Influences of complex modification of P and RE on microstructure and mechanical properties of hypereutectic Al-20Si alloy

CHEN Chong(陈 冲), LIU Zhong-xia(刘忠侠), REN Bo(任 波),

WANG Ming-xing(王明星), WENG Yong-gang(翁永刚), LIU Zhi-yong(刘志勇)

Key Laboratory of Material Physics of Ministry of Education, Zhengzhou University, Zhengzhou 450052, China

Received 30 August 2006; accepted 12 January 2007

Abstract: P and RE complex modification of hypereutectic Al-Si alloys was conducted. The influences of P, RE content on the microstructure and mechanical properties of alloys were investigated. The complex modifications of P and RE make the coarse block primary silicon obviously refined and the large needle eutectic silicon modified to the fine fibrous or lamella ones. P mainly refines the primary silicon, but excess P is unfavorable to the refinement of primary silicon. RE can well refine the primary and eutectic silicon, but its modification effect on the eutectic silicon is more obvious. P can repress the modification of RE on the eutectic silicon. The alloys with the additions of 0.08% P and 0.60% RE have the optimal microstructure and the highest mechanical properties. Compared with the unmodified alloy, the primary silicon of alloys can be refined from 66.4 μm to 23.3 μm and the eutectic silicon can be refined from 8.3 μm to 5.2 μm. The tensile strength is improved from 256 MPa to 306 MPa and the elongation is improved from 0.35% to 0.48%.

Key words: hypereutectic Al-Si alloy; complex modification; microstructure; mechanical properties

1 Introduction Hypereutectic Al-Si alloys have been widely investigated because of their excellent properties, which include excellent wear and corrosion resistance, high temperature strength, low coefficient of thermal expansion, good cast performance, and high specific strength[1-3]. Therefore, the hypereutectic Al-Si alloys are widely used in aeronautic, astronautic, and auto- mobile industries. It has been documented extensively that the microstructure of hypereutectic Al-Si alloys, prepared by conventional casting routines, usually consist of a coarse primary silicon phase in a fibrous eutectic matrix[4-6]. The brittleness of coarse Si crystals (both eutectic and primary silicon) is the main reason responsible for the poor properties of Al-Si alloys because coarse silicon crystals lead to premature crack initiation and fracture in tension[7-8]. In order to refine the primary silicon, many methods have been carried into execution, such as high-pressure casting, rapid solidifica- tion technique[9], and melt overheating treatment [10-12]. However, these processes are complex and difficult to control. The desired properties can not be obtained or may even become worse. The microstructure control using minor element addition is the most popular method due to its simplicity and effectiveness. Phosphor is the most effective refinement element of primary silicon in hypereutectic Al-Si alloy[13-14]. The size of primary silicon particles can be refined to 20-30 μm by adding minor phosphor. Because the phosphor has not any modification effect on the eutectic silicon, the eutectic silicon can still keep the large needle shape. Recently, attention has been given to the complex modification of primary and eutectic silicon in order to significantly enhance the mechanical properties of hypereutectic Al-Si alloys. It has been documented that rare earth(RE) metal can modify the eutectic silicon in the hypereutectic Al-Si alloys[15-16]. The refinement of primary silicon crystals was also found with addition of rare earth elements [17-18]. If combining with P and RE to complexly alloy the hypereutectic Al-Si alloys, both the primary and eutectic silicon in alloys may be modified and the mechanical properties may be improved In the present study, the P, RE complex modification of hypereutectic Al-20Si alloys was conducted. The influences of P, RE content on the microstructure and mechanical properties of hypereutectic Al-20Si alloy were investigated.

2 Experimental

The hypereutectic Al-20Si-1.6Cu-0.7Mn-0.6Mg alloys were used in this experiment. The tested alloys were produced with silicon, magnesium, Al-50Cu and Al-10Mn master alloys respectively. In order to modify complexly the primary silicon and eutectic silicon, the Cu-10P and Al-10RE master alloys were used. The addition amount of the modifiers is listed in Table 1. For the modifiers were melted completely, the melts must be fully stirred. A columned metallurgical samples and tensile sample billets were cast at 800 ℃ using the permanent mould that had been preheated at 250 ℃. In order to reveal the modification effect of primary silicon and eutectic silicon in the tested alloys, two kinds of metallurgical sample were used respectively. One was cut directly from 25 mm above the bottom of the metallurgical sample billets to reveal the modification effect of primary silicon. Another was cut directly from the grip section of tension test specimens after heat treatment. For comparison, all samples were cut from the same position. The tensile samples were solutized firstly at 510 ℃ for 6 h and aged at 190 ℃ for 10 h. Then the treated samples were machined to the standard tensile samples with 10 mm in diameter and 80 mm in gauge length. The tensile tests were carried out using MTS810 servo-hydraulic material testing system. The microstructure of the tested alloys was observed and quantitatively analyzed using an Olympus BX51 metallographic microscope with an image collection and analysis system.

