文章编号:1004-0609(2012)02-0350-08

喷射成形6061铝合金的热处理工艺

刘丘林,刘允中,杜 良,罗 霞,谢金乐

(华南理工大学 机械与汽车工程学院 国家金属材料近净成形工程技术研究中心,广州 510640)

摘 要:对喷射成形6061铝合金的热处理工艺进行研究,采用硬度测试、拉伸试验和透射电镜等研究固溶温度、时效温度和时效保温时间对合金显微组织和力学性能的影响规律。结果表明:随固溶温度的升高,合金硬度也随之升高,而其抗拉强度、屈服强度和断后伸长率则先增大后减小;合金硬度、抗拉强度和屈服强度随时效温度的升高先增大后减小,断后伸长率却一直减小;合金硬度、抗拉强度和屈服强度曲线随时效温保温时间的延长呈驼峰状变化,断后伸长率则变化不大,只在17 h时有所增大;喷射成形6061铝合金的最佳热处理工艺为530 ℃固溶1 h+175 ℃时效8 h。

关键词:6061铝合金;喷射成形;热处理工艺;组织;性能

中图分类号:TG146.2;TG376 文献标志码:A

Heat treatment process of spray formed 6061 aluminum alloy

LIU Qiu-lin, LIU Yun-zhong, DU Liang, LUO Xia, XIE Jin-le

(National Engineering Research Center of Near-net-shape Forming Technology for Metallic Materials,

School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: The heat treatment of spray-formed 6061 aluminum alloy was studied. The effects of solution temperature, aging temperature and aging holding time on the microstructures and mechanical properties were investigated using hardness measurement, tensile test and TEM. The results show that with increasing the solution temperature, the hardness of alloy increases, while the tensile strength, yield strength and elongation first increase and then decrease. The hardness, tensile strength and yield strength of the alloy first increase then decrease with increasing the aging temperature, while the elongation decreases. The hardness, tensile strength and yield strength curves of the alloy are hump-like change with prolonging the aging holding time, while the elongation changes a little and increases only at 17 h. The best heat treatment process of the spray-forming 6061 aluminum alloy is as follows, solution treated at 530 ℃ for 1 h and then aging at 175 ℃ for 8 h.

Key words: 6061 aluminum alloy; spray forming; heat treatment process; microstructures; properties

6061铝合金属于Al-Mg-Si系合金,具有可热处理强化、良好的塑性、优良的挤压加工性能、可焊性和耐腐蚀性、低密度以及较低的淬火敏感系数、无应力腐蚀开裂倾向等优点[1]。因此,6061铝合金材料被广泛用于航空航天、交通运输、家用电器和现代建筑等领域[2-3]。

采用传统的铸造工艺制备6061铝合金时,存在很多问题,包括:1) 晶粒粗大、组织不均匀、成分偏析、析出相粗大不均匀;2) 强度、塑性、刚度和耐腐蚀性难以进一步提高[4]。而采用喷射成形技术制备的6061铝合金具有晶粒细小、组织均匀、无宏观偏析、析出相细小弥散分布等特点[5-6],其力学性能也能得到较大的提高。

