DOI:10.19476/j.ysxb.1004.0609.2017.10.20

铜阳极泥低温碱性熔炼浸出液中杂质分离

郭学益,徐润泽,田庆华,李 栋

(中南大学 冶金与环境学院,长沙 410083)

摘 要:铜阳极泥经低温碱性熔炼-浸出处理后,铅、砷、硒等进入强碱性浸出液,其中铅和砷分别以Pb(OH)n2-n和AsO43-形式存在。为分离其中的铅、砷等主要杂质元素,通过计算PbS-H2O体系电势-pH图、Ca-As-H2O体系溶解平衡浓度-pH图后,采用硫化沉淀和钙盐沉淀的方式有效去除铅、砷,同时保证硒的低分散度。实验结果表明:采用硫化沉淀,硫化钠过量系数2.5,反应温度20 ℃,反应时间15 min。在此条件下,铅和铜沉淀率都达到99.99%以上,硒损失5%;采用钙盐沉淀,控制溶液pH=10,钙砷比3.5,反应温度90 ℃,反应时间1.5 h。在此条件下,砷沉淀率达到99%以上,硒沉淀率为2.81%。

关键词:铜阳极泥;浸出液;硒;硫化铅;砷酸钙

文章编号:1004-0609(2017)-10-2120-08 中图分类号:TF803.25 文献标志码:A

铜阳极泥为铜冶炼主要产物之一,是稀贵金属回收的重要原料。随着铜冶炼近百年的发展,优质铜矿资源枯竭,贫矿、杂矿冶炼比例越来越大,现有阳极泥处理工艺中稀贵金属分散、直收率低、工艺流程复杂等缺点渐渐凸显[1]。作者所在团队长期致力于低温碱性熔炼技术的进步,研究形成了一套完整的低温碱性熔炼处理铜阳极泥新工艺,该工艺具有流程短、稀贵金属富集程度高等优点[2]。熔炼产物浸出后获得的碱性溶液中包含了砷、硒、铅、铜等元素,为充分回收溶液中的硒,有必要对溶液进行净化。

目前针对碱性溶液中铅、铜等重金属元素的分离方法有:矿物吸附法[3-6]、离子交换法[7]、生物处理 法[8]、化学沉淀法[6, 9-12]等。其中吸附等物理方法去除铅、铜等重金属离子具有反应时间短、处理速度快等特点,但对于处理溶液酸碱性要求严苛等缺点,特别是对于溶液中存在的硒酸根或亚硒酸根这种理化性质与硫酸根非常相似的元素,容易发生夹杂吸附等问题;而现有的生物处理法研究结果显示:生物处理法具有处理流程长、处理量低等缺点不适用于大规模金属生产过程。

目前针对碱性溶液中砷元素的分离方法的研究有:吸附法[13-14]],离子交换法[15]、化学沉淀法[9-10, 16-22]、微生物处理法[23-24]等。其中吸附法与离子交换法具有操作简单、吸附剂种类多、效果良好等特点,但对于溶液pH、溶液中离子种类等有较高要求;微生物处理法不仅可以将溶液中砷还原,还可以将溶液中砷富集于微生物体内,但其反应时间长等缺点难以简单克服;常见的化学沉淀法利用铁、钙、镁、硫化物等来沉淀溶液中砷离子,其具有处理量大、工艺简单等特点,但目前沉淀效率低、二次污染等问题需要克服。

本文的研究目的在于通过对杂质元素沉淀方法的理论分析及实验研究,找到一个合适于处理低温碱性熔炼工艺中含硒浸出液的方法,在高效分离溶液中杂质的同时避免硒元素的分离损失,为后期硒回收提供良好的基础。

