DOI: 10.11817/j.issn.1672-7207.2019.10.002

矿渣-电炉还原渣全固废胶凝材料的水化机理

倪文1, 2,李颖1, 2,许成文1, 2,徐东1, 2,姜瑶琪1, 2,高广军1, 2

(1. 北京科技大学 土木与资源工程学院,北京,100083;

2. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京,100083)

摘要:以我国台湾省的矿渣、电炉还原渣和脱硫石膏为主要原料制备矿渣-电炉还原渣-石膏体系胶凝材料,28 d的胶砂抗压强度达到39 MPa,可在某些场合作为普通水泥来使用。采用3种方法检测胶凝材料的安定性,其结果均符合国家标准;采用X线衍射(XRD)、场发射扫描电镜(FE-SEM)、能量色散谱(EDS)、傅里叶红外光谱(FT-IR)、热重-差示扫描量热法(TG-DSC)和X线光电子能谱(XPS)分析胶凝材料的水化过程。研究结果表明:水化产物主要为钙矾石和C-S-H凝胶,水化产物的聚合度随龄期的增长而增加;在水化反应中,矿渣提供具有潜在水硬活性的硅氧四面体和铝氧四面体,电炉还原渣提供碱性氧化物,石膏提供硫酸根离子;三者协同作用形成的钙矾石类复盐和非晶态的C-S-H凝胶是材料强度的主要来源。

关键词:电炉还原渣;胶凝材料;钙矾石;C-S-H凝胶;协同作用;复盐效应

中图分类号:TU526 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2019)10-2342-10

Hydration mechanism of blast furnace slag-reduction slag based solid waste cementing materials

NI Wen1, 2, LI Ying1, 2, XU Chengwen1, 2, XU Dong1, 2, JIANG Yaoqi1, 2, GAO Guangjun1, 2

(1. School of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Key Laboratory of High-Efficient Mining and Safety of Metal Mines, Ministry of Education,University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Blast furnace slag (BFS), reduction slag of electric furnace (RS) and desulphurization gypsum (DG) from Taiwan Province of China were used to prepare BFS-RS-DG cementitious materials. Compressive strength of cementitions material is 39 MPa at 28 d, which can substitute ordinary portland cement in some cases. Three methods were used to test the soundness of the cementing materials, and the results meet the national standards. The hydration and hardening process of cementing materials was analyzed by X-ray diffraction (XRD), field emission scanning electron microscopy(FE-SEM), energy dispersive spectroscopy(EDS), fourier transform infrared spectroscopy(FT-IR), thermogravimetric-differential scanning calorimetry analysis(TG-DSC) and X-ray photoelectron spectroscopy (XPS). The results show that the main hydration products are ettringite and C-S-H gel, and the degree of polymerization of hydration products increases with the increase of the curing age. In the process of hydration, BFS provides silicon-oxygen tetrahedron and Aluminum-oxygen tetrahedron with basic oxide from RS and sulphate ion from DG. The synergistic reaction of three raw materials forms amorphous C-S-H gel and double salt phases such as ettringite, which provides the main source of strength of materials.

Key words: reduction slag of electric furnace; cementing material; ettringite; C-S-H gel; synergistic reaction; double salt effect

电炉炼钢是以废钢为主要原料的炼钢工艺,我国目前电炉炼钢比例远低于世界平均水平。2017年世界电炉炼钢比例为28%,而中国电炉炼钢比例仅为9%[1]。随着中国钢铁行业逐渐进入“成熟期”,中国废钢产量会逐渐增多,并替代铁矿石成为钢铁生产的主流来源,预计电炉炼钢会在2035年左右成为中国钢铁的主要生产方式[2-4]。以废钢为主要原料的电炉炼钢方式符合循环经济的发展要求,具有节能、节水,减排废气、废水和废渣等优点[5-6]。从长远来看,电炉炼钢在我国会得到较快发展,占炼钢总量的比例会逐步增加。因此,电炉钢渣的资源化利用必将成为产业—经济—社会物质流循环链中的关键环节。电炉还原渣占电炉钢渣总量的30%~40%,特点是含钙和铝高,含铁低,易粉化,碱度高,矿物组成以硅酸盐和铝酸盐为主,其粉体具有显著的水硬性[7]。我国钢铁企业大多将其与脱硫/磷渣、转炉钢渣和电炉氧化渣混合堆置,不仅不能发挥电炉还原渣的作用,而且给钢渣回收带来困难。电炉钢渣可以用于生产建筑材料,但其中含有的游离氧化钙和游离氧化镁,可能导致体积安定性不良,限制了电炉钢渣的应用[8]。国外主要将电炉钢渣利用在沥青混凝土和自密实混凝土中[9-11],也有学者发现将电炉钢渣掺入矿渣石膏水泥,形成钙矾石类的水化产物,可以降低体系的收缩[12-13]。国内的研究认为电炉钢渣经过机械激发和热激发作用,其水化反应活性会有所提高[14],经过某些化学激发剂活化处理的电炉钢渣粉也具有较好的水化活性,可用于生产钢渣水泥和高性能混凝土[15]。为此,本文对矿渣、电炉还原渣和脱硫石膏三元胶凝材料体系的水化机理进行研究,以便为提高电炉还原渣的利用效率提供理论依据。