但是喷射成形材料存在一定的孔隙,后续致密化加工能使材料的综合性能得到进一步提升。为了获得性能更高、更稳定的材料,必须对其进行热处理。

热处理强化是铝合金的主要强化方法[7],因为合金中强化相的数量、大小、形状和分布是影响合金力学性能的关键因素,因此,可以通过改变合金中强化相的数量、大小、形状和分布来改善合金的力学性 能[8]。以往对6000系铝合金的热处理强化已有不少研究。DEMIR和G?ND?Z[9]研究时效处理对6061铝合金机械加工性的影响,发现在180 ℃时不同时效时间和切削速度对工件表面粗糙度有显著的影响,但是对切削力的影响不大。邹永恒等[10]研究6082铝合金的热处理工艺参数,对于d<50 mm合金挤压棒坯经530~570 ℃、1.25~6 h固溶处理后综合性能较佳,随着时效温度的升高,时效强化的速度愈快,达到最大强化效果所需的时间越短。何立子等[11]研究类 6013 铝合金的热处理制度,发现经固溶处理(固溶处理制度为550 ℃、20 min,水淬,人工时效制度为190 ℃、4 h或190 ℃、1.5 h)后,类 6013 铝合金的极限拉伸强度达到450 MPa。陈剑虹等[8]研究了热处理工艺对6061铝合金显微组织及力学性能的影响,发现固溶时效后可以获得大量均匀的Mg2Si强化相,且在固溶温度为530 ℃,保温6 h,时效温度为173 ℃,保温3 h时获得较高的综合力学性能。

然而,对于喷射成形6061铝合金热处理工艺的研究尚未见报道。为了探索其热处理工艺,本文作者研究了不同固溶+时效热处理工艺对喷射成形6061铝合金显微组织和力学性能的影响,并获得喷射成形6061铝合金的最佳热处理工艺。

1 实验

1.1 实验材料

本实验所用原材料是熔铸态6061铝合金,其化学成分如表1所列。以熔铸态6061铝合金为原料,采用喷射成形技术,在ZGSP-0.2型喷射成形设备上制备了6061铝合金坯锭,喷射成形的主要工艺参数如下:过热度100 ℃左右,喷射距离500 mm,雾化压力0.5~0.6 MPa,导流管直径4 mm。然后在喷射态坯锭中线切割出若干d 50 mm×40 mm的挤压试样,在 200 t四柱液压机上对合金进行挤压致密化处理,挤压工艺参数如下:挤压温度250 ℃,挤压比25,得到挤压态合金,即热处理前的材料。

表1 6061铝合金的化学成分

Table 1 Chemical composition of 6061 aluminum alloy (mass fraction, %)

1.2 实验方法

热处理炉选用箱式空气循环电阻炉,热处理实验方案如下:热处理分为3组,每组各进行5次实验,分别对应于某一个主要工艺参数(固溶温度、时效温度、时效时间)的变化。第1组实验对应的固溶温度分别为510、520、530、540和550 ℃,而固溶保温时间均为1 h,然后都在175 ℃时效保温8 h。第2组实验首先在530 ℃固溶1 h,然后分别在145、165、175、185和202 ℃时效保温8 h。第3组实验首先都在530 ℃固溶保温1 h,然后在175 ℃时效分别保温5、8、11、14和17 h。合金固溶加热后从电阻炉中取出迅速水淬以保持其组织,再进行人工时效,时效完成后空冷至室温,得到热处理态合金。

把热处理后的样品线切割成0.6 mm厚的薄片,然后经600、800、1200、1500、2000、5000号金相水磨砂纸磨至0.1 mm厚,然后加工成d 3 mm的小圆片;再用型号为MTP-IA的磁力驱动双喷电解减薄器对薄片进行减薄,电解双喷采用硝酸与甲醇体积比为1:3的电解液,电压10~15 V,温度-25 ℃;之后在JEOL JEM3010透射电镜上进行观察拍照。在HB-3000B布氏硬度计上测量热处理后各试样的硬度,每个试样测5个点,取其算术平均值为最终结果;按标准把热处理后的合金加工成拉伸试样,在微机控制电子万能试验机CMT5105上进行常温拉伸试验,拉伸速度 1 mm/s,抗拉强度和屈服强度由试验机直接采集得到,断后伸长率用游标卡尺测量实验前后试样标距并计算获得。

