文章编号:1004-0609(2009)12-2149-06

原位合成WC颗粒与钨丝混杂增强铁基复合材料

牛立斌,许云华,武 宏,彭建洪

(西安建筑科技大学 机电工程学院,西安 710055)

摘 要:通过对钨丝和灰口铸铁熔体组成的体系施加一定的电磁场,促使钨丝与熔体中的碳原子进行反应, 原位生成WC颗粒。利用SEM、EDS和XRD对复合材料的显微组织进行研究。结果表明:在电磁场频率为4 kHz,电流为15 A时, 原位合成的WC颗粒均匀地分散在钨丝周围,WC颗粒与未反应的钨丝共同组成混杂增强铁基复合材料。两体磨损试验结果表明:与对比试样相比,混杂增强铁基复合材料的耐磨性提高约2.5倍,这可归因于原位合成的WC颗粒硬度较高且弥散分布在基体中。

关键词:WC颗粒;原位合成;混杂增强

中图分类号:TB 333; TG113.25 文献标识码: A

Iron matrix composite reinforced by hybrid of

in-situ WC particles and tungsten wires

NIU Li-bin, XU Yun-hua, WU Hong, PENG Jian-hong

(College of Mechanical and Electrical Engineering,

Xi’an University of Architecture and Technology, Xi’an 710055, China)

Abstract: The in-situ synthesis of WC particles through reaction between tungsten wires and carbon atoms was observed by exerting an electromagnetic field to the system consisting of tungsten wires and melt of gray cast iron. The microstructures of the composites were studied by means of SEM, EDS and XRD. The results show that when the frequency of the electromagnetic field is 4 kHz and the current is 15 A, the WC particles are in-situ synthesized and distribute around the residual tungsten wires. Iron matrix composites reinforced hybridly by in-situ WC particles and the residual tungsten wires are obtained. The results of two-body abrasive test shows that the wear resistance of the hybrid reinforced iron matrix composite is 2.5 times higher than that of the reference sample, this is attributed to the higher hardness of in-situ WC particles and their dispersive distribution in the matrix.

Key words: tungsten carbide; in-situ synthesis; hybrid reinforced

碳化钨颗粒具有硬度高、韧性好、与铁基具有良好的润湿性等优点,因此,材料工作者在制备铁基复合耐磨材料时,将其视为首选增强相,但因在制备过程中其界面易受污染,从而影响到材料性能的发挥。近年来,原位合成铁基复合材料成为材料研究的热点之一,通过元素之间或元素与化合物之间的反应,在金属基体内生成一种或几种高硬度、高弹性模量的硬质增强相,从而达到强化金属基体的目的,其增强相具有热力学稳定、尺寸细小、分布均匀、界面洁净与基体结合良好等特点[1-3]。目前关于在铁基中原位合成TiC的研究较多[4-5],而关于在铁基中原位合成WC的研究较少,主要原因包括:1) Ti属于强碳化物形成元素[6],与碳的结合力较强,Ti在奥氏体中的溶解度较小,与Fe原子形成复相化合物的可能性小,易于得到稳定的TiC相。而W属于弱碳化物形成元素,在奥氏体中的溶解度较大,最高可达7%(质量分数),即便形成了WC相,也易溶解并和熔体发生反应,生成复相碳化物,从而得不到稳定的WC颗粒[7]。2) TiC的绝热温度较高(大于1 800 K),易于发生原位反应;而WC的绝热温度只有1 000 K[8],难以实现原位反应[9-10]。

本研究通过对金属钨丝和灰口铸铁熔体组成的体系施加一定的电磁场,促使钨丝和熔体中的碳原子反应合成WC颗粒。由于钨丝不一定能够反应完全,合成的WC颗粒与未反应的钨丝一起,可组成WC颗粒与钨丝混杂增强的铁基复合材料,使复合材料具有颗粒增强和纤维增强的双重特性。通过对复合材料的微观组织以及磨损特性的分析,为进一步得到高质量的铁基复合材料提供理论依据。

