文章编号:1004-0609(2011)09-2111-08

TC21合金的热压缩变形行为及变形机理

周 舸1, 丁 桦1, 曹富荣1, 赵文娟1, 侯红亮2, 李志强2

(1. 东北大学 材料与冶金学院, 沈阳 110004;2. 北京航空制造工程研究所,北京 100024)

摘 要:对TC21合金的热变形行为进行研究,通过对该合金变形过程中应变速率敏感性指数m值、热变形激活能Q、晶粒指数P的计算,得出不同应变速率和温度下m值、Q值和P值的变化规律。在绘制动态DMM模型热加工图的同时构建含位错数量的双相钛合金高温变形机理图。应用热加工图分析TC21合金热变形工艺,确定加工失稳区以及适合加工区域。运用双相钛合金高温变形机理图,根据不同温度下TC21合金柏氏矢量补偿的晶粒尺寸、模量补偿的应力值和位错数量预报该合金的热变形机理。

关键词:TC21合金;变形激活能;应变速率敏感性指数;晶粒指数;加工图;变形机理图

中图分类号:TG146.2;TG113 文献标志码:A

Hot compression deformation and

deformation mechanisms of TC21 alloy

ZHOU Ge1, DING Hua1, CAO Fu-rong1, ZHAO Wen-juan1, HOU Hong-liang2, LI Zhi-qiang2

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. Beijing Aeronautical Manufacturing Technology Research Institute, Beijing 10024, China)

Abstract: The hot compression deformation of TC21 alloy was investigated. Throngh the calculation of strain rate sensitivity exponent (m), deformation activation energy (Q) and grain size exponent (P) during hot compression deformation, the variations of m, Q and P values at different strain rates and temperatures were obtained. The hot processing map based on the dynamic materials modeling was drawn while the high-temperature deformation mechanism maps incorporating dislocations inside grains were obtained. The processing map was used to analyze the hot deformation behavior and determine the processing instability regime and appropriate processing regimes. Within appropriate processing regime, based on the elevated temperature deformation mechanism maps, the Burgers vector compensated grain size, modulus compensated stress and dislocation quantities of TC21 alloy at different temperatures were calculated to elucidate the hot deformation mechanisms.

Key words: TC21 alloy; deformation activation energy; strain rate sensitivity exponent;grain size exponent; processing map; deformation mechanism map

TC21合金是西北有色金属研究院研制的一种Ti-Al-Sn-Zr-Mo-Cr-Nb (-Ni-Si)系α+β双相钛合金,具有高强度、高断裂韧性和较低的裂纹扩展速率等特点,并且该合金在航空航天领域的结构材料中得到了广泛应用[1-3],因此,对其热成形性研究有着重大的现实意义。据文献[4-5]报道,现阶段对金属的热变形行为的研究大多数是以热变形实验数据为基础,对应变速率敏感性指数m、变形激活能Q进行计算并绘制热加工图。然而在金属热变形过程中,晶粒的细化和晶粒长大现象对合金的成形性能起着重大的作用,已有文献中将变形过程中晶粒尺寸与成形工艺参数相结合的研究相对较少。

变形机理图又称为塑性变形的相图,其基础是本构方程。本构方程的显微基础是位错动力学理论和金属学理论。从定量意义上来说,现有的变形机理图是塑性力学应力与金属学晶粒尺寸等微观定量数据的融合。文献[6-9]提出了归一化的应力与温度的蠕变和超塑性变形机理图。变形机理图已成功应用于不锈钢、铝及铝基复合材料、镁合金、镍及其合金和钛等。ASHBY[6]构造了恒定晶粒尺寸下归一化应力和温度的A机理图,用于预报灯泡中钨丝的蠕变变形。Langdon-Mohanmed构造了归一化晶粒尺寸与温度和应力的L-M机理图,预报了纯铝蠕变变形机理[7-8]。RUANO等[9]构造了归一化晶粒尺寸与应力的R-W-S机理图,预报了奥氏体不锈钢(25Cr-20Ni)超塑性晶界滑移机理。近期文献[10-13]分别报道了铝基复合材料、镍基超合金GTD-111、工业钛合金CP-Ti和AZ61镁合金的变形机理图,实际上它们是A、L-M和R-W-S这3种机理图的发展与运用。但是这些变形机理图均未涉及到位错这个重要的变量,更未见到位错定量的机理图。若将热变形过程中晶粒内部位错数量通过模型引入到R-W-S机理图中,构建含位错数量的双相钛合金变形机理图,不仅可以对双相钛合金的变形机理进行预报,还可以定量的预报双相钛合金在变形过程中位错数量。这对深入研究双相钛合金的变形机理有着重要的指导作用。