2 实验结果

2.1 热处理工艺参数对合金力学性能的影响

2.1.1 对合金硬度的影响

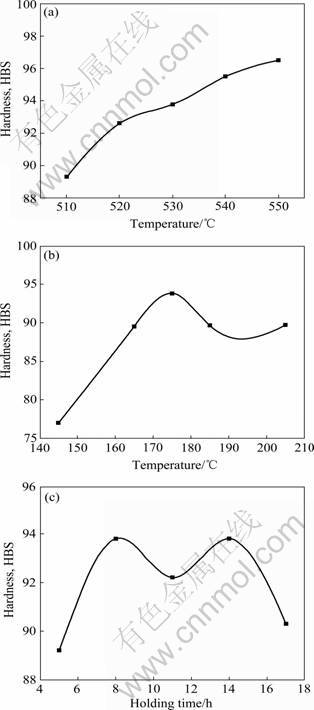

图1所示为合金硬度与热处理工艺参数的关系。从图1(a)可以看到,随着固溶温度的升高,合金硬度逐渐升高,510 ℃时合金硬度为89.3 HBS,550 ℃时达到96.5 HBS。时效温度对合金硬度的影响可以从图1(b)看出,合金硬度随时效温度的升高先升高后降低,时效温度为175 ℃时到达最大值,为93.8 HBS;时效温度为145 ℃时,合金硬度只有77 HBS;而185 ℃时为89.6 HBS;205 ℃时为89.7 HBS。图1(c)所示为时效保温时间对合金硬度的影响,其曲线呈驼峰状,在时效保温时间为8 h和14 h时合金硬度最高,都为 93.8 HBS。

图1 合金硬度与热处理工艺参数的关系

Fig. 1 Relationships between alloy hardness and heat treatment parameters: (a) Solution temperature; (b) Aging temperature; (c) Aging holding time

2.1.2 固溶温度对合金拉伸性能的影响

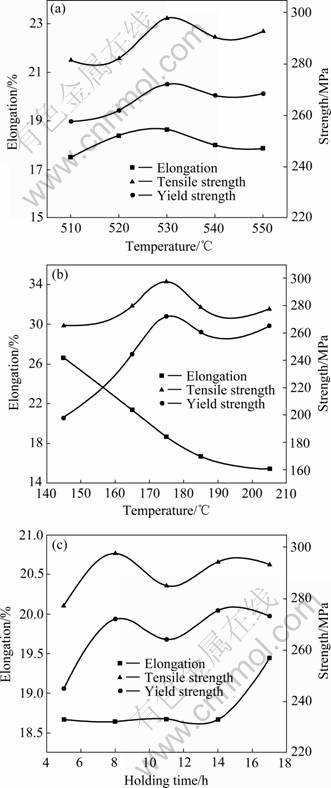

图2(a)所示为固溶温度对合金拉伸性能的影响。从图2(a)可以看到,随固溶温度的升高,不管是抗拉强度、屈服强度还是断后伸长率都呈先增大后减小的趋势,而且最大值都出现在固溶温度为530 ℃时,分别为297.6 MPa、272.1 MPa和18.64%。时效温度固溶温度对合金拉伸性能的影响如图2(b)所示。由图2(b)可以看到,随时效温度的升高,抗拉强度和屈服强度先增大后减小,在时效温度为175 ℃时到达最大,最大值分别为297.6 MPa和272.1 MPa;断后伸长率随时效温度的升高而下降,但是下降速率越来越慢。图2(c)所示为时效保温时间对合金拉伸性能的影响。从图2(c)可以看到,抗拉强度和屈服强度曲线均呈驼峰状,在时效保温时间为8 h和14 h时较高;其中在时效保温时间为8 h时,抗拉强度达到最大值297.6 MPa,屈服强度为272.1 MPa;在时效保温时间为14 h时,抗拉强度为294.3 MPa,屈服强度达到最大值275.3 MPa;断后伸长率在时效保温时间为14 h之前都变化不大,只在18.65%上下有微弱波动,但在时效保温时间为17 h时提高到了19.44%。

图2 合金拉伸性能与热处理工艺参数的关系

Fig. 2 Relationship between alloy tensile properties and heat treatment parameters: (a) Solution temperature; (b) Aging temperature; (c) Aging holding time