1 试验原料与方法

1.1 试验原料

矿渣、电炉还原渣和脱硫石膏由台湾省台钢资源股份有限公司提供。矿渣质量系数K=[m(CaO) + m(MgO) + m(Al2O3)]/[m(SiO2 + m(MnO) +m(TiO2)]=2.37(其中,m为质量),属于高活性矿渣。电炉还原渣的主要矿物组成为硅酸二钙、铝酸三钙、枪晶石、白云石、斜方钙沸石、方解石和方镁石。脱硫石膏的主要矿物组成为二水硫酸钙。主要原料的化学成分如表1所示。图1所示为电炉还原渣的X线衍射(XRD)谱。

胶砂试验采用厦门艾斯欧标准砂有限公司生产的ISO标准砂和北京慕湖建材有限公司生产的固体聚羧酸型高效减水剂。

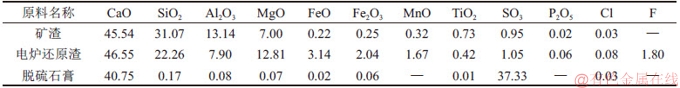

表1 主要原料的化学成分(质量分数)

Table 1 Chemical compositions of main raw materials (mass fraction)%

图1 电炉还原渣XRD谱

Fig. 1 XRD patterns of reduction slag

1.2 试验方法

将除外加剂以外的原料置于40 °C烘箱内烘干8 h以上至恒定质量,保证含水率不大于0.2%。矿渣、电炉还原渣和脱硫石膏分别经5 kg试验用球磨机磨细后备用。表2所示为原料粉磨后的比表面积。

表2 原料粉磨后的比表面积

Table 2 Specific surface area of raw materials after grinding

胶凝材料中矿渣、电炉还原渣和脱硫石膏的质量分数分别为70.5%,17.5%和12.0%。标准稠度用水量试验,安定性试验和胶砂试验依据相关国家标准[16-18]进行。其中安定性按照压蒸法、雷氏夹法和试饼法分别测定。在胶砂试验中,胶凝材料与标准砂质量比为1: 3,水胶比为0.38,减水剂固体掺加质量占胶凝材料总质量的0.2%。试块成型后标准养护24 h脱模,继续标准养护至3,7和28 d龄期,分别测试抗压强度和抗折强度。

净浆试验参考相关国家标准[16]进行,胶凝材料用量为300 g,水胶比为0.32,不掺加减水剂。试块成型后标准养护24 h脱模,继续标准养护至3,7和28 d龄期,破碎后使用无水乙醇终止水化。之后将各龄期净浆样品在40 °C条件下烘干至恒定质量,并研磨成粉末,进行各项微观分析检测。

表3 不同龄期胶砂试块的抗压强度和抗折强度

Table 3 Compression strength and bending strength of mortar samples at different agesMPa

1.3 试验设备和仪器

粉磨设备为SMΦ500×500型球磨机,净浆试验使用NJ-160A型水泥净浆搅拌机,胶砂试验使用JJ-5型水泥胶砂搅拌机。

采用日本理学Ultima Ⅳ X线衍射仪(XRD)测定水化硬化浆体的物相组成;采用德国蔡司SUPRA 55型场发射扫描式电子显微镜(FE-SEM)观察水化硬化浆体的微观形貌;采用英国Link公司LinkNA1000型能谱仪(EDS)测定水化产物微区成分元素种类与原子比例;采用美国Thermo Nicolet公司NEXUS 670型傅里叶红外光谱仪(FT-IR)判断矿物的化学结构,分析水化产物的类别及变化;采用德国 NETZSCH STA 409-QMS高温热分析仪(TG-DSC)确定水化产物及其含水量;采用日本岛津集团Kratos公司AXIS Ultra DLD X线光电子能谱仪(XPS)分析水化反应各阶段Si,O,S,Al和Ca元素的化学结合态。

2 结果与讨论

2.1 安定性

本次采用试饼法、压蒸法和雷氏夹法测量的材料安定性,试验结果符合国家标准[16-17]。孙家瑛[19]认为钢渣粉磨到一定细度后,游离氧化钙和游离氧化镁被活化,在水化早期就参与反应生成氢氧化钙和氢氧化镁,虽然反应产物体积大于反应物体积,但此时材料还处于塑性状态,不会导致安定性问题。武伟娟等[20]分析了钢渣比表面积对钢渣-水泥复合胶凝材料安定性的影响,认为在钢渣掺量相同时,钢渣-水泥净浆的沸煮、压蒸膨胀率随着钢渣比表面积的增加而降低。这说明通过对钢渣进行超细粉磨,有助于解决游离氧化钙和游离氧化镁导致胶凝材料安定性不良的问题。

2.2 胶砂强度

在胶砂试验中,胶砂流动度的平均值为220 mm,表3所示为不同龄期胶砂试块的抗压强度和抗折强度。由表3可见:试块3 d强度能够达到28 d强度的50%,7 d强度能够达到28 d强度的75%以上,说明这种胶凝材料的早期水化反应比较充分,具有一定的早强性能。

