DOI: 10.11817/j.ysxb.1004.0609.2020-35867

气雾化粉末制备用组合式分离器分离性能的数值模拟及实验研究

刘 杨,张国庆,许文勇,郑 亮,李 周

(中国航发北京航空材料研究院 先进高温结构材料重点实验室,北京 100095)

摘 要:基于计算流体力学模拟技术(CFD)和实验结合的方法,设计了一种用于气雾化制粉设备的组合式分离器,开展了高温合金粉末分离性能研究,旨在利用不同结构分离器性能差异直接在制粉过程中实现粗细颗粒分级分离。结果表明,在氩气流量400 m3/h、粉末流量1 kg/min的工况条件下,C1结构的分离器对细微颗粒分离效率偏低,而C2结构的分离器对细微颗粒保持较高的分离效率,两种结构分离器组合能有效地实现粗细颗粒分级分离,从而达到缩短选区激光熔化用金属粉末制备周期和降低成本的目的。

关键词:组合式分离器;数值模拟;气雾化制粉;选区激光熔化

文章编号:1004-0609(2020)-12-2940-11 中图分类号:TF23 文献标志码:A

选区激光熔化(Selective laser melting,SLM)技术是目前最为成熟的金属增材制造技术之一,通过三维模型切片化,激光按设定的路径扫描粉末床,逐层熔化凝固成形,最终实现复杂零件的快速制备,在航空航天、生物医疗、高性能模具等领域得到了广泛的应用[1-5]。

SLM工艺采用金属粉末为原材料,要求粉末具有粒度细小(一般为15~53 μm)、粒度分布集中、球形度高、纯净度较好的特点[6]。目前,国际主流的选区激光熔化用金属粉末主要采用气雾化制粉技术制备,该方法具有细颗粒收得率高(<53 μm)、球形度较高、成本相对较低的优势[7-9]。SLM技术对粉末粒度分布要求不同于传统的粉末冶金工艺,需要去除粒径在15 μm以下的细微颗粒,这是因为其比表面积较大,容易出现团聚,破坏粉末床的连续性和均匀性,影响零件成形性能。然而,由于细微颗粒去除难度较大,采用筛分或分级的方法会增加生产成本,延长生产周期,因此,制备细微颗粒含量较少的金属粉末是降低生产成本的有效途径,也是气雾化制粉领域面临的一个挑战[10-12]。

典型的气雾化制粉过程分为熔炼、雾化、液滴凝固和粉末分离四个阶段,母合金材料通过真空感应熔炼转变为液态熔体,经过导流系统与高速惰性气流交汇,在黏性剪切力作用下破碎为细小液滴,液滴凝固为粉末后被分离器分离于粉罐中[13]。根据GUILDENBECHER等[14]的研究结果,合金熔体破碎过程中无论是低韦伯数(We)的包状破碎还是高韦伯数的片状破碎都会产生细微液滴,因此,在实际制粉过程产生细微颗粒不可避免。基于以上因素,在粉末分离阶段,将细微颗粒和相对较粗颗粒分级分离可有效减少细微颗粒含量,有利于降低粉末筛分和分级阶段的周期和成本,提高SLM用粉末制备效率。

气雾化制粉设备的粉末分离装置主要为切向逆流干式分离器,该设备具有结构简单、制造和维护成本较低、可以在高温高压以及化学腐蚀条件下使用等优点,广泛应用于冶金、化工、能源等领域[15-17]。钟欣等[18]利用CFD技术对一种并联式旋风分离器分离性能进行了研究,结果表明,采用并联结构的分离器对于粒径在5 μm以下的颗粒分离效率显著高于单一分离器结构;袁惠新等[19]利用雷诺应力模型(RSM)分析了不同高宽比矩形入口的旋风分离器分离性能,结果表明,随着入口高宽比的增加,切向速度先增大后减小,入口高宽比保持4.5时对颗粒的分离效率最高;高助威等[20]基于随机轨道模型模拟了旋风分离器内部颗粒浓度分布规律,研究表明,颗粒浓度在分离器不同位置存在差异,径向受内部螺旋运动的影响,导致在内壁位置颗粒浓度较高,轴向由于分离器下部尺寸约束,导致颗粒间距减小进而引起颗粒浓度升高。

目前,气雾化制粉设备采用的分离器设计目的主要是提高粉末分离率、减少粉末损耗以及达到环保排放要求,无法实现细微颗粒和较粗颗粒的分级分离的目标,基于此,本文根据现有气雾化制粉设备结构,设计了一组用于制备选区激光熔化成形用金属粉末的组合式分离器,利用计算流体动力学模拟技术(Computational fluid dynamics,CFD),研究了该组合式分离器气流场分布和金属颗粒运动行为,结合实际制粉实验,验证了分级分离粉末的可行性,为气雾化制粉工艺优化提供参考。

1 物理模型

1.1 组合式分离器几何模型

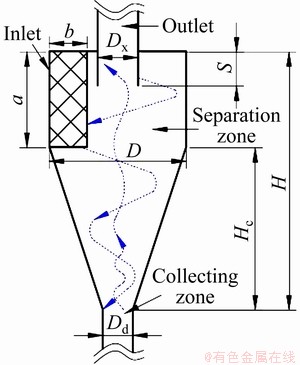

切向逆流式分离器典型内部结构如图1所示,主要由进口、直筒、锥体和排气口组成;含粉末的气流从进气口进入分离器,由于动量矩守恒原则,会沿着分离器壁面做旋流运动;在离心力的作用下,粉末颗粒与分离器内壁发生接触,旋流运动受阻从而沿内壁流入底部被分离,洁净气流则在底部沿轴线逆向从排气口流出[21]。

