DOI: 10.11817/j.ysxb.1004.0609.2021-36544

BiCuSeO硒氧化合物的微波超快合成及Bi, Cu空位对化合物电输运性能的影响

李 雨,杨皓月,郑 睿,雷 鹰,江孝武,谷 峻

(安徽工业大学 冶金工程学院,马鞍山 243032)

摘 要:采用微波加热4 min成功合成了Bi1-xCuSeO和BiCu1-ySeO (x, y=0, 0.02, 0.03, 0.04, 0.05),随后在650 ℃下采用放电等离子烧结5min获得相对致密度约95%的热电块体,并对它们的物相组成、微观结构、电输运性能进行系统研究。X衍射分析表明,样品衍射峰与四方晶系BiCuSeO标准卡片吻合,但部分样品中含有少量杂质;微观结构分析结果表明,空位样品晶粒呈针状、条状,平均晶粒尺寸约为2~4 μm;电性能分析表明,虽然空位样品的塞贝克系数相比非空位BiCuSeO样品的略有降低,但空位处理显著提高了样品的导电性,其中Bi空位浓度对Bi1-xCuSeO电阻率的影响较不规律,BiCu1-ySeO样品电阻率随Cu空位浓度提高呈规律性降低、导电性增强。综合来看,空位处理可以大幅提高样品综合电性能即功率因子,其中Bi0.96CuSeO的功率因子最高达到395.1 μW/(K2·m),BiCu0.95SeO功率因子最高达到481.5 μW/(K2·m),分别为非空位BiCuSeO样品最高功率因子的2.1倍和2.5倍。

关键词:铋铜硒氧;微波合成;Bi/Cu空位;电阻率;功率因子

文章编号:1004-0609(2021)-02-0410-09 中图分类号:TQ174 文献标志码:A

引文格式:李 雨, 杨皓月, 郑 睿, 等. BiCuSeO硒氧化合物的微波超快合成及Bi, Cu空位对化合物电输运性能的影响[J]. 中国有色金属学报, 2021, 31(2): 410-418. DOI: 10.11817/j.ysxb.1004.0609.2021-36544

LI Yu, YANG Hao-yue, ZHENG Rui, et al. Microwave ultra-fast synthesis and influence of Bi/Cu vacancies on electrical transport properties of BiCuSeO oxyselenides[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 410-418. DOI: 10.11817/j.ysxb.1004.0609.2021-36544

铋铜硒氧(BiCuSeO)基硒氧化物热电材料是迄今为止性能最好的含氧热电材料,被认为是一种极具潜在应用前景的新型热电转换材料[1]。BiCuSeO具有独特的层状超晶格结构,这种层状超晶格结构对载流子的限域效应使材料具备大的塞贝克系数,同时层状晶体结构对声子的散射非常有利于降低热导率,为获得理想热电性能创造了条件[1-6]。

BiCuSeO热电材料的主要缺点为电阻率高、导电性差。可以通过元素掺杂,如Bi位受主掺杂低价元素Na[7]、Ag[8]、Mg[9]、Pb[10]、Ca[11]、Ba[12],或掺杂变价稀土元素Eu[13]、Sm[14]、Yb[15]、Nd[16]、Ho[17],来提高载流子浓度从而改善电输运性能。Pb-Ba[18]、Pb-Ca[19]、Pb-Ag[20]、Pb-Mg[21]等调制掺杂不仅可以利用Pb元素提高有效质量,还可以利用与另一元素的原子半径、相对原子质量、原子耦合力的差异降低晶格热导率。此外,采取Bi、Cu、O空位亦可以加强空穴的电荷转移、增大载流子浓度,从而提高材料导电性[22-23]。除了前面所述的成分优化外,结构优化也是提高电输运性能的重要途径,例如晶粒细化、3D调质掺杂、织构化和多相复合等[24-25]。