2.2 TEM观察

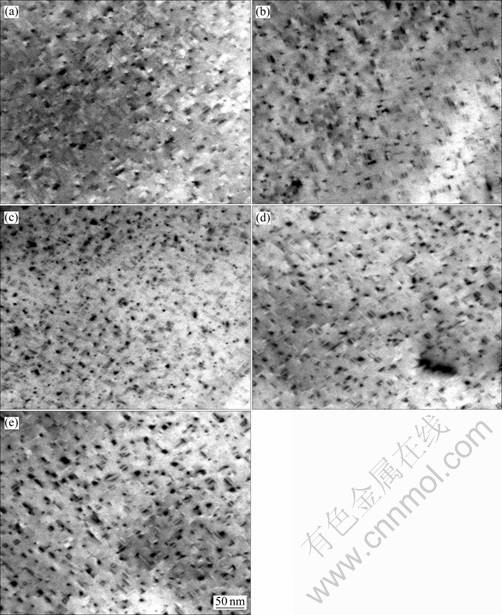

图3所示为经不同固溶温度热处理后合金析出相形貌、尺寸、数量、分布情况对比。由图3可以看出,当固溶温度为510 ℃和520 ℃时,晶内析出与基体共格的球状GP区和针状β″相[12],数量不多,尺寸较大,分布比较稀疏;固溶温度为530 ℃时,晶内析出与基体共格的球状GP区和针状β″相,数量多,尺寸小,分布密集;固溶温度为540 ℃和550 ℃时,晶内析出相主要由与基体共格的针状β″相和与基体半共格的棒状β′相组成[13]。

图3 不同固溶温度时合金晶内析出相的TEM像

Fig. 3 TEM images of precipitates inside grains in alloys at different solution temperatures: (a) 510 ℃; (b) 520 ℃; (c) 530 ℃; (d) 540 ℃; (e) 550 ℃

图4所示为经不同时效温度热处理后合金析出相形貌、尺寸、数量、分布情况对比。结合图4和图3(c)可以看出,时效温度较低为145 ℃时,晶内析出相为数量较少的球状GP区,分布很稀疏;时效温度为 165 ℃时,晶内析出相开始增多,出现球状GP区和针状β″相,但分布还是比较稀疏;时效温度为175 ℃时,晶内析出相主要为球状GP区和针状β″相,且数量较多,分布密集;时效温度为185 ℃时,针状β″相为主要析出相(还有少量棒状β′相),尺寸较大,分布密度低;时效温度为205 ℃时,晶内析出相主要由与基体共格的针状β″相和与基体半共格的棒状β′相组成,且尺寸较粗大。

图5所示为经不同时效保温时间热处理后合金中析出相的形貌、尺寸、数量和分布情况。结合图5和图3(c)可以看出,时效保温时间为5 h时,晶内析出相数量比较少,分布比较稀疏;时效保温时间为8 h时,晶内析出相主要为球状GP区和针状β″相,且数量较多,分布密集;继续延长时效保温时间到11 h时,晶内析出的球状GP区和针状β″相分布又变稀疏;时效保温时间为14 h时,晶内析出相为少量针状β″相和大量与基体呈半共格的棒状β′相,且尺寸较粗大,分布较密集;时效保温时间为17 h时,晶内析出的与基体半共格的棒状β′相分布又变得比14 h时的稀疏。

3 分析与讨论

时效硬化型铝合金的强度主要取决于晶内析出相的性质、形貌及数量。对于6061 铝合金,广为接受的晶内析出序列为α过饱和固溶体→共格GP区(球状)→共格β″相(针状)→半共格β′相(棒状)→非共格β平衡相(条状)[13]。不同固溶、时效处理导致合金的晶内析出相性质、形貌及数量都出现明显改变,从而使得合金力学性能也有显著变化。

