文章编号:1004-0609(2013)10-2882-08

热等静压处理对Zn-Al-Si合金涂层耐蚀性能的影响

周文斌1,姚正军1,魏东博1,蒋 穹1,罗西希1,朱俊谋1,冯立新2

(1. 南京航空航天大学 材料科学与技术学院,南京 211106;

2. 江苏麟龙新材料股份有限公司,无锡 214100)

摘 要:对电弧喷涂Zn-Al-Si合金涂层进行热等静压(HIP)处理,通过电化学测试、盐水(3.5%NaCl,质量分数)全浸实验、扫描电镜观察和能谱分析,研究热等静压处理对电弧喷涂Zn-Al-Si合金涂层耐蚀性能的影响。结果表明:300 ℃、1 h、150 MPa HIP处理能大幅降低电弧喷涂Zn-Al-Si合金涂层的腐蚀电流,促进钝化现象的产生,提高耐腐蚀性能和防护寿命。HIP处理改善了涂层表面不平整结构、促进了表面元素分布;基本消除了涂层孔隙结构,孔隙率降低了87.15%,避免闭塞电池腐蚀的发生和涂层内部孔隙拓展延伸。经HIP处理后,涂层元素的均匀分布、平整的表面结构和致密的内部组织是降低腐蚀电流及产生钝化现象的主要原因。

关键词:Zn-Al-Si合金;热等静压;孔隙率;耐腐蚀性

中图分类号:TG174.22 文献标志码:A

Effect of hot isostatic pressing on corrosion resistance of Zn-Al-Si alloy coating

ZHOU Wen-bin1, YAO Zheng-jun1, WEI Dong-bo1, JIANG Qiong1, LUO Xi-xi1, ZHU Jun-mou1, FENG Li-xin2

(1. Nanjing University of Aeronautics and Astronautics, Nanjing 211106, China;

2. Jiangsu Linlong New Materials Co. Ltd., Wuxi 214100, China)

Abstract: The influence of hot isostatic pressing (HIP) on the corrosion resistance of arc spraying Zn-Al-Si alloy coating was studied by electrochemical test, salt solution (3.5%NaCl, mass fraction) immersion test, scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). The results indicate that when the alloy is HIP-processed at 150 MPa and 300 ℃ for 1 h, the corrosion current of arc spraying Zn-Al-Si coating is greatly reduced, the passivation phenomenon is promoted, and the corrosion resistance and protective life are improved. HIP treatment flats the surface, improves the element distribution, greatly eliminates the pore structure. The porosity is decreased by 87.15%, occluded cell corrosion and pore extension are avoided. Uniform element distribution, flat surface structure and dense internal tissue are the main reasons to cause the reduction of corrosion current and passivation phenomenon.

Key words: Zn-Al-Si alloy; hot isostatic pressing; porosity; corrosion resistance

在钢铁件的海洋防腐领域,电弧喷涂Zn-Al涂层因制备效率高,涂层结合强度高,涂层质量性能稳定等特点而得到广泛应用[1]。但电弧喷涂涂层的形成过程决定了涂层是一个多孔的结构[2-3]。孔隙结构的存在会引起闭塞电池腐蚀[4],涂层在孔隙处腐蚀加剧,孔隙拓展延伸至基体,防护性能下降,涂层对钢铁件的保护时间严重缩短,在零件的服役期内,需要定期对涂层进行维护和修补,耗费大量人力物力。因此,采用合理的工艺手段消除热喷涂涂层的孔隙成为研究热点。

