文章编号:1004-0609(2007)12-1987-06

喷射成形7055铝合金的显微组织和力学性能

李先聚,杨 杰,张 豪,张 捷,张 荻

(上海交通大学 金属基复合材料国家重点实验室,上海 200030)

摘 要:采用全自动控制往复喷射成形工艺制备了7055铝合金的大规格喷射成形锭坯。通过显微组织分析和力学性能测试,研究工业规格喷射成形7055铝合金的初始组织、挤压工艺及热处理制度对显微组织和力学性能的影响。结果表明,喷射成形7055铝合金锭坯规格可达d 260 mm×1600 mm,晶粒为等轴状,粒度宏观均匀,主要在20~30 μm,组织无明显宏观偏析,锭坯致密度达到98.2 %。喷射成形态材料的T6态σb为500~543 MPa,显示控制往复喷射成形铝合金锭坯冶金质量优越。喷射成形锭坯经过小挤压比变形后达到全致密,大规格产品的T6态纵向σb提高到745 MPa,δ为12.8 %。

关键词:7055铝合金;喷射成形;热处理;显微组织;力学性能

中图分类号:TG 146.2 文献标识码:A

Microstructure and mechanical properties

of 7055 Al alloys by spray forming

LI Xian-ju, YANG Jie, ZHANG Hao, ZHANG Jie, ZHANG Di

(State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200030, China)

Abstract: A large-scale 7055 Al alloy billet with a size of d 260 mm×1600 mm was prepared by fully automatic controlled reciprocating spray forming technology. The initial microstructure and the effect of subsequent treatment (including extrusion and heat treatment) on the microstructures and mechanical properties of the 7055 alloy were studied. The results show that the as-deposited billet has an equiaxed and homogeneous structure with a grain size of 20-30 μm and no macro-segregation structure. The relative density of the as-deposited alloy gets up to 98.2%. The ultimate tensile strength of as-deposited materials after T6 heat treatment gets up to 500-543 MPa, which indicates that there is little defect in the as-deposited billets produced by fully automatic controlled reciprocating spray forming technology. After deformation at small extrusion ratio, the billets could be fully densified. The ultimate tensile strength of the large-scale materials at T6 state rises to 745 MPa, and the elongation is 12.8%.

Key words: 7055 Al alloy; spray forming; heat treatment; microstructure; mechanical properties

自英国Swansea大学的Singer教授在1968年提出喷射成形的概念和原理以来[1-2],该技术获得迅速发展,到20世纪90年代中期,已经在高性能钢、铝、铜等金属领域形成产业[3-5]。与传统的铸造工艺相比,喷射成形工艺的冷却速度可以达到102~103 K/s,所以喷射成形工艺制备的材料元素固溶度大、晶粒细小、组织均匀、偏析程度小[6-8]。我国在新材料制备、热处理和后续加工方面取得了丰富的研究成果,有些成果已经达到国际先进水平[9],但是目前在产品工业化水平上,与国际先进水平相比仍存在显著差距。

Al-Zn-Mg-Cu系高强铝合金是以航空航天用材为背景研制并发展起来的一类铝合金材料, 长期以来被广泛用于各种飞机机身、机翼梁、机舱壁板和火箭高强度结构件的制造, 是世界各国航空航天工业中不可缺少的重要材料[10-12]。7055铝合金是由美国开发的超高锌含量的新型铝合金,是当前实际使用的最高强度铝合金,按美国军标其强度达648 MPa。国内很多研究单位利用传统工艺对7055铝合金做了大量研究,该合金抗拉强度已经超过了700 MPa,甚至接近800 MPa。但是这些数据是从铸造的小样品上获得的,无法代表大规格产品的真实性能。铸造大尺寸的7055铝合金锭坯时,由于锌含量比较高,因此合金成分偏析严重且易于形成热裂。虽然开发7055铝合金产品早被我国列入重点攻关项目,但迄今为止,我国铝加工企业尚无法浇铸出具有工业实际应用规格的铸件,严重制约了相关应用领域的发展。另外,我国尚未见到开展喷射成形7055铝合金研究工作的公开报道。

本研究组开展了全自动控制往复喷射成形装备及工艺的大量前期工作[13-16],制备出d 260 mm×1 600 mm的7055铝合金工业规格的锭坯。本文作者研究了该工业规格喷射成形7055铝合金锭坯的原始组织、挤压及热处理工艺对产品的组织和性能的影响,将对我国喷射成形工业生产工艺的发展及其产品的后续加工工艺起到基础性指导作用。

