文章编号:1004-0609(2017)-02-0399-07

聚醚添加剂对Zn(Ⅱ)-NH3-NH4Cl-H2O体系电积锌的影响

林文荣,杨声海,孙彦伟,陈永明,何 静,唐朝波

(中南大学 冶金与环境学院,长沙 410083)

摘 要:针对现行氨法电锌存在的阴极锌板表面不平整、疏松多孔、边缘毛刺突出等一系列问题,研究聚醚添加剂对Zn(Ⅱ)-NH4Cl-NH3-H2O体系电积锌的影响,并考察添加剂浓度对沉积锌表面形貌、沉积锌晶体结构、电流效率、平均槽电压和能耗等各项工艺参数的影响。结果表明:添加剂的使用可以使电积得到的阴极锌表面光滑平整,致密与无毛刺,锌晶面表现出高择优取向,生长择优方向为(110)晶面,晶体为六方密堆结构,晶粒细小;在最佳浓度为1.0 g/L时,平均槽电压为2.76 V,电流效率可高达92.88%,单位能耗为2435.72 kW·h/t。

关键词:聚醚;添加剂;表面形貌;锌;电积

中图分类号:TF813 文献标志码:A

随着锌冶金的不断发展,用于炼锌的主要资源硫化锌矿正日益枯竭,钢铁冶炼过程产生的含锌烟尘以及炼铅炉渣烟化处理过程产生的大量次氧化锌烟灰等二次资源逐渐受到人们的重视[1-4]。但这些二次资源含有大量的F、Cl、As及Cu、Co等重金属有害杂质,在电积过程中氯离子会加快阳极的腐蚀,降低阳极的使用寿命;氟离子则腐蚀阴极,引起剥板困难;砷则会使得阴极析氢反应加剧,电流效率大大降低等[5];而有害重金属杂质则会导致电积出来的锌板质量大大降低,难以满足工业需求。因此,在浸出液的净化阶段,必需很好脱除这些杂质方可进行电积。但若采用常规酸法[6-8]处理时,不管采用原料碱洗脱氯、浸出液亚铜除氯或者离子交换除氯,这些方法均会产生大量含低浓度氯化钠的废水,而且采用一种方法很难对杂质进行脱除干净。这就造成常规的酸法处理成本大大提高,工序更加繁琐。而采用氨-氯化铵体系处理这类烟灰,在浸出阶段,铁、硅、铝、氟等杂质基本不进入溶液,浸出液经锌粉置换除杂后不需脱除Cl即可直接电积产出金属锌[9-11]。该工艺大大简化了净化过程,具有流程短、处理锌废料能力强、槽电压低、电流效率高等优点。