本文作者对TC21合金的热变形行为进行系统的研究,通过计算该合金热变形行为过程中的热变形激活能Q、应变速率敏感性指数m、晶粒指数P、以及建立动态材料模型的DMM加工图,并绘制包含位错数量的双相钛合金高温变形机理图,将其应用于预报TC21合金的热变形机理中,从而为TC21合金的热变形行为研究提供理论依据。

1 实验

本研究采用中国西北有色金属研究院于2003年研制成功的一种集高强、高韧、高损伤容限于一体的α+β两相钛合金。TC21合金的化学成分[14]为Ti-6Al-2Sn-3Mo-1Cr-2Zr-2Nb,其相变点为(950±5) ℃。

将TC21合金试样机加工成d 8×15 mm的小圆柱体在Gleeble-1500热模拟试验机上按以下工艺参数进行热模拟压缩试验。温度为830~1 010 ℃,温度间隔为30 ℃,应变速率为5×10-4~10 s-1,真应变为0.64,加热温度为10 ℃/s;保温3 min,变形后水冷以保存高温组织,在低真空,石墨润滑的条件下,将经过水冷后的TC21试样自然冷却到约250 ℃以下取样。

对压缩变形后的TC21合金试样沿轴向方向,按由粗到细的顺序用砂纸进行打磨并抛光,然后采用20 mL HF+40 mL HNO3+100 mL H2O浸蚀剂进行腐蚀。最后在变形试样热电偶处,通过OLYMPUS GX51光学显微镜对其进行金相组织观察。同时将该试样沿着与压缩轴平行的方向将试样对半切开,沿轴向切取 3 mm的薄片制备透射电镜试样,然后进行酸喷处理,试剂为V(甲醇)?V(正丁醇)?V(高氯酸)= 60%?34%?6%。电流为40~45 mA,电压为50 V,温度为-40~-35 ℃。采用Tecnai G2 20透射电镜对显微组织进行观察和 分析。

2 结果与讨论

2.1 TC21合金应变速率敏感性指数

应变速率敏感性指数m值是衡量材料超塑性的一个重要参数。 Backofen公式反映了超塑性的本质特点,即流动应力σ和应变速率 有关[15-16]:

有关[15-16]:

(1)

(1)

式中:K为由材料决定的常数;m为应变速率敏感性指数。

将式(1)取对数并微分可得

(2)

(2)

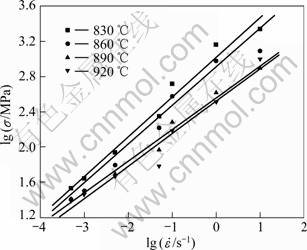

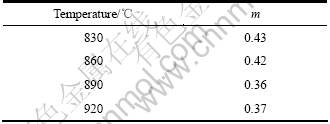

图1所示为TC21合金应变ε=0.6,温度为830、860、890和920 ℃时,应变速率 与流变应力之间的关系图。图中直线的斜率为应变速率敏感性指数m。得出的应变速率敏感指数如表1所示。

与流变应力之间的关系图。图中直线的斜率为应变速率敏感性指数m。得出的应变速率敏感指数如表1所示。

图1 TC21合金的lg σ —lg 曲线

曲线

Fig.1 lg σ —lg curves of TC21 alloy

curves of TC21 alloy

表1 TC21合金不同温度下的m值 (e = 0.6)