2.3 微观分析

2.3.1 X线衍射分析

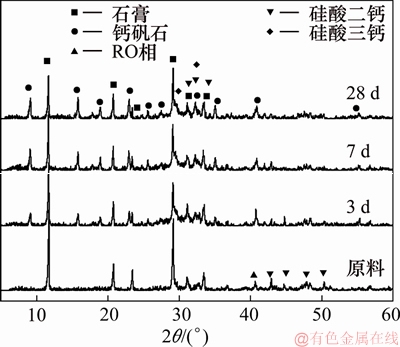

图2所示为不同水化龄期胶凝材料的X线衍射(XRD)谱。由图2可见:胶凝材料各龄期的主要水化产物均为钙钒石和C-S-H凝胶。在水化3 d时,就生成大量钙钒石,随后钙钒石生成速度降低,衍射峰强度变化不大,这与试块3 d强度能够达到28 d强度的50%相对应;随着龄期的增长,石膏、硅酸二钙和硅酸三钙的衍射峰强度有所减弱,说明部分石膏参与生成了钙矾石,部分硅酸二钙和硅酸三钙亦发生了水化,生成了C-S-H凝胶,对强度起到促进作用。值得注意的是,水化产物中并没有检测到氢氧化物。

2.3.2 场发射扫描电镜和能谱分析

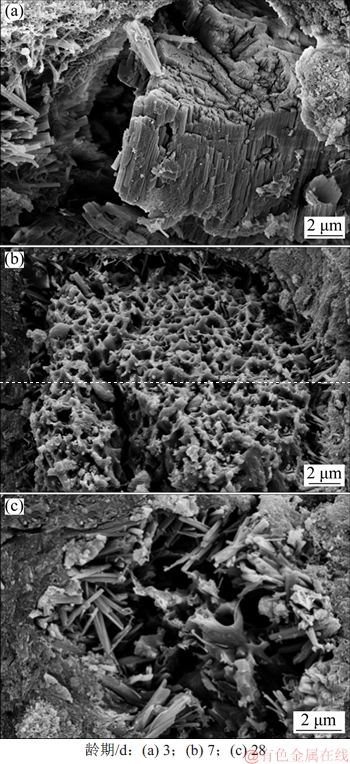

图3所示为不同水化龄期胶凝材料的场发射扫描电镜(FE-SEM)图。由图3(a)可见:球状C-S-H凝胶搭接延伸成稀疏的链状和网状结构,在视野中均匀获取30个点的能谱数据,计算出此时C-S-H凝胶的钙硅比为1.27。由图3(b)可见:针棒状和凝胶状交织的产物可能是钙矾石与C-S-H凝胶组成的复合结构,其中钙矾石结构比较粗壮,C-S-H凝胶还不能完全包裹钙矾石;由图3(c)可见:C-S-H凝胶呈现密实的层状结构,在视野中均匀获取30个点的能谱数据,计算出此时C-S-H凝胶的钙硅比为1.05,钙硅比与早期相比有所下降;由图3(d)可见:针棒状和凝胶状产物组成复合结构,与图3(b)相比,凝胶状产物更加致密,将针棒状产物紧密包裹起来。

图2 不同水化龄期胶凝材料的X线衍射(XRD)谱

Fig. 2 XRD patterns of cementitious material at different hydration times

图3 不同水化龄期胶凝材料的场发射扫描电镜(FE-SEM)图

Fig. 3 FE-SEM images of cementitious material at different hydration times

以上分析结果表明:钙矾石生成于水化早期,这与XRD的分析结果相吻合;C-S-H凝胶亦生成于水化早期,其钙硅比随着龄期增长有所下降,这可能是矿渣持续水化所致;随着龄期增长,C-S-H凝胶的形貌由稀疏的链状和网状结构发展为密实的层状结构,并紧密包裹钙矾石晶体,表明这种复合结构是胶凝材料强度的主要来源。

图4所示为不同水化龄期胶凝材料(石膏相)的场发射扫描电镜(FE-SEM)图。结合能谱分析,可以确定不同龄期的图片中孔洞中心的物质均为石膏,孔壁中向内侧生长的针棒状晶体为钙矾石。由图4可见:随着龄期增长,孔洞中的石膏从最初的密集结晶状态,到多孔蜂窝状态,直至仅剩少量残余,与此同时孔壁上的钙矾石晶体逐渐增多、变粗,填补了石膏消失后的空间。图4反映了石膏参与生成钙矾石的反应过程,即体系中富含石膏且具有孔洞的位置有利于钙矾石生成,而孔洞处往往是结构中比较薄弱的区域,钙矾石的生成对填补薄弱区域和提高早期强度起到了重要作用。

图4 不同水化龄期胶凝材料(石膏相)的场发射扫描电镜(FE-SEM)图

Fig. 4 FE-SEM images of cementitious material (gypsum phase) at different hydration times