在锌电积过程中,添加剂有着不可替代的作用,它可改善金属的沉积形貌和性能,提高金属的光亮度、致密度等。若不加添加剂,得到的阴极锌疏松多孔,表面毛刺突出,难以形成致密、光滑和平整的锌板,此外,对无添加剂下得出的锌进行微观形貌研究发现,沉积出来的锌晶粒粗大不一,瘤状颗粒锌或海绵状锌较多,堆积生长无序等。基于该种情况,国内外相关学者分别进行了不同添加剂对氨性电积锌的影响研究,以寻求性质优良的添加剂。张嘉等[12]对某胶、某阳离子表面活性剂和聚醇对Zn(Ⅱ)-NH4Cl-NH3-H2O电积锌的影响进行了研究,结果表明:得到的阴极锌较为致密,枝晶得以有效抑制,电流效率较高,但表面仍较为粗糙,锌板较脆。而且,投入的添加剂种类多,用量较大,成本较高。王瑞祥等[13]则研究了某胺类衍生物对电积锌的影响,在该添加剂下,电积得到的锌较为致密平整,但锌表面仍有些许凸起,而且添加剂用量较多。张杰等[14]研究发现乙烯吡咯烷酮、EDTA及两者复合使用对锌氨配合物体系电积锌的结构和形貌具有很大影响,在该条件下沉积的锌分别呈棒状、树枝状和针状,粒度较为均匀,但锌堆积密度不够好,添加剂投入成本较高。李丕强等[15]对季铵盐添加剂在锌电沉积过程中的影响进行了探究,其中包括氯化胆碱(CHCl)和甜菜碱盐酸盐(BH)这两种铵盐,结果显示,在CHCl存在的情况下,得到的电锌呈六角形片状,结构较为疏松,致密度较差,难以满足工业需求,加入BH时,电积得到的锌较前者明显变好,锌晶体间隙明显消失,但锌晶粒生长形状不规则,晶粒较为粗大。杨声海等[16]则采用电化学和扫描电镜方法考察了苄叉丙酮在锌-氨-氯化铵体系对电积锌的影响,研究发现,该添加剂能够有效抑制锌离子的还原,减小晶体的生长速率,达到细化晶粒的作用,但电积锌致密性不够好,锌晶体呈现较为杂乱的堆积生长。XIA等[17]则详细探究了骨胶对该体系沉积锌的影响。结果显示,骨胶对阴极锌取向生长具有较强的诱导作用,锌晶粒较为细小,但锌表面仍有瘤状锌颗粒,边缘毛刺较多。桑世华等[18]在氨浸液电积锌工艺研究中也探究了明胶对电积锌板的影响,该添加剂只能在短时间内维持阴极锌板的良好性,用量较大,难以在工业上实现应用。可见,现行氨性体系电积锌过程中还没有单一一种能够使得电积出来的阴极锌板致密性好、表面光滑平整、晶粒细小的添加剂,并且,添加剂对Zn(Ⅱ)-NH4Cl-NH3-H2O体系电积锌的影响的相关文献报道也较少,这也是研究者需要解决的问题。

因此,基于这种情况,本文作者以某聚醚类有机化合物作为添加剂,结合工业生产锌的条件,探究该添加剂对氨性体系电积锌的影响研究,以寻求一种优良的添加剂。采用扫描电子显微镜和X射线衍射研究了在Zn(Ⅱ)-NH4Cl-NH3-H2O (简称MACA)体系下添加剂用量对电积锌的沉积锌表面形貌、晶核生长取向及晶粒尺寸的影响,并考察了该添加剂下电积锌的槽电压、电流效率和能耗等工艺经济参数指标,并确定最佳的添加剂浓度。

1 实验

根据工厂生产的实践经验并结合相关学者的研究,配制成以下成分的电解液:40 g/L Zn2+、NH3·H2O 2.5 mol/L、5 mol/L Cl-。在实验过程中,每次均配制2.5 L电积液于3 L的电解槽中,以石墨板 (有效面积11 cm×11 cm)作为阳极,钛板(有效面积10 cm×10 cm)作为阴极,控制阴极的电流密度为400 A/m2,阴阳极板间距控制在3.5 cm,在温度控制为40 ℃的恒温槽内进行保温电积8 h。其中,控制聚醚添加剂的加入量在0~2.5 g/L的范围内变化。在电积过程中,每隔1 h记录一次槽电压值,并计算每次试验的平均槽电压。电积结束后,将所得的锌板从阴极钛板剥离,并用蒸馏水冲洗干净,随后置于真空干燥箱中进行干燥,称取质量并取样进行表征。

实验所用的试剂主要包括NH3·H2O(分析纯)、ZnCl2(工业级)、NH4Cl(工业级)、添加剂(某聚醚化合物,分析纯)、蒸馏水等。电沉积所用设备包括:容积为3 L的自制PVC电解槽、超级恒温槽、真空干燥箱、电子天平、直流稳压电源等,分析所用的仪器设备包括X射线衍射分析仪(Rigaku D/max2550)和扫描电子显微镜(JEOL JSM-5600LV)。