实验合金经530 ℃固溶1 h+175 ℃时效8 h热处理后,晶内析出相以球状GP区为主,还有少量的针状β″相(见图3(c)),析出相数量多、分布密度大,且GP区和β″相都与基体共格,在基体中会产生严重的共格畸变,从而使合金在该状态下获得高的抗拉强度和屈服强度[14]。固溶温度为510和520 ℃时,由于温度过低,过剩相未能充分溶解到固溶体中,没有为沉淀硬化处理作好准备[15],时效后析出的球状GP区和针状β″相的数量都较少(见图3(a)和(b)),故合金的抗拉强度和屈服强度不高;固溶温度为540和550 ℃时, 合金元素在固溶体内的饱和程度更大,但时效后晶内析出相主要为与基体共格的β″相(针状)和与基体半共格的β′相(棒状)(见图3(d)和(e)),半共格β′相的出现使得晶格畸变程度变小,导致合金的抗拉强度和屈服强度降低。合金断后伸长率随固溶温度的升高先增大后减小,主要是由于固溶温度较低(为510和520 ℃)时,过剩相未能完全溶入到固溶体中,过剩相的存在对合金塑性有不利的影响,使断后伸长率不高;当固溶温度为530 ℃时,过剩相完全溶入固溶体中,析出相大部分为球状GP区,且尺寸小、分布均匀,合金塑性好,断后伸长率高;当固溶温度较高为540和550 ℃时,由于析出相主要为针状β″相,使得合金塑性又变差,断后伸长率降低。决定合金硬度的主要因素是合金晶内析出相的数量和形貌;低于530 ℃时,随固溶温度的升高,晶内析出相数量增加;高于530 ℃时,虽然晶内析出相数量不再增加,但棒状β′相出现,又有助于硬度的增加;因此,合金硬度随固溶温度的升高一直增大。

图4 不同时效温度时合金晶内析出相的TEM像

Fig. 4 TEM images of precipitates inside grains in alloys at different aging temperatures: (a) 145 ℃; (b) 165 ℃; (c) 185 ℃; (d) 205 ℃

图5 不同时效保温时间对合金晶内析出相的TEM像

Fig. 5 TEM images of precipitates inside grains in alloys at different aging holding times: (a) 5 h; (b) 11 h; (c) 14 h; (d) 17 h

随时效温度的升高,合金晶内析出相的数量和形态都发生了变化。例如,在530 ℃固溶1 h+175 ℃时效8 h条件下,晶内析出相主要由球状GP区和针状 β″相组成,而在低于175 ℃进行时效的合金内部仍存在大量的过饱和原子和空位以及一些球状GP区和针状β″相,通过比较可知,随着时效温度的升高,该合金材料的晶内析出相数量显著增加,因此,合金的硬度、抗拉强度和屈服强度也大幅度升高。但是,在高于175 ℃下进行时效后,合金晶内析出相主要由针状β″相和棒状β′相组成(见图4(c)和(d)),与530 ℃固溶1 h+175 ℃时效8 h态相比,时效温度升高,原子扩散速度加快,析出相容易聚集长大,因而析出相的尺寸较大而分布密度较小,且由于析出半共格的β′相,晶格畸变程度变小,因此,合金的硬度、抗拉强度和屈服强度又降低。合金断后伸长率随时效温度的升高而降低,主要是由于当温度低于175 ℃时,析出相数量随时效温度的升高而增多,对位错运动的阻碍作用越来越大,合金塑性变差;当温度高于175 ℃时,析出相随时效温度的升高开始聚集长大,并且出现了与基体半共格的棒状β′相,在合金承载的过程中,这些粗大析出相的尖端容易成为裂纹源,导致材料的塑性降低。因此,合金断后伸长率随时效温度的升高一直降低。

