文章编号:1004-0609(2015)09-2435-10

成型压力对冷等静压-烧结法制备ITO靶材中孔隙缺陷的影响

刘志宏,谌 伟,李玉虎,刘智勇

(中南大学 冶金与环境学院,长沙 410083)

摘 要:孔隙缺陷是影响ITO靶材密度及其均匀性的主要原因。研究冷等静压-常压烧结法制备ITO靶材中孔隙的形成机理及其在成型中的变化过程,分析成型压力(模压和冷等静压)对生坯及靶材孔隙缺陷及相对密度的影响。结果表明:尽管模压压力远低于冷等静压压力,但模压过程对ITO生坯中孔隙缺陷的消除具有重要影响;当模压压力由4 MPa提高到20 MPa时,生坯经200 MPa冷等静压后,孔径在15~45 μm区间的孔隙率由1.09%降低为0.2%。实验所用ITO颗粒的屈服压力约为12 MPa。当模压压力小于12 MPa时,生坯中的ITO颗粒仅发生压缩形变;而当其大于12 MPa时,ITO颗粒破碎,致使生坯致密化,从而消除孔隙缺陷。在模压和冷等静压压力分别为24和250 MPa条件下,ITO生坯相对密度达59.3%,烧结后ITO靶材相对密度高达99.1%。

关键词:ITO靶材;成型压力;孔隙缺陷;形成机理

中图分类号:TF12 文献标志码:A

Effects of forming pressures on pore defects in ITO target prepared by cold isostatic pressing-pressureless sintering

LIU Zhi-hong, CHEN Wei, LI Yu-hu, LIU Zhi-yong

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: Pore defects are the primary cause that affects the density and uniformity of ITO target. The formation mechanism of pores, as well as their evaluation in the forming process, were studied in ITO target preparation by cold isostatic pressing-pressureless sintering. The effects of forming pressures in mould and cold isostatic pressing on pore defects and relative densities of ITO green body and sintered target were investigated. The results show that even though the pressure in mould pressing is much less than those in isostatic pressing, mould pressing has a significant impact on the elimination of pore defects. As the pressure in mould pressing increases from 4 MPa to 20 MPa, the porosity of sizes between 15-45 μm in the green body decreases from 1.09% to 0.2% after cold isostatic pressing at 200 MPa. The yield pressure of ITO granules used in this study is about 12 MPa. When the pressure in mould pressing is lower than 12 MPa, ITO granules in the green body only suffer from compressive deformation; while the pressure is larger than 12 MPa, ITO granules in green body are crushed in mould pressing, resulting in the densification of ITO green body, therefore eliminating the pores. Under pressures of 24 MPa in mould pressing and 250 MPa in isostatic pressing, respectively, the relative density of obtained ITO green body reaches 59.3%, and after pressureless sintering, the relative density of the obtained ITO target reaches up to 99.1%.

Key words: ITO target; forming pressure; pore defect; formation mechanism

铟锡氧化物(Indium tin oxide,ITO)靶材是制备ITO薄膜的关键材料[1-2],其性能,特别是密度及其均匀性,显著影响ITO薄膜的导电和可见光透过性[3-5],而孔隙缺陷是决定ITO靶材密度及其均匀性的主要因素。因此,研究者们广泛开展了高密度ITO靶材制备的研究。NADAUD等[6]研究了TiO2、ZrO2和SiO2对ITO靶材烧结性能的影响,发现添加质量分数小于1%的TiO2,靶材相对密度大于99%。烧结助剂能促进靶材烧结致密化,但会引入杂质恶化ITO薄膜性能。提高成型压力、强化粉末原料湿法球磨分散、采用纳米粉末也可提高靶材密度。KIM等[7]研究了成型压力对ITO靶材密度的影响,当成型压力由25 MPa增加至300 MPa时,靶材相对密度由50%提高至90%。IWASA等[8]研究发现,对ITO粉末进行机械化学处理,有利于ITO靶材的烧结致密化,球磨120 min能将靶材相对密度由75%提升到91%。KIM等[9-10]研究证实,降低ITO粉末粒度有利于靶材的致密化。黄政仁等[11]研究了喷雾造粒SiC粉料成型中的破碎行为,发现喷雾造粒过程能有效改善SiC粉料流动性,从而提高压制性能,而当冷等静压压力大于200 MPa时,能够破碎生坯中硬团聚体,有利于提高生坯密度。徐光亮 等[12]研究表明,当成型压力大于4.6 GPa时,可获得密度为60%的生坯,有利于烧结致密。