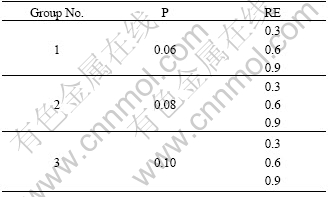

Table 1 Addition amount of modifiers (mass fraction, %)

3 Results and discussion

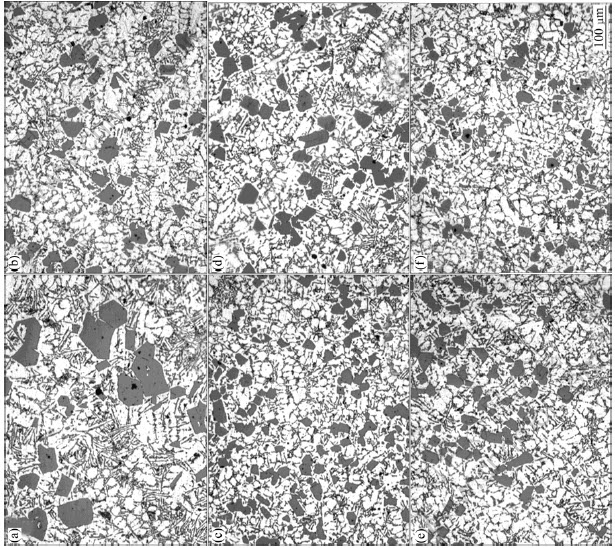

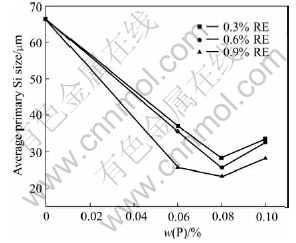

The effect of P on the primary silicon of the hypereutectic Al-20Si alloys is shown in Figs.1(a)-(d). Many coarse block and stripe primary silicon can be found in the unmodified alloy (shown in Fig.1(a)). The addition of P refines obviously the primary silicon. The size of primary silicon decreases with increasing P content. And their edges and angles are passivated (as shown in Figs.1(b)-(d)). The optimal refinement effect of primary silicon is obtained when the alloy contains 0.08% P. Increasing continuously the P content can coarsen the primary silicon of the tested alloys, which means that excess P is unfavorable to the refinement of primary silicon.