1 实验

1.1 材料及试样制备

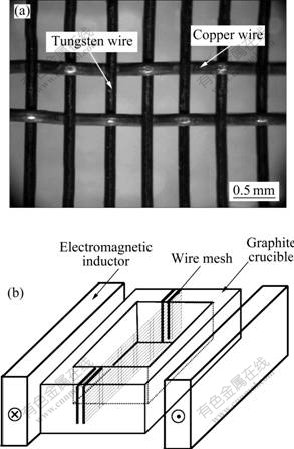

选用灰口铸铁以及纯度为99.7 %、直径为0.22 mm的钨丝作为原材料,灰口铸铁的化学成分见表1。为确保钨丝在复合试样中分布的均匀性,首先将钨丝与铜丝编织成网,如图1(a)所示。钨丝网中的铜丝,在随后处理时,会熔化到基体中,增加基体材料的韧性[11]。将编织好的钨丝网置于石墨模型中, 为固定钨丝网,在石墨模型壁上用电火花切割出一系列的缺口,缺口宽度为0.23 mm,然后在带有钨丝网的石墨模型两侧施加电磁场。如图1(b)所示,电磁场的参数如下:频率4 kHz,电流15 A。灰口铸铁在中频炉内熔化后,于1 573~ 1 603 K之间浇注到金属模具内。从浇注完计时,5 min后关闭电磁场,用石英砂将石墨模型和试样覆盖,缓慢冷却至室温,即可得复合材料。为便于分析,将在未施加电磁场和施加电磁场两种情况下分别得到的复合试样命名为试样A和B。

表1 灰口铸铁的化学成分

Table 1 Composition of gray cast iron (mass fraction, %)

1.2 试验方法

用PHILIPSADS-10型X射线衍射分析仪对复合材 料试样B的物相进行分析。用于X射线衍射分析的 试样尺寸为3 mm×3 mm,由于钨丝的直径较小,在3 mm×3 mm的截面上,包含的钨丝应在15根以上。采用VEGA/TESCAN扫描电镜以及自带能谱仪对复合材料磨损前后的微观组织和界面情况进行分析。采用MHV2000型显微硬度计(载荷 0.98 N、保持时间 10 s)和布氏硬度计(载荷1 500N)对复合材料的硬度进行测试。采用两体磨损试验法测试样的磨损性能,试样尺寸为d6 mm×15 mm,用200号刚玉砂纸作为固定磨料,圆盘转速60 r/min, 每次持续2 min,载荷从10 N依次增加到40 N,用单位时间内的质量损失来评价复合材料的磨损率。

图1 钨丝网和试验装置示意图

Fig.1 Tungsten mesh (a) and schematic diagram of experimental apparatus (b)

2 结果与分析

2.1 复合材料的微观组织

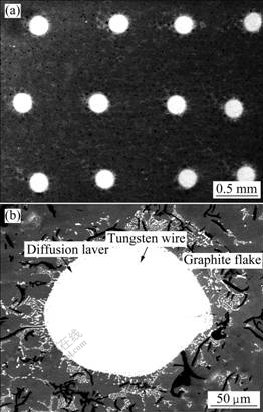

图2所示为试样A的微观组织。未施加电磁场所得复合直径为0.22 mm的钨丝均匀分布在基体中,其横向、纵向间距分别约为0.5和0.8 mm,经计算,钨丝所占复合材料截面的面积约为5.5%。基体中的石墨片较大,且带有尖角,可能是浇注的瞬间,钨丝附近的过冷度较大而形成的大片状石墨;过渡层厚度为10μm左右,达到了冶金结合的程度;在过渡层的外侧有少量粒状及网状组织出现,根据能谱分析,可能是合金渗碳体和M6C化合物。

图2 未施加电磁场所得复合试样A的微观组织

Fig.2 Microstructure of composite A prepared without exerting electromagnetic field: (a) Lower magnification; (b) Higher magnification

图3所示为施加电磁场所得复合试样B的微观组织。由图3可见,基体中石墨片的数量锐减,中间的白色区域为未反应的钨丝,其面积大小与反应的时间和施加的电磁场大小有关;过渡层的厚度大约为30 μm左右,远大于图2(a)中过渡层的厚度;大量的多边形颗粒分布在未反应的钨丝周围,且分布区域较大。