影响分离效率的结构参数主要有主体长度(H)、锥体长度(Hc)、筒体直径(D)、排气口直径(Dx)、排气口深度(S)、进料口尺寸(a,b)以及分离口直径(Dd)[22],依据粗细颗粒分级分离的原则以及Muschelknautz经验模型[23],设计两种不同结构的旋风分离器,其中C1分离器为粗筒结构且排气口深度保持为零,C2分离器为细筒结构并保持一定的排气口伸入距离,具体结构参数如表1所示。

图1 分离器结构示意图

Fig. 1 Schematic diagram of separator structure

表1 两种分离器结构参数

Table 1 Structure parameters of two separators

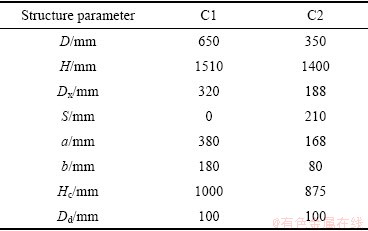

对两种结构的分离器进行三维建模,采用串联连接的方式将C1分离器排气口和C2分离器进气口连接,管道直径为150 mm,根据实际操作条件,两个旋风分离器均在分离口下方装配粉罐(Powder container),容积为18 L,三维几何模型如图2所示。

图2 组合式分离器三维模型

Fig. 2 Three-dimensional model of combined separator

1.2 网格划分

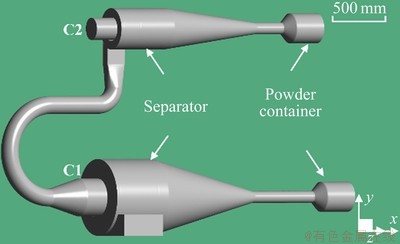

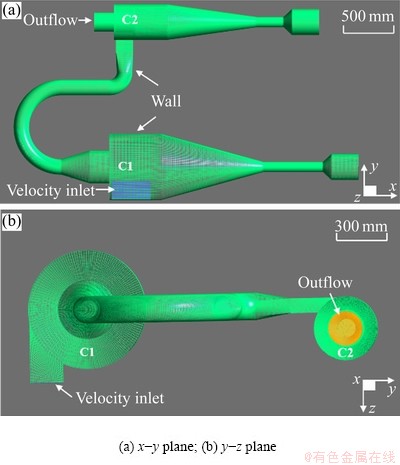

C1和C2分离器主体部分均为三维轴对称结构,但是连接后的结构在空间无对称性,同时为了保证计算的精确度和缩短迭代周期,采用O-block切割延伸的方法对整个三维模型进行网格划分,网格类型为结构化六面体(见图3)。将C1分离器入口设置为Velocity-inlet,将C2分离器排气口设置为Outflow,其余面设置为Wall,在分离器主体壁面边界层进行线性加密,其中第一层设置为0.1,增长率保持1.05。

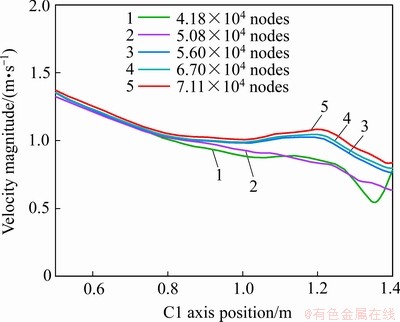

对网格进行无关性检验,分别设置了五组不同计算节点数量的网格,即418×104、508×104、560×104、670×104和711×104,在入口流速1.6 m/s条件下以定常模式迭代3000步长,计算C1分离器内部直筒段和锥体段轴线速度分布(见图4)。结果表明,网格节点数量大于560×104后,C1分离器轴线速度差异相对较小,网格数量对计算结果影响明显减弱,因此最终计算采用节点数量为560×104的网格。

图3 组合式分离器网格

Fig. 3 Combined separator grid

图4 C1分离器不同节点数量网格轴线速度分布曲线

Fig. 4 axis velocity curve of C1 separator with different grid nodes

1.3 计算模型

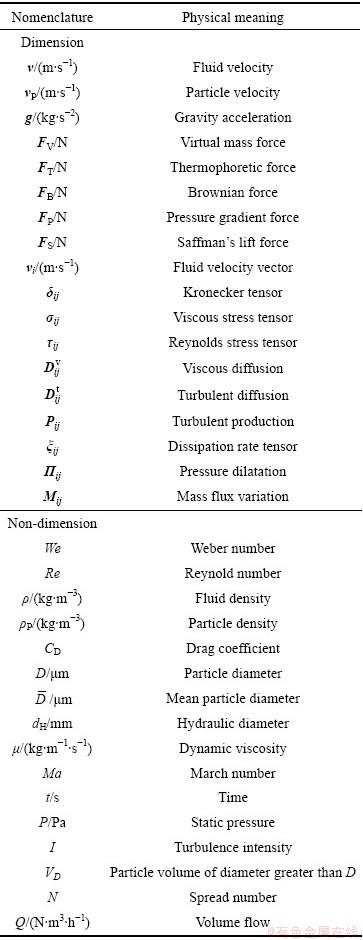

表2 物理量术语

Table 2 Nomenclature of physical symbols

表2所示为本文所涉及的物理量术语对应表。气雾化制粉介质气体采用氩气,根据制粉炉工况条件,雾化过程平均氩气流量Q为400 m3/h,根据表1入口尺寸,计算入口平均流速其入口流速v=1.6 m/s,雷诺数Re定义为:

式中:dH为等效直径,对于矩形截面等效直径计算如下:

由于气流流动马赫数Ma<< 0.3并且雷诺数Re=29813>13800,因此组合式分离器内气流流动可以简化为不可压缩流动进行计算。

1.3.1 控制方程

氩气属于牛顿流体,对于单相不可压牛顿流体流动,描述其流动行为的连续性方程和动量方程笛卡尔张量模式可表示为[24]:

,

,

(1)

(1)

式中:

(2)

(2)

1.3.2 湍流模型

由于分离器内流场是一种三维非对称旋流,选择雷诺应力模型(Reynolds stress model,RSM)求解,雷诺应力模型不同于传统的K-Epsilon模型,没有采用涡黏性的各向同性假设,对旋转流动和管道中应力诱导产生的二次流计算更为精确[24]。雷诺应力模型运输方程可表示为[25]:

(3)

(3)

1.3.3 离散相粒子模型

离散相粒子模型(Diecrete particle model,DPM)是基于拉格朗日结构的双向耦合计算模型,通过连续相和离散相控制方程的交替计算最终达到收敛的目的。离散相控制方式可表示为[26]:

(4)

(4)

1.4 边界条件和计算设置

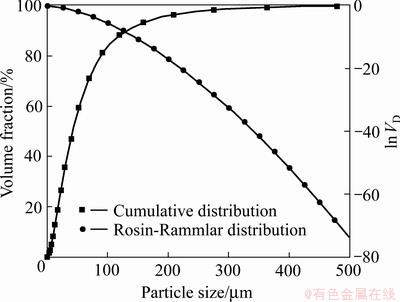

雷诺数Re=29813>13800,因此流动为湍流流动,入口湍流强度 ,计算得到I=4.4%,求解器选择coupled,即对控制方程联立同时求解,保证结果精确同时提高收敛性。颗粒材料选择GH3536镍基高温合金,密度ρ=8.3 g/cm3,根据实际工况含尘密度为1 kg/min,与气流交互作用设置为非定常连续模式,迭代步长和间隔与连续相保持一致。采用激光粒度仪器测试了实际粒度分布曲线,其中累积分布曲线特征值

,计算得到I=4.4%,求解器选择coupled,即对控制方程联立同时求解,保证结果精确同时提高收敛性。颗粒材料选择GH3536镍基高温合金,密度ρ=8.3 g/cm3,根据实际工况含尘密度为1 kg/min,与气流交互作用设置为非定常连续模式,迭代步长和间隔与连续相保持一致。采用激光粒度仪器测试了实际粒度分布曲线,其中累积分布曲线特征值 =11.21 μm,

=11.21 μm, =42.61 μm,

=42.61 μm, =129.02 μm。为了更为准确的描述实际粉末粒度分布,将粒度分布曲线结果转换为Rosin-Rammlar分布,其粒度分布可表示为:

=129.02 μm。为了更为准确的描述实际粉末粒度分布,将粒度分布曲线结果转换为Rosin-Rammlar分布,其粒度分布可表示为:

(5)

(5)

经过计算 =86 μm,N=2.543,转换后的Rosin-Rammlar自然对数分布曲线和原始累积分布曲线如图5所示。

=86 μm,N=2.543,转换后的Rosin-Rammlar自然对数分布曲线和原始累积分布曲线如图5所示。

采用定常计算模式对组合式分离器单相气流场进行迭代计算,残差保持在1×10-3以下并且进口和入口质量流量差波动小于0.01 kg停止计算,加载Rosin- Rammlar分布的GH3536高温合金粉末并采用非定常模型计算,时间间隔设置为0.001 s,所有计算均采用并行计算的方式,计算平台为24核心Xeon CPU 和 Nvidia

CPU 和 Nvidia GPU工作站。

GPU工作站。

图5 粉末Rosin-Rammlar自然对数和累积分布曲线

Fig. 5 Rosin-Rammlar natural logarithmic and cumulative distribution curves of powder

2 模拟结果和分析

2.1 气流场分布

2.1.1 三维流线分布

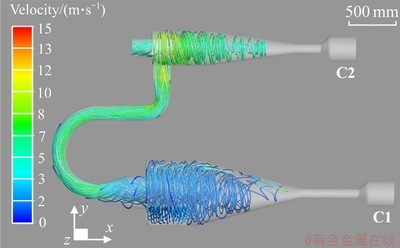

首先对组合式分离器速度流场进行分析,图6所示为定常计算条件组合式分离器速度流线图,气流从进口进入C1分离器后受到壁面约束,在分离器内部做旋向运动,形成了强度和结构不同的涡结构,在分离器锥体底部向上运动,通过排气口沿管道进入C2分离器,气流运动也出现了旋流运动特征。相比而言,分离器C1内部流线较为散乱,气流速度相对较低,保持在7 m/s以下;而分离器C2内部流线回转分布较为规则,气流没有出现散乱分布特征,由于C2分离器直通段直径较小,壁面约束效应较强,气流速度相对较高,最高速度达到了10 m/s左右,这表明C2分离器的内部旋流运动强于C1分离器的,初步判断C1分离器的颗粒分离效率高于C2分离器的。

