文章编号:1004-0609(2015)-03-0747-07

高速压制法制备Al2O3弥散强化铜合金

闫志巧1, 2,陈 峰1,蔡一湘1

(1. 广州有色金属研究院 粉末冶金研究所,广州 510650;

2. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用高速压制(HVC)方法成形Al2O3质量含量分别为0.34%、1.00%和3.19%的3种弥散铜合金粉末,研究不同粉末HVC的成形效果和压坯的烧结性能。结果表明:压坯致密度随冲击能量的增加而增加,随Al2O3含量的增加有所降低。在最大冲击能量为927.5 J时,3种粉末压坯的最大致密度分别达到98.4%、96.2%和93.4%。压坯在氢气中经1080 ℃烧结1 h后,致密度并无明显变化,但导电率显著提高,同时硬度略有降低。所制备的3种Al2O3弥散强化铜合金的导电率分别为81.0%(IACS)、64.1%(IACS)和48.3%(IACS),硬度分别为77.3、85.7和81.3 HRB。3种烧结合金在氢气中经1080 ℃处理2 h后,其硬度基本保持不变。整体而言,采用HVC法制备含0.34%Al2O3的弥散铜合金具有良好的导电率、硬度和抗高温软化性能,可基本满足点焊电极的实际应用需求。

关键词:铜合金;Al2O3弥散强化铜合金;高速压制;导电率;硬度

中图分类号:TF124.36 文献标志码:A

Al2O3 dispersion strengthened copper alloy prepared by high-velocity compaction

YAN Zhi-qiao1, 2, CHEN Feng1, CAI Yi-xiang1

(1. Department of Powder Metallurgy, Guangzhou Research Institute of Non-ferrous Metals, Guangzhou 510650, China;

2. State Key laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The high-velocity compaction (HVC) was applied to press three kinds of dispersion copper alloy powders with Al2O3 mass fraction of 0.34%, 1.00% and 3.19%, respectively. The forming effects of powders and the following sintered properties were studied. The results show that the relative density of green compact increases with increasing the impact energy, and decreases with increasing the Al2O3 content. When the largest impact energy is 927.5 J, the maximum relative densities of compacts of the three powders reaches 98.4%,96.2% and 93.4%, respectively. After being sintered at 1080 ℃ in hydrogen for 1 h, the relative density of compacts has no obvious change, the electrical conductivity is significantly improved and the hardness slightly decreases. The electrical conductivity and hardness of the prepared three Al2O3 dispersion strengthened copper alloys are 81.0%(IACS), 64.1%(IACS) and 48.3%(IACS), and 77.3, 85.7 and 81.3 HRB, respectively. After being heat-treated in hydrogen at 1080 ℃for 2 h, the hardness of three sintered alloys is almost unchanged. In general, the dispersion strengthened copper alloy with 0.34% Al2O3 prepared by HVC has good comprehensive performances and its electrical conductivity, hardness and softening resistance at high temperature can meet the basic requirement of the practical application used as spot welding electrodes.

Key words: copper alloy; Al2O3 dispersion strengthened copper alloy; high-velocity compaction; electrical conductivity; hardness

Al2O3弥散强化铜合金具有突出的室温和高温强度,同时兼备优良的导电、导热性能,在许多要求材料同时具备高导电、导热和高温强度的场合倍受青睐,可广泛应用于电力、电子、机械等工业领域,如用作点焊电极、高强度电力线和集成电路引线框架等[1]。但该合金难以通过传统的粉末冶金方法直接获得高密度的压坯和烧结体,通常需要对烧结体进行变形加工以获得致密的板材或棒材,然后经机加工制成所需产品。Al2O3弥散强化铜合金的传统制备工艺为:CuAl合金+氧源→混合→等静压成形→内氧化-还原-烧 结→变形加工(热挤压+冷轧或拉拔)→合金[2]。整个工艺存在流程复杂、原材料利用率低、能耗大、产品稳定性差和成本高等问题,并且该工艺通常难以制备高Al2O3含量(质量分数≥1%)的合金。因此,急需研发一种短流程、低成本制备高性能Al2O3弥散强化铜合金的新方法。