图3 施加电磁场所得复合试样B的微观组织

Fig.3 Microstructure of composite B prepared with exerting electromagneticfield

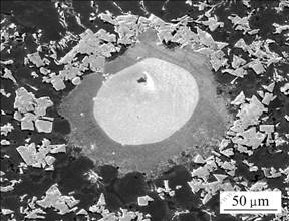

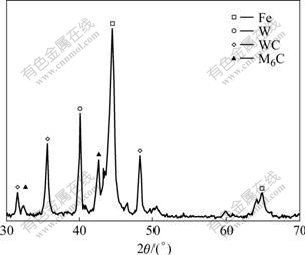

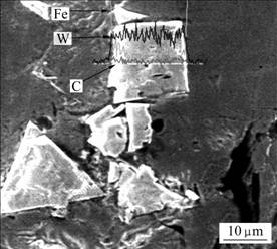

图4所示为施加电磁场所得复合试样B的XRD谱。由图4可见,衍射谱线上除了Fe、W峰外,还有WC峰以及较弱的M6C峰出现。对生成的颗粒进行线扫描,结果如图5所示。由图5可见,当线扫描谱线经过颗粒时,Fe含量突然下降,W和C含量突然增高,由此可以判断:反应生成的颗粒是WC。点能谱对三角形颗粒和四边形颗粒进行成分分析,发现四边形颗粒中,Fe含量略高于三角形颗粒中Fe含量。根据文献[12]介绍,这主要是由于液相中首先析出MC1-x,即在冷却过程中不稳定的MC1-x经过内部转变形成WC,Fe仍嵌在其中。因此,虽然颗粒中检测出少量的Fe,但仍可判断其为WC。

图4 施加电磁场所得复合试样B的XRD谱

Fig.4 XRD pattern of composite B prepared with exerting electromagnetic field

图5 原位合成WC颗粒的元素线扫描结果

Fig.5 Element linear scanning result for in-situ synthesis WC particle

根据热力学数据[13]计算:在铁熔体中,当温度高于1 000 K时,反应[W]+[C]=WC(s) 的 ,反应不能进行。而本研究中,在较高的温度下合成了WC颗粒,可推断是电磁场改变了合成WC的热力学条件,这主要是因为:

,反应不能进行。而本研究中,在较高的温度下合成了WC颗粒,可推断是电磁场改变了合成WC的热力学条件,这主要是因为:

1) 电磁场对熔体的搅拌作用降低了钨丝的表面能,使W原子的溶解速度加快,原子的扩散能力提高,在钨丝附近形成了一个微小的Fe-W-C三元体系,在该体系中,W和C的浓度要高于没有施加磁场时的W和C的浓度;

2) 电磁场的搅拌作用使微小体系的混乱度提高,使各元素的活度系数增大,根据公式

可知,这降低了?GWC, 有利于WC颗粒生成,同时也降低了WC颗粒的形核能,从而使熔体在短时间内能够形成较多的新核[14],因此WC颗粒的分散性较好;

3) 电磁场的搅拌作用可加速晶核周围的传热而使过热度迅速消失,减小了已合成的WC颗粒在高温时的溶解倾向[15],降低了生成复相化合物的机率。几项因素的综合作用使得WC颗粒能够快速合成并保留下来。

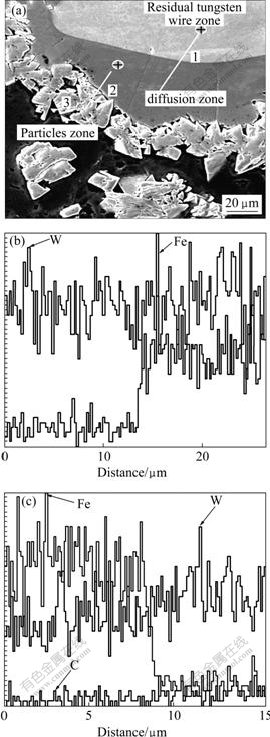

2.2 复合材料的界面分析

图6所示为对合成的WC颗粒与未反应钨丝间的线扫描结果。从图6(b)可见,当经过界面1-2时,只有Fe和W两种元素存在,且变化较明显;C元素可能是含量低的缘故,在仪器本身的精度范围内检测不到,可认为C原子没能扩散到过渡层;该界面较平滑,说明钨丝表面的W原子的溶解较快,不是通过晶界缓慢的溶解、扩散。从图6(c)可见,经过界面2-3时,W的含量变化不大,Fe的含量变化较大。单纯从扩散角度上考虑,Fe在点2处的含量应低于点3处的含量,但事实相反,Fe在点2处的含量高于在点3处的含量,可判断Fe原子是经点3处过滤后,才达到点2处。在扩散的过程中,W和C之间发生反应,形成了WC颗粒,该颗粒对扩散起到阻碍和过滤的作用。在原位合成的颗粒边缘有少量的裂纹出现,可能是熔体凝固速度过快造成的,这一点需在随后的试验中进行探讨。