2.3.3 傅立叶红外光谱分析

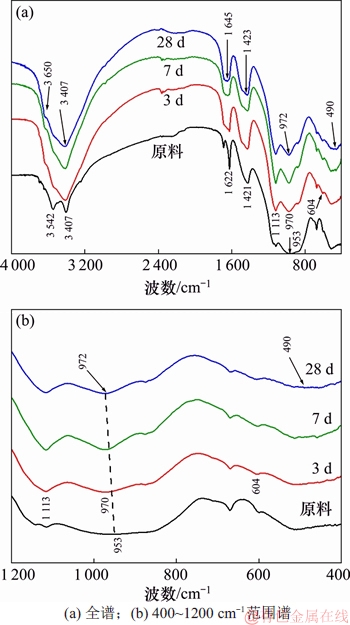

图5所示为不同水化龄期胶凝材料的傅里叶红外光谱(FT-IR),由图5可见:未水化的原料在3 542 cm-1和3 407 cm-1处存在2个明显的吸收峰,这分别是原料石膏中羟基的伸缩振动和典型结晶水中羟基的不对称伸缩振动[21]。水化3 d时,3 542 cm-1和3 407 cm-1处的2个吸收峰变为1个靠近3 407 cm-1处的吸收峰,这说明石膏被消耗生成了钙矾石,羟基水转化为结晶水;水化28 d时,3 407 cm-1和1 645 cm-1处的吸收峰分别属于水化产物结晶水中羟基的不对称伸缩振动和弯曲振动,与原料谱线相比,这2个吸收峰的透过率明显下降,表明原料水化反应生成大量富含结晶水的物质。

图5 不同水化龄期胶凝材料的傅立叶红外光谱(FT-IR)

Fig. 5 FT-IR patterns of cementitious material at different hydration times

水化3 d时,3 650 cm-1处的弱吸收峰对应八面体表面羟基的伸缩振动,1 113 cm-1处的强吸收峰对应 的不对称伸缩振动,604 cm-1处的弱吸收峰对应

的不对称伸缩振动,604 cm-1处的弱吸收峰对应 的弯曲振动,八面体表面羟基和

的弯曲振动,八面体表面羟基和 的特征峰证明钙矾石形成较早,这与XRD和SEM的分析结果相吻合。

的特征峰证明钙矾石形成较早,这与XRD和SEM的分析结果相吻合。

850~1 000 cm-1和490 cm-1处的吸收峰分别对应C-S-H凝胶中Si—O(Al)的不对称伸缩振动和Si—O的面内弯曲振动。随着桥氧数的增多,硅氧四面体的Si—O不对称伸缩振动频率逐渐增大,吸收峰的波长范围趋向变窄。结合原料的化学成分、XRD谱和FT-IR谱推测:原料中聚合度较低的硅酸盐物质,在水化过程中转化成为聚合度较高的链状或架状硅酸盐,使红外光谱的波峰向高波数方向移动,此现象与2.3.2节能谱显示样品随龄期增长钙硅比降低相对应。此外,1 430 cm-1附近的吸收峰表征了 的非对称伸缩振动,这是样品暴露在空气中发生碳化所致 [22-23]。

的非对称伸缩振动,这是样品暴露在空气中发生碳化所致 [22-23]。

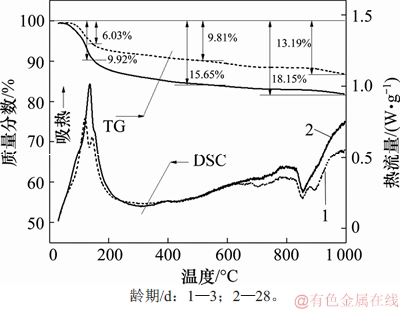

2.3.4 热重-差示扫描量热分析

图6所示为不同水化龄期胶凝材料的热重(TG)-差示扫描量热法(DSC)曲线。由图6可见:3 d时在120 °C和150 °C处有2个明显的吸热峰,而在28 d时120 °C的吸热峰宽化增强并且峰位移动到130 °C左右,150 °C的吸热峰不再突出。120~130 °C时出现的峰是水化产物中C-S-H凝胶和钙矾石的脱水吸热峰,表明水化早期产物即大量生成;随着龄期增长,C-S-H凝胶对钙矾石形成包裹导致钙矾石脱水温度升高[24],这与FE-SEM和FT-IR结果互为印证;150 °C时出现的吸热峰表明脱硫石膏(CaSO4·2H2O)脱水成为半水石膏(CaSO4·0.5H2O),说明水化3 d时还有较多脱硫石膏未参与反应,但随着龄期增长,它们被逐渐消耗,这与XRD和FE-SEM的结论一致。500 °C之前的热重曲线显示水化3 d的胶凝材料质量损失率为9.81%,而水化28 d的质量损失率增大到15.65%,证明水化过程迅速且持久,体系中生成了较多富含结晶水的产物。

图6 不同水化龄期胶凝材料的热重(TG)-差示扫描量热法(DSC)曲线

Fig. 6 TG-DSC curves of cementitious material at different hydration times

600~800 °C区间的细小吸热峰伴随着质量损失,说明样品含有少量CaCO3;850~900 °C区间并未对应出现明显的质量损失,说明此处是C-S-H凝胶发生晶型转变形成β-硅灰石的特征峰[25];接近1 000 °C的吸热峰为体系的熔融吸热峰。500 °C以上仍有质量损失说明水化产物中存在桥氧数为3的硅(铝)氧四面体,即与硅(铝)氧四面体链接的高键能的羟基,这表明水化产物的聚合度较高。