BiCuSeO热电块体材料的制备过程包括化合物合成与块体烧结两步。通常需要几十小时的固相反应或者长时间的机械合金化来获得化合物锭块或粉末,再将所获锭块破碎球磨后,采用热压烧结或放电等离子烧结获得致密化块体。BHASKAR等[26]将Bi2O3、Bi、Cu、Se混合粉末研磨混合20 min后压块,将块体真空密封后,先在573 K下加热反应12 h,再将块体在853 K下加热反应24 h,所获锭块经破碎研磨后采用热压烧结获得BiCuSeO块体材料,最高热电优值为0.07(550 K);WU等[27]以Bi、CuO、Se为原料,在球料比20:1、转速500 r/min 的条件下,球磨9 h制得BiCuSeO单相粉末,所获粉体采用放电等离子烧结获得BiCuSeO块体材料,最高热电优值为0.5(773 K);FAROOQ等[28]将Bi、Bi2O3、Ag、Cu、Se混合粉末球磨5 h后压块,将块体真空密封后,先在573 K下加热反应8 h,再将锭块在873 K下加热反应24 h,经两步热处理获得的锭块采用高能球磨5 h,所获粉体再采用放电等离子烧结获得BiCu1 -xAgxSeO块体材料,最高热电优值为0.64(923 K)。WEN等[29]将BaO,Bi2O3,NiO,Bi,Cu,Se混合粉末球磨12 h后压块,将块体真空密封后,先在573 K下加热反应8 h,再将块体在1023 K下加热反应24 h,经两步热处理获得的块体采用高能球磨8 h,所获粉体再采用放电等离子烧结获得Bi0.875Ba0.125Cu1-xNixSeO块体材料,最高热电优值为0.97(923 K)。

本文作者的研究结果表明[30-32],采用微波能快速合成出半赫斯勒、方钴矿、铋铜硒氧等热电化合物,极大降低材料制备周期和制造成本,使热电材料的应用潜力得到提升。本文作者拟通过微波快速加热合成与SPS相结合的方式制备BiCuSeO热电块体,研究Bi、Cu空位对其电性能的影响规律,进一步探索微波加热技术在热电材料合成制备领域应用的可行性。

1 实验

将Bi粉(99.9%)、Bi2O3粉(99.9%)、Cu粉(99.9%)、Se粉(99.9%)按Bi1-xCuSeO、BiCu1-ySeO(x, y=0, 0.02, 0.03, 0.04, 0.05)的名义组成进行称量配料和充分研磨后,在7 MPa下冷压成片,将冷压片置于石英管中,并将石英管进行真空熔封,使管内真空度小于0.1 Pa;将密封后的石英管置于坩埚中,在坩埚内壁和石英管外壁之间均匀铺上微波辅助吸收体,然后将上述坩埚整体置于微波炉(M3- L236E,美的/中国)中,在100%微波功率下加热合成5 min。合成得到的锭块孔隙多、致密度小,无法直接测试样品性能,需进一步制备成致密块体。将锭块破碎、研磨,对其进行放电等离子体烧结(LABOX-100,Sinter Land INC./日本),烧结温度650 ℃、烧结时间5 min、烧结压力50 MPa。烧结的块状样品采用低速金刚石切割机(SYJ-150,科 晶/中国)切割成不同尺寸,进行微观结构表征和热电测试,更多细节参见文献[30-31]。

采用X射线衍射仪(D8-ADVANCE X射线衍射仪,布鲁克/德国)对样品物相组成进行分析;采用场发射扫描电镜(Nano-SEM430, FEI/荷兰)和能谱仪对样品微观结构和元素分布进行分析,结合粒度分析软件(Nano Measurer 1.2.5)对晶粒尺寸进行了统计;采用霍尔效应测试仪(ResiTest8300,日本电子)测试了样品的室温霍尔系数和载流子浓度;样品电性能采用四探针法进行测试(Namicro-III,嘉仪通/中国)。

2 结果与讨论

2.1 物相和显微结构分析

图1所示为Bi1-xCuSeO和BiCu1-ySeO块体的XRD谱。从图1(a)和(b)可以看出,所有样品的主要衍射峰均与四方晶系BiCuSeO(空间群P4/mmm)的标准卡片(PDF#82-1073)吻合。由于合成过程超快,样品中存在一定量杂质,Bi1-xCuSeO样品中包含少量Bi2O3和Bi2O5Se,对比空白样品物相组成,判断Bi2O3为未反应物、Bi2O5Se为中间化合物。BiCu1-ySeO样品中包含少量CuSe,为中间化合物。采用Jade 5.0(DELL/Materials Data, Inc.)软件对XRD图谱进行拟合计算,获得Bi1-xCuSeO和BiCu1-ySeO的晶格常数,结果见表1和2所示。结果显示Bi1-xCuSeO和BiCu1-ySeO样品的a/b、c轴晶格常数均略小于非空位样品,表明空位处理引入了晶体缺陷、导致晶格畸变。