合金硬度、抗拉强度和屈服强度随时效保温时间的变化曲线呈驼峰状是析出相数量、形态和分布状况随时效保温时间的延长发生变化的结果。随着时效保温时间的延长,原子扩散和相转变在不同的阶段将发生不同的变化。时间较短为5 h时,原子扩散不够充分,晶内球状GP区和针状β″相析出较少(见图5(a)),合金强度、硬度较低;延长时效保温时间延长到8 h,析出相数量增多、分布密度变大(见图3(c)),合金强度、硬度升高;继续延长时间至11 h时,此时那些小于临界尺寸的GP区重新溶入基体,致使稳定的晶核数目减少[16-17],析出相数量变少、弥散程度降低(见图5(b)),合金强度、硬度又降低;但当时效保温时间为14 h时,固溶在基体内的合金元素Mg和Si又形成Mg2Si,继续形核析出,使得析出相数量再次增加、分布密度再次增大(见图5(c)),合金强度、硬度再次升高;当时间过长为17 h时,析出相便长大变粗、数量变少(见图5(d)),合金强度、硬度则又降低。合金断后伸长率在时效保温时间为14 h内都变化不大,但在17 h时增大的原因有待进一步的分析研究。

综上所述,喷射成形6061铝合金的最佳热处理工艺为530 ℃固溶1 h+175 ℃时效8 h。虽然对合金进行530 ℃固溶1 h+175 ℃时效14 h热处理后的力学性能与上述工艺热处理后合金的力学性能差不多,但因其时效保温时间较长,基于提高效率、节约能源、降低成本的角度考虑,不宜采用后一种热处理工艺。

4 结论

1) 合金硬度随固溶温度的升高而升高,抗拉强度、屈服强度和断后伸长率则先增大后减小。

2) 随时效温度的升高合金硬度、抗拉强度和屈服强度先增大后减小,断后伸长率却一直减小。

3) 随时效温保温时间的延长,合金硬度、抗拉强度和屈服强度曲线呈驼峰状变化,断后伸长率则变化不大,只在17 h时有所增大。

4) 喷射成形6061铝合金最佳热处理工艺为530 ℃固溶1 h+175 ℃时效8 h。

REFERENCES

[1] TROEGER L P, STARKE E A. Microstructural and mechanical characterization of a superplastic 6××× aluminum alloy[J]. Materials Science and Engineering A, 2000, 277(10): 2-13.

[2] 车洪艳, 朱 亮, 陈剑虹, 徐文福, 吕先锋. 6061铝合金平板对接焊接接头拉伸性能研究[J]. 兰州理工大学学报, 2008, 34(2): 27-30.

CHE Hong-yan, ZHU Liang, CHEN Jian-hong, XU Wen-fu, L? Xian-feng. Investigation of tension behavior of butt weld on plate of aluminum alloy 6061[J]. Journal of Lanzhou University of Technology, 2008, 34(2): 27-30.

[3] IRVING B. Interest in welded aluminum automobiles gathers momentum worldwide[J]. Weld Journal, 1998, 77(3): 1-5.

[4] 冉 广, 周敬恩, 王永芳, 席生岐. 铸造 A356铝合金的微观组织及其拉伸性能研究[J]. 金属热处理, 2007, 32(3): 13-17.

RAN Guang, ZHOU Jing-en, WANG Yong-fang, XI Sheng-qi. Microstructure and tensile properties of cast A356 aluminum alloy[J]. Heat Treatment of Metals, 2007, 32(3): 13-17.

[5] 孙剑飞, 沈 军, 贾 均, 李庆春. 喷射成形—一种先进的金属热成形技术[J]. 材料开发与应用, 1999, 14(2): 134-136.

SUN Jian-fei, SHEN Jun, JIA Jun, LI Qing-chun. Spray forming—An advanced processing method of materials[J]. Development and Application of Materials, 1999, 14(2): 134-136.

[6] GRANT P S. Spray forming[J]. Progress in Materials Science, 1995, 39: 497-545.

[7] 林 钢, 林慧国, 赵玉涛. 铝合金加工手册[M]. 北京: 机械工业出版社, 2006: 23-28.

LIN Gang, LIN Hui-guo, ZHAO Yu-tao. Aluminum processing manual[M]. Beijing: China Machine Press, 2006: 23-28.