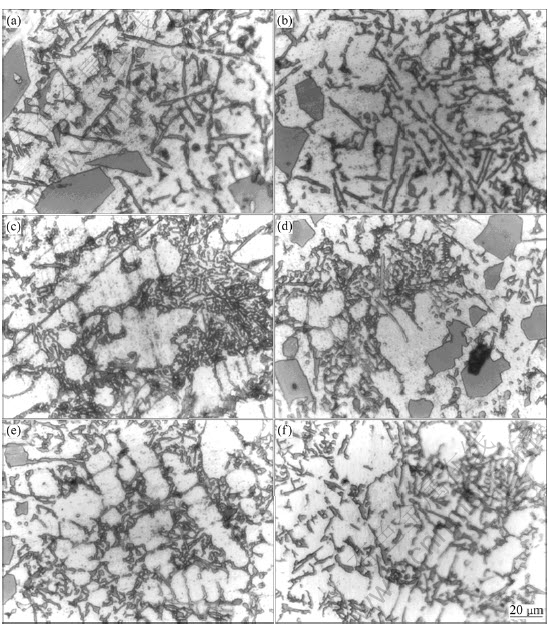

The effect of RE content on the primary silicon of the hypereutectic Al-20Si alloys is shown in Figs.1(c), (e) and (f). It can be found that RE has a little refinement effect on the primary silicon of the alloys with low RE content. A morphological change of the primary silicon is observed only when RE content excesses 0.6%. But the effect on the eutectic silicon is obvious. The effects of P and RE content on the eutectic silicon are shown in Fig.2. It can be found that the large needle eutectic silicon particles are modified to the fine fibers or lamella ones with increasing RE content. It is noticed that the addition of P decreases the modification of RE on the eutectic silicon. The eutectic silicon particles are coarsen with raising P content under the same RE content condition. Fig.3 shows the microstructure parameters of the tested alloys with different P contents. The influence of P on the primary silicon is obvious. The size of primary silicon particles in the alloy is decreased with increasing P content under the same RE content condition. When adding content of P to the alloy is 0.08% P under 0.9% RE condition, the modification of primary silicon particles is optimal and the primary silicon particles are refined from 66.4 μm to 23.3 μm.

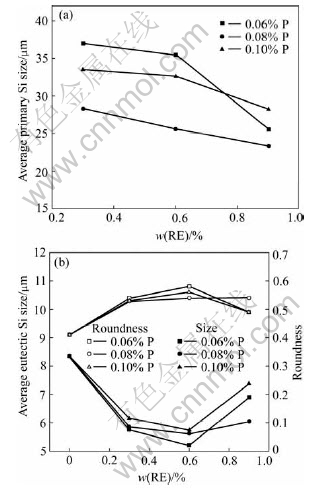

Fig.4 shows the effect of RE on the size of the primary silicon and eutectic silicon of the tested alloys after heat treatment. It can be found that the complex modification of P and RE can well modify the primary silicon and eutectic silicon particles. But the modification effect of RE on the eutectic silicon is more obvious compared with the effect on the primary silicon. Under the same P content condition, the primary silicon particles can also be refined with rising RE content, as shown in Fig.4(a). But the effect on the primary silicon particles is not obvious compared with the effect of P (shown in Fig.3). The size of the eutectic silicon particles decreases obviously with the addition of RE and the roundness of eutectic silicon is also greatly improved. The best modification effect on the eutectic silicon particles can be obtained with the addition of 0.6% RE and 0.06% P. The size of eutectic silicon particles decreases from 8.3 μm to 5.2 μm and the roundness is improved from 0.41 to 0.58.

Fig.1 Primary silicon morphologies of Al-20Si alloys modified with different modifiers: (a) P and RE free; (b) 0.06% P and 0.6% RE; (c) 0.08% P and 0.6% RE; (d) 0.1% P and 0.6% RE; (e) 0.08% P and 0.3% RE; (f) 0.08% P and 0.9% RE

According to Ref.[18], AlP and Si are both diamond cubic with very similar lattice parameters (0.542 nm for silicon, 0.545 nm for AlP). When P is added into the melt of hypereutectic Al-Si alloys, the reaction Al+P→AlP takes place in the modification. AlP can act as the inhomogeneous nucleus of primary silicon particles in the solidification of hypereutectic Al-Si alloys, which results in the refinement of the primary silicon particles [13,18]. For the modification effect of rare earth metals on hypereutectic Al-Si alloys, however, the inconsistent conclusions are obtained for different researchers. It has been found that RE atoms can be absorbed on the growth steps, twin plane of eutectic silicon as well as the two-phrase interface of Al-Si alloys. The morphology of eutectic silicon phase is altered by decreasing the eutectic temperature and restraining the growth process. Therefore, the moderate modification effect of rare earth metals on eutectic silicon is obtained[19]. Though RE has certain refinement effect on the primary silicon, the mechanism of RE metals on refining hypereutectic Al-Si alloys is different from the mechanism of P. RE does not show the distinctive nucleation function. Similar to the effect on the eutectic silicon, the refinement of primary silicon in hypereutectic Al-Si alloys treated with RE is still related to the suppression of the nucleation temperature of silicon phase and the modification of both solid-liquid interfacial energy and the surface energy of solid silicon [15-16]. It is noticed that excess RE causes the decrease of the refinement effect of primary silicon and eutectic silicon. It may be related to the formation of AlCe. CHANG et al[15] has found that some RE bearing compounds determined to AlCe are around primary silicon in the matrix of hypereutectic Al-Si alloys. The precipitation of AlCe consumes certain quantity of RE, which results in the decrease of the effective RE content.