图2和3所示分别为Bi1-xCuSeO和BiCu1-ySeO块体新鲜横断面的扫描电镜图。不同样品晶粒呈针状、条状、板状,紧密堆积。采用粒度分析软件Nano Measurer (V1.2.5,复旦大学)对样品平均晶粒尺寸进行了统计,结果见表1、2所示。结果显示,Bi1-xCuSeO样品x为0.02、0.03、0.04的平均晶粒尺寸为2~3 μm,样品x=0.05的平均晶粒尺寸为3.65 μm;BiCu1-ySeO样品y为0.02、0.03、0.04、0.05的平均晶粒尺寸分别为2.11、3.08、2.55、3.14 μm;Bi空位样品和Cu空位样品的晶粒尺寸均远小于非空位样品平均晶粒8.59 μm,表明晶格畸变以及中间化合物杂质可能会影响晶粒尺寸。不同空位浓度样品的晶粒尺寸变化无明显规律,分析原因之一可能在于微波超快加热较难控制获得的晶粒尺寸。在相同反应时间内,温度越高,晶界移动的激活能就越低,晶界平均迁移率就越高,晶粒长大速率就越快。晶粒越细、晶界越多,可以增强对低频声子散射,有利于降低样品晶格热导率[32]。

图1 Bi1-xCuSeO和BiCu1-ySeO块体XRD谱

Fig. 1 XRD patterns for Bi1-xCuSeO(a) and BiCu1-ySeO(b) bulks

表1 Bi1-xCuSeO相关物理性质

Table 1 Related physical properties of Bi1-xCuSeO

表2 BiCu1-ySeO相关物理性质

Table 2 Related physical properties of BiCu1-ySeO

2.2 电性能分析

对Bi1-xCuSeO和BiCu1-ySeO样品的室温霍尔系数、载流子浓度和迁移率进行了测试,结果如表1和2所示。霍尔系数绝对值的变化趋势与载流子迁移率的变化趋势一致。空位处理加强了空穴的电荷转移、增加了少数载流子浓度,提高了样品的导电性,其中Bi空位Bi1-xCuSeO样品载流子浓度为非空位样品的1.1~4.9倍;Cu空位BiCu1-ySeO样品载流子浓度为非空位样品的2.2~6.3倍,所有样品的载流子浓度变化与空位浓度并非严格相关。迁移率变化趋势与空位位置浓度以及载流子浓度无明显关系。

图4所示为Bi1-xCuSeO、BiCu1-ySeO样品电阻率随温度变化曲线图。非空位BiCuSeO电阻率很大、导电性差,经空位处理后样品的电阻率大幅度降低。图4(a)显示,Bi1-xCuSeO样品电阻率随温度上升逐渐下降,表明随着测试温度提高,样品本征激发增强、载流子浓度提高、样品导电性增大;Bi1-xCuSeO样品电阻率随空位浓度变化较不规律,其中Bi0.98CuSeO样品电阻率最低、导电性最好。根据固体物理知识,材料导电率与载流子浓度和迁移率均呈正比,推测Bi0.98CuSeO样品在测试温度范围内具有较大迁移率,与表1中Bi0.98CuSeO在室温下具有最大载流子迁移率相符。图4(b)中BiCu1-ySeO样品电阻率随温度变化趋势和原因与Bi1-xCuSeO的一致。Bi1-xCuSeO样品电阻率随空位浓度提高呈规律性降低,导电性逐渐增强。

图5所示为Bi1-xCuSeO、BiCu1-ySeO样品塞贝克系数随测试温度变化曲线图。通常由于载流子被限制在绝缘(Bi2O2)2+层和导电(Cu2Se2)2-层形成的 具有二维的自然超晶格结构内[33],使得非空位BiCuSeO具有较大的塞贝克系数;Bi、Cu空位的引入,使得空穴载流子浓度增加,在一定程度上会影响塞贝克系数。图5(a)显示,Bi空位样品Bi0.95CuSeO、Bi0.98CuSeO的塞贝克系数下降较为明显,其他样品并无大幅度下降甚至部分上升;773 K时,Bi0.97CuSeO的塞贝克系数最高为324.8 μV/K。图5(b)显示,部分Cu空位样品塞贝克系数高于Bi空位样品;BiCu0.97SeO在773 K时塞贝克系数最高为339.2 μV/K。

图2 Bi1-xCuSeO块体横断面微观形貌

Fig. 2 Micro-morphologies of cross section for Bi1-xCuSeO

图3 BiCu1-ySeO块体横断面微观形貌

Fig. 3 Micro-morphologies of cross section for BiCu1-ySeO:

图4 样品电阻率随温度的变化曲线

Fig. 4 Change curves of resistivity with increasing temperature

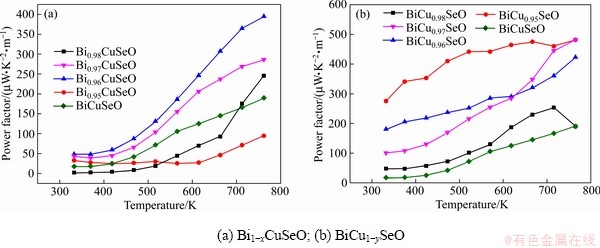

图6所示为Bi1-xCuSeO、BiCu1-ySeO样品功率因子变化曲线图。由于Bi、Cu空位样品导电性相比无掺杂样品导电性大幅提高,而塞贝克系数没有明显降低,使得绝大部分空位样品的功率因子远大于无掺杂样品。图6显示,无掺杂BiCuSeO的功率因子最高为189.8 μW/(K2·m);Bi空位Bi0.96CuSeO功率因子最高达到395.1 μW/(K2·m),是无掺杂样品的2.1倍;Cu空位对功率因子的提升更加明显,BiCu0.95SeO功率因子在773 K获得最大功率因子 481.8 μW/(K2·m),是无掺杂样品的2.5倍,表明空位处理可以显著提升铋铜硒氧热电材料的综合电性能。

图5 样品塞贝克系数随温度的变化曲线

Fig. 5 Change curves of Seebeck coefficient with increasing temperature

图6 样品功率因子随温度的变化曲线

Fig. 6 Change curves of power factor with increasing temperature

3 结论

1) 采用微波加热4 min成功合成了Bi1-xCuSeO和BiCu1-ySeO化合物,随后采用放电等离子烧结5 min即获得相对致密度约为95%的热电块体,样品衍射峰与四方晶系BiCuSeO标准卡片吻合,含有少量杂质。

2) 不同样品晶粒呈针状、条状、板状,紧密堆积。非空位样品平均晶粒尺寸约为8~9 μm,Bi1-xCuSeO、BiCu1-ySeO样品平均晶粒尺寸约为2~4 μm。

3) 空位处理可以显著提高样品导电率,其中Bi空位浓度对Bi1-xCuSeO导电率的影响无规律,BiCu1-ySeO样品电阻率随空位浓度提高呈规律性降低,导电性逐渐增强。

4) 空位样品塞贝克系数相比非空位样品略有降低。结合空位处理对电阻率的影响,得知空位处理可大幅提高样品综合电性能即功率因子,其中Bi0.96CuSeO的功率因子最高达到395.1 μW/(K2·m),BiCu0.95SeO功率因子最高达到481.5 μW/(K2·m),分别是为本文非空位BiCuSeO样品最高功率因子的2.1倍和2.5倍。

REFERENCES

[1] ZHAO L D, HE J, BERARDAN D, et al. BiCuSeO oxyselenides: New promising thermoelectric materials[J]. Energy Environ Sci, 2014, 7(9): 2900-2924.

[2] ZHAO Li-dong, DAVID B, PEI Y L, et al. Bi-Sr-CuSeO oxyselenides as promising thermoelectric materials[J]. Applied Physics Letters, 2010, 97(9): 092118-1-3.

[3] LAN Jin-le, ZHAN Bin, LIU Yao-chun, et al. Doping for higher thermoelectric properties in p-type BiCuSeO oxyselenide[J]. Applied Physics Letters, 2013, 102(12): 123509.

[4] ZOU Dai-feng, XIE Shou-hong, LIU Yun-ya, et al. Electronic structures and thermoelectric properties of layered BiCuOCh oxychalcogenides (Ch=S, Se and Te): First- principles calculations[J]. Journal of Materials Chemistry A, 2013, 1(31): 8888-8896.

[5] CHOU T L, TEWARI G C, SRIVASTAVA D, et al. Efficacies of dopants in thermoelectric BiCuSeO[J]. Materials Chemistry and Physics, 2016, 177: 73-78.

[6] AN T H, LIM Y S, SEO W S, et al. Effects of K-doping on thermoelectric properties of Bi1-xKxCuOTe[J]. Journal of Electronic Materials, 2017, 46: 2717-2723.

[7] LAN Jin-le, DENG Cheng-jie, MA Wen-qiang, et al. Ultra-fast synthesis and high thermoelectric properties of heavy sodium doped BiCuSeO[J]. Journal of Alloys and Compounds, 2017, 708: 955-960.