目前,国内外对降低热喷涂涂层孔隙率的研究已取得了一定进展。MATEOS等[5]对等离子喷涂NiCr/Cr2C3涂层进行了激光重熔,孔隙率由9.2%降到几乎为0,但激光设备价格高昂且热转化效率低,限制了其应用。采用封孔剂进行封孔处理的方式是降低涂层孔隙率的一个有效手段,国内外已研制出一些适应不同腐蚀环境的封孔剂。SUGEHIS等[6]对等离子喷涂Al2O3-13%TiO2涂层进行了苯酚树脂和环氧树脂的封孔处理,研究表明:环氧树脂和苯酚树脂将涂层孔隙率由13.9%分别降至3.7%和5.3%,腐蚀电流分别 降低了75%和66%,极大地提高了涂层的耐腐蚀性 能。但是,有机封孔剂一般存在耐热性差、耐磨性不足等缺点。于惠博等[7]发现,封孔处理会使涂层的剪切强度及弹性模量均有所下降, 这主要是封孔剂进入微裂纹和孔隙中造成涂层延展性下降和裂纹扩展较快造成的。热等静压技术是一种热致密化处理工艺,在高温高压下,以气体为介质向工件施加各向同等的压力,消除孔隙,提高材料致密度。目前,国内外已有学者采用热等静压技术提高涂层的孔隙率。KHOR等[8]用热等静压的方式对等离子喷涂Ni-5Al和Ni-20Al涂层进行封孔,使涂层孔隙率下降了89%,且硬度有所提高。

目前,尚无利用热等静压技术降低Zn-Al系涂层孔隙率的研究。本文作者利用热等静压技术处理电弧喷涂Zn-Al-Si合金涂层,并系统研究热等静压处理对其耐腐蚀性能的影响。

1 实验

1.1 试样制备

试样的制备分为工件表面预处理、工件预热和喷涂3个过程。采用丙酮清洗试样,除去表面的油污和其他脏物,然后对试样的喷涂面进行喷砂处理,喷砂工艺的砂料为棕刚玉,粒度为0.71 mm,气压为0.7 MPa,喷砂角度为45°,喷砂距离为200 mm。喷涂材料选用d 2 mm的Zn-Al-Si合金丝材,喷涂工艺参数见表1。

表1 电弧喷涂工艺参数

Table 1 Technological parameters of arc spraying

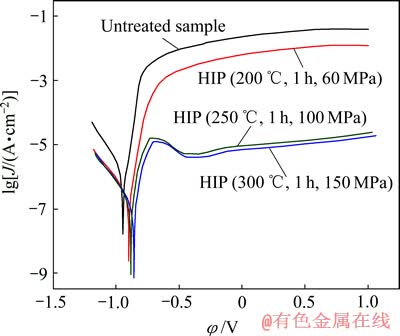

1.2 热等静压处理

HIP工艺处理的前提条件是前期工艺得到的样品必须达到理论密度的92%~98%,然后直接放入HIP装置中进行处理,否则,需要选取包套材料对样品进行包封[9]。且HIP处理过程中,传压气体可能进入Zn-Al-Si涂层内部孔隙,不利于孔隙的闭合,因此本文作者采用包套工艺。HIP处理工艺参数如表2所列。升降温速率均为6 ℃/min,HIP处理完成后随炉冷却,传压介质为氩气(纯度99.99%),最终得到的样品分别为试样1、试样2和试样3。

表2 Zn-Al-Si合金涂层热等静压处理工艺参数

Table 2 Technological parameters of hot isostatic pressing on Zn-Al-Si alloy coating

1.3 测试分析

动电位极化曲线测试:采用CHI660D型电化学工作站,试样尺寸为10 mm×10 mm,用绝缘胶密封,留出涂层面作为工作面,利用三电极体系(铂片为辅助电极、饱和甘汞电极为参比电极、涂层为工作电极)在室温下进行极化曲线测试。为了达到稳定的开路电位,将待测试样浸泡在被测溶液中进行极化曲线测试,选用浓度为3.5%(质量分数)的NaCl水溶液作为电解质溶液。将待测试样浸泡在被测溶液中浸泡30 min后再进行测试,扫描速度为0.01 V/s。

盐水全浸实验:全浸实验根据JB/T 6073—1992规定,在常温及3.5%NaCl的水溶液中进行,每隔6 d更换一次介质,定期记录试样质量。

涂层孔隙率的测定:将涂层的横截面制成金相试样,然后在扫描电镜下对试样进行观察,采用Imagepro-plus图像分析软件对图片灰度值进行处理计算,测定涂层孔隙率。