冷等静压-常压烧结法可制备出相对密度(ITO靶材理论密度为7.15 g/cm3)高达99%的ITO靶材,满足当前屏显ITO薄膜的制备要求,已成为当前高密度ITO靶材制备主流工艺[13-15]。但是,随着产业技术的升级,ITO靶材密度仍有待提高。制备高密度ITO靶材的关键在于降低主要源自成型过程的孔隙缺陷。对ITO靶材成型已有一些研究,但大多集中于工艺优化,对成型中孔隙的形成机理及其演进规律,仍缺乏深入研究。本文作者研究了冷等静压-常压烧结法制备ITO靶材时,成型过程中孔隙的形成机理及其变化过程,以及成型压力(模压和冷等静压)对ITO生坯和靶材中孔隙缺陷及相对密度的影响。

1 实验

1.1 实验原料

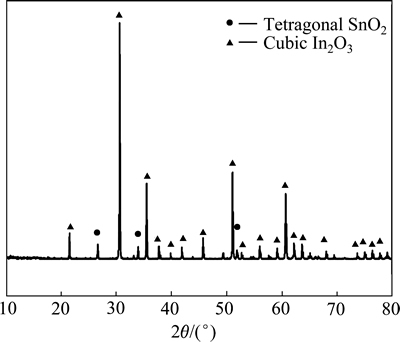

实验原料为喷雾干燥法制备的ITO粉料,其In2O3与SnO2质量比为9:1,比表面积为20.05 m2/g,松装密度为1.95 g/cm3。 ITO粉料的SEM、XRD和XRF分析结果分别如图1、图2和表1所示。

由图1可见,ITO粉料为规则球形颗粒,表面较光滑,平均粒径约为60 μm,部分颗粒带有“酒窝”状缺陷。由图2可知,实验所用ITO粉料的物相为立方晶系方铁锰矿结构In2O3和四方相结构SnO2,无其他杂相存在,结晶度较高。表1所列为ITO粉料XRF分析结果。由表1可知,ITO粉料中杂质总含量为0.0055%(质量分数),满足ITO靶材制备对原料纯度的要求。

图1 ITO粉料的SEM像

Fig. 1 SEM image of ITO granules

图2 ITO粉料的XRD谱

Fig. 2 XRD pattern of ITO granules

表1 ITO粉料的XRF分析结果

Table 1 XRF analysis result of ITO granules (mass fraction, %)

1.2 样品制备

采用模压-冷等静压-脱脂-常压烧结工艺制备ITO靶材。模压:使用直径42 mm圆柱形钢模,单次ITO粉料填装量为25 g,于Y79型全自动粉末制品液压机上进行模压,压力为4~24 MPa,保压时间为1 min;冷等静压:模压生坯真空包装后,于LDJ-350型冷等静压机中冷等静压,压力为100~250 MPa,保压时间为30 min;脱脂:将冷等静压生坯于空气气氛下在600 ℃保温48 h,脱除有机物;常压烧结:将脱脂后生坯于氧气气氛下在1550 ℃烧结6 h,制得ITO靶材。在实验中,分别对模压、冷等静压和常压烧结后的ITO样品取样,观察断面形貌,测定相对密度。

1.3 分析检测

采用S4 PIONEER型X射线荧光光谱仪分析ITO粉料的元素组成及其含量;采用JSM-6360LV 型扫描电镜观察ITO粉料、生坯及靶材断面的显微形貌和结构;采用Quantachrome PoreMaster-60型全自动压汞仪测定ITO生坯孔径分布;采用Rigaku-TTRⅢ型X射线衍射仪(Cu靶,Kα=1.5406  )表征ITO粉料的物相组成; 采用METTLER TOLEDO PL204型分析天平,以排水法测定ITO生坯和靶材密度。

)表征ITO粉料的物相组成; 采用METTLER TOLEDO PL204型分析天平,以排水法测定ITO生坯和靶材密度。

2 结果与讨论

2.1 模压压力对孔隙缺陷的影响

实验研究了模压成型压力对ITO颗粒形变、破碎以及生坯中孔隙缺陷的影响。图3所示为不同压力下模压生坯断面的SEM像。图4所示为不同压力下模压、再经200 MPa冷等静压后生坯断面的SEM像。