Table 1 Values of m of TC21 alloy at different temperatures

从计算结果中可以看出,随着温度的增高,m值有减小的趋势。同时该合金在超塑性变形温度下(830~920 ℃),m值均大于0.3。据文献[17]报道,当应变速率敏感性指数m值大于0.3时合金具有良好的成形性能,因此,在830~920 ℃的温度范围内,TC21合金具有良好的热成形性能。但是在超塑性变形温度范围内,当变形速率过大时,该合金会出现变形失稳现象。为此,本研究在后续讨论中引入动态DMM加工图理论,综合考虑应变为0.6时不同温度、不同应变速率对该合金热变性行为的影响。

2.2 TC21合金的变形激活能

TC21合金高温变形是一个热激活过程,变形温度、应变速率对流变应力的影响可用下式表示:

(3)

(3)

式中:K为常数,σ为流变应力, 为应变速率,n为硬化指数,m为应变速率敏感性指数,R为摩尔气体常数,T为变形温度,Q为变形激活能。当材料处在超塑性状态下,可认为n ≈0。当应变速率恒定时,经过数学变换可得到热变形激活能的表达式:

为应变速率,n为硬化指数,m为应变速率敏感性指数,R为摩尔气体常数,T为变形温度,Q为变形激活能。当材料处在超塑性状态下,可认为n ≈0。当应变速率恒定时,经过数学变换可得到热变形激活能的表达式:

(4)

(4)

式中: ,因此

,因此

(5)

(5)

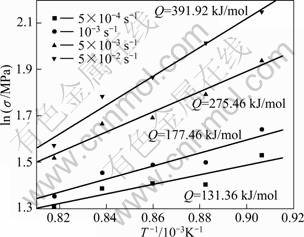

将经过热压缩实验后的TC21合金的试验结果绘成 —1/T曲线(见图2)。曲线中的斜率即为

—1/T曲线(见图2)。曲线中的斜率即为 值,将其同m值带入式(5)即可求出合金热压缩变形过程中的激活能。

值,将其同m值带入式(5)即可求出合金热压缩变形过程中的激活能。

从图2中可以看出,当温度一定时,TC21合金的热变形激活能随着应变速率的增大而增大。这是由于应变速率较高时合金变形过程剧烈,材料内部原子运动加剧,使得热变形激活能提高。高温塑性变形行为存在加工硬化和软化两个显著特点,而热变形激活能值的大小对软化过程产生很大的影响,因此,可以通过热变形激活能来判断合金的软化机制[18]。1982年SARGENT和ASHBY[19]在对前人工作进行总结的基础上,给出α-Ti的自扩散激活能为242 kJ/mol,β-Ti的自扩散激活能为153 kJ/mol。当应变速率较高时TC21合金的热变形激活能大于α-Ti的自扩散激活能,因此该合金在变形过程中的软化机制为晶界滑移。

图2 TC21合金的lgσ —l/T曲线

Fig.2 lgσ —1/T curves of TC21 alloy

2.3 TC21合金热变形过程中晶粒大小的变化

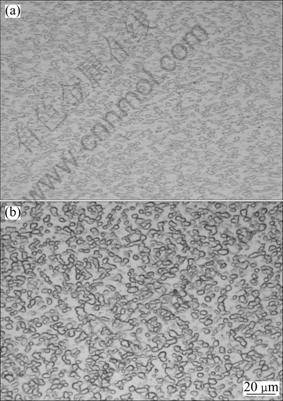

在热变形过程中伴随着合金组织的变化。图3所示为不同应变速率下TC21合金的微观组织。从图3中可以看出,随着应变速率的减小,晶粒尺寸略有增大。经过计算,应变速率10-3和5×10-4 s-1时的晶粒尺寸分别为3.125和3.75 μm。

由文献[20]可知,在变形过程中应变速率 、晶粒尺寸d之间存在下面的关系:

、晶粒尺寸d之间存在下面的关系:

(6)

(6)