2 结果与讨论

2.1 涂层微观组织和成分分析

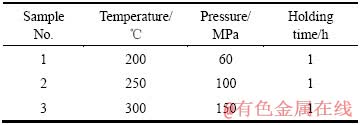

2.1.1 截面形貌

Q235钢表面电弧喷涂的Zn-Al-Si合金涂层截面的SEM像如图1所示。涂层与基体结合良好,厚度均匀,大约为200 μm。

对电弧喷涂的Zn-Al-Si合金涂层和经HIP处理后的涂层进行扫描电镜观察,其截面形貌如图2所示。

图1 Zn-Al-Si涂层截面的SEM像

Fig. 1 Cross section SEM image of Zn-Al-Si coating

图2(a)~(d)所示分别为未处理试样、试样1、试样2和试样3的截面显微形貌。由图2可以看出,经HIP处理后涂层的孔隙数量和尺寸明显减小,截面组织变得更加致密。采用Image pro-plus图像分析软件测试涂层孔隙率,其结果如表3所列,未经HIP处理的涂层孔隙率较大,达到12.14%。3种HIP工艺(200 ℃,1 h,60 MPa;250 ℃,1 h,100 MPa;300 ℃,1 h,150 MPa)分别使涂层的孔隙率降至8.37%、4.81%和1.56%,这是因为在高温高压的双重因素作用下,原子活动能力增加,颗粒之间的元素相互扩散,孔隙被压实闭合,使得涂层孔隙率减小,致密度增大[10-13]。采用HIP(300 ℃,1 h,150 MPa)处理后,涂层孔隙率下降了87.15%,孔隙基本消除。

表3 Zn-Al-Si涂层孔隙率

Table 3 Porosity of Zn-Al-Si coating

2.1.2 表面形貌

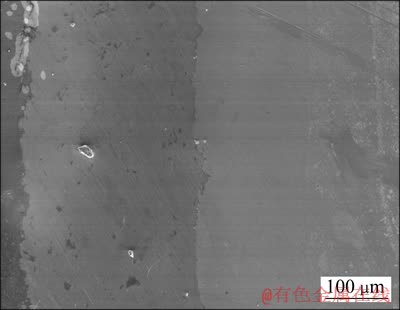

图3(a)和(b)所示分别为未处理样品和在150 MPa、300 ℃、1 h HIP处理后样品的表面形貌和元素分布。由图3可以看出,未处理样品的表面形貌呈层状组织平铺堆叠而成,层与层之间存在缝隙和孔洞。

图2 HIP处理对电弧喷涂Zn-Al-Si涂层截面SEM像的影响

Fig. 2 Influence of HIP pressing process on cross section SEM image of Zn-Al-Si arc coating

图3 Zn-Al-Si涂层表面形貌和元素分布

Fig. 3 Surface morphologies((a), (b)) and element distribution((c), (d)) of Zn-Al-Si coating

这是因为喷涂过程中喷涂材料经加热、融化、熔滴喷射至基体表面,相互撞击堆叠形成层状结构,而喷涂过程中的液态粒子不能完全铺开和填充到底层的孔隙中,而造成涂层的孔隙结构[13]。由图3(b)可以看出,Zn-Al-Si涂层经150 MPa、300 ℃、1 h HIP处理后,未见明显的层状结构,表面变得致密平整,孔隙减少,这是因为HIP的高温高压作用将疏松的层状组织压紧,层与层之间的孔隙闭合,改善了涂层表面质量。对300 ℃、1 h、150 MPa HIP处理样品的表面进行能谱分析,结果如图3(c)和(d)所示。Al元素整体分布较为均匀,左下角出现一个贫Al带,这可能是因为HIP处理下,不均匀的结构使Al元素发生了择优扩散;Zn元素分布均匀,这有利于在腐蚀过程中Zn的腐蚀产物连接成片,形成钝化膜(腐蚀产物膜)[4]。