图3 不同压力下模压生坯断面的SEM像

Fig. 3 SEM images of fracture surfaces of green bodies after mould pressing at different pressures

图4 不同压力下模压再经200 MPa冷等静压后ITO生坯断面的SEM像

Fig. 4 SEM images of fracture surfaces of ITO green bodies obtained by mould pressing at different pressures and then cold isostatic pressing at 200 MPa

由图3可见,当模压压力为4 MPa时,生坯中部分ITO颗粒仅发生形变而未破碎,颗粒形貌基本未发生改变;在未破碎ITO颗粒之间,存在未贴合界面和交联点(见图3(a)中黑色孔洞),模压生坯中孔隙缺陷较多。当模压压力增大到12 MPa后,ITO颗粒基本破碎,生坯明显致密化,孔隙缺陷基本消失。由图4可见,当模压压力小于12 MPa时,即使再经200 MPa冷等静压处理,生坯中仍可见未破碎ITO颗粒,虽然颗粒间未贴合界面已基本消失,“酒窝”状缺陷颗粒所造成的孔隙尺寸也有所减小,但生坯中仍存在孔隙缺陷。当模压压力达到或超过20 MPa、再经200 MPa冷等静压后,生坯中未破碎ITO颗粒完全消失、孔隙缺陷也基本消失。

对比模压与冷等静压后生坯断面的SEM像可知,模压过程对生坯中孔隙缺陷的去除,特别是对由“酒窝”状缺陷ITO颗粒所致孔隙缺陷的去除具有关键作用。喷雾造粒ITO粉料流动性好,模压过程中,颗粒在模具内受到挤压,发生重排,伴随破碎坍塌;破碎颗粒在压力作用下填充到孔隙中,包括颗粒间未贴合孔隙、多颗粒交联点孔隙、由带“酒窝”状缺陷ITO颗粒破碎后形成的孔隙等。然而,由于在ITO粉末内部、以及生坯与模具之间,存在因相对滑动产生的摩擦,使得生坯内部压力梯度较大,且随模压压力的增加,生坯内部压力梯度进一步增大,过大的压力梯度使生坯的组织均匀性降低。因此,仅通过提高模压压力,不仅不能完全消除孔隙,同时还会导致新的孔隙产生[16]。因此,采用单一模压处理难以制备出相对密度高、均匀性好的ITO生坯。

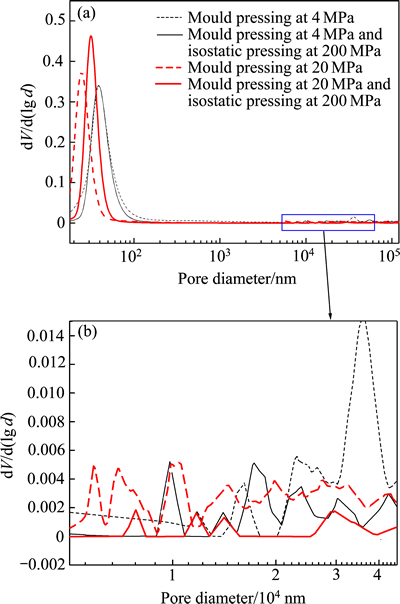

图5所示为4 MPa与20 MPa模压生坯、及其再经200 MPa冷等静压后生坯的孔径分布曲线。由图5可知,冷等静压生坯中微米级孔隙显著减少,模压压力对生坯微米级孔隙率具有重大影响,模压压力20 MPa与4 MPa比较,无论在200 MPa冷等静压处理前还是处理后,前者所得生坯中微米级孔隙率均远低于后者的。

表2所列为不同成型压力组合下生坯的孔径分布。由表2可知,经200 MPa冷等静压后,在模压压力分别为4 MPa和20 MPa的生坯中,孔径在1~15 μm和15~45 μm区间的孔隙率都有所降低,但其幅度差别较大。20 MPa模压压力下,冷等静压处理前后,孔径在15~45 μm区间的孔隙率变化更为明显,这与图3和图4中对应模压与冷等静压下生坯断面的SEM像所示结果一致,表明模压压力对孔隙的消除起关键作用,高的模压压力有助于生坯中孔隙缺陷的“坍塌”、收缩和消除。