1 理论分析

1.1 硫化沉铅理论分析

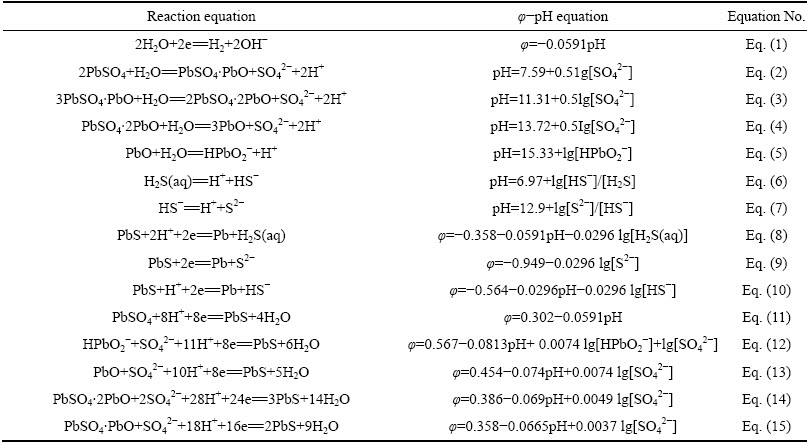

在低温碱性熔炼过程中,铅化合物会与氢氧化钠发生反应生成铅单质,随后在浸出过程中,铅以Pb(OH)n2-n的形式溶解[25]。在碱性溶液中硫化铅的溶度积为9.04×10-29[26],根据查找的碱性条件下铅与硫反应方程式制作Pb-S-H2O系φ-pH图,计算过程如表1所示[27-29],结果如图1所示。

表 1 PbS-H2O系反应式及φ-pH计算式

Table 1 Reaction of PbS-H2O and its φ-pH

图1 PbS-H2O体系电势-pH图(图中略去标注SO42-离子存在区域)

Fig. 1 Potential-pH diagram of PbS-H2O (Region of SO42- is omitted in diagram)

理论计算结果显示在碱性溶液中硫化铅有较大的可稳定存在范围,不易转化为可溶性铅离子,采用硫化沉淀的方式在理论上可以将溶液中铅以硫化铅的形式沉淀,使得溶液中铅离子与其他离子有效分离。

1.2 钙盐沉砷理论分析

经过低温碱性熔炼-浸出后,溶液中的砷主要以AsO43-的形式存在[25]。采用氢氧化钙沉淀溶液中砷的反应如下[30]:

5Ca(OH)2+3AsO43-=Ca5(AsO4)3OH↓+9OH-,

Ksp=10-38.04 (16)

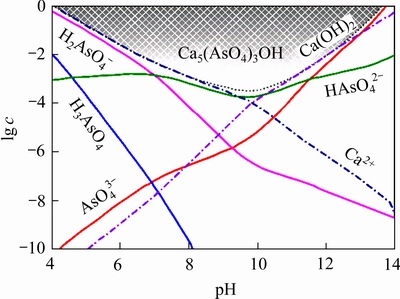

根据文献研究的热力学数据[30-32],在加入氢氧化钙后Ca-As-H2O体系可能发生的反应及其溶解平衡常数如表2所示:

表2 Ca-As-H2O体系可能反应及其溶解平衡常数

Table 2 Reaction of Ca-As-H2O and equilibrium constant

根据表2中的反应式及反应常数,计算各个离子浓度与[H+]的关系,绘制Ca-As-H2O体系溶解平衡浓度-pH图,如图2所示。

图2中阴影部分为碱式砷酸钙的稳定区,理论分析结果显示在pH=10时溶液中砷浓度达到最低;当pH大于10时,溶液中砷主要以砷酸根的形式溶解,当pH小于10时,溶液中的砷则会以砷酸氢根的形式溶解,为使溶液中砷沉淀率达到最大,应控制pH值稳定为10。

图2 Ca-As-H2O体系溶解平衡浓度-pH图(25 ℃)

Fig. 2 Solubility equilibrium-pH diagram Ca-As-H2O (25 ℃)

2 实验

2.1 原料及设备

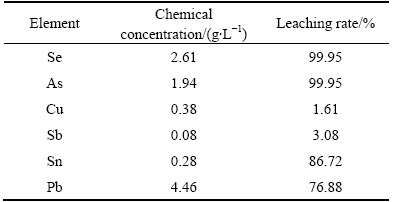

本试验中采用的铜阳极泥来自国内某铜冶炼厂的电解精炼车间,对铜阳极泥采用低温碱性熔炼工艺处理,获得的浸出液成分见表3。经过低温碱性熔炼-浸出工艺处理后获得的碱性浸出液属于高碱度溶液,氢氧化钠含量为2.5 mol/L,主要含有铅、砷、硒,包含微量的锑、锡、铜。