2.3 复合材料的硬度和耐磨性

表2所列为复合材料试样A和B的硬度测试值。由图2可知,两种试样的数据均显示过渡层的硬度略高于钨丝中心的硬度,主要是由于Fe和W的相互扩散,形成了置换型固溶体,起到了固溶强化的效果。试样B的基体硬度高于试样A的基体硬度,因为在高温熔体时, 有少量的W原子溶解到奥氏体内,当温度下降后,一部分以合金渗碳体的形式析出,起到固溶强化的效果。试样B中的WC颗粒硬度最高, 这对提高材料的耐磨性非常有利。

图6 界面的元素线扫描结果

Fig.6 Element linear scanning results of Interfaces: (a) Scanning zone; (b) Interface 1-2; (b) Interface 2-3

表2 复合试样中不同区域的硬度值

Table 2 Hardness values of different regions for composites

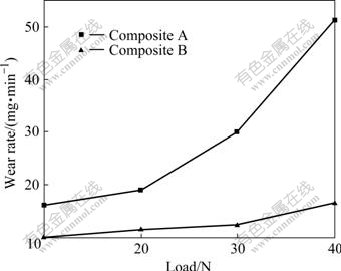

图7所示为两种复合材料的磨损试验结果。由图7可见,低载荷时,二者的磨损率相差不大;随着载荷的增加,磨损率的差别逐渐增大;当载荷为40N时,试样A的磨损率为试样B的磨损率的3.5倍, 也就是说,试样B相对于试样A在耐磨性方面提高了2.5倍。

图7 不同载荷下复合材料的磨损率.

Fig.7 Wear rate of composites at different loads

图8(a)所示为载荷为10 N时试样A磨损后的形貌。由图8(a)可见,磨粒对不同区域的切削程度不同,在未反应的钨丝截面上留下划痕,而在过渡层以及颗粒弥散分布的区域,没有留下划痕。当载荷增加到40 N时,磨粒对试样A的切削较为严重,不论是钨丝还是基体,都留下了深而宽的划痕(见图8(b));对试样B而言,虽然划痕略明显,但是没有颗粒的拔出和脱落(见图8(c)),表明原位生成的WC颗粒和基体结合较好。

从图8可以看出,不论载荷多大,两种复合材料的磨损机制均为切削磨损。耐磨性的区别在于二者的增强体组成、分布以及硬度发生了变化。对于试样A而言,虽然钨丝的硬度高于基体的硬度,但所占试样截面的比例仅为5.5%左右,其承载能力有限,造成了磨粒对基体的切削严重。对于试样B而言,一方面,原位生成了高硬度的WC颗粒硬质相,而且有高于钨丝硬度的过渡层;另一方面,合成的WC颗粒,弥散分布在钨丝周围,扩大了增强体的分布面积,使复合材料的承载能力大大提高。因此,这两项因素的综合作用使试样表现出优异的耐磨性。

图8 不同载荷下复合材料的磨损形貌

Fig.8 Worn morphologies of composites at different loads: (a) Composite B, at 10 N; (b) Composite A, at 40 N; (c) Composite B, at40 N

3 结论

1) 通过对由金属钨丝和灰口铸铁熔体组成的体系施加一定的电磁场,使钨丝和熔体中的C原子能够快速反应合成WC颗粒。WC颗粒均匀分布在钨丝周围,对C原子以及Fe原子的进一步扩散起到阻碍和过滤作用,使生成复相化合物的机率降低。

2) 原位合成的WC颗粒与未反应的钨丝一起,得到混杂增强铁基复合材料。由于WC颗粒较高的硬度以及弥散分布在基体,扩大了增强体的承载能力。两体磨损测试结果表明:施加电磁场得到的混杂增强铁基复合材料的耐磨性比未施加电磁场的复合材料的耐磨性提高了2.5倍。

REFERENCES

[1] TJONG S C, MA Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites[J]. Mater Sci Eng R, 2000, 29: 49-113.

[2] 武晓雷, 陈光南. 激光形成原位TiC-颗粒增强涂层的组织与性能[J]. 金属学报, 1998, 34(12): 1284-1288.

WU Xiao-lei, CHEN Guang-nan. Microstructural characteristics and wear properties of in situ formed TiC particles reinforced coating by laser cladding[J]. Acta Metllurgica Sinica, 1998, 34(12): 1284-1288.