式中:P为晶粒指数,通过P值可以判断材料在变形过程中是否存在超塑性阶段。当P≥2时材料发生超塑性变形。

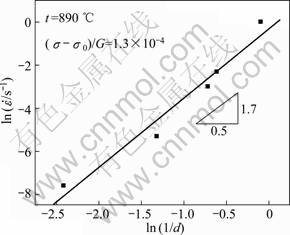

将890 ℃时不同应变速率下经过热压缩变形后的晶粒尺寸以及应变速率代入式(6),得出 —ln(1/d)之间的关系,如图4所示。

—ln(1/d)之间的关系,如图4所示。

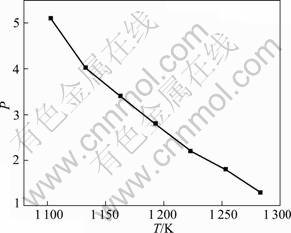

图4中斜率为P值。在890 ℃时,TC21合金的晶粒指数为3.4。P>2,表明该温度下TC21合金发生超塑性变形。上面计算出890 ℃时该合金的m值为0.36,m值大于0.3属于超塑性变形范围,这与P值计算结果(P>2属于超塑性变形)相对应。依据上述方法,可以计算出不同温度下的P值,如图5所示。

图3 不同应变速率下的微观组织 (T= 890 ℃, ε=0.6)

Fig.3 Microstructures of TC21 deformed at different strain rates: (a) 10-3 s-1; (b) 5×10-4 s-1

图4 TC21合金的 —ln(1/d)曲线

—ln(1/d)曲线

Fig.4  —ln(1/d) curves of TC21 alloy

—ln(1/d) curves of TC21 alloy

如图5所示,随着变形温度的增加,晶粒指数P逐渐减小。这说明温度的升高,TC21合金在变形过程中发生动态再结晶的晶粒出现晶粒长大行为,使得该合金塑性降低。当变形温度高于980 ℃时P值小于2,此时变形过程不再是超塑性变形。

图5 TC21合金温度T—晶粒指数P曲线

Fig.5 T—P curves of TC21 alloy

2.4 TC21合金的动态DMM加工图

动态DMM加工图理论将热成形工艺与成形性能有机的结合在一起,能清晰准确地反映金属在热变形过程中变形温度、应变速率与金属的成型性能之间的关系。动态DMM加工图是将功率耗散率图与失稳图叠加获得。通过式(7)和(8)可以分别确定功率耗散率等值曲线和流变失稳范围[21]。

(7)

(7)

式中:η为该合金在变形过程中用于组织变化能量的耗散率,m为应变速率敏感性指数。

(8)

(8)

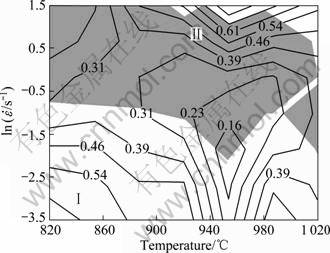

将TC21合金的试验数据代入式(7)和(8),运用Origin软件可以绘制出TC21合金动态DMM加工图,如图6所示,图中曲线为功率耗散率的等值曲线,阴影部分为TC21合金变形过程中的流变失稳区。

从图6中可以看出,温度范围在820~880 ℃,应变速率为5×10-4~5×10-3 s-1(Ⅰ区), 峰值效率为54%,峰值对应的温度和应变速率分别为860 ℃和5×10-3 s-1。此区域为TC21合金应变为0.6时的适合加工成形区域。温度范围在820~1 020 ℃,应变速率为0.01~10 s-1。在此区域 <0,说明该合金发生流变失稳,出现大范围的流变失稳区。

<0,说明该合金发生流变失稳,出现大范围的流变失稳区。

从图6中还可以看出,功率耗散率值较大的区域有两个,Ⅱ区虽然功率耗散率较高,但落在了流变失稳区内,因此不适合成形加工。这说明功率耗散率较大时不一定都具有良好的塑性成形性能,还应综合考虑流变失稳情况。应变量较大时,应变速率的增大使得该合金的成形性能明显下降,不利于热加工成形。因为当应变速率增大时,在变形过程中大量的热量难以散出,出现了绝热剪效应。绝热剪切带的形成使得该合金在绝热剪切带处出现流变失稳现象。因此,在TC21合金热加工过程中应该合理控制应变速率。

