文章编号:1004-0609(2010)S1-s0123-04

中温旋锻变形Ti2448合金的显微组织及力学性能

张振波1,李述军1,郝玉琳1,杨 锐1,郭正晓2

(1. 中国科学院 金属研究所 沈阳材料国家(联合)实验室,沈阳 110016;

2. Department of Chemistry, University College London, London WC1H 0AJ)

摘 要:采用XRD、TEM等手段对Ti-24Nb-4Zr-8Sn(质量分数,%)合金中温旋锻变形后的显微组织进行研究。结果表明,经过较大的中温变形后,合金呈旋涡状大理石花纹组织且具有与旋锻轴向平行的强烈的á110?丝织构,这种典型的组织是由于具有á110?取向的晶粒在轴向拉应力状态下发生平面应变所致。TEM分析显示组织中含有高密度的小角晶界,应变分布不均匀。旋锻变形后,合金具有3.3%的超弹性变形和微弱的加工硬化行为。由于变形组织中留有大量的分布不均匀的残余应力,合金的塑性较差,在600 ℃下5 min去应力退火处理后,合金的塑性增强。

关键词:Ti-24Nb-4Zr-8Sn;中温旋锻;织构;平面应变

中图分类号:TF 804.3 文献标志码:A

Microstructure and mechanical properties of

warm-swaged Ti2448 alloy

ZHANG Zhen-bo1, LI Shu-jun1, HAO Yu-lin1, YANG Rui1, GUO Zheng-xiao2

(1. Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences,

Shenyang 110016, China;

2. Department of Chemistry, University College London, London WC1H 0AJ)

Abstract: The warm-swaged structure of Ti-24Nb-4Zr-8Sn (mass fraction, %) was studied by XRD and TEM. The results show that the warm-swaged alloy presents a swirled marble-like structure and has a pronounced fibrous á110? texture along the swaging axis. This typical swirled structure forms owing to the planar strain deformation of the á110?-textured grains. According to the TEM observation, there are high densities of low angle grain boundaries, dislocations and asymmetric strain in the deformed structure. The warm-swaged alloy characterizes as prominent non-liner elasticity, 3.3% recoverable elastic strain, and trivial work hardening behavior. Due to the large and asymmetric strain, the plasticity of the deformed alloy is deteriorated, which can be improved after 5 min heat treatment at 600 ℃.

Key words: Ti-24Nb-4Zr-8Sn; warm-swaged; texture; planar strain

Ti-24Nb-4Zr-8Sn合金(以下简称Ti2448)是一种兼具高强度、低模量和超弹性等优良性能的新型医用β钛合金,在生物医疗等领域有着广阔的应用前景[1]。高度局域化非均匀的塑性变形使得Ti2448合金表现出特殊的塑性变形行为,研究发现通过常规冷轧变形就可以获得晶粒尺寸小于50 nm的板材[2-3]。因此,研究不同塑性加工手段下合金的组织、性能和变形机制有助于认识和理解Ti2448合金特殊的变形行为,挖掘其它可以获得更高性能的加工方式。

本文作者研究中温旋锻后Ti2448合金的微观组织和力学性能,针对变形后合金典型的组织特征并结合微观力学理论分析了Ti2448合金旋锻变形机制。

1 实验

成分为Ti-24Nb-4Zr-7.9Sn-0.16O合金铸锭由真空自耗电弧炉熔炼获得,经850 ℃锻造成直径为55 mm 的棒材。截取1 m长的棒材试样,经6道次均匀旋锻变形后,棒材试样的直径为25 mm,总变形量约80%。为了达到低温大面积旋锻变形的效果且避免变形后合金中存在α″马氏体而影响性能,旋锻变形在300 ℃进行。采用AXiovert 200MAT型金相显微镜观察变形后的横、纵截面的组织。用D/MAX2400型X射线衍射仪对合金进行相组成分析,用D8DISCOVER 型X射线衍射仪对旋锻变形后合金进行织构分析。透射样品均取自合金的横截面,用双喷减薄方法制得,双喷用电解液为9%高氯酸+32%正丁醇+59%甲醇(体积分数,%) 溶液, 双喷电压为12 V,温度为-25 ℃。采用TECNAI20透射电子显微镜对减薄样品进行观察。拉伸和循环拉伸实验在Instron8872拉伸疲劳试验机上进行,速率为4.3×10-4 s-1。

2 结果与分析

2.1 Ti2448合金温旋锻变形组织

Ti2448合金旋锻变形后的显微组织如图1所示。旋锻变形使得合金由初始的等轴组织转化为旋涡状组织。变形组织中有两种形态典型的晶粒,比较粗大的弯曲晶粒和严重扭曲的细小晶粒。在旋锻棒纵截面方向上,纤维状晶粒沿旋锻轴向排列。