高速压制(High-velocity comapaction, HVC)技术是一种极具优势的粉末成形技术,兼具动态压制的高冲击能量和传统压制的高效平稳等共同特征,可实现冷态下粉末的高致密成形和连续化生产,具有成本低、压坯密度高且分布均匀、低弹性后效和高精度等特点[3-4]。目前,HVC技术不仅在压制Fe[5]、Cu[6]等延性金属粉末时取得了显著优于传统成形方法的效果,而且在压制传统方法难成形的粉末时也表现了一定的优势。如Ti粉采用温压[7]和冷等静压[8]成形时通常仅能获得85%致密度的压坯,而采用HVC成形的纯Ti粉[9]、Ti-10Mo[10]和Ti-4.5Al-6.8Mo-1.5Fe[11]混合粉末的压坯致密度均能达到95%以上。总之,HVC为实现传统难成形粉末的高致密成形提供了可能。

Al2O3弥散铜合金粉末与钛基粉末具有相似的加工硬化特性。基于HVC在成形钛基粉末时所展现出来的良好效果,采用HVC成形Al2O3弥散铜合金粉末所能获得的效果值得期待。因此,本研究中以内氧化法制备的3种不同Al2O3含量的弥散铜合金粉末为原料,考察不同粉末的HVC成形效果以及压坯的烧结行为,并表征其性能,以期为短流程、低成本制备Al2O3弥散强化铜合金提供参考。

1 实验

原料粉末为粒径小于150 μm的3种水雾化Cu-Al合金粉,其中Al含量分别为0.18%、0.55%和1.95%(质量分数)(见表1)。以Cu2O为氧源,按Al发生完全氧化所消耗Cu2O的质量且分别过量30%、30%和20%(即氧源因数k[12]依次为1.3、1.3和1.2)进行配料,充分混合后,在氮气中于900 ℃内氧化2 h,在氢气中于900 ℃还原1 h,经粉碎、过筛后制得3种粒径小于150 μm的Al2O3弥散铜合金粉末,相应粉末的成分及性能见表1,显微形貌如图1所示。

采用HYP35-2型高速冲击压机对3种粉末进行成形。所用模具为截面直径20 mm的圆柱模具,装粉高度15.5 mm。成形时选用的冲击行程依次为20、25、30和35 mm,由经验公式E=26.5S(E和S分别为冲击能量和冲击行程)[13]计算相应的冲击能量依次为530、662.5、795和927.5 J。将HVC成形的压坯在氢气中于1080 ℃烧结1 h,制得Al2O3弥散强化铜合金。

依据Cu-Al合金粉中的Al发生完全氧化且过量的Cu2O发生充分还原,计算Al2O3弥散铜合金粉末的理论密度(见表1)。采用排水法测试试样的密度,根据测试值和理论值计算致密度。采用POLYYVRA-MET型金相显微镜和JXA-8100型扫描电镜观察试样的显微组织和形貌,采用Zwick显微硬度计测试粉末的显微硬度(HV0.01),采用FD-101型涡流电导率仪测试试样的导电率,采用HR-150A型洛氏硬度计测试烧结合金及其经氢气中1080 ℃处理2 h后的硬度(HRB)。