[8] LIU Yao-chun, ZHENG Yuan-hua, ZHAN Bin, et al. Influence of Ag doping on thermoelectric properties of BiCuSeO[J]. Journal of the European Ceramic Society, 2015, 35(2): 845-849.

[9] LI Jing, SUI Jie-he, BARRETEAU C, et al. Thermoelectric properties of Mg doped p-type BiCuSeO oxyselenides[J]. Journal of Alloys and Compounds, 2013, 551: 649-653.

[10] ANDREI N, ILLIA S, EVGENY K, et al. Ultrafast synthesis of Pb-doped BiCuSeO oxyselenides by high-energy ball milling[J]. Materials Letters, 2020, 262: 127184.

[11] HSIAO Chun-lung, QI Xiao-ding. The oxidation states of elements in pure and Ca-doped BiCuSeO thermoelectric oxides[J]. Acta Materialia, 2016, 102: 88-96.

[12] FENG Dan, ZHENG Feng-shan, WU Di, et al. Investigation into the extremely low thermal conductivity in Ba heavily doped BiCuSeO[J]. Nano Energy, 2016, 27: 167-174.

[13] 康慧君, 张校影, 王燕遐, 等. 变价稀土元素Eu掺杂BiCuSeO热电性能的研究[J]. 无机材料学报, 2020, 35(25): 85-90.

KANG Hui-jun, ZHANG Xiao-ying, WANG Yan-ya, et al. Study on thermoelectric properties of EU-doped BiCuSeO variable valence Rare earth element[J]. Chinese Journal of Inorganic Materials, 2020, 35(25): 85-90.

[14] KANG Hui-jun, ZHANG Xiao-ying, WANG Yan-xia, et al. Enhanced thermoelectric performance of variable-valence element Sm-doped BiCuSeO oxyselenides[J]. Materials Research Bulletin, 2020, 126: 110841.

[15] 李金玲. 变价稀土元素Yb掺杂协同优化BiCuSeO微结构及热电性能[D]. 大连: 大连理工大学, 2018.

LI Jin-ling. Collaborative optimization of microstructure and thermoelectric properties of variable valence rare earth element Yb doping[D]. Dalian: Dalian University of Technology, 2018.

[16] NOVITSKII A, GUELOU G, MOSKOVSKIKH D, et al. Reactive spark plasma sintering and thermoelectric properties of Nd-substituted BiCuSeO oxyselenides[J]. Journal of Alloys and Compounds, 2019, 785: 96-104.

[17] FENG Bo, LI Guang-qiang, HU Xiao-ming, et al. Improvement of thermoelectric performance in BiCuSeO oxide by ho doping and band modulation[J]. Chinese Physics Letters, 2020, 37(3): 037201.

[18] FENG Bo, LI Guang-qiang, PAN Zhao, et al. Effect of Ba and Pb dual doping on the thermoelectric properties of BiCuSeO ceramics[J]. Data in Brief, 2018, 21: 86-87.

[19] FENG Bo, LI Guang-qiang, PAN Zhao, et al. Effect of synthesis processes on the thermoelectric properties of BiCuSeO oxyselenides[J]. Journal of Alloys and Compounds, 2018, 754: 131-138.

[20] LI Fu, ZHENG Zhuang-hao, CHANG Yi, et al. Synergetic tuning of the electrical and thermal transport properties via Pb/Ag dual doping in BiCuSeO[J]. ACS Applied Materials & Interfaces, 2019, 11(49): 45737-45745.

[21] LIU Yong, ZHU Ying-cai, LIU Wei-shu, et al. Synergetic tuning of electrical/thermal transport via dual-doping in Bi0.96-xMgxPb0.06CuSeO[J]. Journal of the American Ceramic Society, 2019, 102(4): 1541-1547.

[22] LIU Y, ZHAO L D, LIU Y, et al. Remarkable enhancement in thermo-electric performance of BiCuSeO by Cu deficiencies[J]. J Am ChemSoc, 2011, 133(50): 20112-20115.

[23] LI Zhou, XIAO Chong, FAN Shao-juan, et al. Dual vacancies: An effective strategy realizing synergistic optimization of thermoelectric property in BiCuSeO.[J]. Journal of the American Chemical Society, 2015, 137(20): 6587-6593.

[24] FENG Bo, LI Guang-qiang, HU Xiao-ming, et al. Enhancement of thermoelectric performances of BiCuSeO through Y doping and grain refining[J]. Journal of Materials Science: Materials in Electronics, 2020, 31(6): 4915-4923.