2 结果与讨论

2.1 添加剂用量对沉积锌形貌的影响

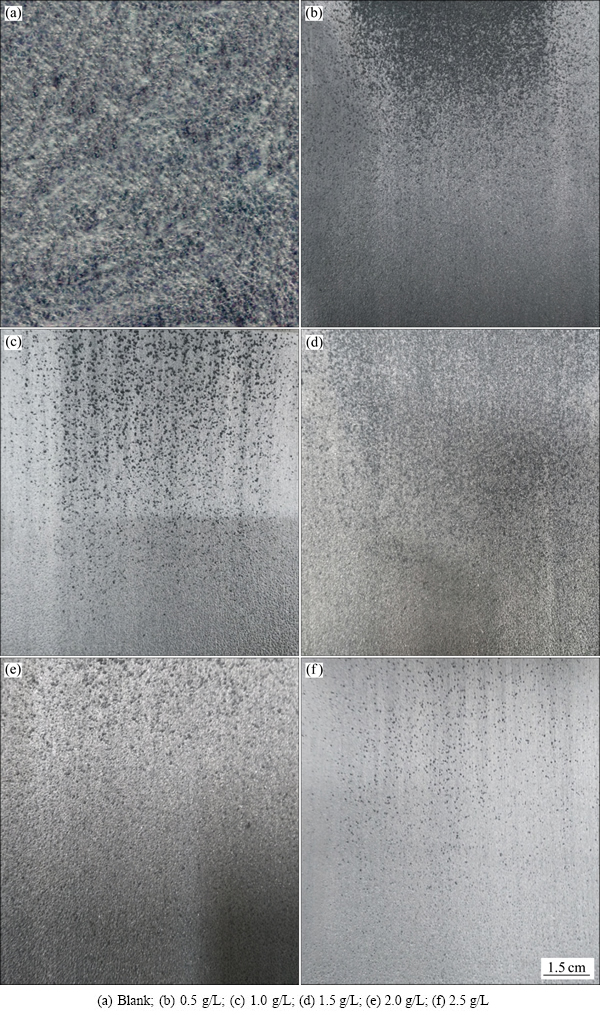

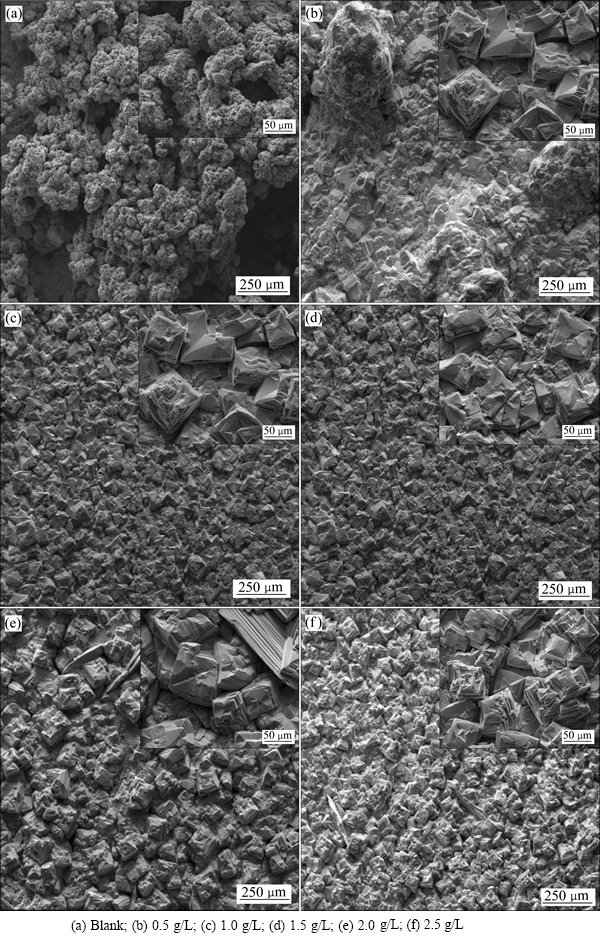

在上述电积条件下,通过改变添加剂的浓度,探究其对电沉积锌的表面形貌的影响,其结果如图1和图2所示。

由图1的宏观形貌可以看出,该添加剂对氨性体系电沉积锌具有很大的影响。由图1(a)可知,氨性体系电沉积锌的过程中,当没有加入添加剂时,得到的锌疏松多孔,呈海绵状,难以形成致密的阴极锌板;当加入0.5 g/L的添加剂时,得到的阴极锌表面形貌就开始发生很大的变化,锌表面变得较为光滑平整、严实致密(见图1(b));在添加剂浓度为1.0 g/L时,由于电积体系添加剂较为充足,得到的锌板更为致密,并且锌表面“黑点”大为减少,光滑而平整(见图1(c));添加剂浓度继续增加时,阴极锌板一定程度上变得更为光亮,但致密度变化不是很大(见图1(d)~(f))。