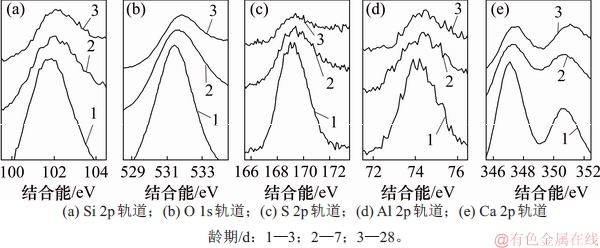

2.3.5 X线光电子能谱分析

利用X线光电子能谱(XPS)测定水化不同时期Si,O,S,Al和Ca元素的次外层电子激发能变化规律,可以从微观角度解析水化过程中各元素间旧组合分解和新组合形成的过程。图7所示为不同水化龄期胶凝材料的XPS曲线。由图7可见:随着水化龄期的增长,Si,O,S,Ac和Ca的次外层电子激发能均逐渐增大。

1) Si结合态。Si 2p轨道激发能随龄期增长呈现升高趋势,这主要有2个原因:一是原料中尤其是矿渣玻璃相中的富硅相活性很强,在电炉还原渣水化形成的碱性环境里,Si—O键容易发生断裂水解,这种水解的本质是水中的H+与 结合形成[H2SiO4]2-和[H3SiO4]-,此时氢原子核对氧的核外电子云形成静电引力,使氧的核外电子云向氢偏移,而硅氧四面体中心处硅的核外电子云将向氧原子偏移,造成硅的核外电子云密度降低,Si 2p轨道激发能升高;二是硅酸盐聚合度提高也会导致Si 2p轨道激发能升高[26-27]。因此,Si 2p轨道激发能升高,说明富硅相水解生成了水化硅酸盐,而水化硅酸盐很可能由岛状、链状硅酸盐转变成为聚合度更高链状甚至架状硅酸盐,这与FT-IR的分析结论相符。

结合形成[H2SiO4]2-和[H3SiO4]-,此时氢原子核对氧的核外电子云形成静电引力,使氧的核外电子云向氢偏移,而硅氧四面体中心处硅的核外电子云将向氧原子偏移,造成硅的核外电子云密度降低,Si 2p轨道激发能升高;二是硅酸盐聚合度提高也会导致Si 2p轨道激发能升高[26-27]。因此,Si 2p轨道激发能升高,说明富硅相水解生成了水化硅酸盐,而水化硅酸盐很可能由岛状、链状硅酸盐转变成为聚合度更高链状甚至架状硅酸盐,这与FT-IR的分析结论相符。

图7 不同水化龄期胶凝材料的XPS曲线

Fig. 7 XPS curves of cementitious material at different hydration times

2) O结合态。有研究表明,非桥氧键、桥氧键、氢氧化物和水的O 1s轨道激发能分别为530.0~530.5,531.5~532.7,533~533.5和534.0 eV[28]。因此,O 1s轨道激发能在531.5~532.0 eV间峰位随水化龄期增长不断升高,可以推断出胶凝材料在水化过程中部分非桥氧键转变成了桥氧键,水化硅酸盐的聚合度提高,这与FT-IR和Si结合态分析结论相符。

3) S结合态。随着龄期增长,S 2p3/2轨道激发能从169.2 eV升高到169.4 eV。鉴于169.0 eV处属于 的特征峰,而169.5 eV处属于硫酸盐复盐的特征峰[29],可知体系中的脱硫石膏参与了反应,体系在水化早期就生成了含硫酸根的复盐矿物,使S 2p3/2轨道激发能升高,这与2.3.4节中关于早期钙矾石生成量的分析结论相符。

的特征峰,而169.5 eV处属于硫酸盐复盐的特征峰[29],可知体系中的脱硫石膏参与了反应,体系在水化早期就生成了含硫酸根的复盐矿物,使S 2p3/2轨道激发能升高,这与2.3.4节中关于早期钙矾石生成量的分析结论相符。

4) Al结合态。Al 2p轨道激发能峰形不对称且与其他元素的峰形相比较为宽化,随着水化时间的延长,Al 2p轨道激发能从73.9 eV升高到74.4 eV,这是因为体系中无羟基的低聚合度硅(铝)氧四面体转变成了含羟基的高聚合度硅(铝)氧四面体,由于铝从硅酸盐网络体中解聚出来进入了钙矾石类复盐相,使核外电子云能态降低,Al 2p轨道激发能升高。另外,硅(铝)氧四面体从无羟基的低聚合度向有羟基的高聚合度转变是放热过程,会降低体系能态,使Al 2p轨道激发能升高。而Al 2p轨道激发能的增量不大,可能是原料中Al的质量分数不高,进入反应体系的Al不多造成的。

5) Ca结合态。Ca 2p轨道激发能的峰形包含2个特征峰,分属Ca 2p3/2轨道(左)和Ca 2p5/2轨道(右)。随着龄期增长,Ca 2p轨道激发能逐渐增大,这是因为原料中的富钙相溶解,产生大量游离态Ca2+,又与[H2SiO4]2-,[H3SiO4]-,[H3AlO4]2-, ,OH-和H2O等基团结合,形成新的含钙相。尤其是电炉还原渣中CaO水化生成的Ca(OH)2,一般为亚微米级至纳米级颗粒,其活性高、溶解速度快,在非平衡动态反应过程中可以为体系提供更多的Ca2+,并使溶液的pH升高,促进生成更多的低能稳定态水化产物,使Ca 2p轨道激发能增大。