[25] PEI Y L, WU H, WU D, et al. High thermoelectric performance realized in a BiCuSeO system by improving carrier mobility through. 3D modulation doping[J]. J Am Chem Soc, 2014,136(39) : 13902-13908.

[26] BHASKAR A, LAI R T, CHANG K C, et al. High thermoelectric performance of BiCuSeO prepared by solid state reaction and sol-gel process[J]. Scripta Mater., 2017, 134: 100-104.

[27] WU J, LI F, WEI T R, et al. Mechanical alloying and spark plasma sintering of BiCuSeO oxyselenide: Synthesis process and thermoelectric properties[J]. J Am Chem Soc, 2016, 99: 507-514.

[28] FAROOQ M U, BUTT S, GAO K W, et al. Improved thermoelectric performance of BiCuSeO by Ag substitution at Cu site[J]. J Alloys Compd, 2017, 691: 572-577.

[29] WEN Q, CHANG C, PAN L, et al. Enhanced thermoelectric performance of BiCuSeO by increasing Seebeck coefficient through magnetic ion incorporation[H]. J Mater Chem A, 2017, 5: 13392-13399.

[30] LEI Ying, GAO Wen-sheng, ZHENG Rui, et al. Rapid synthesis, microstructure, and thermoelectric properties of skutterudites[J]. Journal of Alloys and Compounds, 2019, 806: 537-542.

[31] LEI Ying, GAO Wen-sheng, ZHENG Rui, et al. Ultrafast synthesis of Te-doped CoSb3 with excellent thermoelectric properties[J]. ACS Applied Energy Materials, 2019, 2(6): 4477-4485.

[32] LI Yu, CHENG Cheng, LEI Ying, et al. Ultra-fast preparation of high-performance thermoelectric bulk TiNiSb0.05Sn0.95 by microwave synthesis[J]. Dalton Transactions, 2017, 46: 33-38.

[33] LI Fu, LI Jing-feng, ZHAO Li-dong, et al. Polycrystalline BiCuSeO oxide as a potential thermoelectric material[J]. Energy & Environmental Science, 2012, 5: 7189-7193.

Microwave ultra-fast synthesis and influence of Bi/Cu vacancies on electrical transport properties of BiCuSeO oxyselenides

LI Yu, YANG Hao-yue, ZHENG Rui, LEI Ying, JIANG Xiao-wu, GU Jun

(School of Metallurgical Engineering, Anhui University of Technology, Ma’anshan 243032, China)

Abstract: The series of oxyselenides thermoelectric compounds Bi1-xCuSeO and BiCu1-ySeO (x, y=0, 0.02, 0.03, 0.04, 0.05) were successful synthesized in 4 min via microwave heating for the first time, and the corresponding bulks were subsequent fabricated with spark plasma sintering at 650 ℃ for 5 min. The phase composition, microstructure and electrical transport properties were investigated. The analysis of XRD patterns show that the diffraction peaks for all samples are matching to tetragonal BiCuSeO standard card. However, some samples contain small amounts of impurities. The analysis of microstructure shows that the grains of samples with vacancy show needle-like and strip-like, with average grain sizes of about 2-4 μm. The analyses of electrical transport properties show that the seebeck coefficients of samples with vacancy are slightly lower than that of non-vacancy BiCuSeO, nevertheless, the vacancy treatment significantly improves the conductivity. Bi vacancy concentration has an irregular influence on the resistivity of Bi1-xCuSeO samples, and the resistivity of BiCu1-ySeO samples decrease regularly with the increase of Cu vacancy concentration, respectively. In general, the vacancy treatment can greatly improve the comprehensive electrical performance, namely, enhance the power factor, the maximum power factors for Bi0.96CuSeO and BiCu0.95SeO are 395.1 and 481.5 μW/(K2·m), respectively, which are 2.1 times and 2.5 times compared to that of the non-vacancy BiCuSeO.

Key words: BiCuSeO; microwave synthesis; Bi/Cu vacancy; resistivity; power factor

Foundation item: Projects(51974005, 51574134) supported by the National Natural Science Foundation of China

Received date: 2020-02-27; Accepted date: 2020-08-17

Corresponding author: LEI Ying; Tel: +86-18755589227; E-mail:leiyingahut@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51974005,51574134)

收稿日期:2020-02-27;修订日期:2020-08-17

通信作者:雷 鹰,副教授,博士;电话:18755589227;E-mail:leiyingahut@163.com