图6 组合式分离器速度流线图

Fig. 6 Velocity streamline of combined separator

2.1.2 速度分布

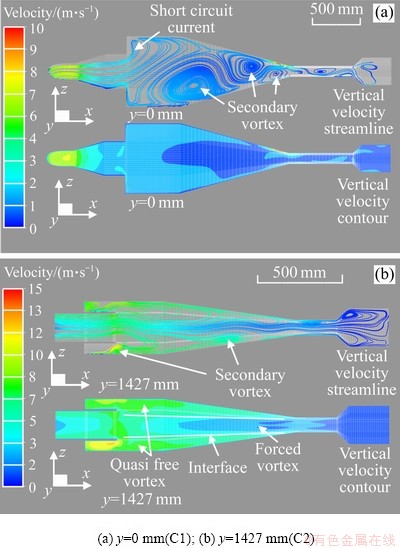

在三维流线的基础上,分析C1和C2分离器内部不同位置流动行为。图7(a)所示为C1分离器纵向截面气流速度流线和速度云图,在C1分离器内部存在两个相对较大范围的二次涡结构(Secondary vortex),二次涡的存在消耗了气流动能阻碍了内部强制涡(Forced vortex)的形成,在直筒段气流保持较低的流动速度,最大流速仅为3 m/s,不利于细微颗粒的分离。同时,气流速度流线显示,部分气体并没有进入直通段形成涡流参与颗粒的分离,而是直接从排气口流出,形成了典型的短路流特征(Short circuit current),短路流会携带部分颗粒从分离器排气口直接逸出,进一步降低分离效率。C2分离器由于直通段和锥体段的结构对气流约束用更强,形成了以排气口延长线为分界面(Interface)的双层涡结构,外层涡为准自由涡(Quasi free vortex),内层为强制涡,准自由涡气流速度高于强制涡气流速度。此外,y=1427 mm截面流线显示C2分离器内部也存在二次涡,相比于C1分离器二次涡的范围明显偏小,对强制涡的形成干扰有限,没有出现短路流特征(见图7(b)),从气流场和涡流结构判断,在组合使用条件下,C1分离器排气口逸出的颗粒数量可能会高于C2分离器排气口逸出的颗粒数量。

2.1.3 速度矢量分布

图8所示为C1和C2分离器不同截面速度矢量图。C1分离器y=0 mm截面二次涡位置气流出现纵向大范围回旋特征;水平截面x=120 mm和x=960 mm矢量图显示气流在直筒段和锥体段以x轴为法线方向旋转,不同截面存在偏心运动特征(见图8(a))。C2分离器中靠近壁面位置的气流沿x轴方向分量为正,强制涡区域气流速度x轴方向分量为负,这也说明强制涡和准自由涡区域气流流动行为存在较大差异;准自由涡气流沿壁面向锥体底部流动,强制涡气流沿x轴方向从排气口排出,二者保持动态平衡,在不同位置水平截面气流也以x轴为法线旋转,准自由涡和强制涡界面特征明显。相比于C1分离器的气流流动状态,C2分离器内部不同截面气流流动并没有出现明显的偏心特征(见图8(b)),这说明在组合使用条件下C2分离器内部气流流动规律性较高,而C1分离器内部气流流动存在较强的随机性,从而导致颗粒受曳力作用呈现不同的运动状态,影响颗粒的分离效率。

图7 截面速度流线和速度云图

Fig. 7 Velocity streamline and contour of different sections

图8 不同截面速度矢量

Fig. 8 Velocity vectors of different sections

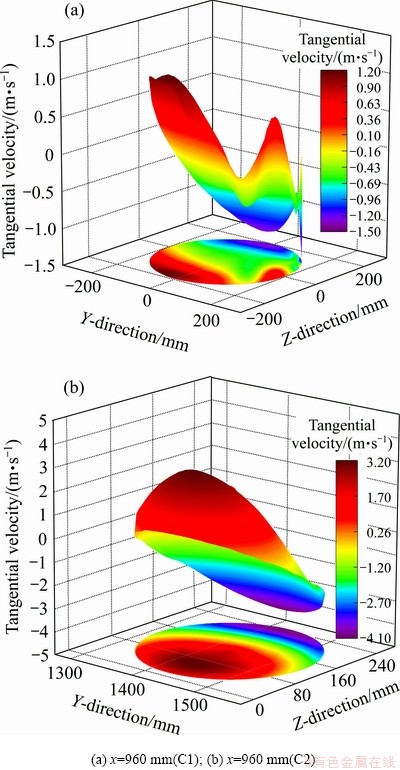

2.1.4 切向速度分布

气流切向速度是表征分离器分离效率的重要指标,切向速度越大对颗粒产生的切向曳力也越大,带动颗粒在分离器内部发生旋转,在离心力的作用下与分离器内壁发生接触减速,最终达到分离的目的。图9所示为分离器锥体水平截面(x=960 mm)切向速度分布图,由图9可知,气流在C1分离器锥体位置处于紊乱流动状态,水平截面切向速度分布无明显规律,且切向速度正值区域投影面积占比仅为39%左右,这表明C1分离器锥体位置切向曳力较低;而C2分离器锥体水平截面切向速度分布为较为规则,呈半球形分布,切向速度正值区域投影面积达到了50%以上,表明C2分离器在锥体位置产生的切向曳力较大,颗粒受到径向的离心力也随之提高,对于细微颗粒的分离效率相比C1分离器理论上更高。