,OH-和H2O等基团结合,形成新的含钙相。尤其是电炉还原渣中CaO水化生成的Ca(OH)2,一般为亚微米级至纳米级颗粒,其活性高、溶解速度快,在非平衡动态反应过程中可以为体系提供更多的Ca2+,并使溶液的pH升高,促进生成更多的低能稳定态水化产物,使Ca 2p轨道激发能增大。

2.4 体系水化硬化及安定性机理分析

2.4.1 体系水化硬化机理分析

一般钢渣由于铁的质量分数较高,大量残余微米级金属铁粒子在粉磨过程中会产生磁团聚和磁黏附,造成粉磨困难。如果对钢渣进行超细粉磨,必须在粉磨过程中及时除去暴露出来的金属铁微粒,这将大大增加超细钢渣粉的生产成本。由表1可知:电炉还原渣中铁的质量分数较低,使用球磨机粉磨30 min后,比表面积可达到600 m2/kg,易磨性与水泥熟料的相近。以电炉还原渣代替一般钢渣,可以解决粉磨成本高的难题。

本文研究的矿渣-电炉还原渣-石膏体系中,矿渣是主要成分,矿渣中以玻璃体结构为主,玻璃体以四配位体 (硅氧四面体)作为主要结构单元,其中存在少量结晶度极低的铝硅酸盐微晶体。矿渣中的硅氧四面体聚合度低,O-Si-O键相对数量少,化学活性较强。在矿渣的玻璃体中,还有部分Al3+替代Si4+,形成比硅氧四面体活性更高的铝氧四面体,而且矿渣比水泥熟料具有更大的[n(SiO2)+n(Al2O3)]/[n(CaO)+n(MgO)](其中,n为物质的量),其含有潜在水硬活性的硅氧四面体和铝氧四面体比水泥熟料更多。将矿渣、电炉还原渣和脱硫石膏磨细后混合,可以发挥三者的协同作用,制成不含水泥熟料又可用于高性能混凝土的全固废胶凝材料,这种协同作用主要体现在以下2个方面。

(硅氧四面体)作为主要结构单元,其中存在少量结晶度极低的铝硅酸盐微晶体。矿渣中的硅氧四面体聚合度低,O-Si-O键相对数量少,化学活性较强。在矿渣的玻璃体中,还有部分Al3+替代Si4+,形成比硅氧四面体活性更高的铝氧四面体,而且矿渣比水泥熟料具有更大的[n(SiO2)+n(Al2O3)]/[n(CaO)+n(MgO)](其中,n为物质的量),其含有潜在水硬活性的硅氧四面体和铝氧四面体比水泥熟料更多。将矿渣、电炉还原渣和脱硫石膏磨细后混合,可以发挥三者的协同作用,制成不含水泥熟料又可用于高性能混凝土的全固废胶凝材料,这种协同作用主要体现在以下2个方面。

1) 复盐效应。电炉还原渣中二价金属氧化物(CaO,MgO和FeO)的总质量分数达到60%以上,这些物质水化后能够给体系提供强碱性环境,石膏能够提供钙矾石形成所必需的SO42-,二者共同夺取体系中的Al3+,Fe3+形成钙矾石类复盐:

2(Al3+, Fe3+)+12(Ca2+, Mg2+)+18OH-+6SO42-+55H2O→2{3(CaO, MgO)·(Al2O3, Fe2O3)·3(CaSO4)·32(H2O)} (钙矾石类复盐) (1)

在碱性条件下,钙矾石类复盐具有极低溶解度,其溶度积常数为10-111.6,一旦形成就较为稳定。这种钙矾石类复盐是具有纳米直径的针棒状晶体,对硬化体具有增强增韧效应,水化初期快速形成这种复盐能促进早期强度的增长。

2) 电炉还原渣和石膏复和激发矿渣。矿渣不仅可以在强碱性环境中解聚并再次聚合为凝胶类物质,也可以在石膏参与的条件下生成C-S-H凝胶和钙矾石,由于钙矾石和凝胶类物质在常温下都具有极低的溶解度,在体系中存在大量矿渣的条件下,反应式(2)和式(3)都有很大的化学驱动力。

aSiO2·bAl2O3·qCaO+rCa(OH)2+sH2O→aSiO2·bAl2O3·(q+r)CaO·(s+r)H2O (2)

aSiO2·bAl2O3·qCaO +rCa(OH)2+sH2O+3bCaSO4·2H2O→aSiO2·(q+r-3b)CaO·(s+r-27b)H2O +b(3CaO·Al2O3·3CaSO4·32H2O) (3)

(C-S-H凝胶)

(钙矾石)

利用矿渣、电炉还原渣和石膏3种微粉的协 同激发作用,可以使针棒状复盐晶体和非晶态C-S-H凝胶同时大量生成,促使凝胶紧密包裹复盐晶体,形成针棒状复盐晶体纤维增强复合结构,大幅度提高体系的稳定性。

2.4.2 体系安定性机理分析

钢渣在混凝土类水泥制品中造成安定性不良的基本原理是钢渣中游离氧化钙和游离氧化镁水化反应生成固体氢氧化物。综合多种检测分析结果可见:反应体系中未出现结晶态的Ca(OH)2和Mg(OH)2。由于没有明显生成固体Ca(OH)2和Mg(OH)2,可以推断本体系能够避免安定性不良问题。