图6 应变为0.6时TC21合金的热加工图

Fig.6 Processing map of TC21 alloy at

2.5 含位错的TC21合金高温变形机理图理论预报

RWS机理图仅获得应力、应变速率、晶粒尺寸这3方面的信息,是不含位错的变形机理图。下面将本构方程组与位错模型相结合,获得应力、应变速率、晶粒尺寸和位错数的机理图。

2.5.1 含位错数的变形机理图的构建

以柏氏矢量补偿的晶粒尺寸为纵坐标、以模量补偿的流动应力为横坐标构建不同温度下的应变速率控制的高温变形机理图。每种变形机理都可以用一个速度控制方程来表达。服从下式:

(9)

(9)

式中:Si是状态变量,描述当前的显微状态。Pj是材料性能诸如点阵参数、原子体积、结合能、模量、速控过程的扩散系数等。根据不同的变形机理Si、Pj代表不同的数值和代数式。具体来说,一般的金属高温变形机理可用如下形式的本构方程描述:

(10)

(10)

式中: 为稳态应变速率;

为稳态应变速率; 、m和P是材料常数,依据不同的机理取不同的值;

、m和P是材料常数,依据不同的机理取不同的值; 为应力;E为弹性模量;

为应力;E为弹性模量; 是晶粒尺寸;b是柏氏矢量;D是扩散系数,根据不同的机理D或等于晶格扩散系数DL,或等于位错管扩散系数DP,或者等于晶界扩散系数Dgb。

是晶粒尺寸;b是柏氏矢量;D是扩散系数,根据不同的机理D或等于晶格扩散系数DL,或等于位错管扩散系数DP,或者等于晶界扩散系数Dgb。

将不同变形机理的数据带入式(10)中,从而获得流动扩散机制、晶界滑移、滑移三类本构方程,并且求解上述本构方程不同机理区域的分界线和节点数据。以模量补偿应力作为横坐标,以柏氏矢量补偿的晶粒尺寸作为纵坐标,应用计算机绘图软件绘制出RWS变形机理图。

单个晶粒内部位错根数计算公式如下[22]:

(11)

(11)

式中: 为晶粒内部位错根数,ν为泊松比,

为晶粒内部位错根数,ν为泊松比, 为切应力(MPa),

为切应力(MPa), 。将TC21试验数据代入式(11)并且结合RWS变形机理图求出各个节点处的位错数量,将各点的位错数量标在上述RWS变形机理图的节点处,得到含位错的TC21合金高温变形机理图。在计算过程中,所运用到的钛合金的基本物理参数如下:α-Ti的b=2.95×10-10 m,在不同温度下合金的剪切模量

。将TC21试验数据代入式(11)并且结合RWS变形机理图求出各个节点处的位错数量,将各点的位错数量标在上述RWS变形机理图的节点处,得到含位错的TC21合金高温变形机理图。在计算过程中,所运用到的钛合金的基本物理参数如下:α-Ti的b=2.95×10-10 m,在不同温度下合金的剪切模量 ;β-Ti的b=2.86×10-10 m,在不同温度下合金的剪切模量

;β-Ti的b=2.86×10-10 m,在不同温度下合金的剪切模量 ;钛合金的泊松比ν=0.34;波尔兹曼常数k =1.38×10-23 J/K;