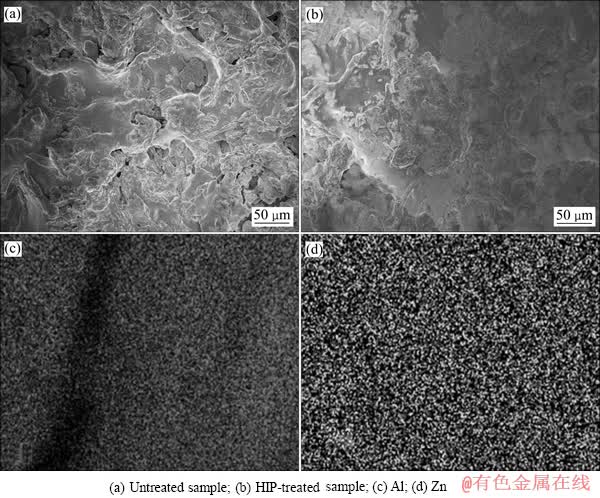

2.2 动电位极化曲线

图4所示为各样品的动电位极化曲线。极化曲线显示电极电位和电流密度之间的关系,通常选用自腐蚀电位和自腐蚀电流作为判定材料耐腐蚀性的标准[14]。根据电化学腐蚀原理,材料的自腐蚀电位越高,自腐蚀电流密度越小,腐蚀速率越慢,即耐蚀性能越好[15]。

从极化曲线测得特征参数自腐蚀电位φcorr、自腐蚀电流密度lg Jcorr、钝化临界电流密度lg Jcr、维钝电流密度lg Jp,其具体数值如表4所列。由表4可知,样品耐腐蚀性能由优到劣的顺序为试样3、试样2、试样1、未处理样品。由图4可以看出,各曲线的相对位置按未处理和HIP温度升高的顺序而向右下方移动,说明经HIP处理后耐腐蚀性能有所提高。从极化曲线的位置和形态上看,200 ℃、1 h、60 MPa HIP处理对涂层耐腐蚀性能影响较小;250 ℃、1 h、100 MPa HIP处理和300 ℃、1 h、150 MPa HIP处理对涂层耐腐蚀性能影响较大,从位置上看,在相同极化电位下,腐蚀电流出现大幅度下降。从形态上看,未处理样品和200 ℃、1 h、60 MPa HIP处理样品的极化曲线未出现钝化平台,极化电流密度随极化电位的增大而快速上升,当极化电位达到-0.75 V附近时,极化电流密度上升速度减缓。250 ℃、1 h、100 MPa HIP处理和300 ℃、1.5 h、150 MPa HIP处理样品的极化曲线在-0.7 V附近出现转折点,极化电流密度开始下降进而趋于平缓,出现了钝化现象,这与HIP处理改变了Al-Zn-Si涂层的组织结构和化学成分密切相关。

图4 样品的动电位极化曲线

Fig. 4 Potentiodynamic polarization curves of samples

表4 Zn-Al-Si涂层在NaCl溶液中的极化曲线特征值

Table 4 Characteristic value of Zn-Al-Si coating’s polarization curve in NaCl solution

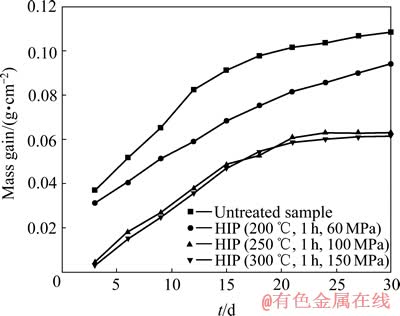

2.3 盐水(3.5%NaCl)全浸实验

图5所示为Al-Zn-Si涂层在3.5% NaCl水溶液中的腐蚀增益曲线。从图5中可以看出,腐蚀增益曲线的相对位置按未处理和HIP温度升高的顺序而向下方移动。说明经HIP处理后,样品在盐水中的腐蚀程度下降,耐腐蚀性能提高,这与极化曲线的分析结果一致。从曲线变化趋势看,未处理样品和经200 ℃、1 h、60 MPa HIP处理样品在浸泡大约20 d后,质量增益曲线的斜率开始下降,这可能是因为Al-Zn-Si合金涂层的腐蚀产物(碱式碳酸锌铝水合物等)逐渐积附在样品表面,这些碱式碳酸锌铝水合物难溶于水,覆盖在涂层表面或沉积在涂层孔隙处,阻碍氧原子、水分子的渗透和腐蚀介质中活性粒子的电荷传递[16-18],使腐蚀电阻增大,腐蚀速率下降,但是两者一直处于腐蚀质量增加的状态,说明未处理样品和200 ℃、1 h、60 MPa HIP处理样品没有产生钝化现象,这在动电位极化曲线的分析已经证实。经250 ℃、1 h、100 MPa HIP处理和经300 ℃、1.5 h、150 MPa HIP处理样品在腐蚀初始阶段速率与未处理样品相近,在腐蚀大约25 d后质量增加速率开始下降,并趋于平缓。这是因为发生了钝化现象,这已在极化曲线的分析中得到证实,钝化膜产生了屏蔽作用,阻碍了涂层进一步腐蚀。