表3 低温碱性熔炼处理铜阳极泥后各元素浓度及浸出率

Table 3 Chemical concentration and leaching rate of LTAS-leaching solution

沉淀实验均在三口瓶中进行,高温实验中采用蛇形冷凝管回流蒸发的溶液,反应温度采用集热式恒温加热磁力搅拌器(DF-101S,予华仪器有限公司)水浴控制,溶液pH值采用0.1 mol/L稀盐酸调节,溶液pH采用pH检测仪实时监控(雷磁,PHS-3C,每次实验前均采用标准pH=4、pH=6.86、pH=9.18缓冲液校准并调节仪器温度为实验控制温度值。),实验药品均采用国药集团分析纯产品,纯水为纯水仪制备(ZOOMWO,ZWL-HLPA1-60,18MΩ·cm),液固分离采用真空抽滤并用纯水洗涤固体3次,洗液计入滤液。

2.2 流程及方法

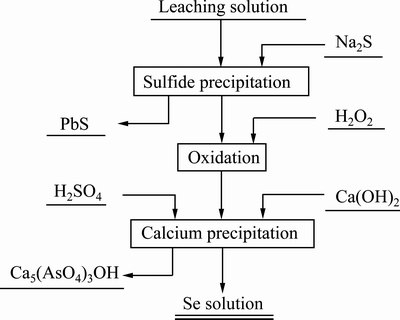

铜阳极泥低温碱性熔炼浸出液除杂流程图如图3所示。

图3 工艺流程图

Fig. 3 Process flow of separation program

本试验中采用Baird Corp PS-6型ICP-AES分析仪测定溶液中铅砷等元素含量,德国Bruker AXS公司的S4-Pioneer型荧光光谱仪分析固体中元素含量,物相分析采用了日本理学的TTRAX-3型XRD衍射仪。

3 结果与讨论

3.1 硫化钠沉淀法分离回收浸出液中的铅

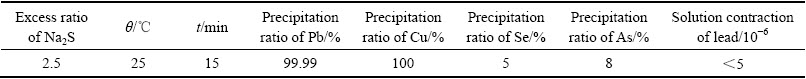

根据前期理论分析结论,采用添加硫化钠的方式沉淀溶液中的铅,实验获得的最优实验条件及实验结果如表4所示。

表4 硫化沉淀最优实验条件及实验结果

Table 4 Optimal experimental conditions and precipitation ratio of sulfide precipitation

实验结果显示,硫化沉淀可以有效的将溶液中铜、铅杂质沉淀分离,对溶液中硒不产生影响。溶液中铜离子沉淀率高于铅离子沉淀率的主要原因是:1) 铜离子与硫化钠反应生成硫化铜溶度积为8.0×10-48,远低于硫化铅溶度积(9.04×10-29),所以硫化钠优先沉淀铜离子,剩余的硫离子沉淀溶液中的Pb(OH)n2-n;2) 溶液中铜离子浓度低,加入沉铅理论量2.5倍的硫化钠后,溶液中硫离子为硫化铜沉淀理论量的9倍,较大的过量系数保证了铜离子沉淀率达到100%。

硒离子沉淀的主要原因是:1) 在硫离子取代原铅配合物中氢氧根离子时,会有部分Na2Pb(OH)mS(4-m)/2沉淀物生成,氢氧根配离子的结构使其具有胶体的性质,吸引沉淀物附近的砷、硒离子一同沉淀;2) 溶液中多余的硫离子会发生水解反应产生硫氰根离子,而硫氰根离子集团容易包裹在硫化铅沉淀周围[33],吸附溶液中砷、硒离子;3) 硫化钠沉铅反应速度比较快,产生的沉淀物颗粒粒径比较大,具有良好的沉淀性能[34],溶液中快速成核会夹带部分砷、硒进入沉淀物中。