图9 锥体截面切向速度分布图

Fig. 9 Tangential velocity profile of centrum section

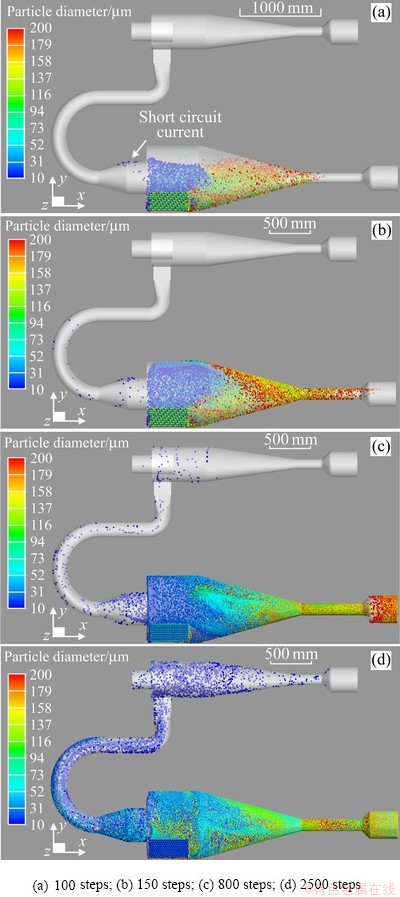

2.2 颗粒飞行行为

在气流场模拟的基础上,以非定常迭代的方式加载GH3536高温合金粉末,开展颗粒在组合式分离器内部飞行行为研究,初始入射速度和气流入射速度保持一致,迭代2500步长后停止计算,经过统计总共计算了540×104个颗粒。图10所示为不同时间步长粉末分布图。由图10可以看出,在ts=100时粉末随气流流入C1分离器内部,此时粉末尚未完全在分离器均匀分散,受重力和曳力综合作用粉末发生初步分级,较粗的颗粒沿内壁向分离器锥体运动,较细的颗粒则大部分停留在分离器直筒段,受短路流影响,有部分细粒度颗粒直接从排气口逸出;在ts=150时粉末分级现象更为明显,较粗的颗粒布满整个分离器锥体,部分已经分离流入粉罐中;在ts=800时粉末布满整个C1分离器,粉罐内也分离了大量粗粒度颗粒,细微粒度颗粒受短路流和二次涡影响持续从排气口逸出,通过连接管道进入C2分离器;受计算条件的限制,粒子迭代最终在ts=2500步长时停止,此时已有大量的细微颗粒(主要为粒径30 μm以下)从C1分离器流入C2分离器,有部分粒径40 μm以上的颗粒也开始通过管道进入C2分离器,这是因为随着颗粒浓度增大,气流分离效率会逐渐下降,从而导致有超过临界尺寸的颗粒逸出的现象,这也说明实际制粉过程中分离器设计要考虑颗粒浓度对分离效率的影响。通过颗粒的飞行行为研究表明,组合式分离器在气流量和粉末流量分别为400 m3/h和1 kg/min的工况条件能够实现GH3536高温合金粉末的粗细颗粒分级分离。

2.3 颗粒分离效率

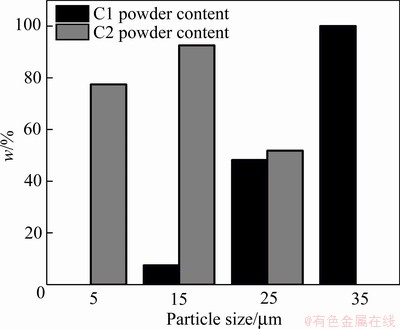

在单相气流场模拟计算的基础上,以粒径为5、15、25和35 μm的GH3536高温合金粉末为研究对象,采用定常模式的DPM模型进行分离效率研究。

图11所示为C1和C2分离器对于不同粒度的GH3536高温合金粉末的分离质量分数对比。随颗粒粒径的增大,C1分离器分离效率显著提高,对于粒径达到35 μm的颗粒,分离质量分数接近100%,而对于粒径小于15 μm的颗粒,分离质量分数不足10%;相比而言,C2分离器对细微颗粒具有更为优良的分离效果,但也存在粒径为5 μm的颗粒无法分离的现象。

图10 不同时间步长颗粒分布图

Fig. 10 Particle distributions at different time steps

图11 C1和C2分离器的分离结果对比

Fig. 11 Comparison of separation results of C1 and C2 separators

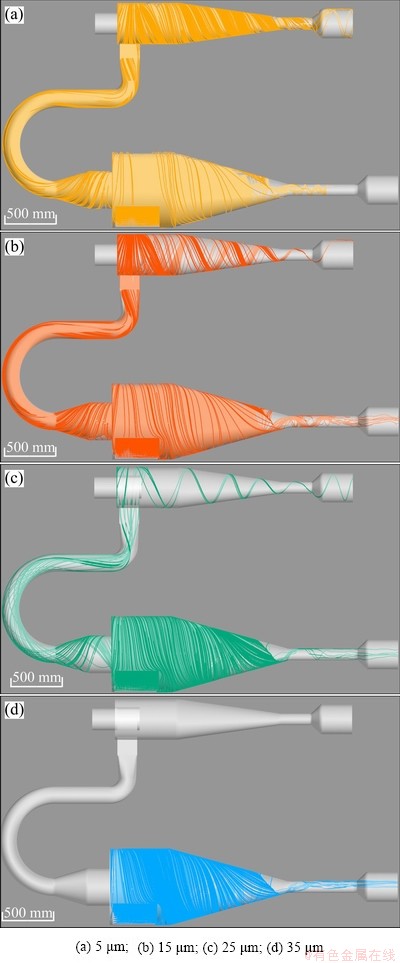

图12所示为不同粒径颗粒在组合式分离器内部轨迹图。从图12可以看出,不同粒径的颗粒流动轨迹存在差异,粒径为5 μm的颗粒受短路流和离心力不足的因素在C1分离器内无法被有效分离于C1粉罐,通过C1分离器排气口流动至C2分离器,而C2分离器内部较强的双涡结构和切向速度促使粒径为5 μm的颗粒沿着内壁被分离至C2粉罐(见图12(a));粒径为15 μm和25 μm的颗粒流动行为出现分化,C1和C2分离器均能实现该粒度颗粒的分离,区别在于C1分离器对于粒径为25 μm的颗粒分离数量更多,从C1分离器排气口进入C2分离器的颗粒数量相对更少,这也说明C1分离器对于粒径较大的颗粒分离效率更高(见图12(b)和(c));当颗粒粒径达到35 μm时,C1分离器已经可以实现完全分离,在定常计算条件下没有出现从排气口流动至C2分离器的颗粒(见图12(d))。基于以上研究,表明组合式分离器在氩气流量400 m3/h以及粉末流量为1 kg/min的工况条件下,粗细颗粒分级分离的临界粒径为25~35 μm。