[8] 陈剑虹, 李明娥, 余江瑞, 乔及森. 热处理工艺对6061铝合金显微组织及力学性能的影响[J]. 兰州理工大学学报, 2010, 36(2): 15-17.

CHEN Jian-hong, LI Ming-e, YU Jiang-rui, QIAO Ji-sen. Influence of heat treatment on microstructure and mechanical properties of 6061 aluminum alloy[J]. Journal of Lanzhou University of Technology, 2010, 36(2): 15-17.

[9] DEMIR H, G?ND?Z S. The effects of aging on machinability of 6061 aluminium alloy[J]. Materials and Design, 2009, 30: 1480-1483.

[10] 邹永恒, 陶 虹, 徐国明, 李永佳, 朱浩峰. 6082铝合金热处理工艺参数的研究[J]. 金属热处理, 2007, 32(10): 71-76.

ZOU Yong-heng, TAO Hong, XU Guo-ming, LI Yong-jia, ZHU Hao-feng. Research on heat treatment parameters of 6082 aluminum alloy[J]. Heat Treatment of Metals, 2007, 32(10): 71-76.

[11] 何立子, 张晓博, 崔建忠. 类6013铝合金热处理制度的研究[J]. 宇航材料工艺, 1999(1): 42-46.

HE Li-zi, ZHANG Xiao-bo, CUI Jian-zhong. Investigation of heat treatment of a 6013 aluminium type alloy[J]. Aerospace Materials & Technology, 1999(1): 42-46.

[12] 潘道召, 王芝秀, 李海, 郑子樵. 双级时效对6061铝合金拉伸性能和晶间腐蚀性能的影响[J]. 中国有色金属学报, 2010, 20(3): 435-440.

PAN Dao-zhao, WANG Zhi-xiu, LI Hai, ZHENG Zi-qiao. Effects of two-step ageing treatment on tensile properties and intergranular corrosion of 6061 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 435-440.

[13] BUHA J, LUMLEY R N, CROSKY A G. Microstructural development and mechanical properties of interrupted aged Al-Mg-Si-Cu alloy[J]. Metallurgical and Materials Transactions, 2006, 10(37): 3119-3130.

[14] STAAB T E M, KRAUSE-REHBERG R, HORNAUER U, ZSCHECH E. Study of artificial aging in AlMgSi (6061) and AlMgSiCu (6013) alloys by positron annihilation[J]. Journal of Materials Science, 2006, 41(4): 1059-1066.

[15] 丁惠麟, 辛智华. 实用铝、铜及其合金金相热处理和失效分析[M]. 北京: 机械工业出版社, 2007: 63-70.

DING Hui-ling, XIN Zhi-hua. Practical aluminum, copper and its alloys metallurgical heat treatment and failure analysis[M]. Beijing: China Machine Press, 2007: 63-70.

[16] 陈 准, 谭澄宇. 热处理制度对6013和6061合金拉伸性能的影响[J]. 轻合金加工技术, 2001, 29(4): 25-27.

CHEN Zhun, TAN Cheng-yu. The effect of heat treatment on the tensile properties of 6013 and 6061 alloys[J]. Light Alloy Fabrication Technology, 2001, 29(4): 25-27.

[17] HOCKAUF M, MEYER L W, ZILLMANN B, HIETSCHOLD M, SCHULZE S, KR?GER L. Simultaneous improvement of strength and ductility of Al-Mg-Si alloys by combining equal- channel angular extrusion with subsequent high-temperature short-time aging[J]. Materials Science and Engineering A, 2009, 503: 167-171.

(编辑 龙怀中)

基金项目:中央高校基本科研业务费专项资金重点项目(2011ZZ0010)

收稿日期:2011-03-24;修订日期:2011-08-24

通信作者:刘允中,教授,博士;电话:020-87110099;E-mail: yzhliu@scut.edu.cn