3.2 氧化-钙盐脱砷研究

3.2.1 钙盐直接沉淀

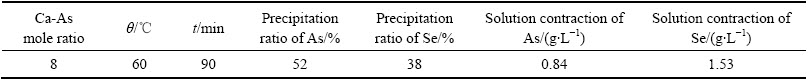

在90 ℃条件下,向沉铅后液中加入氢氧化钙进行脱砷实验,反应时间2 h,实验条件与结果如表5所示。

由表5可知,溶液中砷离子沉淀率仅为52%,并且有38%的硒损失。这是由于溶液中含有部分As(III)离子,这类亚砷酸根的存在难以直接去除[35]。同时,溶液中存在亚硒酸根离子,其与钙生成一种微溶的亚硒酸钙,进而引起溶液中硒离子的损失。基于以上分析,先缓慢向沉铅后液中加入30%(体积分数)双氧水20 mL(理论氧化量3倍),搅拌3 h后再进行后续沉砷实验。

3.2.2 pH值对钙盐脱砷效果的影响

针对氧化后的沉铅后液,在温度为90 ℃,反应时间3 h,钙砷摩尔比为3的条件下,研究不同pH值对钙盐沉淀脱砷效果的影响,砷沉淀率变化结果如图4所示。

由图4可以看出,不同pH值对砷沉淀率影响显著。当溶液pH=13时,砷离子的沉淀率不足50%,随后砷离子的沉淀率随pH值的降低而升高,在pH=10时达到99.3%,pH=9时砷离子沉淀率维持在99%以上,但在pH小于8后,砷离子沉淀率随pH值的下降而大幅度的降低,当调节溶液pH=3时,溶液中砷离子沉淀率不足33%,实验结果与前文中热力学分析相符,同时发现硒离子沉淀率随pH下降而从2.9%下降至1.0%,在pH=10 的条件下,硒沉淀率为2.38%。综合上述实验现象,选择pH=10为最优沉淀pH值进行后续实验。

图4 不同pH值对脱砷效果的影响

Fig. 4 Effect of pH on As precipitation

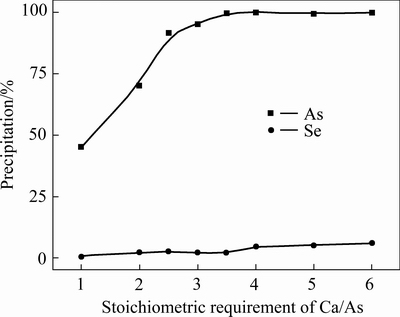

3.2.3 钙盐加入量的影响

选择pH=10,反应温度90 ℃,反应时间3 h的条件下,考察了不同钙砷摩尔比对钙盐沉淀脱砷效果的影响,砷沉淀率变化结果如图5所示。

由图5可以看出,钙砷摩尔比的增大有利于浸出液中砷的沉淀。砷离子在钙砷摩尔比为3.5时达到最大沉淀率99.4%。溶液中硒的沉淀率也随着氢氧化钙的加入量的增大而增大:从钙砷摩尔比为1时的沉淀率为0.76%增长到钙砷摩尔比为6时的6.05%。硒离子沉淀率有较明显的变化,其主要原因为:氢氧化钙在碱溶液中属于微溶物,会在溶液中形成以钙离子为中心的层状氢氧化物结构(Layered double hydroxides, LDH),此类结构会对溶液中硒酸根离子产生复杂的电场吸附、物理吸附等作用,产生硒的沉淀损失。为保证砷的沉淀分离效果的同时减少硒损失,选择钙砷比为3.5为最优氢氧化钙加入量。

表5 钙盐沉淀砷实验中实验条件及结果

Table 5 Experimental conditions and precipitation ratio of calcium precipitation

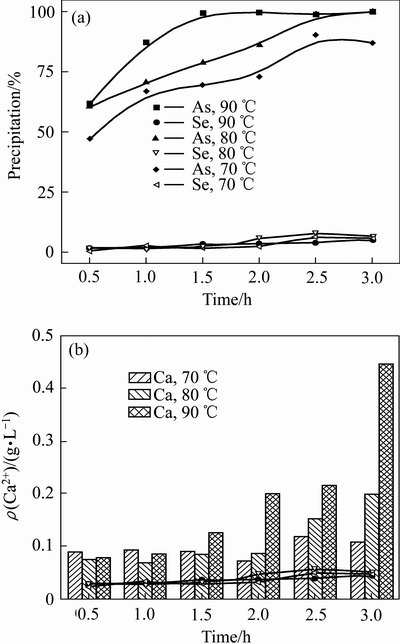

3.2.4 反应温度-时间影响

选取pH=10,钙砷比为3.5的条件下研究了反应温度-时间对砷离子沉淀率的交互影响,实验结果如图6所示。

图5 不同钙砷比对脱砷效果的影响

Fig. 5 Effects of n(Ca)/n(As) on As precipitation

图6 反应温度-时间对脱砷效果的影响

Fig. 6 Effect of reaction temperature and time on As precipitation(a) and Ca concentration(b)

