DOI: 10.11817/j.ysxb.1004.0609.2020-35745

机械活化强化钒渣钙化提钒工艺

黄青云1,向俊一2, 3,裴贵尚2,王 鑫2,吕学伟2, 3

(1. 重庆科技学院 冶金与材料学院,重庆 401331;

2. 重庆大学 材料科学与工程学院,重庆 400044;

3. 重庆大学 钒钛冶金及新材料重庆市重点实验室,重庆 400044)

摘 要:针对转炉钒渣钙化焙烧酸浸工艺中存在的钒转浸率低的问题,采用高能球磨对钒渣进行活化预处理,以期强化其提钒效果。采用激光粒度分析仪、BET比表面积测定仪和XRD对活化前后钒渣进行了粒度、比表面积及物相结构分析;采用浸出实验研究了机械活化对钙化焙烧和浸出的影响规律。结果表明:机械活化法增大了钒渣的比表面积,增加了晶格畸变与微观应力,使含钒物相充分解离,由此可改善钒渣钙化焙烧的动力学条件。在浸出20 min条件下,机械活化80 min可将钒浸出率提高10%,最佳焙烧温度降低100 ℃。

关键词:钒渣;机械活化;钙化焙烧;酸浸;浸出率

文章编号:1004-0609(2020)-04-0858-08 中图分类号:TF111 文献标志码:A

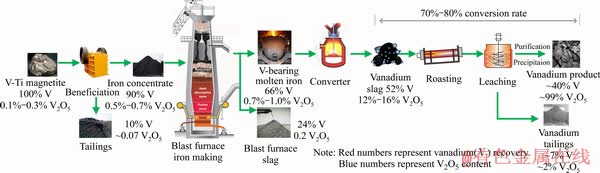

我国具有丰富的钒钛磁铁矿资源,主要分布在四川攀西和河北承德地区[1-2]。在上述地区主要采用钒钛磁铁精矿高炉冶炼-铁水提钒-钒渣生产氧化钒工艺[3-4]。该工艺是以钢铁生产为主提钒为辅的工艺,也是目前钒钛磁铁精矿回收钒最主要和经济的工艺。以攀钢现有的选冶流程为例,钒元素在钒钛磁铁矿选冶提钒流程中的走向如图1所示。

从图1可以看出,钒钛磁铁矿中钒元素在选矿、高炉冶炼、转炉提钒、钒渣焙烧浸出过程的作业回收率分别达到了90%、73%、79%、75%。从单个流程的回收率来看,高炉冶炼、转炉吹钒、钒渣焙烧浸出过程的回收率仍有一定的提升空间。要提高钒在高炉过程中的回收率,则需要进一步提高高炉的还原率,但是生产实践已经证明,在目前钒钛矿比例已达到65%的情况下,提高高炉的还原率存在较大的风险。由于进一步提高高炉还原率会促进钛的还原,导致泡沫渣和渣铁难分等一系列影响炉况顺行的问题[5-6]。转炉提钒不仅要在有限的时间内做到“脱钒保碳”,自身工艺要求极为苛刻,工艺控制窗口小,操作难度较大,而且还受到了铁水预处理和后续连铸工序的双重制约[7]。与炼铁主流程相比,钒渣的焙烧和浸出流程则是相对独立的,其工艺参数调整的空间较大。因此,提高钒渣焙烧和浸出过程钒的回收率对全流程钒回收率的贡献是最有效可行的。

钠化焙烧和钙化焙烧工艺是目前最成熟的两种以转炉钒渣为原料的提钒工艺,但钠化工艺由于排放腐蚀性气体和高盐废水,环境污染严重[8]。钙化提钒是一种可替代传统钠化提钒的清洁生产工艺,也是未来的发展方向[8-9]。该工艺不排放有害气体,废水可以全部在提钒厂内循环,而且提钒尾渣不含碱金属,三废处理成本大幅下降[10-11]。2009年以前,俄罗斯图拉提钒厂是全球唯一采用该工艺进行钒渣提钒的企业,于1974年建成并投产。攀钢于上世纪90年代开始对该工艺进行研究,并于2011年底将该工艺推广到生产线,在攀钢集团西昌钢钒有限公司钒制品厂应用,设计钒渣年处理能力达16万t。虽然目前工艺流程已打通,但仍存在钒回收率低的缺点[12]。然而,钙化提钒工艺仍存在钒回收率低的缺点。