1 实验

7055铝合金名义成分为Al-8.2Zn-2.2Mg-2.4Cu- 0.2Zr(质量分数,%),熔炼在中频炉中进行,熔炼温度控制在700~740 ℃。熔体经过精炼和除渣后,在自主开发的全自动控制往复喷射成形设备上制备了d 260 mm×1 600 mm的铝合金锭坯。喷射工艺雾化气体为氮气。基本工艺参数如下:斜喷角10?~30?,接收距离600 mm,接收盘转速40~60 r/min,下降速度2~4 mm/s,雾化温度 750~850 ℃,雾化压力为 0.8 MPa。将完整的锭坯车圆,测量体积,精度为1 mm,称量质量,精度为1 kg,计算致密度。挤压温度为420 ℃,选择d 270 mm挤压筒,分别挤压成d 120 mm和d 110 mm的棒材,挤压比分别约为5和6。选择合适的模具,将材料挤压成外径d 127 mm,内径d 78 mm的管,挤压比约6.1。

利用光学显微镜观察了合金不同状态的显微组织,以X射线衍射技术(XRD)对组织进行了物相分析。拉伸力学试样按照GBT228-2002《金属材料 室温拉伸实验方法》制成圆棒形拉伸试样,同一状态取3根。拉伸实验在SHIMADZU AG-100KNA的万能实验机上进行。断口形貌观察在菲利浦S-515的扫描电镜上进行。

2 实验结果

2.1 喷射成形坯宏观形貌

图1所示为7055铝合金的喷射成形坯的宏观照片,本文研究对象是图中最高的锭坯,其直径约260 mm,高约1 600 mm,喷射成形坯上下均匀,表面细致,表面车圆2~3 mm即可。车圆后经过测量,喷射成形坯致密度达到98.2%。

图1 喷射成形坯形貌

Fig.1 Appearance of as-deposited billet

2.2 合金的显微组织及其演变

2.2.1 喷射成形坯显微组织观察及其物相分析

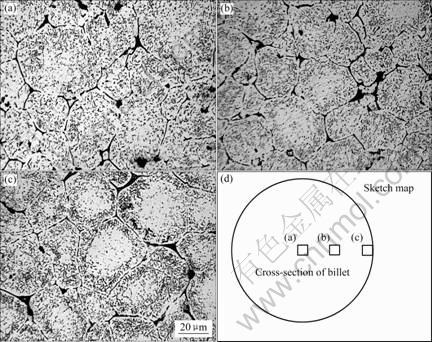

对喷射成形坯件不同部位的组织进行了显微观察,如图2所示。对比圆心处(图2(a)),截面半径中点处(图2(b))和边缘处(图2(c))三处的金相组织可知,三处金相组织非常接近,晶粒均为等轴状,粒度宏观均匀,主要在20~30 μm,组织无明显宏观偏析。晶内弥散分布着大量细小的一次析出相, 晶界上则析出不连续的条状相。

图2 喷射成形坯横截面上不同区域的显微组织

Fig.2 Microstructures of different areas on cross section of as-deposited billet: (a) Center; (b) Center of semidiameter; (c) Edge

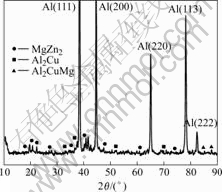

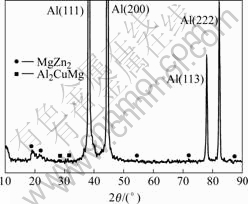

喷射成形坯的XRD谱如图3所示。经分析得知喷射成形坯组织主要由α(Al)和MgZn2组成,同时有少量的Al2Cu和Al2CuMg。

图3 喷射成形坯的XRD谱

Fig.3 XRD pattern of as-deposited billet

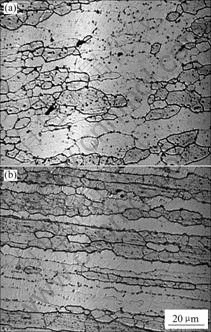

2.2.2 挤压态显微组织观察

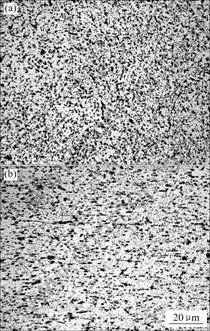

图4所示为经过热挤压的金相组织。经过挤压后,等轴晶被破碎,组织明显的致密化,且第二相分布更加均匀,整体上孔隙基本消除。如图4(b)所示,组织有明显的方向性,析出相沿挤压方向分布。