图5 Zn-Al-Si涂层在3.5% NaCl溶液中的腐蚀增益曲线

Fig. 5 Corrosion mass gain curves of Zn-Al-Si coating in 3.5%NaCl solution

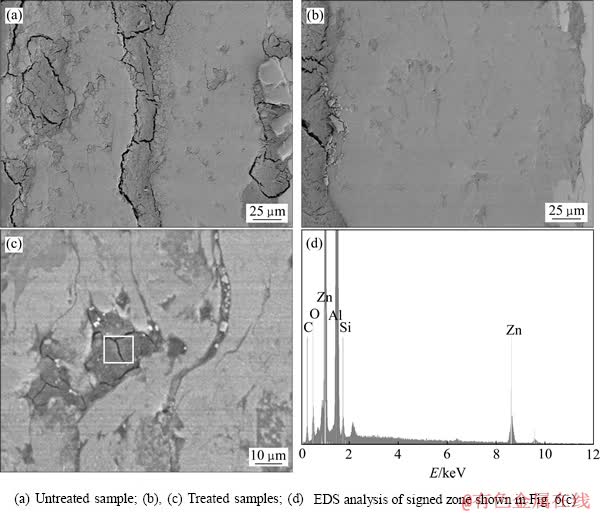

2.4 腐蚀形貌与产物

在3.5% NaCl水溶液中浸泡30 d后的未处理样品和300 ℃、1 h、150 MPa HIP处理样品的截面腐蚀形貌如图6所示。图6(a)所示为未处理样品的腐蚀形貌。由图6(a)可以发现,截面分布着暗灰色块状组织,块状组织与明亮部分分离,之间存在微裂纹。对图6(c)所示暗灰色区域进行能谱分析,结果如图6(d)所示。由图6(d)可知,除了Zn、Al和Si元素外,还出现了C和O等元素,表明暗灰色块状组织为腐蚀产物,锌在腐蚀介质中起化学反应生成不溶性的碱式氧化锌及碱式碳酸锌等腐蚀产物[19-20],这些腐蚀产物填补到涂层的部分孔隙,对延缓涂层的腐蚀起到一定的作用[21-22]。腐蚀通过孔隙深入到涂层内部,孔隙处腐蚀加剧,拓展延伸形成微裂纹,其腐蚀模型为闭塞电池腐蚀。图6(b)所示为经300 ℃、1 h、150 MPa HIP处理样品的腐蚀形貌,相比未处理样品,组织内部未发现明显孔隙和裂纹,说明经HIP处理的Zn-Al-Si合金涂层在盐水全浸环境中腐蚀未深入到涂层内部,腐蚀过程只在表面进行。这是因为经HIP处理后,Zn-Al-Si合金涂层的孔隙基本消除,腐蚀过程中没有腐蚀通道,涂层内部未发生孔蚀和缝隙腐蚀,耐腐蚀性能大幅度提高。