图1 钒在钒钛磁铁矿选冶提钒流程中的走向

Fig. 1 Trend of vanadium during vanadium extraction process from V-Ti magnetite

钒渣焙烧浸出提钒工艺的基本原理是通过高温物相重构使钒渣中的钒铁尖晶石转化为可溶性的钒酸盐。因此,提高高温物相重构过程中可溶性钒酸盐的转化率并提高后续浸出过程的溶解率是提高钒回收率的关键。从焙烧过程来看,一是部分钒未能生成可溶性的钒酸盐导致钒转化率不足;二是高温物料烧结导致部分钒被玻璃相包裹无法被有效浸出。钙化焙烧过程中随着温度的升高(660~900 ℃)钒酸盐的形态由少量浸染状逐渐向微质点、无定形熔态带状变化,并向渣粒外侧迁移,高于900 ℃渣中出现液相阻碍氧化反应[13]。在生产中当焙烧温度高于900 ℃会导致烧成带距离延长,加上金属铁氧化的局部放热效应,会使物料严重烧结,造成回转窑结圈,严重影响生产顺行[14]。从浸出过程来看,一是焙烧过程产生的多种钒酸钙盐在酸中的溶解度存在差异[15-16];二是副产物硫酸钙对钒渣熟料的包裹作用,会抑制浸出过程[17-18]。

针对上述两个方面,从热力学角度出发提高回转窑内的焙烧温度可提高焙烧效率,然而由于受原料中硅含量和氧化亚铁含量的影响,提高温度极易造成原料的烧结形成结圈。实际生产中可行的是改善氧化过程的动力学条件,在回转窑本身已经固定的情况下,提高原料的混合效果、增加反应物的接触面积是一条可选途径。有研究者发现一个效应,并将其称作“机械活化”。即矿物在机械力作用下会产生晶格畸变和局部破坏,并形成各种缺陷,导致其内能增大,反应活性增强,从而可以改变矿物反应的条件[19]。最近的研究表明,机械力对物质的作用可以归纳为3种机理:1) 物理效应,包括颗粒和晶粒细化、产生裂纹、表观和真密度变化、比表面积增大等;2) 结晶态变化,包括产生晶格缺陷、晶格发生畸变、结晶程度降低甚至无定形化、晶型转变等;3) 化学变化,包括结晶水或羟基的脱除,降低体系反应活化能,形成新化合物的晶格或细晶、形成合金或固溶体、化学键的断裂及体系发生化学变化等[20-21]。

鉴于机械活化工艺可以提高颗粒的表面能,从而使实际的化学反应可以在更接近于理论最低温度下发生,并且在热力学条件相同的情况下,可以改善化学反应的动力学条件。因此,本文采用机械活化强化钒渣钙化法提钒,系统地研究了机械活化对钒渣形貌变化及其对钙化焙烧与浸出过程的强化作用。

1 实验

1.1 实验原料和仪器

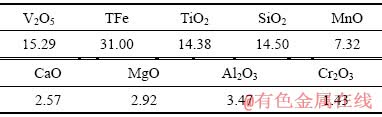

实验原料为攀钢生产的转炉钒渣,经手工去除块铁,球磨-磁选所得钒渣精粉的化学成分见表1。钙化焙烧所用添加剂为分析纯CaCO3粉末,呈方解石晶型。

表1钒渣的化学成分

Table 1 Chemical compositions of vanadium slag (mass fraction, %)

采用行星式球磨机(Retsch PM100)对样品进行机械活化;采用高温综合热分析仪(Setsys EVO TG-DTA 1750)进行热重分析;采用电感耦合等离子发射光谱仪(Thermo Fisher ICAP 6000)测定元素含量;采用X射线衍射仪(Rigaku D/max 2500 PC)分析进行物相分析;采用激光粒度分析仪(Malvern Mastersizer 2000)进行粒度分析;采用全自动比表面积孔径分析仪(Micromeritics ASAP 2020M)进行比表面积分析,采用扫描电镜(Tescan vega 3 LMH)进行表面形貌分析。

1.2 实验方法

钒渣机械活化:为了避免球磨对混料的影响,球磨时不配加碳酸钙仅单独球磨钒渣样品。将100 g未球磨钒渣样品与500 g直径为10 mm氧化锆球一同装入锆质研磨罐中,锁紧研磨盖,然后从气阀中充入高纯氩气(99.999%)做保护气,以400 r/min转速球磨一定时间得到机械活化钒渣样品。