图4 挤压态的显微组织

Fig.4 Microstructures of extrusion phase: (a) Transverse; (b) Longitude

2.2.3 挤压后T6态显微组织观察及其物相分析

图5所示为挤压后经过T6热处理的金相显微组织。由图5(a)和(b)所示的金相组织可以看出,大量细小的第二相在晶内和晶界上析出。在图5(b)中还可以发现组织有明显的方向性,基体之间有第二相析出。

图5 挤压后T6态的显微组织

Fig.5 Microstructures of as-extruded samples after T6 treatment: (a) Transverse; (b) Longitude

对挤压后T6态组织进行了XRD物相分析,实验结果如图6所示。经过分析可以得知,析出相大部分为η′(MgZn2)和少量S(Al2CuMg)。与图3对比, Al(220) 峰消失,Al(222)峰强度明显增加,这显示挤压使合金产生了织构。

图6 挤压后T6态试样的XRD谱

Fig.6 XRD pattern of as-extruded samples after T6 treatment

2.3 合金力学性能

各状态材料的力学性能列于表1。L表示平行于锭坯或挤压棒(管)轴向,T表示垂直于锭坯或挤压棒(管)轴向。样品9从外径127mm、内径78mm的挤压管上截取,再进行T6处理:先在450 ℃温度下保温2 h,然后上升到480 ℃,保温2 h,水中淬火,然后在120 ℃时效24 h。由表1可以看到,喷射成形态材料σb达222~252 MPa,经过T6热处理后,σb达到500~543 MPa,横向比纵向要高出几十MPa,δ都在1%左右。喷射成形态材料经过挤压后,纵向的δ都在10%以上。很明显,经过挤压+T6处理的样品的纵向σb和σs比横向σb和σs分别高出约60~100 MPa和80~130 MPa,纵向的伸长率都远高于横向的。挤压比为6的样品的纵向σb和σs分别比挤压比为5的样品的高出约40 MPa和60 MPa。横向的拉伸性能受挤压比的影响不大。样品9为挤压管,σb高达745 MPa,σs为702 MPa,δ达12.8 %。

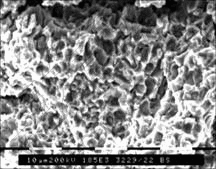

2.4 室温拉伸断口形貌观察

图7所示为7055铝合金挤压后T6态室温拉伸断口的SEM像。可以看出,拉伸断口为典型的韧性断裂,韧窝均匀。

图7 挤压后T6态试样室温拉伸断口SEM 像

Fig.7 SEM image of tensile fracture of as-extruded sample after T6 treatment

表1 不同状态的力学性能

Table 1 Mechanical properties of different conditions

3 讨论与分析

本研究采用全自动控制往复喷射成形工艺制备了大规格锭坯,其宏观形貌上下均匀,表面细致(图1),车圆废料比较少。喷射沉积坯显微组织为等轴晶,宏观均匀(见图2),经测量,致密度达98.2%,而国际上工业产品的致密度约为97%左右,这显示了本研究所采用的喷射成形工艺适于制备高致密度的工业规格铝合金锭坯。经过T6热处理后,喷射成形坯的σb最高达543 MPa,这在国内相关文献中还未见报道。经过热挤压后,等轴晶被破碎,组织进一步细化均匀化,材料基本上达到全致密(见图4)。由于晶粒的细化,晶界增多,第二相形核的几率增加,这有利于后续的热处理。

喷射成形态组织的冶金结合质量低于变形后的,存在微量的空隙和冷粉,因此,力学性能无论是强度还是伸长率,都比变形后相对要低(见表1中样品1和2)。喷射成形态组织经过T6热处理后,σb达到 500~543 MPa,明显高于铸态铝合金的强度,表明本研究喷射成形的快速凝固组织有效地克服了传统铸造工艺中形成的粗大组织,同时大幅度减少了喷射成形工艺中易于产生的孔隙和冷粉等缺陷,保证了较高的拉伸性能。喷射成形坯是沿纵向连续逐层生长而成的,孔隙和冷粉等组织缺陷易在层界面处形成,因此纵向组织结合力就会相对地低于横向的,进而纵向的σb低于横向的。经过挤压后,原始层结构被打乱,组织进一步细化和均匀化,基本消除了喷射成形态可能存在的少量缺陷,材料性能得到了显著提高。由表1中样品5、7和9的性能数据可知,在一定限度内,挤压比越大,纵向力学性能就越高,这可能是由于挤压比越大,组织的方向性就越强,织构组织越细致,第二相析出就更加弥散的原因。挤压后纵向显微组织有明显的织构现象(见图4(b)和图5(b)),垂直挤压方向的组织结合力低于平行挤压方向的,因此,纵向的力学性能明显高于横向的(见表1中样品5和6、7和8)。样品9的σb比样品5和7高出约10 MPa, 这可能是由于挤压管的挤压比更大,也可能是由于挤压管厚度小,比挤压棒的淬火效果更好。