XRD分析结果显示,在300 ℃大面积旋锻变形后合金组织为单一β相,不存在应力诱发α″等亚稳相。采用XRD对变形后合金进行织构分析,结果如图2所示。由{110}和{200}XRD正极图可以明显看出,Ti2448合金经中温旋锻变形后具有极强的与旋锻轴向平行的á110?丝织构。

为了分析旋锻变形后Ti2448合金的微观亚结构,对旋锻后棒材横截面取样进行透射电镜观察。图3所示为TEM明场像,由于冷变形合金中积聚了大量的应变,形貌像中产生一些不均匀的明暗衬度。由图3(a) 可以看出,亚结构中含有大量小角度晶界和应变集中区,亚晶粒呈长条状。如图3(b)所示,由于剧烈变形导致晶粒细化和扭曲,合金中存在大量的位错和不均区,亚晶粒呈长条状。如图3(b)所示,由于剧烈变形导致晶粒细化和扭曲,合金中存在大量的位错和不均匀的弹性应变场,位错互相缠结,错综排列。而在与其相邻的变形较小的区域,位错密度较低,形貌清晰,表明该处积累应变较少。这些结果也表明,旋锻过程中,合金变形较不均匀,在细小纤维组织处变形量较大,位错密度高,晶粒细化扭曲严重以协调变形,在弯曲的大晶粒区域变形量小,变形主要通过位错滑移进行,小角度晶界的产生对变形有很大贡献。

图1 旋锻Ti2448合金的金相显微组织

Fig.1 Optical microstructures of swaged Ti2448: (a) Cross section; (b) Longitudinal section

图2 旋锻变形后合金横截面的XRD 极图

Fig.2 XRD pole figures of warm-swaged Ti2448: (a) {110} pole figure; (b) {200} pole figure

图3 温旋锻Ti2448合金横截面TEM明场像

Fig.3 TEM bright-field images of warm-swaged Ti2448 alloy

2.2 形变组织形成机理探讨

温旋锻变形后,Ti2448合金呈现典型的旋涡状组织,这与Nb、Fe、Ta等BCC金属[4-5]及Ti-Nb-Ta-Zr-O合金[6](Gum metal)经拉拔或旋锻后的显微组织相似,且都具有沿轴向强烈的á110?丝织构。

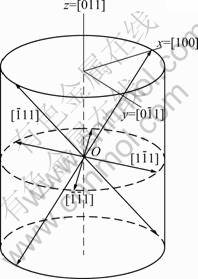

旋锻变形时材料承受两向压应力和一向压应力的应力状态,这与挤压时材料承受的应力状态相似。BCC金属在挤压变形时,{110}、{112}和{123}á111?滑移系可以开动,随着变形的进行,各晶粒的á110?晶向逐渐趋于旋锻轴向排列,形成沿轴向的á110?丝织构。已经具有á110?取向的晶粒在继续旋锻变形时,承受一个沿á110?方向的拉应力和垂直柱面方向的压应力。在沿á110?方向拉应力作用下,晶体的4个á111?滑移方向中的[111]和 两个优先开动,如图4所示。[111]和

两个优先开动,如图4所示。[111]和 滑移方向均处于[011]和[100]方向所组成的平面内,即xOz平面内。位错沿这两个方向滑移使得晶粒在平行于[011]方向伸长,沿[100]方向收缩,而在垂直于xOz平面的

滑移方向均处于[011]和[100]方向所组成的平面内,即xOz平面内。位错沿这两个方向滑移使得晶粒在平行于[011]方向伸长,沿[100]方向收缩,而在垂直于xOz平面的 方向没有变化,也就是应变集中在xOz

方向没有变化,也就是应变集中在xOz 平面内。由于这种平面应变的作用,晶粒沿[011]方向被拉长,形成沿旋锻轴向的纤维状组织,同时晶粒在平行于[100]方向收缩,而在与[100]垂直的

平面内。由于这种平面应变的作用,晶粒沿[011]方向被拉长,形成沿旋锻轴向的纤维状组织,同时晶粒在平行于[100]方向收缩,而在与[100]垂直的 方向晶粒尺寸基本保持不变,于是在垂直于旋锻轴向的(011)平面上逐渐形成椭圆状组织,变形量越大椭圆长轴与短轴差越大。TEM对变形后的亚结构观察也证实了这一点,如图3所示,入射电子束平行于á110?方向, 若将其定为[011], 则晶粒的尺寸短的方向近似平行于[100],而长的方向近似平行于