图5 4 MPa与20 MPa模压生坯、及其再经200 MPa冷等静压后生坯的孔径微分分布曲线

Fig. 5 Pore size differential distribution curves of ITO green bodies obtained by mould pressing at 4 MPa and 20 MPa respectively, as well as by further cold isostatic pressing at 200 MPa

表2 不同模压与冷等静压压力组合下成型后生坯孔径分布

Table 2 Pore size distributions of ITO green bodies obtained under different pressure combinations between mould and cold isostatic pressing

2.2 冷等静压压力对孔隙缺陷的影响

图6所示为24 MPa下模压,再分别经过100、150、200和250 MPa冷等静压后生坯断面的SEM像。由图6可见,随着冷等静压压力增大,生坯断面中孔隙数量明显减少,断面均匀性更好。当冷等静压压力达到或超过200 MPa时,生坯断面中几乎见不到较大的孔隙。

图7所示为模压压力24 MPa,冷等静压力分别为100和250 MPa条件下所得生坯的孔径分布曲线。由图7可知,250 MPa冷等静压所得生坯,其微米级孔隙率显著低于100 MPa冷等静压生坯的。由表2可知,在24 MPa模压后,当冷等静压压力由100 MPa增加至250 MPa时,生坯中孔径在1~15 μm和15~45 μm区间的孔隙率分别由1.12%和1.08%降低至0.23%和0.26%,这说明增大冷等静压压力有助于生坯中孔隙的闭合消除。

图8所示为在不同模压与冷等静压压力组合下,生坯中由带“酒窝”状缺陷ITO颗粒所致孔隙缺陷形态变化的SEM像(见图8中黑色矩形框)。当模压压力为4 MPa时,200 MPa冷等静压后带“酒窝”状缺陷ITO颗粒所致孔隙呈类球形(见图8(a));当模压压力提高到24 MPa后(见图8(b)和(c)),带“酒窝”状缺陷的ITO颗粒破碎,且随冷等静压压力增大,因其形成的孔隙逐渐闭合。对比不同模压与冷等静压压力下孔隙在生坯中的存在形态可以确定,若带“酒窝”状缺陷ITO颗粒在模压处理中未被压碎,其所致类球形孔隙通过冷等静压也很难破碎和闭合;反之,其所形成的孔隙在冷等静压中随着压力的增大会逐渐闭合。究其原因在于,冷等静压中ITO生坯均匀受力收缩,未破碎ITO颗粒间各方向摩擦力几乎一致,使得颗粒间不会发生类似于模压中的滑动、颗粒重排与相互填充,导致这类孔隙在冷等静压中仅发生相对收缩,而几乎完整地保留在生坯中。

2.3 成型压力对生坯和靶材致密化的影响

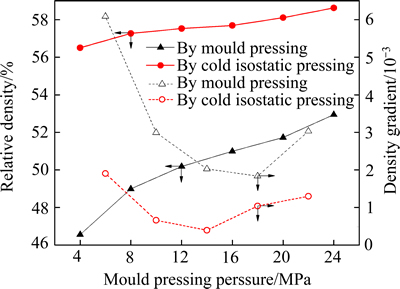

图9所示为不同压力下模压生坯和其再经200 MPa冷等静压生坯的相对密度及密度变化梯度。由图9可见,模压压力由4 MPa增加至24 MPa,模压生坯相对密度由46.6%增加至52.9%,经200 MPa等静压,对应生坯的相对密度分别增加至56.5%和 58.6%。模压与冷等静压生坯相对密度随模压压力变化趋势相同,均随模压压力的增大同步增加。尤为明显的是,模压压力越大,其生坯经冷等静压后密度也越大。以上结果表明,虽然冷等静压压力远高于模压压力,但其并不能取代模压过程。