本研究制备的喷射成形7055铝合金的强度比美国采用传统工艺制造的合金高出15 %,这与析出相的弥散程度和晶粒度指标改善密切相关。为了获得最大强化效果,时效组织应该以G.P区和过渡相为主,但是过渡相一般在缺陷和晶界处择优形成,即非均匀形核[17-18]。本研究中喷射成形铝合金由等轴晶组成,晶粒细小,没有宏观偏析(见图2),经过挤压后,晶粒进一步细化和均匀化(见图4),显著消除了喷射成形态组织可能存在的微量缺陷。与铸造铝合金相比,喷射成形铝合金的晶粒更加细小均匀,晶界数量相对更多,因而过渡相η′(MgZn2)在晶界上非均匀形核的几率更大,从而使得析出相更加弥散。根据弥散强化 Orowan机制[19],析出相弥散程度越高,合金强度就越高。因此,喷射成形铝合金的力学性能比传统工艺制造的铝合金的要高得多。另外,根据Hall-Petch公式[20],晶粒直径越小,强度就越高,这也是喷射成形铝合金力学性能优越的原因。

4 结论

1) 采用全自动控制往复喷射成形技术制备了d 260 mm×1 600 mm的7055铝合金喷射成形坯。喷射成形坯晶粒为等轴状,粒度均匀,主要在20~30 μm之间,组织无明显宏观偏析,致密度达到98.2%,不低于国际先进工业产品的致密度。

2) 7055铝合金喷射成形态材料经过T6热处理后,σb为500~543 MPa,显示出全自动控制往复喷射成形铝合金锭坯的缺陷少,冶金结合质量优越。

3) 由于喷射成形锭坯是逐层生长的,沿纵向易于富集孔隙和冷粉等组织缺陷,因此,喷射成形锭坯的纵向强度略低于横向强度。

4) 经过挤压变形和T6热处理后,该喷射成形7055铝合金大规格产品的σb最高达745 MPa,δ达12.8%,超过对应规格的美国军标。

REFERENCES

[1] Grant P S. Spray forming[J]. Progress in Materials Science, 1995, 39(4/5): 497-545.

[2] Jenabali Jahromi S A. Creep behavior of spray-cast 7XXX aluminum alloy[J]. Materials and Design, 2002, 23(2): 169-172.

[3] 米国发, 田世藩, 曾松岩, 李庆春. 雾化喷射沉积技术的发展概况及展望[J]. 材料科学与工程, 1996, 14(4): 8-13.

MI Guo-fa, TIAN Shi-fan, ZENG Song-yan, LI Qing-chun. The status and prospect of the metal spray atomization and deposition technique[J]. Materials Science and Engineering, 1996, 14(4): 8-13.

[4] 张济山, 陈国良. 雾化喷射沉积成形材料制备技术的新进展[J]. 北京科技大学学报, 1997, 19(1): 15-21.

ZHANG Ji-shan, CHEN Guo-liang. Recent progress in spray forming technique for materials processing[J]. Journal of University of Science and Technology Beijing, 1997, 19(1): 15-21.

[5] 范洪波, 沈 军, 崔成松, 曹福洋, 李庆春. 喷射成形快速凝固技术在铝合金中的应用[J]. 粉末冶金技术, 1998, 16(2): 137-142.

FAN Hong-bo, SHEN Jun, CHUI Cheng-song, CAO Fu-yang, LI Qing-chun. The research and use status of spray-forming rapidly solidifying technique in aluminum alloys[J]. Powder Metallurgy Technology, 1998, 16(2): 137-142.

[6] 张永安, 熊柏青, 刘 江, 张少明, 石力开, 刘 勇, 王 峰. 喷射成型过程中雾化粒滴的数值模拟[J]. 中国有色金属学报, 1999, 9(S1): 78-83.

ZHANG Yong-an, XIONG Bai-qing, LIU Jiang, ZHANG Shao-ming, SHI Li-kai, LIU Yong, WANG Feng. Computer simulation of droplets in flight stage during spray forming process[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(S1): 78-83.