图12 不同粒径颗粒轨迹图

Fig. 12 Trajectories of particles with different sizes

3 实验研究

根据模拟结果,利用C1和C2结构的组合式分离器可以实现细微颗粒和较粗颗粒的分级分离,因此基于C1和C2内部结构,加工了一套组合式分离器(见图13),该分离器采用双层结构,内壁为表1尺寸,外壁为尺寸相近的水冷套件,安装在北京航空材料研究院220 kg级雾化制粉设备上,保持氩气流量为400 m3/h左右,压强为3.5 MPa,进行了制粉实验,制备了GH3536高温合金粉末。

图13 组合式分离器照片

Fig. 13 Photograph of combined separator

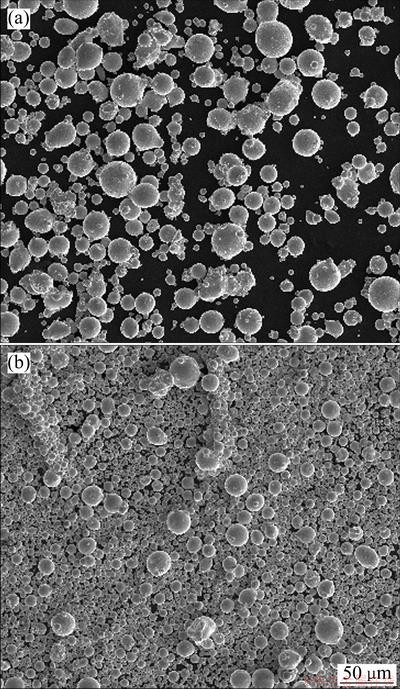

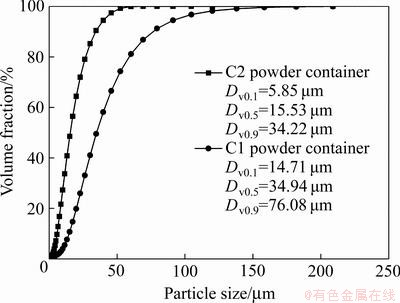

经过测试,C1粉罐和C2粉罐中粉末质量比约为5:1,取样采用250目筛网(孔径58 μm)机械筛分后,采用扫描电镜和激光粒度仪分析了C1和C2罐粉末微观形貌和粒径分布。图14所示为C1和C2粉罐中的粉末SEM像。由图14可见,C1粉罐内的粉末分散程度较好,细微颗粒含量相对较少(见图14(a));C2分离器分离的粉末中细微颗粒含量较多,粉末出现了团聚现象难以分散(见图14(b))。图15所示为C1和C2分离器粉罐粉末粒径累积分布曲线。两条激光粒径分布曲线反映了两个分离器分离粉末粒径的差异。C1粉罐中粒径小于14.71 μm的颗粒占比不足10%,而C2粉罐中粒径小于34.22 μm的颗粒占比达到90%以上(见图15),这表明C1分离器对于粒径小于15 μm的细微颗粒分离率较低,而C2分离器对于相同粒径的颗粒表现出较高的分离率。由此可见,该型组合式分离器在400 m3/h以及粉末流量为1 kg/min的工况条件下,实际粗细颗粒分级分离的临界粒径约为 34.22 μm,符合定常DPM模拟结果范围。

图14 C1和C2粉罐中的粉末SEM像

Fig. 14 SEM images of powder in C1(a) and C2(b) powder containers

图15 C1和C2分离器粉罐中的粉末粒径累积分布曲线

Fig. 15 Particle size cumulative distribution curves of powder in C1 and C2 separator powder containers(-250 mesh size)

以上结果表明,采用基于RSM和DPM模型计算组合式分离器分离性能的方法可行性和准确性较高,经过实验验证,两种结果一致性较好,与此同时该结构的组合式分离器在选区激光熔化用粉末制备中可以达到分级分离的目的,对细微颗粒去除效果显著。

4 结论

1) 采用RSM和DPM叠加模型计算气雾化制粉用组合式分离器分离性能结果较为准确,与实验结果吻合度较高。

2) 在流量400 m3/h、粉末流量为1 kg/min的工况条件下,C1结构的分离器无法形成准自由涡和强制涡结构,造成切向速度不足,仅能分离粒径较粗的颗粒,对细微颗粒分离效率偏低;而相同工况条件下C2结构的分离器可以形成典型的双层涡结构,保证了足够的切向速度,对细微颗粒分离效率相对较高。

3) 采用两种结构串联的组合式分离器在气雾化粉末制备中能有效地完成粗细颗粒的分级分离,缩短了后期对细微颗粒的分离处理周期,有助于降低选区激光熔化成形用金属粉末的制备成本。

REFERENCES

[1] 林 鑫, 黄卫东. 应用于航空领域的金属高性能增材制造技术[J]. 中国材料进展, 2015, 34(9): 684-688.

LIN Xin, HUANG Wei-dong. High performance metal additive manufacturing technology applied in aviation field[J]. Materials China, 2015, 34(9): 684-688.

[2] XIAO Dong-ming, YANG Yong-qiang, SU Xu-bin, WANG Di, LUO Zi-yi. Topology optimization of microstructure and selective laser melting fabrication for metallic biomaterial scaffolds[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2554-2561.

[3] 文世峰, 季宪泰, 周 燕, 魏青松. 激光选区熔化成形模具钢的发展现状及前景[J]. 激光与光电子学进展, 2018, 55(1): 41-51.

WEN Shi-feng, JI Xian-tai, ZHOU Yan, WEI Qing-song. Development status and prospect of selective laser melting of mould steels[J]. Laser and Optoelectronics Process, 2018, 55(1): 41-51.