方向晶粒尺寸基本保持不变,于是在垂直于旋锻轴向的(011)平面上逐渐形成椭圆状组织,变形量越大椭圆长轴与短轴差越大。TEM对变形后的亚结构观察也证实了这一点,如图3所示,入射电子束平行于á110?方向, 若将其定为[011], 则晶粒的尺寸短的方向近似平行于[100],而长的方向近似平行于 ,与上述分析结果吻合良好。在变形过程中,晶粒之间为了协调变形,椭圆状组织发生弯曲,周向压应力的存在也促使了漩涡状组织的形成。在具有á110?取向的晶粒发生平面应变的同时,其它取向随机的晶粒的á110?方向也逐渐趋向于沿旋锻轴向排列,最终形成强烈的á110?丝织构。随着变形量的继续增大,较早发生平面应变形成椭圆状的晶粒严重扭曲、破碎来协调后续变形,而在较大椭圆状晶粒内部形成大量亚晶界,其中部分由于弯曲变形受限而发生破裂。这些在图1所示的金相显微组织中可观察到。

,与上述分析结果吻合良好。在变形过程中,晶粒之间为了协调变形,椭圆状组织发生弯曲,周向压应力的存在也促使了漩涡状组织的形成。在具有á110?取向的晶粒发生平面应变的同时,其它取向随机的晶粒的á110?方向也逐渐趋向于沿旋锻轴向排列,最终形成强烈的á110?丝织构。随着变形量的继续增大,较早发生平面应变形成椭圆状的晶粒严重扭曲、破碎来协调后续变形,而在较大椭圆状晶粒内部形成大量亚晶界,其中部分由于弯曲变形受限而发生破裂。这些在图1所示的金相显微组织中可观察到。

图4 具有á110?取向的晶粒在沿á110?方向拉应力下发生平面应变示意图[5]

Fig.4 Schematic diagram of slip system of á110?-oriented grain under tension stress along á110? direction[5]

2.3 中温旋锻变形Ti2448合金的力学性能

图5所示为中温旋锻变形后合金的应力—位移曲线和循环应力—应变曲线。从图5可以看出, 旋锻变形后,Ti2448合金明显具有非线弹性现象,超弹性约为3.3%。为了减少中温加工缺陷和残余应力对性能的影响,并且使材料仍保持单一β相,选择在600 ℃进行5 min短时退火处理。退火后,合金的强度基本保持为870 MPa不变,而断后伸长率从7.1%提高到11.5%。采用TEM对退火后合金亚结构进行分析显示,与退火前合金组织亚结构相比,退火后亚晶界数量明显减少,位错缠结程度减弱并部分湮灭,多数区域中积聚的应变得到释放,从而导致合金的塑性有所提高。

图5 旋锻变形后Ti2448合金的应力—位移曲线和循环应力—应变曲线

Fig.5 Stress—displacement curve(a) and cyclic stress—strain curves(b) of warm-swaged Ti2448 alloy

3 结论

1) 300 ℃中温旋锻变形后Ti2448合金横截面呈漩涡状大理石花纹组织,并具有沿旋锻轴向强烈的á110?丝织构,变形后合金中产生了高密度的小角度晶界和分布不均匀的应力。

2) 漩涡状变形组织的产生可能是由于具有á110?取向的晶粒在旋锻变形时发生平面应变,椭圆状晶粒发生弯曲以协调变形所导致。

3) 变形后Ti2448合金仍具有非线弹性变形特征,超弹性约为3.3%,加工硬化效应极弱,经600 ℃退火处理5 min后,材料塑性有所提高。

REFERENCES

[1] HAO Yu-lin, LI Shu-jun, SUN Shu-ying, ZHENG Cai-yun, HU Qing-miao, YANG Rui. Super-elastic titanium alloy with unstable plastic deformation [J]. Applied Physics Letters, 2005, 87(9): 091906-3.

[2] HAO Yu-lin, LI Shu-jun, SUI Man-ling, YANG Rui. Ductile titanium alloy with low Poisson's ratio [J]. Phys Rev Lett, 2007, 98(21): 216405.

[3] LI Shu-jun, CUI Tian-cheng, LI Yu-lan, HAO Yu-lin, YANG Rui. Ultrafine-grained beta-type titanium alloy with nonlinear elasticity and high ductility [J]. Applied Physics Letters, 2008, 92(4): 043128-3.

[4] SANDIM H R Z, MCQUEEN H J, BlUM W. Microstructure of cold swaged tantalum at large strains[J].Script Materialia, 1999, 42(2): 151-156.

[5] HOSFORD W. Microstructural changes during deformation of [011] fiber-textured metals [J]. Trans TMS-AIME, 1964, 230(1): 12-15.

[6] GUO W Y, XING H, SUN J, LI X L, WU J S, CHEN R. Evolution of microstructure and texture during recrystallization of the cold-swaged Ti-Nb-Ta-Zr-O alloy [J]. Metall Mater Trans A, 2008, 39(3): 672-667.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(50631030, 50901080);辽宁省自然科学基金资助项目(20092075)

通信作者:郝玉琳,研究员,博士;电话:024-83978841;E-mail:ylhao@imr.ac.cn