由图6可以看出,反应温度和反应时间对砷离子的沉淀率有显著影响:1) 提高反应温度有利于砷离子的沉淀。在反应时间为1.5 h时,90 ℃反应中砷离子沉淀率为80 ℃反应中砷离子沉淀率的1.3倍,为70 ℃的1.6倍。2) 延长反应时间有利于砷离子的沉淀。在反应温度为80 ℃,2.5 h反应中砷离子沉淀率为2 h反应中砷离子沉淀率的1.1倍,为1 h反应的1.5倍。

溶液中钙离子浓度受反应温度和反应时间的影响较为明显,在反应温度相同的实验中,溶液中钙离子的浓度随着反应时间的延长而增大;而在反应时间相同的实验中,溶液中钙离子的浓度随着反应温度的升高而增大。

根据上述实验现象得出以下结论:提高反应温度、延长反应时间促进了钙离子的溶解,在有效提高溶液中溶解的钙离子浓度后,钙盐直接沉淀的方法可以将溶液中砷充分沉淀。现有学术研究偏向于认为钙盐无法单独深度除砷,但本实验研究显示:在提高溶液中钙离子浓度后,砷离子沉淀率可以达到99.45%。本实验通过提高反应温度、延长反应时间这两种手段有效提高了碱性溶液中溶解的钙离子浓度,进而打破了钙-砷反应中钙离子浓度低的瓶颈,提高了砷的沉淀率;这也解释了为什么以前对碱性溶液中砷离子沉淀多采用多段沉淀法或多种盐类(如钙盐-铁盐联合)沉淀法等方法才能获得良好的沉淀率。

溶液中硒离子沉淀率呈现以下规律:1) 温度对硒沉淀经变化没有显著影响。以反应时间为1 h为例,硒沉淀率分别为2.22%(70 ℃)、1.64(80 ℃)和1.65% (90 ℃)。2) 延长反应时间,硒沉淀率上升。以反应温度为90 ℃为例,硒沉淀率分别为1.65%(1 h)、3.35(2 h)和5.03%(3 h)。硒离子沉淀规律符合钙离子氢氧化物吸附沉淀规律。综合考虑最优反应条件为90 ℃,1.5 h,pH=10,钙砷摩尔比为3.5,此时砷沉淀率达到99.45%,硒沉淀率为2.81%。

4 结论

1) 采用硫化沉淀重金属、钙盐沉淀砷的工艺有效分离溶液中的铅、砷等杂质,并使硒的沉淀率达到最低。在25 ℃,反应时间15 min,硫化钠过量系数2.5倍的条件下,铅、铜沉淀率高于99.99%,硒沉淀率小于5%。

2) 采用双氧水氧化沉铅后液,控制pH=10, 90 ℃,钙砷比为3.5,反应时间1.5 h,砷离子沉淀率达到99.45%,剩余浓度低至8×10-6,硒沉淀率为2.81%。采用本研究工艺可以有效分离杂质元素同时保证较小的硒元素损失,为低温碱性熔炼工艺获得浸出液回收硒元素提供了良好的基础。

REFERENCES

[1] 李 栋, 徐润泽, 许志鹏, 郭学益. 硒资源及其提取技术研究进展[J]. 有色金属科学与工程, 2015, 6(1): 18-23.

LI Dong, XU Run-ze, XU Zhi-peng, GUO Xue-yi. Research development of selenium resource and its extraction technology [J] Nonferrous Metals Science and Engineering, 2015, 6(1): 18-23.

[2] 郭学益, 许志鹏, 田庆华, 李 栋. 低温碱性熔炼分离富集铜阳极泥中的有价金属[J]. 中国有色金属学报, 2015, 25(8): 2243-2250.