3 结论

1) 采用质量分数分别为70.5%,17.50%和12.0%的矿渣、电炉还原渣和脱硫石膏制备的胶凝材料,其安定性符合国家标准。

2) 将这种胶凝材料与标准砂以1:3的质量比混合,采用0.38的水胶比制备胶砂试块,28 d抗压强度可达39 MPa,3 d和7 d强度分别达到28 d强度的50%和75%。

3) 微观分析显示矿渣-电炉还原渣-石膏体系的主要水化产物是C-S-H凝胶和钙矾石,随着龄期增长,该体系水化产物的聚合度逐渐增加。

4) 在矿渣-电炉还原渣-石膏体系中,矿渣提供具有潜在水硬活性的硅氧四面体和铝氧四面体,电炉还原渣提供钙、镁等碱性物质,脱硫石膏提供硫酸根离子,三者协同作用形成极低溶解度的钙矾石类复盐和非晶态的C-S-H凝胶,二者形成的针棒状复盐晶体纤维增强复合结构,是硬化体强度的主要来源。

参考文献:

[1] The world steel association. World steel in figures 2018 now available[J/OL].[2018-06-25].https://www.worldsteel.org/zh/media-centre/press-releases/2018/world-steel-in-figures-2018.html.

[2] PAULIUK S, MILFORD R L, MULLER D B, et al. The steel scrap age[J]. Environmental Science &Technology, 2013, 47: 3448-3454.

[3] 汪鹏, 姜泽毅, 张欣欣, 等. 中国钢铁工业流程结构、能耗和排放长期情景预测[J]. 北京科技大学学报, 2014, 36(12): 1683-1693.

WANG Peng, JIANG Zeyi, ZHANG Xinxin, et al. Long-erm scenario forecast of production routes, energy consumption and emissions for Chinese steel industry[J]. Journal of University of Science and Technology Beijing, 2014, 36(12): 1683-1693.

[4] 傅杰, 柴毅忠, 毛新平. 中国电炉炼钢问题[J]. 钢铁, 2007, 42(12): 1-6.

FU Jie, CHAI Yizhong, MAO Xinping. Problems of EAF steelmaking in China[J]. Iron & Steel, 2007, 42(12): 1-6.

[5] 李思锐, 江秀龙, 马德武, 等. 我国电弧炉炼钢发展现状及前景[J]. 四川冶金, 2018, 40(2): 19-21, 42

LI Sirui, JIANG Xiulong, MA Dewu, et al. The development and challenge of EAF[J].Sichuan Metallurgy, 2018, 40(2): 19-21, 42.

[6] 刘全义, 张贵杰, 王凯, 等. 以废钢为原料的电炉短流程炼钢工艺的研究进展[C]//2016互联网+与钢铁工业智能制造高峰论坛论文集. 唐山, 2016: 185-188.

LIU Quanyi, ZHANG Guijie, WANG Kai, et al. Research progress in electric steelmaking short process with scrap as raw material[C]// 2016 Internet + and Intelligent Manufacturing Peak BBS on Iron and Steel Industry. Tangshan, 2016: 185-188.

[7] 黄亚鹤, 刘承军. 电炉渣的综合利用分析[J]. 工业加热, 2008, 37(5): 4-7.

HUANG Yahe, LIU Chengjun. Analysis on comprehensive utilization of electric furnace slag[J]. Industrial Heating, 2008, 37(5): 4-7.

[8] SANTAMARIA A, FALESCHINI F, GIACOMELLO G, et al. Dimensional stability of electric arc furnace slag in civil engineering applications[J]. Journal of Cleaner Production, 2018, 205: 599-609.

[9] PASETTO M, BALIELLO A, GIACOMELLO G, et al. Sustainable solutions for road pavements: A multi-scale characterization of warm mix asphalts containing steel slags[J]. Journal of Cleaner Production, 2017, 166: 835-843.

[10] MARTINHO F C G, PICADO-SANTOS L G, CAPIT O S D. Influence of recycled concrete and steel slag aggregates on warm-mix asphalt properties[J]. Construction and Building Materials, 2018, 185: 684-696.

O S D. Influence of recycled concrete and steel slag aggregates on warm-mix asphalt properties[J]. Construction and Building Materials, 2018, 185: 684-696.

[11] SANTAMAR A A, ORBE A, LOSA

A A, ORBE A, LOSA EZ M M, et al. Self-compacting concrete incorporating electric arc-furnace steelmaking slag as aggregate[J]. Materials & Design, 2017, 115: 179-193.

EZ M M, et al. Self-compacting concrete incorporating electric arc-furnace steelmaking slag as aggregate[J]. Materials & Design, 2017, 115: 179-193.

[12] CHO B S, CHOI Y C. Hydration properties of STS-refining slag-blended blast furnace slag cement[J]. Advances in Materials Science and Engineering, 2018: 1-9.

[13] MUHMOOD L, VITTA S, VENKATESWARAN D. Cementitious and pozzolanic behavior of electric arc furnace steel slags[J]. Cement and Concrete Research, 2009, 39(2): 102-109.