[4] 滕 庆, 李 帅, 薛鹏举, 田 健, 魏青松, 史玉升. 激光选区熔化Inconel718合金高温腐蚀性能[J]. 中国有色金属学报, 2019, 29(7): 1417-1426.

TENG Qin, LI Shuai, XUE Peng-ju, TIAN Jian, WEI Qing-song, SHI Yu-shen. High-temperature corrosion resistance of Inconel 718 fabricated by selective laser melting[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(7): 1417-1426.

[5] 王赟达, 杨永强, 宋长辉, 刘凤美, 麦淑珍. 基于响应面法优化激光选区熔化成型CoCrMo合金工艺及其电化学行为[J]. 中国有色金属学报, 2014, 24(10): 2497-2505.

WANG Bing-da, YANG Yong-qiang, SONG Chang-hui, LIU Feng-mei, MAI Shu-zhen. Process optimization and electrochemical behavior of CoCrMo alloy fabricated by selective laser melting based on response surface method[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2497-2505.

[6] 张学军, 唐思熠, 肇恒跃, 郭绍庆, 李 能, 孙兵兵, 陈冰清. 3D打印技术研究现状和关键技术[J]. 材料工程, 2016, 44(2): 122-128.

ZHANG Xue-jun, TANG Si-yi, ZHAO Heng-yue, GUO Shao-qing, LI Neng, SUN Bing-bing, CHEN Bing-qing. Research status and key technologies of 3D printing[J]. Journal of Materials Engineering, 2016, 44(2): 122-128.

[7] 袁 华, 李 周, 许文勇, 张国庆. 氩气雾化制备高温合金粉末的研究[J]. 粉末冶金工业, 2010, 20(4): 1-5.

YUAN Hua, LI Zhou, XU Wen-yong, ZHANG Guo-qing. The study of argon atomized superalloy powders[J]. Powder Metallurgy Industry, 2010, 20(4): 1-5.

[8] 韩寿波, 张义文, 迟 悦, 贾 健, 董建新. C和Hf对FGH97粉末冶金高温合金热力学平衡相析出的影响[J]. 粉末冶金工业, 2009, 19(6): 21-27.

HAN Shou-bo, ZHANG Yi-wen, CHI Rui, JIA Jian, DONG Jian-xin. Effect of C and Hf on thermodynamic equilibrium phase precipitation in FGH97 PM superalloy[J]. Powder Metallurgy Industry, 2009, 19(6): 21-27.

[9] 覃思思, 余 勇, 曾归余, 肖明清. 3D打印用金属粉末的制备研究[J]. 粉末冶金工业, 2016, 26(5): 21-24.

QING Si-si, YU Yong, ZENG Gui-yu, XIAO Ming-qing. Research on the preparation of metal powder for 3D printing[J]. Powder Metallurgy Industry, 2016, 26(5): 21-24.

[10] 熊博文, 徐志锋, 严青松, 蔡长春, 郑玉惠. 直接选区激光烧结金属粉末材料的研究进展[J]. 热加工工艺, 2008, 37(9): 92-94, 99.

XIONG Bo-wen, XU Zhi-feng, YAN Qing-song, CAI Chang-chun, ZHENG Yu-hui. Progress on metal powder materials used for direct selective laser sintering[J]. Hot Working Technology, 2008, 37(9): 92-94, 99.

[11] 欧阳鸿武, 何世文, 刘 咏. 金属粉末性能对选区激光烧结件质量的影响[J]. 粉末冶金材料科学与工程, 2004, 9(2): 106-111.

OUYANG Hong-wu, HE Shi-wen, LIU Yong. Effects of properties of metal powder on selective laser sintering[J]. Powder Metallurgy Materials Science and Engineering, 2004, 9(2): 106-111.

[12] 高超峰, 余伟泳, 朱权利, 肖志瑜. 3D打印用金属粉末的性能特征及研究进展[J]. 粉末冶金工业, 2017, 27(5): 53-58.

GAO Chao-feng, YU Wei-yong, ZHU Quan-li, XIAO Zhi-yu. Performance characteristics and research progress of metal powders for 3D printing[J]. Powder Metallurgy Industry, 2017, 27(5): 53-58.

[13] 刘 杨, 李 周, 张国庆, 许文勇, 袁 华, 刘 娜, 郑 亮, MI J. 双层雾化器流场的模拟研究[J]. 航空材料学报, 2015, 35(5): 63-69.

LIU Yang, LI Zhou, ZHANG Guo-qing, XU Wen-yong, YUAN Hua, LIU Na, ZHENG Liang, MI J. Flow field of double layer atomizer[J]. Journal of Aeronautical Materials, 2015, 35(5): 63-69.

[14] GUILDENBECHER D R, LOPEZ-RIVERA C, SOJKA P E. Secondary atomization[J]. Experiments in Fluids, 2009, 46(3): 371-402.

[15] 房 华, 张占元, 蒋 虹, 叶劲非. 旋风分离器在航天粉煤气化流程中的应用研究[J]. 煤化工, 2016, 44(3): 66-68.

FANG Hua, ZHANG Zhan-yuan, JIANG Hong, YE Jing-fei. Study on the application of cyclone separator in HT-L pulverized coal gasification[J]. Coal Chemical Industry, 2016, 44(3): 66-68.

[16] 袁晓云, 赵 飞, 李雅华, 陈 晗, 武彦勇, 孙晓飞. 沉降器旋风分离器直连技术的工业应用[J]. 石油炼制与化工, 2018, 49(5): 31-34.

YUAN Xiao-yun, ZHAO Fei, LI Ya-hua, CHEN Han, WU Yan-yong, SUN Xiao-fei. Industrial application of cyclone separator direct connection technology[J]. Petroleum Processing and Petrochemicals, 2018, 49(5): 31-34.