由图2的SEM表征形貌可见,聚醚对锌的沉积有很大影响。由图2(a)可以看到,当没有加入添加剂时,得到的阴极锌伴有大量的瘤状物,颗粒粗大,沉积方向为无序性,疏松多孔;当加入0.5 g/L的添加剂时,从图2(b)可以得到,锌仍然存在有少数不规则的瘤状结构的锌颗粒,但锌表面的致密性得以改善,颗粒变小,这主要是因为电沉积过程中,有机添加剂能够吸附于阴极表面,尤其是晶粒突起部分,有效抑制突起晶粒的继续生长,使得沉积锌生长平整[19],但添加剂用量较少,未能很好抑制枝晶的生长,导致锌表面存在一些瘤状锌颗粒,此外,阴极锌主要由规则的片状和少许颗粒状的锌晶粒叠加而成,堆积结构之间的空隙明显比未加添加剂时的小;随着添加剂的浓度逐渐增加,得到的阴极锌形貌得到了很大的提升,在添加剂浓度为1.0 g/L时,由于电积体系添加剂较为充足,电积过程中,这些添加剂能够很好覆盖于阴极表面及锌晶粒突起部分,抑制枝晶的生长,使得锌的沉积更为均匀,锌晶粒尺寸得到了进一步的细化,瘤状锌基本上不存在,由图2(c)可见,锌晶粒仍以片状锌逐层叠加而成,但空隙进一步缩小;添加剂浓度增加至1.5 g/L时,由于聚醚在阴极的很好吸附,沉积锌枝晶的抑制生长更加明显,晶粒较为细小(见图2(d));添加剂浓度继续增加时,阴极锌板一定程度上变得更为光亮,但锌晶粒细化程度没有明显变化,锌的形貌基本上变化不大,锌的沉积仍主要以片状的结构堆积而成(见图2(e), (f))。

图1 不同添加剂浓度下电沉积锌的表面形貌

Fig. 1 Surface morphologies of zinc electrodeposition at different concentrations of additive