[3] CUI Cheng-yun, GUO Zuo-xing, WANG Hong-ying, HU Jian-dong. In situ TiC particles reinforced grey cast iron composite fabricated by laser cladding of Ni-Ti-C system[J]. Journal of Materials Processing Technology, 2007, 183: 380-385.

[4] LIU Hui-yuan, HUANG Ji-hua, YIN Chang-feng, ZHANG Jian-gang, LIN Guo-biao. Microstructure and properties of TiC-Fe cermet coatings by reactive flame spraying using asphalt as carbonaceous precursor[J]. Ceramics International, 2007, 33: 827-835.

[5] JIANG Q C, ZHAO F, WANG H Y, ZHANG Z Q. In situ TiC-reinforced steel composite fabricated via self-propagating high-temperature synthesis of Ni-Ti-C system[J]. Materials Letters, 2005, 59: 2043-2047.

[6] HACKFNHFRG R E, SHIFLET G J. Austenite decomposition to carbide-rich products in Fe-0.30C-6.3W[J]. Metallurgical and Materials Transactions A, 2002, 33: 3619-3633.

[7] 尤显卿, 马建国, 宋雪峰, 任 昊, 黄曼平. 电冶熔铸WC/钢复合材料中WC的溶解行[J]. 中国有色金属学报, 2005, 15(9): 1363-1368.

YOU Xian-qing, MA Jian-guo, SONG Xue-feng, REN Hao, HUANG Man-ping. Dissolution behavior of WC particles in WC steel matrix composites by electroslag melting and casting method[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(9): 1363-1368.

[8] MAS-GUINDAL M J, CONTRERAS L, TURRILLAS X, VAUGHAN G B M, KVICK A, RODRIGUEZ M A. Self-propagating high-temperature synthesis of TiC-WC composite materials[J]. Journal of Alloys and Compounds, 2006, 419(1): 227-233.

[9] MAN H C, YANG Y Q, LEE W B. Laser induced reaction synthesis of TiC+WC reinforced metal matrix composites coatings on Al 6061[J]. Surface & Coatings Technology, 2004, 185: 74-80.

[10] JIANG Guo-jian, ZHUANG Han-rui, LI Wen-lan. Mechanistic investigation of the field-activated combustion synthesis of tungsten carbide with or without cobalt added[J]. Combustion and Flame, 2003, 135: 113-121.

[11] HSU C H, SHY Y H, YU Y H, LEE S C. Effect of austempering heat treatment on fracture toughness of copper alloyed gray iron[J]. Mater Chem Phys, 2000, 63: 75-81.

[12] ANTONI-ZDZIOBEK A, SHEN J Y, DURAND-CHARRE M M. About one stable and three metastable eutectic microconstituents in the Fe-W-C system[J]. International Journal of Refractory Metals & Hard Materials, 2008, 26(4): 372-382.

[13] LUPIS C H P. Chemical thermodynamics of materials[M]. North-Holland, New York, AMSTERDAM, Oxford: Elseiver Science Publishing Co. Inc., 1983: 125-134.

[14] 李桂荣, 王宏明, 赵玉涛, 陈 刚, 戴起勋, 程晓农. 低频电磁场下原位合成Al-Zr-O系复合材料机制研究[J]. 材料科学与工艺, 2008, 16(2): 161-162.

LI Gui-rong, WANG Hong-ming, ZHAO Yu-tao, CHEN Gang, DAI Qi-xun, CHENG Xiao-nong. Mechanism of in situ fabricating composites in the system of Al-Zr-O in low frequency electromagnetic field[J]. Materials Science & Technology, 2008, 16(2): 161-162.

[15] 张伟强. 金属电磁凝固原理与技术[M]. 北京: 冶金工业出版社, 2004: 12-13.

ZHANG Wei-qiang. Technology and principle of metal electromagnetic solidification[M]. Beijing: Metallurgical Industry Press, 2004: 12-13.

基金项目:陕西省重大科技创新计划资助项目(2004ZKC05-02);陕西省2007年“13115”科技创新工程工程技术研究中心资助项目(2007ZDGC-17)

收稿日期:2008-12-25;修订日期:2009-05-15

通信作者:牛立斌,博士;电话:029-82202531;E-mail: libinniu123@yahoo.com.cn

(编辑 何学锋)