Fig.2 Eutectic silicon morphologies of Al-20Si alloys modified with different modifiers: (a) P and RE free; (b) 0.06% P and 0.3% RE; (c) 0.06% P and 0.6% RE; (d) 0.06% P and 0.9% RE; (e) 0.08% P and 0.6% RE; (f) 0.10% P and 0.6% RE

Fig.3 Effect of P content on primary Si size of Al-20Si alloys under same RE content condition

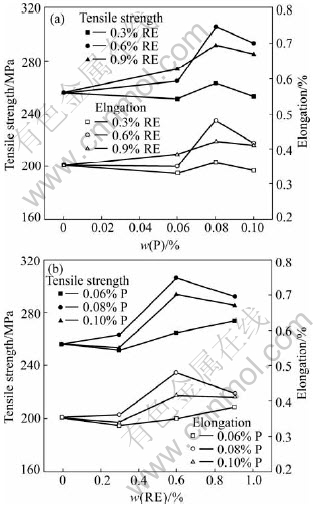

Fig.5 shows the mechanical properties of hypereutectic Al-20Si alloys with different modifiers. The tensile strength and elongation of hypereutectic Al-20Si alloys are improved obviously with the addition of P and RE. Both strength and elongation increase with raising P content and RE content. When the tested alloys modified with 0.08% P and 0.6% RE, the optimal combination of strength and plasticity is obtained. The tensile strength is improved to 306 MPa from 256 MPa of the unmodified alloy, increased by 20%. The elongation is improved to 0.48% from 0.35%, increased by 40%. This optimal P and RE content is not in corre- spondence with the optimal contents of P and RE that make the alloys have the optimal refinement effect of the primary and eutectic silicon. It is clear that the beneficial effect of complex modification of P and RE on the mechanical properties of alloys is related to the refinement of primary and eutectic silicon.

Fig.4 Effect of RE content on microstructure parameters of primary Si and eutectic Si of Al-20Si alloys: (a) Primary Si; (b) Eutectic Si

The mechanical properties of hypereutectic Al-Si alloys are determined by the primary silicon and eutectic silicon. The cracks always initiate by the brittle fracture of the primary silicon and eutectic silicon particles or debonding of silicon particles from the α phase matrix, and then propagate through the α phase matrix and along interdendritic channels during tension. The refinement of primary silicon and eutectic silicon decreases the probability of crack initiation by premature fracture of primary and eutectic silicon. The tensile strength and ductility are improved obviously. It is noticed that the content of P that makes the alloys have the optimal combination of strength and ductility is not in correspondence with that makes the alloys have the optimal modification effect of eutectic silicon. It is

Fig.5 Effect of P and RE content on mechanical properties of Al-20Si alloys: (a) P content; (b) RE content

because the size of primary silicon is larger than that of eutectic silicon. The probability of cracks initiated from primary silicon is larger than that from eutectic silicon. The primary silicon plays a more critical role than the eutectic silicon crystals in determining the properties [12,17]. The optimal modification effect of eutectic silicon is obtained when adding 0.06% P and 0.6% RE, but the refinement effect of primary silicon is not in optimal state.

4 Conclusions

1) The complex modification of P and RE can obviously modify the primary silicon and the refinement effect of P on the primary silicon is more distinct. The size of primary silicon decreases with increasing P content. The edges and angles of silicon are passivated. The optimal refinement effect of primary silicon is obtained when the alloy contains 0.08% P under the 0.90% RE condition. The primary silicon particles are refined to 23.3 μm from 66.4 μm of the unmodified alloys. Excess P is unfavorable to the refinement of primary silicon.

2) RE can obviously modify the eutectic silicon particles. The large needle eutectic silicon particles are modified to the fine fiber or lamella ones with increasing RE content. The size of the eutectic silicon decreases obviously with the addition of RE. The best modification effect on the eutectic silicon particles can be obtained with the addition of 0.60% RE and 0.06% P. The size of eutectic silicon particles decreases to 5.2 μm from 8.3 μm. P decreases the modification of RE on the eutectic silicon.

3) The mechanical properties of hypereutectic Al-20Si alloys are improved obviously with the addition of P and RE. When the tested alloys are modified with 0.08% P and 0.60% RE, the optimal combination of strength and plasticity is obtained. The tensile strength is improved to 306 MPa from 256 MPa of the unmodified alloy, increased by 20%. The elongation is improved to 0.48% from 0.35%, increased by 40%.

References

[1] TIMMERMANS G, FROYEN L. Fretting wear behaviour of hypereutectic P/M Al-Si in oil environment [J]. Wear, 1999, 230(2): 105-117.