GUO Xue-yi, XU Zhi-peng, TIAN Qing-hua, LI Dong. Valuable metals separation from copper anode slime by low-temperature alkaline smelting process[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2243-2250.

[3] 曹 伟, 傅佩玉. 天然沸石处理含铅废水的试验研究[J]. 环境导报, 1998(2): 20-22.

CAO Wei FU Pei-yu, HAN Zhong-hua, XU Jie, LI Xu-zhi. Treating the Pb in waste water by zeolite[J]. Environment Herald, 1998(2): 20-22.

[4] 孙洪良, 朱利中. 表面活性剂改性的螯合剂有机膨润土对水中有机污染物和重金属的协同吸附研究[J]. 高等学校化学学报, 2007, 28(8): 1475-1479.

SUN Hong-liang, ZHU Li-zhong. Simultaneous adsorption of organic pollutant and heavy metal onto surfactant-modified organ bentonites with chelating ligands[J] Chemical Journal of Chinese Universities, 2007, 28(8): 1475-1479.

[5] 何 翊, 牛 盾, 门 阅. 高岭石对铅离子吸附性能的特征研究[J]. 金属矿山, 2005(10): 60-64.

HE Yi, NIU Dun, MEN Yue. Studies on characteristics of Pb2+ adsorption to kaolinite[J]. Metal Mine, 2005(10): 60-64.

[6] 杨津津, 徐晓军, 王 刚, 王 盼, 韩振宇, 管堂珍, 田 蕊. 微电解絮凝耦合技术处理含重金属铅锌冶炼废水[J]. 中国有色金属学报, 2012, 22(7): 2125-2132.

YANG Jin-jin, XU Xiao-jun, WANG Gang, WANG Pan, HAN Zhen-yu, GUAN Tang-zhen, TIAN Rui. Treatment of zinc and lead smelting wastewater containing heavy metals by combined process of micro-electrolysis with flocculation[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 2125-2132

[7] SRINIVASA RAO K, DASH P K, SARANGI D, DASH P K, ROY CHAUDHURY G. Treatment of wastewater containing Pb and Fe using ion-exchange techniques[J]. Journal of Chemical Technology and Biotechnology, 2005, 80(8): 892-898.

[8] HUANG Ling-zhi, ZENG Guang-ming, HUANG Dan-lian, LI Li-feng, HUANG Peng-mian, XIA Chang-bin. Adsorption of lead (Ⅱ) from aqueous solution onto hydrilla verticillata[J]. Biodegradation, 2009, 20(5): 651-660.

[9] PENG Y, ZHENG Y, ZHOU W, CHEN W. Separation and recovery of Cu and As during purification of copper electrolyte[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2268-2273.

[10] ZHENG Y, PENG Y, KE L, CHEN W. Separation and recovery of Cu and As from copper electrolyte through electrowinning and SO2 reduction[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 2166-2173.

[11] 刘伟锋, 杨天足, 刘又年, 陈 霖, 张杜超, 唐谟堂. 脱除铅阳极泥中贱金属的预处理工艺选择[J]. 中国有色金属学报, 2013, 23(2): 549-558.

LIU Wei-feng, YANG Tian-zu, LIU You-nian, CHEN Lin, ZHANG Du-chao, TANG Mo-tang. Selection of pretreatment process for removing base metals from lead anode slime[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 549-558

[12] 施 勇, 王学谦, 郭晓龙, 马懿星, 王郎郎, 宁 平. 采用硫化铵去除冶炼烟气中的重金属[J]. 中国有色金属学报, 2014, 24(11): 2900-2905.

SHI Yong, WANG Xue-qian, GUO Xiao-long, MA Yi-xing, WANG Lang-lang, NING Ping. Removal of heavy metals from smelting flue gas by ammonium sulfide[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2900-2905.

[13] CHAKRAVARTY S, DUREJA V, BHATTACHARYYA G, et al. Removal of arsenic from groundwater using low cost ferruginous manganese ore[J]. Water Research, 2002, 36(3): 625-632.

[14] 喻德忠, 邹 菁, 艾 军. 纳米二氧化锆对砷(Ⅲ)和砷(Ⅴ)的吸附性质研究[J]. 武汉化工学院化工与制药学院, 2004, 26(3): 1-3.