[7] 张永安, 熊柏青, 刘红伟, 朱宝宏, 石力开, 张济山, 夏芧栗. CuCr25触头材料的喷射成形制备及组织分析[J]. 中国有色金属学报, 2003, 13(5): 1067-1070.

ZHANG Yong-an, XIONG Bai-qing, LIU Hong-wei, ZHU Bao-hong, SHI Li-kai, ZHANG Ji-shan, XIA Xu-li. Spray forming process and microstructure of CuCr25 contactor material[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1067-1070.

[8] YU Fu-xiao, CUI Jian-zhong, Ranganathan S, Dwarakadasa E S. Fundamental differences between spray forming and other semisolid processes[J]. Mater Sci Eng A, 2001, 304/306: 621-626.

[9] 彭超群, 黄伯云. 喷射沉积技术[J]. 有色金属, 2002, 54(1): 12-26.

PENG Chao-qun, HUANG Bai-yun. Spray depositon technology[J]. Nonferrous Metals, 2002, 54(1): 12-26.

[10] 张永安, 朱宝宏, 刘红伟, 张智慧, 熊柏青, 石力开. Zn含量对喷射成形7×××系高强铝合金组织与性能的影响[J]. 中国有色金属学报, 2005, 15(7): 1013-1018.

ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, ZHANG Zhi-hui, XIONG Bai-qing, SHI Li-kai. Influence of Zn content on microstructure and properties of spray-formed 7××× series aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1013-1018.

[11] Dumont D, Deschamps A, Brechet Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy[J]. Mater Sci Eng A, 2003, 356(1/2): 326-336.

[12] WANG Feng, XIONG Bai-qing, ZHANG Yong-an, ZHANG Zhi-hui, WANG Zhi-xing, ZHU Bao-hong, LIU Hong-wei. Microstructure and mechanical properties of spray-deposited Al-Zn-Mg-Cu alloy[J]. Materials and Design, 2007, 28(4): 1154-1158.

[13] 张 豪. 多层喷射沉积过程及其材料的研究[D]. 长沙:中南工业大学, 1998.

ZHANG Hao. Study on Multi-Layer spray deposition process and materials[D]. Changsha: Central South University of Technology, 1998.

[14] 张 豪. 控制往复喷射成形装置. 中国专利 03230878. 7[P]. 2004-05.

ZHANG Hao. Setup of controlled reciprocating spray forming. CN 03230878.7[P]. 2004-05.

[15] 张 豪, 张 荻, 张 捷, 宋 立. 控制往复喷射成形工艺. 中国专利 03117066.8[P]. 2004-02.

ZHANG Hao, ZHANG Di, ZHANG Jie, SONG Li. Process of controlled reciprocating spray forming. CN 03117066.8[P]. 2004-02.

[16] 马万太, 王晓勇, 张 豪, 张 捷. 往复式喷射沉积管坯制备中喷射高度的闭环控制[J]. 中国有色金属学报, 2007, 17(2): 254-259.

MA Wan-tai, WANG Xiao-yong, ZHANG Hao, ZHANG Jie. Closed loop control of spray height in tubular preparation with reciprocating spray deposition process[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(2): 254-259.

[17] 张宝昌. 有色金属及其热处理[M]. 西安: 西北工业大学出版社, 1993: 8-75.

ZHANG Bao-chang. Nonferrous metal and heat treatment[M]. Xi’an: Northwestern Polytechnical University Press, 1993: 8-75.

[18] Zheng L J, Chen C Q, Bai P C, Zhou T T, Liu P Y, Dong B Z. Small-angle X-ray scattering study of precipitates in AlZnMgCu-1.0%Li alloy[J]. Materials Letters, 2003, 58(1/2): 25-28.

[19] 张俊善. 材料强度学[M]. 哈尔滨: 哈尔滨工业大学出版社, 2004: 66-67.

ZHANG Jun-shan. Strength of materials[M]. Harbin: Harbin Institute of Technology Press, 2004: 66-67.

[20] 王晓敏. 工程材料学[M]. 哈尔滨: 哈尔滨工业大学出版社, 2002: 12-13.

WANG Xiao-min. Engineering material science[M]. Harbin: Harbin Institute of Technology Press, 2002: 12-13.

收稿日期:2007-05-24;修订日期:2007-09-24

通讯作者:张 豪,副教授,博士;电话:021-62932511; E-mail: zhanghao@sjtu.edu.cn

(编辑 陈爱华)