钒渣热重实验:钒渣样品的氧化热重实验在高温综合热分析仪中进行,每次实验样品量为100 mg,采用瓶装空气为反应气体(O2 21%、N2 79% (体积分数)),气体流量20 mL/min,以10 ℃/min的升温速率从室温加热至1100 ℃。

钒渣钙化焙烧:将100 g活化钒渣样品与12.3 g碳酸钙在混料机中充分混匀,然后称取20 g装入直径50 mm的刚玉坩埚中,然后在马弗炉内设定温度下进行氧化焙烧。为了保证足够的空气进入炉膛内,在焙烧过程中保持马弗炉门半开状态。焙烧2 h后取出坩埚空冷至室温。随后球磨筛分至所有颗粒粒径小于75 μm,用于后续浸出。

焙烧熟料浸出:实验前先将300 mL浸出液加热至50 ℃,然后加入20 g钒渣熟料,通过不断滴加15%硫酸调节浸出溶液pH始终为2.5±0.2。浸出结束后,迅速将浸出浆料固液分离,测定滤液中的钒含量,计算钒浸出率 :

:

式中:V为浸出滤液体积,mL; 为浸出液的钒浓度,g/mL;m为实验所用钒渣熟料的质量,g;w为实验所用钒渣熟料的钒含量,%。

为浸出液的钒浓度,g/mL;m为实验所用钒渣熟料的质量,g;w为实验所用钒渣熟料的钒含量,%。

2 结果与讨论

2.1 机械活化对钒渣物理性质的影响

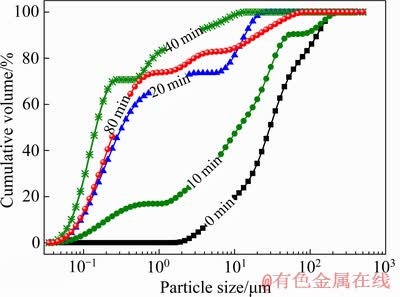

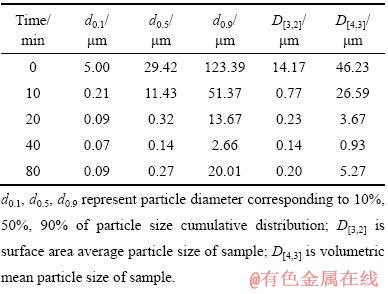

不同活化时间下钒渣样品的粒度分布曲线如图2所示,其粒度特征值见表2。随着活化时间由0 min延长至40 min,钒渣样品的粒度分布明显向粒度尺寸较小的方向移动,但延长活化时间至80 min,钒渣样品的粒度分布曲线反而略微向粒度尺寸较大的方向移动。由表2亦可见,活化时间由0 min逐渐延长至40 min时,钒渣的粒径d0.9由123.39 μm急剧降低至2.66 μm,继续延长活化时间至80 min,钒渣的粒径d0.9反而增大至20.01 μm。这是由于已细化的微小颗粒在表面能、范德华力及静电力等的作用下相互团聚成二次颗粒导致的粒度的“增大”。从体积平均粒径D[4,3]可以明显看出,钒渣样品粒度随活化时间的变化,当活化时间延长至20 min时,体积平均粒径由46.23 μm急剧降低至3.67 μm;当活化时间延长至40 min时,体积平均粒径继续降低至最低值0.93 μm;当延长至80 min时,钒渣粒径团聚的体积平均粒径略微增加至5.27 μm。

图2 不同活化时间钒渣的粒度分析

Fig. 2 Particle size analysis for vanadium slag with different activation time

表2 不同活化时间钒渣粒度特征值

Table 2 Characteristic particle size value for vanadium slag with different activation time