YU De-zhong, ZOU Jing, AI Jun. Study on the adsorption properties of nanometer sized zirconium dioxide to As(Ⅲ) and As(Ⅴ)[J]. J Wuhan Inst Chem Tech, 2004, 26(3): 1-3.

[15] KORNGOLD E, BELAYEV N, ARONOV L. Removal of arsenic from drinking water by anion exchangers[J]. Desalination, 2001, 141(1): 81-84.

[16] 郭恒萍. 冶炼含砷污酸与酸性含砷废水处理试验及应用研 究[D]. 西安: 长安大学, 2010.

GUO Hen-ping. Smelting contains the arsenie wastewater disposal experiment and applied research including the arsenic dirt acid and the acidity[D]. Xi’an: Chang’an University, 2010.

[17] HANSEN H K, NUNEZ P, JIL C. Removal of arsenic from wastewaters by airlift electrocoagulation. Part 1: Batch reactor experiments[J]. Separation Science and Technology, 2008, 43(1): 212-224.

[18] 王 勇, 曹龙文, 罗 园. 硫酸装置含砷废水处理及三氧化二砷制备[J]. 硫酸工业, 2010(4): 21-25.

WANG Yong, CAO Long-wen, LUO Yuan. Treatment of arsenic-containing waste water from sulphuric acid plants and preparation of As2O3[J]. Sulphuric Acid Industry, 2010 (4): 21-25.

[19] 陈维平, 牛秋雅, 田一庄. 铟生产过程中AsH3气体污染治理的研究[J]. 环境工程, 2002, 20(5): 31-33.

CHEN Wei-pin, NIU Qiu-ya, TIAN Yi-zhuang. Study on the treatment of AsH3 gas pollution in the process of indium production[J]. Environmental Engineering, 2002, 20(5): 31-33.

[20] GUO X, YI Y, SHI J, TIAN Q. Leaching behavior of metals from high-arsenic dust by NaOH-Na2S alkaline leaching[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 575-580.

[21] 李 鹏, 唐谟堂, 鲁君乐. 由含砷烟灰直接制取砷酸铜[J]. 中国有色金属学报, 1997, 7(1): 40-42.

LI Peng, TANG Mo-tang, LU Jun-le. Direct production of copper arsenate from bearing arsenic dusts[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(1): 40-42.

[22] 易 宇, 石 靖, 田庆华, 郭学益. 高砷烟尘碱浸渣制备焦锑酸钠的新工艺[J]. 中国有色金属学报, 2015, 25(1): 241-249.

YI Yu, SHI Jing, TIAN Qing-hua, GUO Xue-yi. Novel technology for preparation of sodium pyroantimonate from alkali leaching residue of high arsenic dust[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 241-249

[23] BUSETTI F, BADOER S, CUOMO M, et al. occurrence and removal of potentially toxic metals and heavy metals in the wastewater treatment plant of Fusina (Venice, Italy)[J]. Industrial & Engineering Chemistry Research, 2005, 44(24): 9264-9272

[24] 廖 敏, 王 锐. 菌藻共生体去除废水中砷初探[J]. 环境污染与防治, 1997, 19(2): 11-12.

LIAO Ming, WANG Rui. A primary study on removal of arsenic in wastewater by arsenic-resistant helotism[J] Environmental Pollution & Control, 1997, 19(2): 11-12.

[25] 郭学益, 刘静欣, 田庆华, 李 栋. 有色金属复杂资源低温碱性熔炼原理与方法[J]. 有色金属科学与工程, 2013, 4(2): 8-13.

GUO Xue-yi, LIU Jing-xin, TIAN Qing-hua, LI Dong. Principle and method of low temperature alkaline smelting in non-ferrous metallurgy complicated resources[J]. Nonferrous Metals Science and Engineering, 2013, 4(2): 8-13.

[26] 郝润蓉, 方锡义, 钮少冲. 无机化学丛书(第三卷): 碳硅锗分族[M]. 北京: 科学出版社, 1988.

HE Run-rong, FANG Xi-yi, NIU Shao-chong. Inorganic chemistry (Vol III): Carbon group[M]. Beijing: Science Press, 1988.