图2 不同添加剂浓度下电沉积锌的扫面电镜表征形貌

Fig. 2 SEM images of zinc deposits at different concentrations of additive

2.2 添加剂对沉积锌生长取向的影响

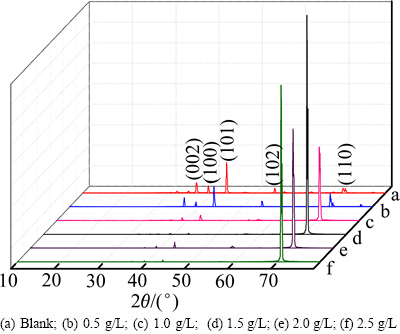

对不同添加剂浓度下电沉积所得的锌进行XRD表征,结果如图3所示。

从图3可以看出,氨性体系电积出来的锌为密排六方堆积结构,并且锌晶粒以(002),(100),(101),(102)和 (110) 晶面生长。在未加添加剂时,各晶面峰强度相差不是很大,因此,锌的沉积生长随机性较大,即各向性生长,结晶性能较差,得到的锌因此疏松多孔,难以形成致密光滑的锌板;当加入0.5 g/L的添加剂时,锌在(101)晶面的峰强度相对于不加添加剂时有所削弱,而在(110)晶面的峰强度有所增强,这是由于聚醚的加入,对锌离子在(110)面具有诱导生长作用,因此,锌的生长变得有序,并沿着(110)面生长,结晶性能有所改善,锌板呈现出金属的光泽,较为致密平整;添加剂继续增加至1.0 g/L时,添加剂的诱导生长效应增强,而对其他晶面则产生抑制生长作用,因此,(110)面的峰衍射强度急剧增大,锌晶体表现出高择优取向,生长方向基本上以(110)晶面为主,锌的结晶度更好,锌板变得更为光滑致密;当添加剂浓度为1.5 g/L时,所得到的(110)面XRD衍射峰强度最强;其他晶面的峰高基本上已被掩盖,锌的结晶度表现的越好;在浓度为2.0 g/L时,(110)晶面的峰相对强度有所变小,但整体上仍然比其他晶面的高出很多。聚醚浓度继续增加,(110)晶面的衍射峰强度较前者又有所增强。可见,聚醚的存在,对沉积锌的(110)晶面具有很强的诱导生长效应,尤其是在聚醚添加剂浓度大于1.0 g/L时,锌晶体的均表现出高择优取向,择优生长方向为(110)晶面,得到的锌板结晶度好,表面变得光亮[20]。

图3 不同添加剂浓度下电沉积锌的XRD谱

Fig. 3 XRD patterns of zinc electrodeposition at different concentrations of additive

2.3 添加剂用量对电积锌晶粒尺寸的影响

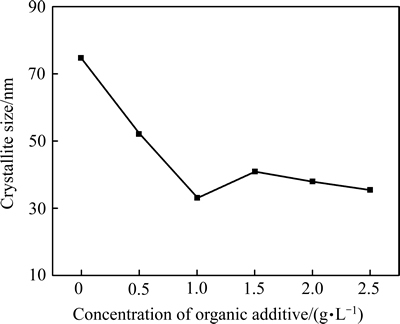

由于该添加剂存在下,氨性体系电沉积锌得到的晶体基本上以(110)面生长,因此,由XRD分析结果并结合谢乐公式,则可以计算出该添加剂对沉积锌晶粒尺寸大小的影响。结果如图4所示。

由图4可以得到,有添加剂的氨性体系电沉积锌过程中,该添加剂能够细化晶粒的作用。在没有加入添加剂时,得到的锌晶粒尺寸为75 nm;当添加剂浓度为0.5 g/L时,由于聚醚的吸附作用,使得锌晶体的生长受到抑制,晶粒得到细化,因此,晶粒尺寸迅速降低至53 nm,浓度继续增大,锌的晶粒逐渐减小;在浓度为1.0 g/L时,晶粒尺寸最小,为33 nm,在该基础上增加添加剂用量时,晶粒尺寸有所起伏,但基本维持在30~37 nm的范围。可见,聚醚的加入可以有效细化晶粒,使其变得更加致密,锌板表面更加平整光滑。

图4 不同添加剂浓度下电积锌晶核按(110)面计算的晶粒尺寸

Fig. 4 Crystallite size distribution based on (110) reflection with different concentrations of additive

2.4 添加剂用量对电积锌电流效率的影响

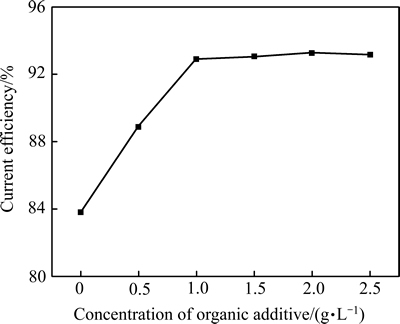

根据电积结束后称取所得沉积锌的质量,可计算出不同添加剂浓度下的电流效率,其结果如图5所示。

由图5可以看出,该添加剂对电沉积锌的电流效率有着很大的影响。当没有加入添加剂时,由于阴极伴随有析氢的副反应发生,电沉积的电流效率较低,仅为83.78%,;当加入0.5~1.0 g/L的聚醚添加剂时,电流效率随着添加剂浓度的增加而急剧上升,在1.0 g/L时,电流效率高达92.88%,这主要是因为在电沉积过程中,析氢现象大大削弱甚至消失,可见,添加剂能够在阴极表面形成一层吸附层,阻碍氢的活化吸附点,有效抑制了氢的析出;添加剂浓度继续增加时,电流效率虽有一定的提高,但变化不是很大,基本上维持在93.5%左右。