以生坯相对密度变化曲线中相邻两个点的斜率近似代替生坯相对密度变化梯度,以此判断生坯密度随模压压力增大而变化的快慢程度。由图9可见,模压和冷等静压生坯的密度变化梯度曲线均呈“U”形,由此可以推断,模压中颗粒的屈服压力[17-18]为12 MPa左右。这是因为当模压压力小于12 MPa时,ITO颗粒在压力驱动下仅发生重排、形变,由于球形粉末良好的流动性,使得生坯密度迅速提高,在此阶段,颗粒重排和形变在生坯致密化过程中起主要作用(见图3(b)),生坯中颗粒间孔隙已大量消失,但由于模压压力小于颗粒的屈服压力,生坯中颗粒未破碎,单个颗粒存在仍清晰可见;当模压压力达到20 MPa时,模压压力已高于颗粒的屈服压力,颗粒破碎成为生坯致密化的主要原因,大部分颗粒已经破碎坍塌,破碎形成的小粒子填充到生坯孔隙处,生坯密度进一步提高(见图3(e)和3(f));当模压压力为20 MPa时所得生坯,其微米级孔隙率远低于模压压力为4 MPa时生坯的(见图5),这再次证实了模压压力对孔隙缺陷消除的作用。随着模压压力的增大,孔隙发生破碎、填充现象,使得孔径减小。模压过程中,存在两种不同的致密机理,使得生坯密度变化梯度先减小再增大。SHINOHARA等[19]研究表明,粉料颗粒破碎有利于生坯中孔隙消除和生坯密度的提高。

图8 不同模压与冷等静压压力组合处理后生坯中由带“酒窝”状缺陷ITO颗粒所致孔隙缺陷形态变化SEM像

Fig. 8 SEM images on morphological evaluation of porosity defect resulted by dimpled ITO granule under different combination treatment between mould and isostatic pressing pressures

图9 模压压力对模压生坯及再经200 MPa冷等静压生坯相对密度和密度梯度的影响

Fig. 9 Effects of mould pressing pressures on relative densities and density gradients of green bodies obtained by mould pressing or by mould pressing plus cold isostatic pressing at 200 MPa

图10所示为24 MPa模压后再经冷等静压所得生坯相对密度与冷等静压压力的关系。由图10可见,当冷等静压压力从100 MPa增加至250 MPa时,生坯相对密度变化较小,仅由57.9%增加至59.3%。结合图3~8中孔隙缺陷的演变可以确定,在ITO生坯致密化过程中,生坯中由“酒窝”状缺陷颗粒所致孔隙缺陷的消除有两个过程:第一步,模压中颗粒破碎崩塌,部分颗粒碎片填充到孔隙处;第二步,崩塌的孔隙在冷等静压作用下收缩闭合。这类孔隙若在模压中未能破碎消除,经冷等静压后依然会保留下来,仅尺寸有所减小。

图11所示为不同模压与冷等静压压力组合下成型后烧结靶材断面的SEM像。由图11可以看出,当模压压力小于20 MPa,或者冷等静压小于200 MPa时,靶材中都明显存在较多孔隙。

图10 24 MPa下模压再经不同压力下冷等静压所得生坯的相对密度

Fig. 10 Relative densities of green bodies obtained by mould pressing at 24 MPa and then by cold isostatic pressing at different pressures

表3所列为不同模压与冷等静压压力组合下成型后烧结靶材的相对密度。24 MPa模压后再经250 MPa冷等静压处理,烧结靶材的相对密度可达99.1%。此外,在烧结过程中生坯中较小的微孔(<1 μm)会逐渐消失,而由图3~8中所示的生坯孔隙的变化趋势可以确定,由“酒窝”状缺陷ITO颗粒所致大尺寸孔隙,若在压制过程中未破碎闭合,最终会保留在烧结后的靶材中。这些孔隙的尺寸在10 μm左右,而靶材晶粒粒度通常仅为5~10 μm,因而烧结无法使其完全闭合[20-21]。

SHINOHARA等[22]和ABE等[23]分别研究表明,烧结体中部分缺陷,源自于粉料颗粒“酒窝”状缺陷和空心缺陷所致、保留在生坯中的孔隙缺陷。因此,提高成型压力特别是模压压力,有助于消除生坯中的孔隙缺陷,从而提高ITO靶材的密度。

图11 不同模压与冷等静压压力组合下成型后烧结靶材断面的SEM像

Fig. 11 SEM images of fracture surfaces of sintered ITO targets under different pressure combinations between mould pressing and cold isostatic pressing

表3 不同模压与冷等静压压力组合下成型后烧结靶材的相对密度

Table 3 Relative densities of sintered ITO targets under different pressure combinations between mould pressing and cold isostatic pressing