;钛合金的泊松比ν=0.34;波尔兹曼常数k =1.38×10-23 J/K; 。

。

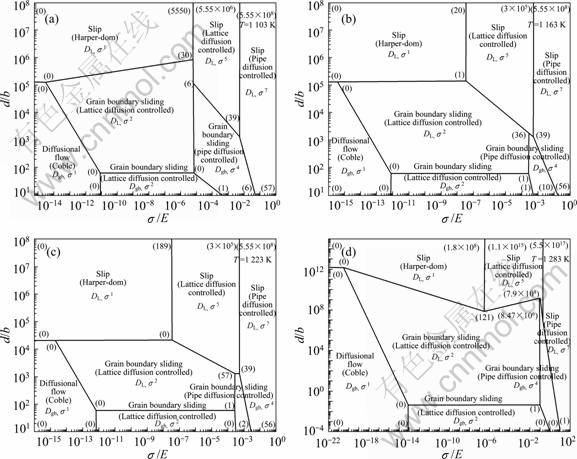

2.5.2 应用含位错数的变形机理图对TC21合金变形行为的分析

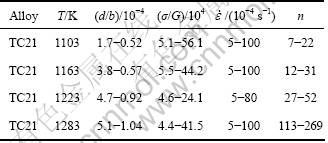

按照以上方法分别绘制出830、890、950和 1 010 ℃的钛合金变形机理图,如图7(a)~(d)所示。对TC21合金830、890、950和1 010 ℃时的热变形行为过程中的柏氏矢量补的晶粒尺寸、模量补偿的应力值、位错数量进行计算,将计算得出的结果参照图7(a)~(d)得出TC21合金不同成形工艺的变形机理。计算结果如表2所示。

表2 TC21合金热变形实验数据计算结果

Table 2 Calculated results for hot compression deformation of TC21 alloy

图7 双相钛合金在1 103~1 283 K温度下构建的热变形机理图

Fig.7 Rate controlling deformation mechanism maps for two-phase titanium alloy constructed at 1 103-1 283 K: (a) 1 103 K; (b) 1 163 K; (c) 1 223 K; (d) 1 283 K

据图7(a)所示,TC21合金在1 103 K时可以得出,当应变速率较低时落入位错多边形(0)-(30)-(6)-(0)-(0)中,说明该区域的应力指数为2,变形机理为晶格扩散控制的超塑性晶界滑移。而当应变速率较大时落入(6)-(39)-(6)-(1)-(0)的位错多边形中,说明该区域的应力指数为4,变形机理为位错管晶界滑移。

据图7(b)所示,TC21合金在1 163 K时可以得出,此时落入位错多边形(0)-(0)-(1)-(36)-(1)中,说明该区域的应力指数为2,变形机理为晶格扩散控制的超塑性晶界滑移。

据图7(c) 所示,TC21合金在1223K时可以得出,此时落入位错多边形(0)-(0)-(1)-(5)-(0)中,说明该区域的应力指数为2,变形机理为晶格扩散控制的超塑性晶界滑移。

据图7(d) 所示,TC21合金在1283K时可以得出,此时落入位错多边形(0)-(0)-(1)-(7.9×108)-(121)中,说明该区域的应力指数为2,变形机理为晶格扩散控制的超塑性晶界滑移。

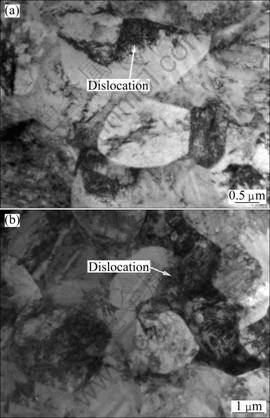

通过上述分析可见,TC21合金在热变形过程中,变形机理为晶格扩散控制的超塑性晶界滑移和位错管晶界滑移。根据Ball-Hutchison模型,认为在晶界滑移过程中将几个晶粒看作为一个组态。在滑动晶界的顶端存在着起障碍作用的晶粒,在该处引起应力集中,并在此障碍晶粒内部产生位错源,如图8所示。位错源发射的位错在晶粒内运动遇到障碍后塞积在对侧的晶界上,当塞积群中的领先位错沿晶界攀移到晶界相消点(三晶粒相交处),塞积群的反应力就会松弛,晶内位错源又会再发射新位错,使晶界滑动一段距离。在高温下,位错攀移会不断进行,这种机制所产生的晶界滑动就会不断进行。包含位错数量的双相钛合金高温变形机理图中的位错多边形定量的给出了钛合金不同变形机理的位错数。同时也验证了图8(a)和(b)中位错的存在。