[17] 唐子腾, 常玉龙, 徐 磊, 黄 渊, 汪华林. 螺旋并联分配管对旋风分离器分离性能的影响[J]. 化工学报, 2018, 69(11):282-289.

TANG Zi-teng, CHANG Yu-long, XU Lei, HUANG Yuan, WANG Hua-lin. Effects of spiral channel on separation efficiency in cyclones[J]. CIESC Journal, 2018, 69(11): 282-289.

[18] 钟 欣, 杜浩宇, 朱诗杰, 刘润哲, 陈雪莉. 不同数量并联微旋风分离器分离性能影响研究[J]. 高校化学工程学报, 2019, 33(3): 548-556.

ZHONG Xin, DU Hao-yu, LIU Run-zhe, CHENG Xue-li. Effects of numbers of parallel micro-cyclone separators on separation performance[J]. Journal of Chemical Engineering of Chinese Universities, 2019, 33(3): 548-556.

[19] 袁惠新, 石斌磊, 付双成, 朱星茼, 贾俊贤. 旋风分离器矩形入口高宽比对流场及性能的影响研究[J]. 流体机械, 2019, 47(5): 39-43.

YUAN Hui-xin, SHI Bing-lei, FU Shuang-cheng, ZHU Xing-tong, JIA Jun-xian. Research on the influence of aspect ratio of rectangular inlet of cyclone separator on flow field and performance[J]. Fluid Machinery, 2019, 47(5): 39-43.

[20] 高助威, 王 娟, 王江云, 冯留海, 毛 羽, 魏耀东. 基于DPM模型的旋风分离器内颗粒浓度场模拟分析[J]. 石油学报(石油加工), 2018, 34(3): 507-514.

GAO Zhu-wei, WANG Juan, WANG Jiang-yun, FENG Liu-hai, MAO Yu, WEI Yao-dong. Simulation analysis of particle concentration of cyclone separator using the DPM model[J]. Acta Petrolei Sinica (Petroleum Processing Section) 2018, 34(3): 507-514.

[21] 周 韬. 旋风分离器的气固两相特性研究与数值模拟[D]. 上海: 上海交通大学, 2007: 1-3.

ZHOU Tao. Study and numerical simulation on gas-solid two-phase characteristic of cyclone separator[J]. Shanghai: Shanghai Jiao Tong University, 2007: 1-3.

[22] HOFFMANN A C, STEIN L E. 旋风分离器原理、设计和工程应用[M]. 彭维明, 姬忠礼, 译. 北京: 化学工业出版社, 2004: 6-10.

HOFFMANN A C, STEIN L E. Gas cyclones and swirl tubes[M]. PENG Wei-ming, JI Zhong-li, transl. Beijing: Chemical Industry Press, 2004: 6-10.

[23] BRUNO C. Numerical predictions of channel flows with fluid injection using reynolds-stress model[J]. Journal of Propulsion and Power, 2002, 18(2): 295-303.

[24] 程会川. 高温合金熔滴在雾化冷却凝固过程中的流动换热特性研究[D]. 北京: 北京航空航天大学, 2016: 29-33.

CHENG Hui-chuan. Flow and heat transfer characteristics of superalloy droplets under processes of atomization and cooling solidification[D]. Beijing: Beihang University, 2016: 29-33.

[25] CHENAULT C F, BERAN P S, BOWERSOX R D W. Numerical investigation of supersonic injection using a Reynolds-stress turbulence model[J]. AIAA Journal, 1999, 37(10): 1257-1269.

[26] TARPAGKOU R, PANTOKRATORAS A. The influence of lamellar settler in sedimentation tanks for potable water treatment—A computational fluid dynamic study[J]. Powder Technology, 2014, 268(1): 139-149.

Numerical simulation and experimental study on separation performance of combined separator for gas atomized powder production

LIU Yang, ZHANG Guo-qing, XU Wen-yong, ZHENG Liang, LI Zhou

(Science and Technology on Advanced High Temperature Structural Materials Laboratory, AECC Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: A kind of combined separator for gas atomization equipment was designed. The combination of computational fluid dynamics(CFD) simulation and experiment were employed to investigate the separation performance. Based on the separation performance difference between two different structure separators, the coarse and fine particles can be hierarchically collected during the powder preparation process, so that the preparation cycle and the cost of alloy powder for selective laser melting(SLM) can be reduced. The results indicate that the collection efficiency of C1 structure separator for fine alloy particles is lower under the condition of argon flow rate of 400 m3/h and powder flow rate of 1kg/min, while C2 structure separator exhibits a high collection efficiency for fine alloy particles under the same gas atomization condition. These two structure separators in series connection can effectively classify fine and coarse particles, thus the separation treatment cycle in the next process can be shorten.

Key words: combined separator; numerical simulation; gas atomization powder preparation; selective laser melting

Foundation item: Project(2017YFB0305800) supported by the National Key Research and Development Program of China; Project (51434007) supported by the National Natural Science Foundation of China; Project (Z181100003318001) supported by the Beijing Municipal Science and Technology Project, China; Project(ZZCX-2019-001) supported by the Independent Innovation Project of Aero Engine Corporation of China

Received date: 2019-12-02; Accepted date: 2020-08-06

Corresponding author: ZHANG Guo-qing; Tel: +86-10-62496137; E-mail: g.zhang@126.com

(编辑 何学锋)

基金项目:国家重点研发计划资助项目(2017YFB0305800);国家自然科学基金资助项目(51434007);北京市科技计划资助项目(Z181100003318001);中国航发自主创新专项资助项目(ZZCX-2019-001)

收稿日期:2019-12-02;修订日期:2020-08-06

通信作者:张国庆,研究员,博士;电话:010-62496137,E-mall:g.zhang@126.com