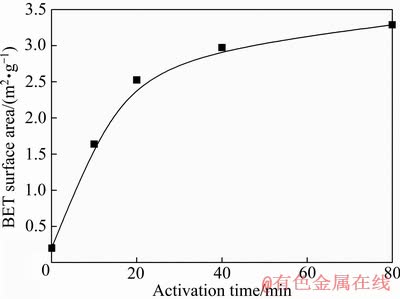

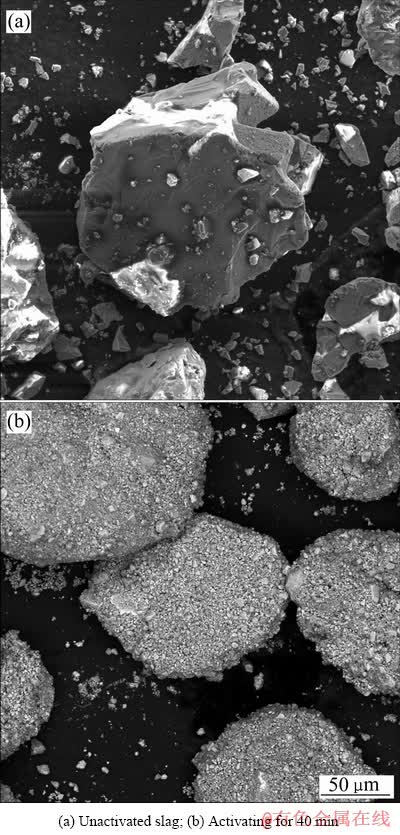

不同活化时间下钒渣样品的BET比表面积测试结果如图3所示。未活化钒渣BET比表面积仅0.19 m2/g,机械活化20 min比表面积增大了13倍,达到2.5 m2/g。活化时间大于20 min时,BET比表面积随着活化时间的延长继续增加,但增幅较小。从图4扫描电镜图可以看出,机械活化之后钒渣颗粒由光滑的棱角状转变为近似球形的圆球状,颗粒直径减小至几微米,颗粒的粗糙程度显著增加,微小的颗粒明显团聚,形成二次颗粒。

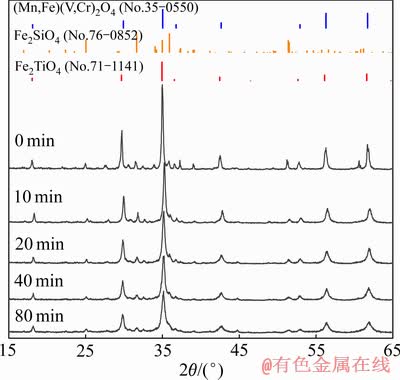

不同活化时间钒渣样品的XRD谱如图5所示。其主要物相为钛尖晶石(Fe2TiO4)、钒尖晶石((Mn,Fe) (V,Cr)2O4)和铁橄榄石(Fe2SiO4)。随着活化时间的延长,钒渣主要物相未发生改变,但特征衍射峰逐渐宽化,强度明显减弱,这说明机械活化过程中研磨球的冲击能量改变了样品的晶面间距,使得键耦合解离,从而产生了晶格畸变。机械活化对钒渣物相结构的影响一是晶粒尺寸的细化,二是微观应变的增加。随着粉碎的进行,晶格畸变加重,微观应变增加,晶粒尺寸减小,部分机械能逐渐转化为晶体的内能,使之处于不稳定状态。内能增大的直接结果是样品的活性提高,这将使得样品在后续的反应中反应速率提高,反应限度增大,反应温度降低。从图中还可以看出,特征衍射峰的位置也随着活化时间的延长逐渐向小角度偏移,这也是由应力的增加引起的。

图3 不同活化时间钒渣的BET比表面积

Fig. 3 BET surface area for vanadium slag with different activation time

图4 不同活化时间钒渣的SEM像

Fig. 4 SEM images of vanadium slag with different activation time

图5 不同活化时间钒渣的XRD谱

Fig. 5 XRD patterns of vanadium slag with different activation time

2.2 机械活化对钒渣焙烧的影响

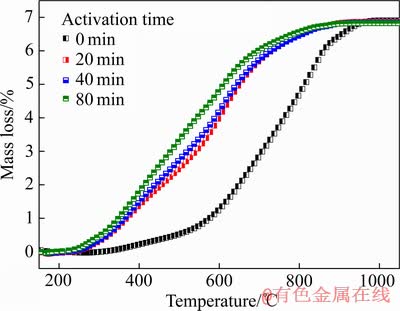

不同活化时间钒渣样品的非等温热重曲线如图6所示。升温速率为10 ℃/min,反应气为空气(O2 21%、N2 79% (体积分数))。实验结果表明,未活化钒渣的热重曲线与活化钒渣的热重曲线区别明显,未活化钒渣在200~500 ℃区间内质量增加缓慢;在600~800 ℃区间内,质量快速增加,高于约800 ℃后,质量增加速率逐渐降低,质量增加趋于稳定;然而活化20、40和80 min的钒渣在温度300~700 ℃区间以几乎恒定的速率实现质量快速增加;高于700 ℃后,质量增加速率逐渐降低,且质量增加逐渐趋于稳定。