图8 TC21合金在890 ℃和应变速率为0.001 s-1时的TEM像

Fig.8 TEM images of TC21 alloy compressed at 890 ℃ and 0.001 s-1

3 结论

1) 通过对TC21合金变形热压缩变形数据的计算,得出应变为0.6时,超塑性变形温度(830~920 ℃)下的应变速率敏感性指数m值均大于0.3。应变速率为 =5×10-4~5×10-2 s-1时,其热变形激活能Q=131.36~391.92 kJ/mol。温度小于980 ℃时的晶粒指数P>2,合金发生超塑性变形。

=5×10-4~5×10-2 s-1时,其热变形激活能Q=131.36~391.92 kJ/mol。温度小于980 ℃时的晶粒指数P>2,合金发生超塑性变形。

2) 从TC21合金热加工图中可以得出温度在820~1 020 ℃,应变速率在0.01~10 s-1区域内合金发生流变失稳。实际加工过程中应予以避免。

3) 获得了包含位错数的双相钛合金高温变形机理图,给出了流变应力、晶粒尺寸以及位错数量之间的定量关系,对变形机理进行了准确的预报,为TC21合金的应用提供了深入的理论依据。

REFERENCES

[1] 郭鸿镇, 张 维, 赵张龙, 姚泽坤, 虢迎光, 王保善, 赵永庆, 曲恒磊. TC21新型钛合金的超塑性拉伸行为及组织演化[J]. 稀有金属材料与工程, 2005, 34(12): 1935-1939.

GUO Hong-zhen, ZHANG wei, ZHAO Zhang-long, YAO Ze-shen, WANG Bao-shan, ZHAO Yong-qing, QU Heng-lei. The superplastic tensile deformation behavior and structure evolution of new type titanium alloy-TC21[J]. Rare Metal Materials and Engineering, 2005, 34(12): 1935-1939.

[2] 曲恒磊, 赵永庆, 冯 亮, 奚正平, 李 辉, 夏源明. TC21钛合金不同变形条件下的显微组织研究[J]. 材料工程, 2006(s1): 274-277.

QU Heng-lei, ZHAO Yong-qing, FENG liang, XI Zheng-ping, Li hui, XIA Yuan-ming. Study on microstructures of TC21 alloy under different deformation conditions[J]. Journal of Materials Engineering, 2006(s1): 274-277.

[3] 冯 亮, 曲恒磊, 赵永庆, 李 辉, 张颖楠, 曾卫东. TC21合金的高温变形行为[J]. 航空材料学报, 2004, 24(4): 11-13.

FENG liang, QU Heng-lei, ZHAO Yong-qing, LI hui, ZHANG Ying-nan, ZENG Wei-dong. High temperature deformation behavior of TC21 alloy[J]. Journal of Aeronautical Materials, 2004, 24(4): 11-13.

[4] 戚运连, 曾卫东, 赵永庆, 奚正平, 王蕊宁, 杜 宇, 洪 权, 郭 萍. Ti-Al-Zr-Sn-Mo-Si-Y合金高温塑性变形行为及加工图[J]. 稀有金属材料与工程, 2007, 36(11): 1891-1895.

QI Yun-lian, ZENG Wei-dong, ZHAO Yong-qing, XI Zheng-ping, WANG Xin-ning, DU Yu, HONG Quan, GUO Ping. Hot plastic deformation and the processing map of Ti-Al-Zr-Sn-Mo-Si-Y alloy[J]. Rare Metal Materials and Engineering, 2007, 36(11): 1891-1895.

[5] 王蕊宁, 奚正平, 赵永庆, 戚运连, 杜 宇. Ti53311S合金高温塑性变形行为及加工图[J]. 稀有金属材料与工程, 2008, 37(1): 10-13.

WANG Xin-ning, XI Zheng-ping, ZHAO Yong-qing, QI Yun-lian, DU Yu. Map of hot plastic deformation for Ti53311S alloy[J]. Rare Metal Materials and Engineering, 2008, 37(1): 10-13.

[6] ASHBY M F. A first report of deformation mechanism map[J]. Acta Metal, 1972, 20: 887-897.

[7] MOHAMED F A, LANGDON T G. Deformation mechanism maps based on grain size[J]. Metal Trans A, 1974, 5: 2339-2345.