图5 添加剂用量对电流效率的影响

Fig. 5 Effect of dosage of additive on current efficiency

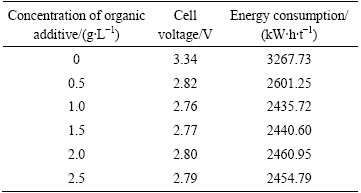

2.5 添加剂用量对电积锌槽电压及能耗的影响

经在电沉积过程中记录所得的电压并结合所得的电流效率可以计算得到不同浓度添加剂下的单位能耗。其结果如表1所列。由表1可以看出,当没有加入任何添加剂时,平均槽电压和能耗均较高,分别为3.34 V和3267.73 kW·h/t;在添加剂浓度≤1.0 g/L时,增加添加剂用量,平均槽电压和能耗均相应有所下降;而继续增加添加剂的用量时,槽电压和能耗均相应有所上升,这是因为加入继续增加添加剂时,添加剂在电极表面的吸附作用会加剧,在金属表面形成了一层过量的添加剂吸附层,这在一定程度上导致溶液-电极界面黏度的增加,阻碍了传质的过程,因此,槽电压会升高,继而电能消耗也会升高。在添加剂用量为1.0 g/L时,平均槽电压和电耗均达到最小值,分别为2.76 V、2435.72 kW·h/t。综合槽电压、电流效率和能耗等工艺指标,可见,聚醚添加剂的最佳用量为1.0 g/L。

表1 添加剂用量对锌电沉积槽电压和能耗的影响

Table 1 Effects of dosage of additive on cell voltage and energy consumption during zinc electrodeposition

3 结论

1) 聚醚添加剂对氨性体系电沉积锌具有很大的影响,在该添加剂存在的情况下,锌晶体结构为密排六方堆积结构,沉积锌的生长方向以(110)晶面为主。

2) 随着添加剂浓度的增加,锌晶粒得到进一步的细化,在最佳浓度1.0 g/L的条件下,所得到的锌结晶度好,晶粒得到很好的细化,晶粒尺寸可达到33 nm,锌板光滑致密,平整而富有金属光泽,基本上没有毛刺或凸起部分,平均槽电压低至2.76 V,电流效率高达92.88%,单位能耗为2435.72 kW·h/t。

REFERENCES

[1] DUTRA A J B, PAIVA P R P, TAVARES L M. Alkaline leaching of zinc from electric arc furnace steel dust[J]. Minerals Engineering, 2006, 19(5): 478-485.

[2] 姜 艳, 李自静, 孙丽达, 鲁顺利, 张 婷, 周应全. 真空碳热还原高炉炼铁烟尘提取锌[J]. 有色金属工程, 2014, 4(4): 47-49.

JIANG Yan, LI Zi-jing, SUN Li-da, LU Shun-li, ZHANG Ting, ZHOU Ying-quan. Extraction of zinc from blast furnace dust by vacuum carbon thermal reduction[J]. Nonferrous Metals Engineering, 2014, 4(4): 47-49.

[3] 佟志芳, 杨光华, 李红超, 杨 龙, 简 云. 氨浸出含锌烟尘制取活性氧化锌[J]. 化工与环保, 2009, 29(6): 534-537.

TONG Zhi-fang, YANG Guang-hua, LI hong-chao, YANG Long, JIAN Yun. Preparation of activated zinc oxide from zinc dust by ammonia leaching process[J]. 2009, 29(6): 534-537.

[4] ORHAN G. Leaching and cementation of heavy metals from electric arc furnace dust in alkaline medium[J]. Hydrometallurgy, 2005, 78(3/4): 236-245.

[5] YU Xiao-hua, XIE Gang, LI Rong-xing, LI Yong-gang, LU Ying. Behavior of arsenic in zinc electrowinning[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S1): s50-s54.