[2] OTT R D, BLUE C A, SANTELLA M L, BLAU P J. The influence of a heat treatment on the tribological performance of a high wear resistant high Si Al-Si alloy weld overlay [J]. Wear, 2001, 250/251(2): 868-874.

[3] YILMAZ F, ELLIOTT R. Microstructure and mechanical properties of unidirectionally solidified Al-Si alloys [J]. Journal of Materials Science, 1989, 24(6): 2065-2070.

[4] ZHANG Di, YI Hong-kun, LU Wei-jie, FAN Tong-xiang. Influence of La on microstructure of hypereutectic Al-Si alloys [J]. Trans Nonferrous Met Soc China, 2003, 13(3): 541-545.

[5] KUROISHI N, ODANI Y, TAKEDA Y. High strength, high wear resistance aluminum-silicon PM alloys [J]. Metal Powder Report, 1985, 11(40): 642-645.

[6] JEONG H G, YOON D J, KIM E Z, PARK H J, NAK H. The influence by hydrostatic extrusion on the microstructure and extrudability of the IM processed hypereutectic Al-Si-X alloys [J]. Journal of Materials Processing Technology, 2002, 20(130/131): 438-443.

[7] SANO H. Spray formed aluminum alloy finds engine role [J]. Metal Powder Report, 1994, 49(1): 26-31.

[8] YAMAUCHI I, OHNAKA I, KAWAMOTO S, FUKUSAKO T. Hot extrusion of rapidly solidified Al-Si alloy powder by the rotation-water-atomization process [J]. Transactions of the Japan Institute of Metals, 1986, 27(3): 195-203.

[9] LI Shu-suo, ZHAO Ai-min, MAO Wei-min, ZHONG Xue-you. Mechanical properties of hypereutectic Al-Si alloy by semisolid processing [J]. Trans Nonferrous Met Soc China, 2000, 10(4): 441-444.

[10] ESTRADA J L, AUSZCZYK J. Characteristics of rapidly solidified Al-Si-X powders for high-performance application [J]. Journal of Materials Science, 1990, 2A(25): 886-904.

[11] WANG Jun, HE Shu-xian, SUN Bao-de, GUO Qi-xin, NISHIO M. Grain refinement of Al-Si alloy (A356) by melt thermal treatment [J]. Journal of Materials Processing Technology, 2003, 141(1): 29-34.

[12] ZHANG Rong, CAO Qiu-fang, PANG Shu-xian, WEI Yun, LIU Lin. Dissolution kinetics of primary silicon in hypereutectic Al-Si melt [J]. Science and Technology of Advanced Materials, 2001, 2(1): 3-5.

[13] LIU Xiang-fa, WU Yu-ying, BIAN Xiu-fang. The nucleation sites of primary Si in Al-Si alloys after addition of boron and phosphorus [J]. Journal of Alloys and Compounds , 2005, 391(1/2): 90-94.

[14] SRIVASTAVA V C, MANDAL R K, OJHA S N. Evolution of microstructure in spray formed Al-18%Si alloy [J]. Materials Science and Engineering, 2004, 383(1): 14-20.

[15] CHANG J Y, MOON I G, CHOI C S. Refinement of cast microstructure of hypereutectic Al-Si alloys through the addition of rare earth metals [J]. Journal of Materials Science, 1998, 33(20): 5015-5023.

[16] CHANG J Y, KIM G H, MOON I G, CHOI C S. Rare earth concentration in the primary Si crystal in rare earth added Al-21wt.%Si alloy [J]. Scripta Materialia, 1998, 39(3): 307-314.

[17] XIONG Bai-qing, ZHANG Yong-gan, WEI Qiang. The study of primary Si phase in spray forming hypereutectic Al-Si alloy [J]. Journal of Materials Processing Technology, 2003, 137(1/3): 183-186.

[18] HO C R, CANTOR B. Heterogeneous nucleation of solidification of Si in Al-Si and Al-Si-P alloys [J]. Acta Metallurgica et Materialia, 1995, 43(8): 3231-3246.

[19] YI Hong-kun, ZHANG Di, SAKATA T, MORI H. Microstructures and La-rich compounds in a Cu-containing hypereutectic Al-Si alloy [J]. Journal of Alloys and Compounds, 2003, 354(1/2): 159-164.

(Edited by YANG Hua)