图6 截面微观腐蚀形貌及EDS能谱分析

Fig. 6 Cross section corrosion morphologies((a), (b), (c)) and EDS analysis

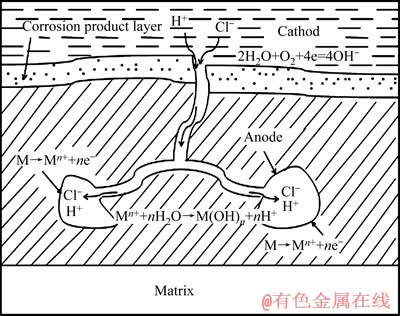

2.5 HIP处理对Al-Zn-Si涂层耐腐蚀性能的影响机理

1) Al-Zn-Si涂层处于盐水全浸环境中时,腐蚀产物在转化过程中被周围的铝相所包围,形成遮挡层[4],起到一定的屏蔽作用,延缓涂层腐蚀,但腐蚀介质相对静止状态和涂层的孔隙结构,导致涂层发生闭塞电池腐蚀[23]。图7所示为Al-Zn-Si涂层闭塞电池腐蚀模型示意图。如图7所示,由于腐蚀产物的覆盖,孔隙内外形成氧浓差,外部介质相对富氧,内部介质相对贫氧。耗氧阴极反应在外部进行:2H2O+O2+4e=4OH-;阳极反应在内部进行:Zn=Zn2++2e、Al=Al3++3e。由于闭塞区内产生过多金属阳离子,在电场作用下,外部Cl-迁移到孔隙内部,同时金属离子发生水解:Zn2++2H2O→Zn(OH)2+2H+;Al3++2H2O→Al(OH)3+3H+,使得H+浓度增加,pH值下降,闭塞区内Cl-及H+促进金属的溶解,又使Cl-迁移增加,pH值进一步降低,产生自催化效应[24],介质重力的影响使孔隙不断向深处发展。涂层孔隙和裂纹的腐蚀拓展、热喷涂涂层表面的不平整结构和Cl-的破坏穿透腐蚀产物层三重因素导致Al-Zn-Si合金涂层表面不能形成完整致密的腐蚀产物膜而形成钝化现象。

图7 Zn-Al-Si涂层闭塞电池腐蚀模型示意图

Fig. 7 Schematic diagram of occluded cell corrosion model of Zn-Al-Si coating

2) 采用热等静压技术对Al-Zn-Si涂层进行处理,使得表面组织变得平整,有利于生成的腐蚀产物连接成完整的钝化膜;合金涂层Zn元素均匀分布,Zn的腐蚀产物能够很快地相互连接成完整的遮挡层[4],产生钝化现象;基本消除涂层内部孔隙结构,避免孔隙处发生闭塞电池腐蚀,降低了腐蚀电流,且有利钝化现象的产生,提高了涂层的抗腐蚀性。

3 结论

1) 采用HIP (200 ℃、1 h、60 MPa)、HIP(250 ℃、1 h、100 MPa)和 HIP(300 ℃、1 h、150 MPa)对电弧喷涂Zn-Al-Si合金涂层进行处理,降低了涂层的孔隙率,随着处理温度的升高和压强的增大,孔隙率呈下降趋势。当采用300 ℃、1 h、150 MPa HIP处理涂层时,孔隙率仅为1.56%,较原始涂层的孔隙率下降了87.15%,孔隙基本消除;300 ℃、1 h、150 MPa HIP处理将Zn-Al-Si涂层表面堆垛层状结构转变为致密平整结构,提高了涂层表面质量。

2) 未经HIP处理的电弧喷涂Zn-Al-Si合金涂层在3.5%NaCl溶液中发生孔隙腐蚀,降低了涂层的防护性能。孔隙和裂纹的腐蚀拓展、热喷涂涂层表面的不平整结构和Cl-的破坏穿透作用,三重因素导致Al-Zn-Si合金涂层表面不能形成完整致密的腐蚀产物膜而产生钝化现象。

3) 300 ℃、1 h、150 MPa HIP处理降低了涂层腐蚀电流密度,涂层的抗腐蚀性能大幅度提高。HIP处理改善了涂层的表面结构,促进Al、Zn元素整体上的均匀分布(其中Al元素在局部发生选择分布),获得致密的内部结构是弧喷涂Zn-Al-Si合金涂层产生钝化现象的重要因素。

REFERENCES

[1] 王 麟, 陶诗君, 萧以德, 萧弘烨 伍建华. 热喷涂鋅-铝合金涂层对钢结构防护性能研究[J]. 公路交通科技, 2010, 9(27): 25-30.

WANG Lin, TAO Shi-jun, XIAO Yi-de, XIAO Hong-ye, WU Jiang-hua. Study on corrosion resistance of spray Zn85Al alloy coating for steel structure[J]. Journal of Highway and Transportation Research and Development, 2010, 9(27): 25-30.

[2] 陈 琳, 张三平, 周学杰. 降低热喷涂涂层孔隙率的工艺技术[J]. 上海金属, 2004, 26(4): 41-43.

CHEN Lin, ZHANG San-ping, ZHOU Xue-jie. The technology for reducing the porosity of thermal spray coating[J]. Shanghai Metals, 2004, 26(4): 41-43.