图6 机械活化钒渣氧化的TG曲线(10 ℃/min)

Fig. 6 TG curves for oxidation of mechanically activated slag (Heating rate of 10 ℃/min)

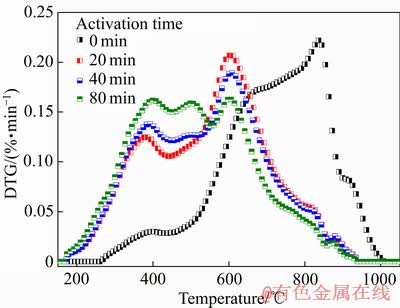

不同活化时间的钒渣的DTG曲线如图7所示。钒渣化学成分复杂,在氧化焙烧时发生的化学反应较多,这导致了DTG曲线出现了3~4个峰,说明在这些峰位置发生了不同的化学反应导致了DTG值的变化。钒渣活化时间越长,DTG曲线的峰形越完整。钒渣中各个物相的氧化在热力学上是存在明显差异的,但是对于未活化钒渣动力学的扩散过程掩盖了热力学上的差异,使得多个DTG的特征峰未能凸显。机械活化使得钒渣中各个物相解离的更加充分,进而使各个物相的氧化反应区分度增大,各反应的竞争作用逐渐减弱。

图7 机械活化钒渣氧化的DTG曲线(10 ℃/min)

Fig. 7 DTG curves for oxidation of mechanically activated slag (Heating rate of 10 ℃/min)

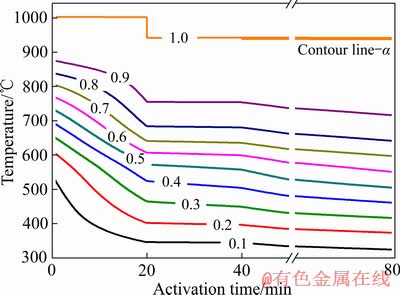

机械活化显著提高了钒渣在低温下的氧化速率,降低了氧化温度。根据图6钒渣氧化的TG数据,可以绘制出不同活化时间和氧化焙烧温度下钒渣氧化率的等值线图,如图8所示。从图8中可以看出,机械活化对焙烧温度的降低影响显著,其中活化20 min对焙烧温度的降低最为明显,活化时间超过20 min后,虽然降低了焙烧温度,但效果不明显。在达到同样的转化率0.9时,未活化钒渣的非等温焙烧温度需要876 ℃,活化20 min后温度降低到了754 ℃,延长活化时间至80 min,焙烧温度继续降低至716 ℃。

2.3 机械活化对钒渣浸出的影响

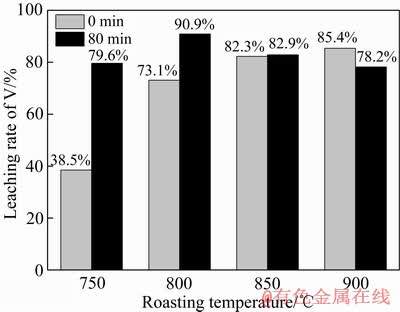

将未活化钒渣与活化80 min钒渣分别配加碳酸钙粉末后在相同的温度下焙烧2 h,空冷后均破至粒度小于75 μm,然后按上述实验部分给出的条件浸出60 min。钒浸出率结果见图9。

图8 不同机械活化时间和温度下的氧化率等值曲线(10 K/min)

Fig. 8 Oxidation degree isograms versus activation time and oxidation temperature (Heating rate of 10 K/min)

由图9可以看出,未活化钒渣在750 ℃时钙化焙烧不充分导致钒浸出率不足40%,提高焙烧温度至800 ℃,钒浸出率急剧增大至73%,继续提高焙烧温度至850 ℃和900 ℃时,钒浸出率逐步提高至85.4%。然而机械活化80 min钒渣中钒浸出率随着焙烧温度呈先增后减的趋势,在800 ℃时钙化焙烧效果最佳,钒浸出率达90.9%,继续提高焙烧温度至850 ℃甚至更高时,钒的浸出率反而下降。提高焙烧温度一方面可以促进酸溶性钒酸钙生成,另一方面又使硅酸盐玻璃相对钒酸盐相的包裹作用增强。当焙烧温度过高,玻璃相的包裹作用逐渐凸显出来,钒的浸出率受扩散阻力的增大反而降低。