[14] 程从密, 何娟, 唐兵, 等.电炉钢渣活性激发研究[J]. 广州大学学报(自然科学版), 2012, 11(1): 53-57.

CHENG Congmi, HE Juan, TANG Bing, et al. The investigation of hydraulic activated EAF slag[J]. Journal of Guangzhou University(Natural Science Edition), 2012, 11(1): 53-57.

[15] 刘智伟, 李宇, 苍大强. 电炉氧化钢渣在水泥和混凝土中的应用研究[J]. 混凝土, 2014, (2): 57-60.

LIU Zhiwei, LI Yu, CANG Daqiang. Investigation to application of electric furnace oxidizing slag being used in cement and concrete[J]. Concrete, 2014, (2): 57-60.

[16] GB/T 1346—2011. 水泥标准稠度用水量、凝结时间、安定性检验方法[S].

GB/T 1346—2011. Test methods for water requirement of normal consistency, setting time and soundness of the portland cement[S].

[17] GB/T 750—1992. 水泥压蒸安定性试验方法[S].

GB/T 750—1992. Test method for autoclave soundness of portland cement[S].

[18] GB/T 17671—1999. 水泥胶砂强度检验方法(ISO法)[S].

GB/T 17671—1999. Method of testing cements—Determination of strength(ISO)[S].

[19] 孙家瑛. 钢渣细度对水泥混凝土物理力学性能影响[J]. 粉煤灰综合利用, 2004, 17(5): 3-5.

SUN Jiaying. Influence of slag fine on the physical mechanics property cement concrete[J]. Fly Ash Comprehensive Utilization, 2004, 17(5): 3-5.

[20] 武伟娟, 刘家祥, 贾瑞权. 钢渣比表面积对钢渣-水泥复合胶凝材料安定性的影响[J]. 矿产综合利用, 2018(1): 133-136, 91.

WU Weijuan, LIU Jiaxiang, JIA Ruiquan. Effect of specific surface area of steel slag on volumetric stability of steel slag-cement composite gelling materials[J]. Multipurpose Utilization of Mineral Resources, 2018(1): 133-136, 91.

[21] ZHANG Xufang, NI Wen, WU Junyu, et al. Hydration mechanism of a cementitious material prepared with Si-Mn slag[J]. International Journal of Minerals, Metallurgy, and Materials, 2011, 18(2): 234-239.

[22] TREZZA M A, LAVAT A E. Analysis of the system 3CaO·Al2O3—CaSO4·2H2O—CaCO3—H2O by FT-IR spectroscopy[J]. Cement and Concrete Research, 2001, 31(6): 869-872.

[23] 崔孝炜, 倪文,耿碧瑶, 等.透辉石粉的火山灰反应特性[J]. 工程科学学报, 2018, 40(6): 658-664.

CUI Xiaowei, NI Wen, GENG Biyao, et al. Ash reactivity characteristics of diopside powder[J]. Chinese Journal of Engineering, 2018, 40(6): 658-664.

[24] 冯乃谦. 新实用混凝土大全[M].2版. 北京: 科学出版社, 2005: 26-27.

FENG Naiqian. New practical concrete encyclopedia[M]. 2nd ed. Beijing: Science Press, 2005: 26-27.

[25] 杨南如, 岳文海. 无机非金属材料图谱手册[M]. 武汉:武汉工业大学出版社, 2000: 250-251.

YANG Nanru, YUE Wenhai. The handbook of inorganic metalloid materials atlas[M]. Wuhan: Wuhan Industrial University Press, 2000: 250-251.

[26] 祝丽萍. 赤泥-矿渣胶结剂制备全尾砂膏体充填料[D]. 北京: 北京科技大学土木与环境工程学院, 2012: 78-81.

ZHU Liping. Development of whole-tailings paste backfilling material using red mud and slag as the major components of cementing agent [D]. Beijing: University of Science and Technology Beijing. School of Civil and Environment Engineering, 2012: 78-81.

[27] OKADA K, KAMESHIMA Y, YASUMORI A. Chemical shifts of silicon X-ray photoelectron spectra by polymerization structures of silicates[J]. Journal of the American Ceramic Society, 2005, 81(7): 1970-1972.

[28] BLACK L, GARBEV K, BEUCHLE G, et al. X-ray photoelectron spectroscopic investigation of nanocrystalline calcium silicate hydrates synthesised by reactive milling[J]. Cement and Concrete Research, 2006, 36(6): 1023-1031.

[29] COMANS R N J, EIGHMY T T, SHAW E L. Reference spectra for environmentally important secondary minerals: ettringite (Ca6Al2(SO4)3(OH)12·26H2O) by XPS[J]. Surface Science Spectra, 1996, 4(2): 150-156.

(编辑 秦明阳)

收稿日期: 2019 -02 -22; 修回日期: 2019 -04 -17

基金项目(Foundation item):国家自然科学基金资助项目(41472043);国家重点研发计划重点专项项目(2017YFC0210301) (Project(41472043) supported by the National Natural Science Foundation of China; Project(2017YFC0210301) supported by the Key Project of National Key Research and Development Plan)

通信作者:倪文,博士,教授,从事矿物材料和固体废弃物资源化研究;E-mail: niwen@ces.ustb.edu.cn