[6] 陈 勇, 王 晖, 符剑刚, 揭轩敏. 某钢厂烟尘灰中锌的酸性浸出试验研究[J]. 应用化工, 2015(6): 1101-1103.

CHEN Yong, WANG Hui, FU Jian-gang, JIE Xuan-min. Study on leaching zinc from dust ash of steel plant using sulfuric acid[J]. Applied Chemical Industry, 2015(6): 1101-1103.

[7] 李 岩, 杨丽梅, 徐 政, 徐 瑞, 王 巍. 某含锌烟尘中性-酸性两段浸出试验[J]. 金属矿山, 2013, 42(2): 164-168.

LI Yan, YANG Li-mei, XU Zheng, XU Rui, WANG Wei. Study about two-stage neutral-acid leaching process on a zinc dust[J]. Metal Mine, 2013, 42(2): 164-168.

[8] SHAWABKEH R A. Hydrometallurgical extraction of zinc from Jordanian electric arc dust[J]. Hydrometallurgy, 2010, 104(1): 61-65.

[9] 王 杰, 熊 玮, 张保平. 高炉瓦斯灰氨法脱锌工艺分析[J]. 环境科学与技术, 2014, 37(5): 138-142.

WANG Jie, XIONG Wei, ZHANG Bao-ping. Dezincing process analysis on blast furnace gas ash by ammonia leaching[J]. Environmental Science and Technology, 2014, 37(5): 138-142.

[10] 杨声海, 唐谟堂, 邓昌雄, 张顺应. 由氧化锌烟灰氨法制取高纯锌[J]. 中国有色金属学报, 2001, 11(6): 1110-1113.

YANG Sheng-hai, TANG Mo-tang, DENG Chang-xiong, ZHANG Shun-ying. Making high-purity zinc from zinc oxide fume dusts[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(6): 1110-1113.

[11] LI J, CHEN Q Y, HU H, WANG W Z. Deep purification of zinc ammoniacal leaching solution by cementation with zinc dust[J]. The Chinese Journal of Engineering, 2010, 10(5): 879-885.

[12] 张 嘉, 闫康平, 田 间, 王 伟. Zn(Ⅱ)-NH3-NH4Cl-H2O体系电积锌的添加剂研究[J]. 南方金属, 2007(4): 4-7.

ZHANG Jia, YAN Kang-ping, TIAN Jian, WANG Wei. A study of additives in the Zn(Ⅱ)-NH3-NH4Cl-H2O system for electrowinning zinc[J]. Southern Metals, 2007(4): 4-7.

[13] 王瑞祥, 毛继勇, 谢博毅, 张兆雪, 熊家春. 氨性体系下新型添加剂对电积锌的影响研究[J]. 有色金属(冶炼部分), 2014(11): 1-3.

WANG Rui-xiang, MAO Ji-yong, XIE Bo-yi, ZHANG Zhao-xue, XIONG Jia-chun. Effect of novel additive on zinc electrowinning in ammonia system[J]. Non-ferrous Metal (Smelting Section), 2014(11): 1-3.

[14] 张 杰, 戴亚堂, 张 欢, 周龙平, 李常雄, 贾玉蓉. 添加剂对电沉积锌粉结构和形貌的影响[J]. 武汉理工大学学报, 2012, 34(2): 17-21.

ZHANG Jie, DAI Ya-tang, ZHANG Huan, ZHOU Long-ping, LI Chang-xiong, JIA Yu-rong. Effect of additives on structure and morphology of zinc powder by electrolysis[J]. Journal of Wuhan University of Technology, 2012, 34(2): 17-21.

[15] 李丕强, 徐存英, 华一新, 李 艳, 饶 帅, 汝娟坚. 季铵盐添加剂对锌电沉积的影响[J]. 矿冶, 2014, 23(4): 60-64.

LI Pi-qiang, XU Cun-ying, HUA Yi-xin, LI Yan, RAO Shuai, RU Juan-jian. Effect of quaternary ammonium salt additive on electrodeposition of zinc[J]. Mining and Metallurgy, 2014, 23(4):60-64.