3 结论

1) 在模压过程中,ITO粉料在压力作用下发生颗粒重排、形变、破碎和颗粒碎片对孔隙的填充。当模压压力较小、颗粒未大量破碎时,生坯内存在3种孔隙缺陷,分别为两颗粒间未贴合孔隙、多颗粒交联处孔隙和由带“酒窝”状缺陷颗粒所形成的孔隙。

2) 实验所用ITO粉末颗粒的屈服压力约为12 MPa。当模压压力超过ITO粉料颗粒屈服压力后,颗粒发生破碎,碎片向孔隙缺陷处填充。当模压压力由4 MPa提高到20 MPa时,生坯中孔径在15~45 μm区间的孔隙率由1.97%降低为1.5%,再经200 MPa冷等静压处理后,生坯中孔径在15~45 μm区间的孔隙率分别降低至1.09%和0.2%。模压压力对消除孔隙缺陷,特别是由“酒窝”状缺陷颗粒所致尺度较大的孔隙缺陷,具有关键作用。

3) 24 MPa模压生坯,再分别在100 MPa和250 MPa冷等静压处理,生坯中孔径在1~15 μm和15~45 μm区间的孔隙率分别由1.12%和1.08%降低至0.23%和0.26%,冷等静压处理可使模压生坯中孔隙缺陷闭合,进一步提高生坯密度。

4) 实验所用ITO粉料经24 MPa模压处理后,生坯相对密度为52.9%,再经250 MPa冷等静压处理,生坯相对密度提升至59.3%,烧结后靶材相对密度高达99.1%。

REFERENCES

[1] HAMBERG I, GRANQVIST C G. Evaporated Sn-doped In2O3 films: Basic optical properties and applications to energy- efficient windows[J]. Journal of Applied Physics, 1986, 60(11): 123-160.

[2] COX P A, FLAVELL W R, EGDELL R G. Solid-state and surface chemistry of Sn-doped In2O3 ceramics[J]. Journal of Solid State Chemistry, 1987, 68(2): 340-350.

[3] WEN S J, CAMPET G, PORTIER J, COUTURIER G, GOODENOUGH J B. Correlations between the electronic properties of doped indium oxide ceramics and the nature of the doping element[J]. Materials Science and Engineering B, 1992, 14(1): 115-119.

[4] GNEHMAN B L, JONSSON S, RUDOLPH T, SCHERER M, WEIGERT M, WERNER R. Influence of manufacturing process of indium tin oxide sputtering targets on sputtering behavior[J]. Thin Solid Films, 1992, 220(1): 333-336.

[5] ISHIBASHI S, HIGUCHI Y, OTA Y, NAKAMURA K. Low resistivity indium-tin oxide transparent conductive films. II. Effect of sputtering voltage on electrical property of films[J]. Journal of Vacuum Science & Technology A, 1990, 8(3): 1403-1406.

[6] NADAUD N, NANOT M, BOCH P. Sintering and electrical properties of titania- and zirconia-containing In2O3-SnO2 (ITO) ceramics[J]. Journal of the American Ceramic Society, 1994, 77(3): 843-846.

[7] KIM B C, LEE J H, KIM J J. Effect of forming pressure on densification behavior of nanocrystalline ITO powder[J]. Journal of the European Ceramic Society, 2007, 27(2): 807-812.

[8] IWASA K, ISOBE T, SENNA M. Enhanced densification of indium-tin oxide ceramics for sputter target through wet mechanochemical processing[J]. Solid State Ionics, 1997, 101: 71-78.

[9] KIM S M, SEO K H, LEE J H, KIM J J, LEE H Y, LEE J S. Preparation and sintering of nanocrystalline ITO powders with different SnO2 content[J]. Journal of the European Ceramic Society, 2006, 26(1): 73-80.

[10] KIM S M, LEE J H, KIM J J. Reaction-sintering behavior of nanocrystalline indium tin oxide with varying SnO2 content and particle size[J]. Scripta Materialia, 2007, 56(4): 293-296.

[11] 黄政仁, 江东亮, 谭寿洪. 喷雾造粒SiC粉料在成型过程中的破碎行为[J]. 硅酸盐学报, 2000, 28(3): 204-209.

HUANG Zheng-ren, JIANG Dong-liang, TAN Shou-hong. Crushing behavior of SiC granule prepared by spray pelletization during compaction[J]. Journal of the Chinese Ceramic Society, 2000, 28(3): 204-209.