[3] 李言涛, 姜信德, 侯保荣. 喷涂锌铝(ZAZA)覆盖层在海洋环境中的腐蚀[J]. 腐蚀与防护, 2010, 31(8): 591-594.

LI Yan-tao, JIANG Xin-de, HOU Bao-rong. Corrosion behavior of sprayed zinc-aluminum (ZAZA) coatings in marine environment[J]. Corrosion and Protection, 2010, 31(8): 591-594.

[4] 李春玲. Zn-Al伪合金涂层的制备及耐海洋腐蚀性能研究[D]. 北京: 中国石油大学, 2010.

LI Chun-ling. Preparation and performance study of marine corrosion resistance of the Zn-Al pseudo alloy coating[D]. Beijing: China University of Petroleum, 2010.

[5] MATEOS J, CUETOS J M, VIJANDE R, et al. Tribological properties of plasma sprayed and laser remelted 75/25Cr3C2/NiCr coatings[J]. Tribology International, 2001, 34: 345-351.

[6] SUGEHIS L, LINDA G, MARIANA H S. Correlation between microstructural characteristics and the abrasion wear resistance of sealed thermal-sprayed coatings[J]. Surf Coat Technology, 2005, 200(5): 1310-1314.

[7] 于惠博, 孙宏飞, 武 彬, 刘美淋. 降低涂层孔隙率的研究进展[J]. 材料导报, 2007, 21(1): 68-71.

YU Hui-bo, SUN Hong-fei, WU Bin, LIU Mei-lin. Research progress of reducing coating porosity[J]. Materials Review, 2007, 21(1): 68-71.

[8] ALLAN M L, BERNDT C C. Plasma sprayed Ni-Al coatings for safe ending heat exchanger tubes[R]. DE-AC02-98CHl0886. Washington DC. 1998.

[9] 张羽廷. 热等静压处理对铀表面铝(钛)镀层及界面特性的影响[D]. 绵阳: 中国工程物理研究院, 2010.

ZHANG Yu-tin. Effect of hot isostatic pressing on aluminum (titanium) coating on uranium surface and interface characteristics[D]. Mianyang: China Academy of Engineering Physics, 2010.

[10] 王庆福, 张羽廷, 谢东华, 张鹏程, 刘婷婷. 热等静压处理对铀表面铝镀层耐腐蚀性能的影响[J]. 稀有金属材料与工程, 2011, 40(9): 1671-1675.

WANG Qin-fu, ZHANG Yu-tin, XIE Dong-hua, ZHANG Peng-cheng, LIU Ting-ting. Effect of hot isostatic pressing on corrosion resistance of aluminum coating on uranium surface[J]. Rare Metal Materials and Engineering, 2011, 40(9): 1671-1675.

[11] ZHENG Li-yun, XIONG Wei-hao, YAN Xian-mei, LI Guo-an. Microstructure and mechanical properties of hot isostatically pressed cermets with TiN coatings[J]. Rare Metals, 2006, 25(6): 643-648.

[12] AMINUL I, ZOHEIR N F. The influence of porosity and hot isostatic pressing treatment on wear characteristics of cast and P/M aluminum alloys[J]. Wear, 2011, 271(9/10): 1594-1601.

[13] 周庆生,李俊兰, 阚月琴, 陈增泉. 热喷涂涂层的形成过程和涂层结构的特性[J]. 机械科学与技术, 1990(4): 38-41.

ZHOU Qing-sheng, LI Jun-lan, KAN Yue-qin, CHEN Zeng-quan. Forming course and coating structure characteristics of thermal spraying coating[J]. Mechanical Science and Technology, 1990, 4: 38-41.

[14] 张鉴清. 电化学测试技术[M]. 北京: 化学工业出版社, 2011: 160.

ZHANG Jian-qing. Electrochemical measurement technology [M]. Beijing: Chemical Industry Press, 2011: 160.

[15]  J, URUCHURTU J, GALLIANO F, LANDOLT D. Effect of an inhibitive pigment zinc-aluminum-phosphate (ZAP) on the corrosion mechanisms of steel in waterborne coatings[J]. Prog Org Coat, 2006, 56(2/3): 199-206.