图9 机械活化对钙化焙烧效果的影响

Fig. 9 Effect of mechanical activation and roasting temperature on leaching of vanadium

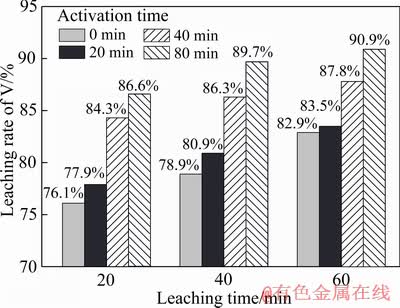

机械活化时间对钒浸出率的影响如图10所示。由图10可知,钒的浸出率随着活化时间的延长逐步提高。当浸出时间为20 min时,未活化钒渣中钒的浸出率约为76%,而活化80 min钒渣中钒的浸出率接近87%。随着活化时间的延长,浸出时间明显缩短,未活化及活化20 min钒渣在浸出时间为20~60 min范围内,钒的浸出率始终在缓慢增大,然而对于活化40 min和80 min的钒渣在浸出20 min后钒的浸出率增长十分缓慢,在浸出40 min后钒的浸出率几乎稳定。活化时间由20 min延长至40 min对钒浸出率的贡献最为明显,而由40 min延长至80 min对钒浸出率的贡献开始减弱。由此可见,延长活化时间不仅有利于提高钒的浸出率,而且可以缩短浸出时间。

图10 活化时间对钒浸出率的影响

Fig. 10 Effect of activation time on leaching efficiency of vanadium

机械活化对钒浸出率的影响有多方面的原因,一是机械活化后的钒渣中物相能够充分解离,焙烧过程中钒尖晶石与碳酸钙转化为钒酸钙的转化率更高,使得可溶性钒含量提高;二是机械活化后钒渣表面的多孔结构有利于浸出;三是高能球磨对钒渣引起的活化作用使钒渣处于不稳定态,使得化学反应更容易发生,进而降低了浸出活化能。

从以上实验数据中对比分析可得:当机械活化时间较短时(小于40 min),机械活化对钒渣的物理效应占主导作用,随着活化时间延长样品粒度明显降低,比表面积显著增大,钒渣氧化率明显提高,钒浸出率也明显提升,这主要是由于反应界面增大所致;当机械活化时间较长时(大于40 min),钒渣的粒度和比表面积基本已趋于稳定,并且出现了明显的团聚现象,钒渣氧化率与浸出率提升均不明显,这时机械活化的主要作用是矿物的晶格畸变。从整个机械活化钒渣提钒过程来看,比表面积增大起主要作用,矿物的晶格畸变起次要作用。

3 结论

1) 机械活化对钒渣样品的物理性质影响显著,随活化时间的延长样品的粒度先急剧减小后由于团聚又略微增大,同时比表面积也逐渐增大。随着活化时间的延长样品的晶格畸变加剧,微观应力增加,晶粒尺寸减小。

2) 钒渣的非等温氧化热分析表明机械活化显著提高了钒渣在低温段(300~600 ℃)的氧化速率;机械活化改善了钒渣中各物相反应的氧化动力学条件;在相同的氧化率条件下,机械活化将钒渣的氧化温度降低了100 ℃左右。

3) 机械活化对提钒效果影响较大,延长活化时间可以提高钒的浸出率,缩短浸出时间,浸出时间为20 min时,活化80 min可将钒浸出率由76%提高至近87%。机械活化也可在一定程度上降低钙化焙烧温度,活化80 min可将钙化焙烧最佳温度降低100 ℃。

REFERENCES

[1] 赵海燕. 钒资源利用概况及我国钒市场需求分析[J]. 矿产保护与利用, 2014(2): 54-58.

ZHAO Hai-yan. Analysis of vanadium resources utilization and demand for vanadium in China[J]. Conservation and Utilization of Mineral Resources, 2014(2): 54-58.

[2] 孙朝晖. 钒新技术及钒产业发展前景分析[J]. 钢铁钒钛, 2012, 33(1): 1-7.