[12] 徐光亮, 宋春军, 曹林洪, 熊 昆. 超高压成型与无压烧结制备细晶碳化硅陶瓷[J]. 硅酸盐学报, 2008, 36(11): 1629-1632.

XU Guang-liang, SONG Chun-jun, CAO Lin-hong, XIONG Kun. Ultrahigh pressure compacting and pressureless sintering of fine grain silicon carbide ceramics[J]. Journal of the Chinese Ceramic Society, 2008, 36(11): 1629-1632.

[13] 王 松, 谢 明, 王塞北, 杨云峰, 付作鑫. 高密度氧化铟锡 (ITO) 靶材制备工艺的研究进展[J]. 材料导报, 2013, 27(1): 207-210.

WANG Song, XIE Ming, WANG Sai-bei, YANG Yun-feng, FU Zuo-xin. Research developing of preparing high density ITO target[J]. Materials Review, 2013, 27(1): 207-210.

[14] 彭 平, 陈敬超, 王 鹏, 陈守东. 高致密 ITO 靶材制备工艺的研究现状和发展趋势[J]. 热加工工艺, 2012, 41(24): 31-34.

PENG Ping, CHEN Jing-chao, WANG Peng, CHEN Shou-dong. Preparation process research status and development trend of high density ITO target[J]. Hot Working Technology, 2012, 41(24): 31-34.

[15] 李 晶, 赵晓东, 李芝华, 任冬燕. 喷雾干燥-冷等静压-烧结法制备 ITO 靶材的工艺研究[J]. 稀有金属与硬质合金, 2011, 39(2): 38-41.

LI Jing, ZHAO Xiao-dong, LI Zhi-hua, REN Dong-yan. Preparation of ITO target material by spraying drying-cold isostatic pressing-sintering[J]. Rare Metals and Cemented Carbides, 2011, 39(2): 38-41.

[16] FU Y, TAO Z, HOU X. Weibull distribution of the fracture strength of 99% alumina ceramic reshaped by cold isostatic pressing[J]. Ceramics International, 2014, 40(6): 7661-7667.

[17] YOUSHAW R A, HALLORAN J W. Compaction of spray-dried powders[J]. Am Ceram Soc Bull, 1982, 61(2): 227.

[18] SAMIMI A, HASSANPOUR A, GHADIRI M. Single and bulk compressions of soft granules: experimental study and DEM evaluation[J]. Chemical Engineering Science, 2005, 60(14): 3993-4004.

[19] SHINOHARA N, KATORI S, OKUMIYA M, HOTTA T, NAKAHIRA K, NAITO M, CHO Y I, UEMASTU K. Effect of heat treatment of alumina granules on the compaction behavior and properties of green and sintered bodies[J]. Journal of the European Ceramic Society, 2002, 22(16): 2841-2848.

[20] 施剑林. 固相烧结—Ⅰ气孔显微结构模型及其热力学稳定性, 致密化方程[J]. 硅酸盐学报, 1997, 25(5): 499-513.

SHI Jian-lin. Solid state sintering—Ⅰ Pore microstructural model and thermodynamic stability, densification equations[J]. Journal of the Chinese Ceramic Society, 1997, 25(5): 499-513.

[21] SHINOHARA N, OKUMIYA M, HOTTA T, NAKAHIRA K, NAITO M, UEMATSU K. Formation mechanisms of processing defects and their relevance to the strength in alumina ceramics made by powder compaction process[J]. Journal of Materials Science, 1999, 34(17): 4271-4277.

[22] SHINOHARA N, OKUMIYA M, HOTTA T, NAKAHIRA K, NAITO M, UEMATSU K. Morphological changes in process-related large pores of granular compacted and sintered alumina[J]. Journal of the American Ceramic Society, 2000, 83(7): 1633-1640.

[23] ABE H, NAITO M, HOTTA T, KAMIYA H, UEMATSU K. Pore defects related to slurry character and their relevance to strength distribution in alumina ceramics[J]. Powder Technology, 2003, 134(1): 58-64.

(编辑 龙怀中)

基金项目:教育部新世纪优秀人才计划资助项目(NCET-11-0517);中国博士后科学基金面上项目(2012M521544)

收稿日期:2014-12-22;修订日期:2015-06-19

通信作者:李玉虎,讲师,博士;电话:0731-88830478;E-mail: lyh_csu@163.com