1998, 34(2): 29-33.

[16] St-Laurent S, Chagnon F. 为温压工艺设计的混合粉[J]. 言小雄, 译. 粉末冶金技术, 1998, 16(1): 40-51.

St-Laurent S, Chagnon F. Mixed powder for warm compaction[J]. YAN Xiao-xiong, transl. Powder Metallurgy Technology, 1998, 16(1): 40-51.

[17] 李明怡, 果世驹, 林 涛. 压制参数对压坯致密化过程的影响[J].粉末冶金工业, 2001, 11(3): 29-33.

LI Ming-yi, GUO Shi-ju, LIN Tao. The effect of compacting parameters on densification of warm compacted iron powders[J]. Powder Metallurgy Industry, 2001, 11(3): 29-33.

(编辑 龙怀中)

基金项目:民口配套“十五”重点资助项目(MKPT-2004-09ZD)

收稿日期:2006-12-01;修订日期:2007-06-18

通讯作者:易健宏,教授,博士;电话:0731-8877328;E-mail: yijianhong2007@sohu.com