SUN Zhao-hui. Analysis on new vanadium technologies and prospects of vanadium industry[J]. Iron Steel Vanadium Titanium, 2012, 33(1): 1-7.

[3] 付自碧. 钒钛磁铁矿提钒工艺发展历程及趋势[J]. 中国有色冶金, 2011(6): 29-33.

FU Zi-bi. Development process and trends of vanadium extraction from vanadium-titanium magnetite ore[J]. China Nonferrous Metallurgy, 2011(6): 29-33.

[4] TAYLOR P R, SHUEY S A, VIDAL E E, GOMEZ J C. Extractive metallurgy of vanadium-containing titaniferous magnetite ores: A review[J]. Minerals and Metallurgical Processing, 2006, 23(2): 80-86.

[5] MARTINSSON J, GLASER B, DU Si-chen. Study on apparent viscosity of foaming slag-cold model and high temperature experiments[C]//Advances in Molten Slags, Fluxes, and Salts: Proceedings of the 10th International Conference on Molten Slags, Fluxes and Salts 2016. Washington: Springer International Publishing, 2016: 431-438.

[6] ZHU Tai-xi, COLEY K S, IRONS G A. Progress in slag foaming in metallurgical processes[J]. Metallurgical and Materials Transactions B, 2012, 43(4): 751-757.

[7] KARPOV A A, KOZLOV V A. Theoretical representations of formation of vanadium-bearing manganese converter slag[J].Metallurgy, 2000, 44(8): 408-413.

[8] XIANG Jun-yi, HUANG Qing-yun, Lü Xue-wei, BAI Chen-guang. Extraction of vanadium from converter slag by two-step sulfuric acid leaching process[J]. Journal of Cleaner Production,2018, 170: 1089-1101,

[9] LI Hong-yi, WANG Kang, HUA Wei-hao, ZHAO Yang, ZHOU Wang, XIE Bing. Selective leaching of vanadium in calcification-roasted vanadium slag by ammonium carbonate[J]. Hydrometallurgy, 2016, 160: 18-25.

[10] WEN Jing, JIANG Tao, XU Ying-zhe, LIU Jia-yi, XUE Xiang-xin. Efficient separation and extraction of vanadium and chromium in high chromium vanadium slag by selective two-stage roasting-leaching[J]. Metallurgical and Materials Transactions B, 2018, 49: 1471-1481.

[11] ZHANG Ju-hua, ZHANG Wei, ZHANG Li, GU Song-qing. Mechanism of vanadium slag roasting with calcium oxide[J]. International Journal of Mineral Process, 2015, 138: 20-29.

[12] 王春琼, 杨 兵, 刘学志, 熊开伟, 严 勇, 孙玉中. 降低钙化焙烧酸性提钒残渣中可溶钒研究[J]. 钢铁钒钛, 2017, 38(5): 26-30.

WANG Chun-qiong, YANG Bing, LIU Xue-zhi, XIONG Kai-wei, YAN Xiong, SUN Yu-zhong. Study on reducing soluble vanadium content in the residue after sulfuric acid leaching of vanadium slag roasted with calcium oxide[J]. Iron Steel Vanadium Titanium, 2017, 38(5): 26-30.

[13] 付念新, 张 林, 刘武汉, 赵 博, 涂赣峰, 隋智通. 钒渣钙化焙烧相变过程的机理分析[J]. 中国有色金属学报, 2018, 28(2): 377-386.

FU Nian-xin, ZHANG Lin, LIU Wu-han, ZHAO Bo, TU Gan-feng, SUI Zhi-tong. Mechanism analysis of phase transformation process in calcified roasting of vanadium slags[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(2): 377-386.

[14] 王春琼, 刘武汉, 刘恢前, 朱福平, 张 林, 孙玉中. 钒渣钙化焙烧烧结现象研究[J]. 钢铁钒钛, 2013, 34(6): 6-11.

WANG Chun-qiong, LIU Wu-han, LIU Hui-qian, ZHU Fu-ping, ZHANG Lin, SUN Yu-zhong. Research on sintering phenomenon during calcination of vanadium slag[J]. Iron Steel Vanadium Titanium, 2013, 34(6): 6-11.

[15] 尹丹凤, 彭 毅, 孙朝晖, 何文艺. 攀钢钒渣钙化焙烧影响因素研究及过程热分析[J]. 金属矿山, 2012(4): 91-94.