[8] LANGDON T G, MOHAMED F A. A new type of deformation mechanism map for high-temperature creep[J]. Mater Sci Eng A, 1978, 32: 103-112.

[9] RUANO O A, WADSWORTH J, SHERBY O D. Deformation mechanisms in an austenitic stainless steel (25Cr-20Ni) at elevated temperature[J]. J Mater Sci, 1985, 20: 3735-3744.

[10] MISHRA R S, MUKERJEE A K. The rate controlling deformation mechanism in high strain rate superplasticity [J]. Mater Sci Eng A, 1997, 234/236: 1023-1025.

[11] SAJJADI S A, NATEGH S. A high temperature deformation mechanism map for the high performance Ni-base superalloy GTD-111[J]. Mater Sci Eng A, 2001, 307: 158-164.

[12] TANAKA H, YAMADA T, SATO E, JIMBO Z. Distinguishing the ambient-temperature creep region in a deformation mechanism map of annealed CP-Ti[J]. Scripta Materialia, 2006, 54: 121-124.

[13] CHUNG S W, HIGASHI K, KIM W J. Supperplastic gas pressure forming of fine-grained AZ61 magnesium alloy sheet[J]. Mater Sci Eng A, 2004, 372: 15-20.

[14] 宫旭辉, 王 宇, 夏源明, 葛 鹏, 赵永庆. TC21合金的高温动态拉伸力学行为[J]. 中国有色金属学报, 2010, 20(4): 647-654.

GONG Xu-hui, WANG Yu, XIA Yuan-ming, GE Peng, ZHAO Yong-qing. Dynamic tensile behavior of TC21 titanium alloys at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 647-654.

[15] BACKOFEN W A, TURNER I R, AVERY D H. Superplasticity in an Al-Zn alloy [J]. ASM Trans Qaurt, 1964, 57: 980-990.

[16] PEREVEZENTSEV V N, CHUVILDEEV V N, LARIN S A. Deformation micromechanisims and superplastic flow rheology in a wide strain rate range [J]. Superplasticity in Advanced Materials, 1994, (5): 613-618.

[17] 赵晓宾, 王高潮, 曹春晓, 李臻熙, 杨 刚, 范定兵. TC11钛合金的最大m值超塑性变形研究[J]. 航空材料学报, 2008, 28(2): 5-8.

ZHAO Xiao-bin, WANG Gao-chao, CAO Chun-xiao, LI Zhen-xi, YANG Gang, FAN Ding-bing. Maximum m superplasticity deformation for TC11 titanium alloy[J]. Journal of Aeronautical Materials, 2008, 28(2): 5-8.

[18] CHEN C C, COYNE J E. Deformation characteristics of Ti-6Al-4V alloy under isothermal forging conditions [J]. Materials and Transaction A, 1975, 7(12): 1931-1941.

[19] SARGENT P M, ASHBY M F. Deformation maps of titanium and zirconium [J]. Scripta Materialia, 1982, 16(12): 1415-1422.

[20] WATANABE H, MUKAI T, KOHZU M, TANABE S, HIGASHI K. Effect of temperature and grain size on the dominant diffusion process for superplastic flow in an AZ61 magnesium alloy[J]. Acta Mater, 1999, 47(14): 3753-3758.

[21] 赵建国. TC21合金的热变形行为及组织演变[D]. 大连: 大连理工大学, 2008.

ZHAO Jian-guo. TC21 alloy: Hot deformation behavior and microstructure evolution of TC21 alloy during hot working[D]. Dalian: Dalian University of Technology, 2008.

[22] 曹富荣. 超轻镁合金在高温下的制备及变形机理[J]. 沈阳: 东北大学, 1999: 26-36, 94.

CAO Fu-rong. Preparation and their deformation mechanism of ultralight magnesium alloys at elevated temperatures [D]. Shenyang: Northeastern University, 1999: 26-36, 94.

(编辑 何学锋)

基金项目:国家安全重大基础研究项目

收稿日期:2010-09-02;修订日期:2011-01-05

通信作者:丁 桦,教授,博士;电话:024-83687746;E-mail:hding@263.com