[16] 杨声海, 段良洪, 夏志美, 陈永明, 唐朝波, 何 静. 苄叉丙酮对锌-氨-氯化铵溶液电沉积锌的影响[J]. 有色金属(冶炼部分), 2015(11): 1-6.

YANG Sheng-hai, DUAN Liang-hong, XIA Zhi-mei, CHEN Yong-ming, TANG Chao-bo, HE Jing. Effect of benzylidenacetone on zinc electrodeposition in Zn(Ⅱ)-NH3- NH4Cl solution[J]. Non-ferrous Metal (Smelting Section), 2015(11): 1-6.

[17] XIA Zhi-mei, YANG Sheng-hai, TANG Mo-tang. Nucleation and growth orientation of zinc electrocrystallization in the presence of gelatin in Zn(Ⅱ)-NH3-NH4Cl-H2O electrolytes[J]. RSC Advances, 2015, 5(4): 2663-2668.

[18] 桑世华, 王 渊, 胡咏霞, 唐明林. 氧化锌矿氨浸液电积锌工艺研究[J]. 有色金属(冶炼部分), 2014(8): 1-4.

SANG Shi-hua, WANG Yuan, HU Yong-xia, TANG Ming-lin. Study of zinc electrowinning of ammonia leaching solution from zinc oxide ore[J]. Non-ferrous Metal (Smelting Section), 2014(8): 1-4.

[19] 刘建华, 郭忠诚, 陈步明, 石凤浜. 添加剂在锌电沉积中的行为研究进展[J]. 电镀与精饰, 2012, 34(3): 23-27.

LIU Jian-hua, GUO Zhong-cheng, CHEN Bu-ming, SHI Feng-bang. Research progress of the additive behavior in zinc electrowinning[J]. Plating & Finishing, 2012, 34(3): 23-27.

[20] 杜 楠, 舒伟发, 赵 晴, 陈庆龙, 王帅星. (110)晶面全择优取向镀锌层的制备及其耐腐蚀性能[J]. 中国有色金属学报, 2013, 23(2): 426-434.

DU Nan, SHU Wei-fa, ZHAO Qing, CHEN Qing-long, WANG Shuai-xing. Preparation of zinc electrodeposits with (110) lattice plane fully preferred orientation and its corrosion resistance[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 426-434.

Effect of polyether additive on zinc electrodeposition in Zn(Ⅱ)-NH3-NH4Cl-H2O system

LIN Wen-rong, YANG Sheng-hai, SUN Yan-wei, CHEN Yong-ming, HE Jing, TANG Chao-bo

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: In view of series of shortcomings existing in current zinc electrodeposition in ammoniacal system such as uneven surface, loose and porous, raised burr on the edge of the surface of electrodeposited zinc, the effect of a polyether additive on zinc electrowinning in Zn(Ⅱ)-NH4Cl-NH3-H2O system was investigated. The effects of different concentration of the additive on surface morphology, crystallographic structure, cell voltage, current efficiency and power consumption were evaluated, respectively. The results show that deposited zinc is smoothy and compact, zinc crystal shows a highly preferred orientation, the crystallographic orientation is (110), the structure of zinc crystal is close-packed hexagonal, the grain size is small, average cell voltage is lower than 2.79 V, current efficiency is up to 92.88%, and low energy consumption of 2435.72 kW·h/t is obtained under the optimum concentration of 1.0 g/L for the polyether additive.

Key words: polyether; additive; surface morphology; zinc; electrodeposition

Foundation item: Project(2014CB643404) supported by the National Basic Research and Program of China; Project (51374254) supported by the National Natural Science Foundation of China

Received date: 2016-03-11; Accepted date: 2016-06-24

Corresponding author: YANG Sheng-hai; Tel: +86-731-88830470; E-mail: 75894838@163.com

(编辑 王 超)

基金项目:国家重点基础研究发展计划资助项目(2014CB643404);国家自然科学基金资助项目(51374254)

收稿日期:2016-03-11;修订日期:2016-06-24

通信作者:杨声海,博士,教授;电话:0731-88830470;E-mail: 75894838@163.com