YIN Dan-feng, PENG Yi, SUN Zhao-hui, HE Wen-yi. Influencing factors of calcified roasting and thermal analysis to the process of vanadium slag produced from Pangang[J]. Metal Mine, 2012(4): 91-94.

[16] 范 坤, 李曾超, 李子申, 王炜鹏, 章苇玲, 郑海燕, 沈峰满. 不同钙化剂对高钒渣酸浸提钒的影响[J]. 重庆大学学报(自然科学版), 2015, 38(5): 151-156.

FAN Kun, LI Zeng-chao, LI Zhi-shen, WANG Wei-peng, ZHANG Wei-ling, ZHENG Hai-yan, SHEN Feng-man. Effect of different calcification agents on vanadium extraction from high-vanadium slag by calcified roasting-acid leaching[J]. Journal of Chongqing University (Natural Science), 2015, 38(5): 151-156.

[17] 张菊花, 张 伟, 张 力, 顾松青. 酸浸对钙化焙烧提钒工艺钒浸出率的影响[J]. 东北大学学报(自然科学版), 2014, 35(11): 1574-1578.

ZHANG Ju-hua, ZHANG Wei, ZHANG Li, Gu Song-qing. Effect of acid leaching on the vanadium leaching rate in process of vanadium extraction using calcium roasting[J]. Journal of Northeastern University (Natural Science), 2014, 35(11): 1574-1578.

[18] ZHAO Yang, LI Hong-yi, YIN Xu-chen, YAN Zhi-ming, YAN Xiao-man, XIE Bing. Leaching kinetics of calcification roasted vanadium slag with high CaO content by sulfuric acid[J]. International Journal of Mineral Processing, 2014, 133: 105-111.

[19] PETER B. Mechochemistry in nanoscience and minerals engineering[M]. Germany: Springer Science & Business Media, 2008: 257-292.

[20] ROGACHEV A S. Mechanical activation of heterogeneous exothermic reactions in powder mixtures[J]. Russian Chemical Reviews, 2019, 88 (9): 875-900.

[21] WEI Bo, ZHANG Yi-min, BAO Shen-xu. Preparation of geopolymers from vanadium tailings by mechanical activation[J]. Construction and Building Materials, 2017, 145: 236-242.

Mechanical activation on extraction of vanadium from vanadium slag by calcification roasting-acid leaching process

HUANG Qing-yun1, XIANG Jun-yi2, 3, PEI Gui-shang2, WANG Xin2, Lü Xue-wei2, 3

(1. College of Materials and Metallurgical Engineering, Chongqing University of Science and Technology, Chongqing 401331, China;

2. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

3. Chongqing Key Laboratory of Vanadium-titanium Metallurgy and Advanced Materials, Chongqing University, Chongqing 400044, China)

Abstract: In order to account the fact that the extraction of vanadium from vanadium-bearing converter slag by calcification roasting-acid leaching process is limited, an attempt was exploited for improving the extraction of vanadium with high energy ball milling pretreatment. The particle size distribution, specific surface area and phase transformation of the vanadium slag before and after activation were investigated by laser diffraction particle size analyser, micro-pore physisorption analyser, and XRD, respectively. The effects of mechanical activation on the calcification roasting and leaching were also investigated. The results demonstrate that the mechanical activation significantly increases the specific surface area, lattice distortion, and microscopic stress of the vanadium slag, and reduces the particle size, thus improves the kinetic conditions of the calcification roasting. Under the condition of leaching for 20 min, the leaching efficiency of vanadium can be increased by 10% by mechanical activation for 80 min, and the optimal roasting temperature can be reduced by 100 ℃.

Key words: vanadium slag; mechanical activation; calcification roasting; acid leaching; leaching fraction

Foundation item: Project(2018M640898) supported by China Postdoctoral Science Foundation; Project(51404047) supported by the National Natural Science Foundation of China

Received date: 2019-04-08; Accepted date: 2019-10-23

Corresponding author: XIANG Jun-yi; Tel: +86-23-65112631; E-mail: xiangjunyi126@126.com

(编辑 李艳红)

基金项目:中国博士后科学基金资助项目(2018M640898);国家自然科学基金青年科学基金资助项目(51404047)

收稿日期:2019-04-08;修订日期:2019-10-23

通信作者:向俊一,助理研究员,博士;电话:023-65112631;E-mail:xiangjunyi126@126.com