J, URUCHURTU J, GALLIANO F, LANDOLT D. Effect of an inhibitive pigment zinc-aluminum-phosphate (ZAP) on the corrosion mechanisms of steel in waterborne coatings[J]. Prog Org Coat, 2006, 56(2/3): 199-206.

[16] LIU Yan, ZHU Zi-xin, CHEN Yong-xiong, XU Bin-shi, MA Shi-ning, LI Zhou-xin. Electrochemical corrosion behavior of arc sprayed Zn-Al coatings[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(S1): s443-s445.

[17] YADAV A P, KATAYAMA H, NODA K, MASUDA H, NJSHIKATA A, TSURU T. Effect of Al on the galvanic ability of Zn-Al coating under thin layer of electrolyte[J]. Electrochimica Acta, 2007, 52(7): 2411-2422.

[18] PENG D Q, BAI X D, CHEN X W, ZHOU Q C, LIU X Y, YU R H. Comparison of electrochemical behavior of zirconium and zircaloy-4 implanted with Y and Ce ions[J]. Applied Surface Science, 2004, 221(1/4): 259.

[19] 韩树民, 郑炀曾, 于升学, 徐军明. 锌铝铬膜的防腐性能与机理[J]. 中国有色金属学报, 2002, 12(3): 619-623.

HAN Shu-min, ZHENG Yang-zeng, YU Sheng-xue, XU Jun-ming. Corrosion prevention characteristics and mechanism of zinc-aluminum-chromium coating[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 619-623.

[20] 杨振波, 杨忠林, 郭万生, 宋广成. 鳞片状富锌涂层耐蚀机理的研究[J]. 中国涂料, 2006, 21(1): 19-21.

YANG Zheng-bo, YANG Zhong-lin, GUO Wan-sheng, SONG Guang-cheng. Study on the anticorrosion mechanism of flake zinc-rich coatings film[J]. China Coatings, 2006, 21(1): 19-21.

[21] 蒋 穹, 缪 强, 姚正军, 魏小昕. 水性Zn-Al-Si合金涂层微观组织及腐蚀性能研究[J]. 中国腐蚀与防护学报, 2012, 32(4): 311-316.

JIANG Qiong, MIU Qiang, YAO Zheng-jun, WEI Xiao-xin. Microstructure and corrosion properties of Waterborne Zn-Al-Si alloy coating[J]. Chinese Journal of Corrosion and Protection, 2012, 32(4): 311-316.

[22] 刘安强, 肖 葵, 董超芳, 王恩清, 魏 丹, 高 瑾, 李晓刚. 电弧喷涂锌铝伪合金涂层的耐中性盐雾腐蚀性能[J]. 材料保护, 2011, 44(12): 12-15.

LIU An-qiang, XIAO Kui, DONG Chao-fang, WANG En-qing, WEI Dan, GAO Jin, LI Xiao-gang. Corrosion behavior of arc sprayed zinc-aluminum pseudo-alloy coatings in neutral salt-fog environment[J]. Materials Protection, 2011, 44(12): 12-15.

[23] 刘幼平. 蚀孔、缝隙及裂缝内闭塞电池腐蚀行为及其控制方法. Ⅰ: 闭塞电池腐蚀理论研究方法及微区环境效应[J]. 腐蚀与防护, 1995, 16(3): 110-114.

LIU You-ping. Occluded cell corrosion behavior and its control method within corrosion hole, slot and cracks. Ⅰ: Theory research method and Microenvironment effect of occluded cell corrosion[J]. Corrosion and Protection, 1995, 16(3): 110-114.

[24] 曹楚南. 腐蚀电化学原理[M]. 北京: 化学工业出版社, 1985: 323.

CAO Chu-nan. Principles of corrosion electrochemistry[M]. Beijing: Chemical Industry Press, 1985: 323.

(编辑 陈卫萍)

基金项目:江苏产学研联合创新资金-前瞻性联合研究项目(BY2011101);江苏省普通高校研究生科研创新计划资助项目(CXLX12_0149)

收稿日期:2012-11-13;修订日期:2013-08-20

通信作者:姚正军,教授,博士;电话:13951818597;E-mail: yaozj@nuaa.edu.cn