[27] DEAN J A. 兰氏化学手册[M]. 魏俊发, 译. 北京: 科学出版社, 2003.

DEAN J A. Lange’s handbook of chemistry[M]. WEI Jun-fa, transl. Beijing: Science Press, 2003.

[28] 李洪桂. 冶金原理[M]. 北京: 科学出版社, 2005.

LI Hong-gui. Metallurgical theory[M]. Beijing: Science Press, 2005.

[29] 彭容秋. 铅冶金[M]. 长沙: 中南大学出版社, 2004.

PENG Rong-qiu. Lead metallurgy[M]. Changsha: Central South University Press, 2004.

[30] BOTHE JR. J V, BROWN P W. The stabilities of calcium arsenates at (23±1) ℃[J]. Journal of Hazardous Materials, 1999, 69(2): 197-207.

[31] DUCHESNE J, REARDON E J. Measurement and prediction of portlandite solubility in alkali solutions[J]. Cement and Concrete Research, 1995, 25(5): 1043-1053.

[32] PARKER V B, EVANS W H, NUTTALL R L. The thermochemical measurements on rubidium compounds: a comparison of measured values with those predicted from the NBS tables of chemical and thermodynamic properties[J]. Journal of Physical and Chemical Reference Data, 1987, 16(1): 7-59.

[33] 李静文. 硫化钠沉淀法处理含铅废水研究[J]. 赤峰学院学报(自然科学版), 2013, 29(2): 8-10.

LI Jin-wen. Study on treatment of wastewater containing lead sulfide precipitation method[J]. Journal of Chifeng University (Natural Science Edition), 2013, 29(2): 8-10.

[34] 何绪文, 胡建龙, 李静文, 等. 硫化物沉淀法处理含铅废水[J]. 环境工程学报, 2013, 7(4): 1394-1398.

HE Xu-wen, HU Jian-long, LI Jing-wen, ZHANG Jing-jing, WANG Jian-bing, GE Peng. Treatment of wastewater containing lead by sodium sulfide precipitation[J]. Chinese Journal of Environmental Engineering, 2013, 7(4): 1394-1398.

[35] 李 莉. 碱性体系下As(Ⅲ)的催化氧化及其机理研究[D]. 长沙: 中南大学, 2009.

LI Li. Efficiency and mechanism of As(III) catalytic oxidation in alkaline system[D]. Changsha: Central South University, 2009.

Separation of Pb and As in low-temperature alkaline smelting-leaching solution of copper anode slime

GUO Xue-yi, XU Run-ze, TIAN Qin-hua, LI Dong

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: The leaching solution of low-temperature alkaline smelting-leaching process contains selenium, arsenic and lead, which exist in forms of SeO42-, Pb(OH)n2-n and AsO43-, respectively. In order to recover selenium, it is necessary to fully precipitate the lead and arsenic. After calculating the potential-pH diagram of PbS-H2O system and the solubility-pH diagram of Ca-As-H2O system, the lead and arsenic were removed by the sulfurized precipitation and calcified precipitation progress, while ensured the low dispersion of selenium. The results show that the lead can be effectively separated from other metals under the optimum conditions which are stoichiometric requirement of Na2S of 2.5, reaction temperature of 20 ℃, reaction time of 15 min. The copper and lead precipitation can reach 99.99% when the arsenic and selenium precipitation rate is less than 5%. The arsenic precipitation ratio reaches 99% when the reaction conditions are pH=10, n(Ca)/n(As)=3.5, bath temperature of 90 ℃ and reaction time of 1.5 h.

Key words: copper anode slime; leaching solution; selenium; lead sulfide; calcium arsenate

Foundation item: Project(51234009) supported by the National Natural Science Foundation of China; Project (2014DFA90520) supported by the National Science and Technology Cooperation of China

Received date: 2017-02-21; Accepted date: 2017-07-02

Corresponding author: LI Dong; Tel: +86-731-88876089; E-mail: yejin013_18@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51234009);国家国际科技合作专项项目(2014DFA90520)

收稿日期:2017-02-21;修订日期:2017-07-02

通信作者:李 栋,讲师,博士;电话:0731-88876089;E-mail: yejin013_18@163.com