表1 3种粉末及试样的成分及性能

Table 1 Composition and properties of three kinds of powders and samples

图1 3种合金粉末的SEM像

Fig. 1 SEM images of three kinds of alloy powders

2 结果与讨论

2.1 压坯密度与微观组织

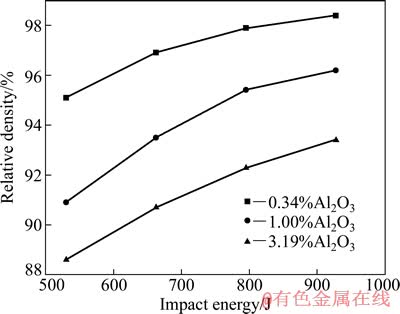

HVC方法成形3种Al2O3弥散铜合金粉末的压坯致密度如图2所示。由图2可以看出,随冲击能量的增加,3种粉末的压坯致密度增加,但增加的幅度均有所减缓,表明继续增大冲击能量对致密化的贡献逐渐减小。整体而言,采用HVC方法成形Al2O3弥散铜合金粉末能获得较好的成形效果,特别是对于低Al2O3含量的粉末,如含0.34%Al2O3的粉末在冲击能量为927.5 J时,所获得的压坯密度为8.71 g/cm3(见表1,98.4%RD)。随Al2O3含量的增加,在相同的冲击能量下,HVC成形获得的压坯致密度有所降低。含1.00%和3.19% Al2O3的粉末所获得的最大压坯密度分别为8.44和7.98 g/cm3,相应的致密度分别为96.2%和93.4%。

图2 HVC成形3种Al2O3弥散铜合金粉末的压坯致密度

Fig. 2 Relative density (RD) of three kinds of Al2O3 dispersion Cu alloy powders prepared by HVC

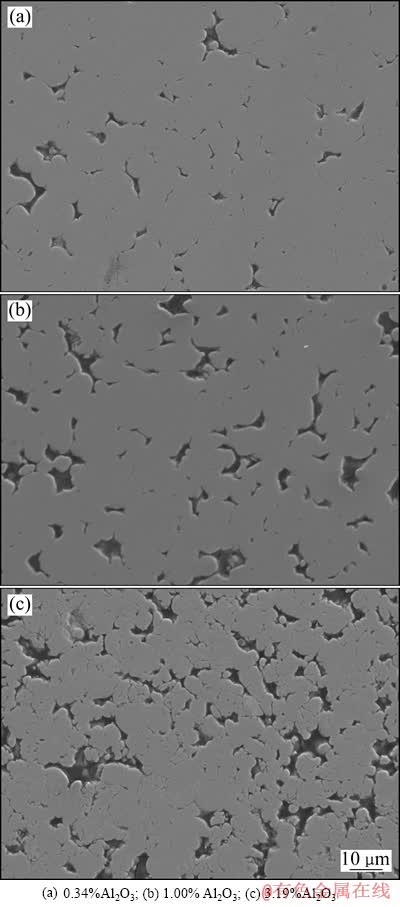

图3 3种最大致密度合金粉末压坯的SEM像

Fig. 3 SEM images of three green compacts with maximum relative density

图3所示为3种最大致密度合金粉末压坯的SEM像。由图3所示的3种最大致密度合金粉末压坯的微观形貌可以看出,随Al2O3含量的增加,压坯中的孔隙增多,致密度下降。对比图3(a)与图1(a)发现,含0.34% Al2O3压坯中的颗粒尺寸明显大于原始粉末的颗粒尺寸。一部分原因是由于压制过程中粉末颗粒发生了较大程度的塑性变形,颗粒扁平化现象十分明显;另一部分原因在于大量粉末颗粒之间发生熔焊,部分颗粒边界消失(见图3(a)中箭头所指),使得数个颗粒以一个整体的形式呈现。随Al2O3含量的增加,颗粒扁平化变形程度减弱,颗粒界面熔合程度降低,压坯中颗粒尺寸逐渐与原始粉末颗粒尺寸接近。在含3.19%Al2O3的压坯中(见图3(c)),粉末扁平化变形程度最小,且颗粒内部出现了破裂现象。这可能是由于该粉末具有更高的加工硬化速率,在发生较小应变的情况下就导致内应力急剧增加,致使粉末颗粒发生破裂。

对比Al2O3弥散铜合金粉末中Al2O3含量和压坯致密度的变化趋势可知,HVC的成形效果与Al2O3含量呈负相关性。即当Al2O3含量较低时,所成形压坯的致密度较高。随Al2O3含量的增加,压坯致密度降低。这可能是由于随Al2O3含量的增加,合金粉末的显微硬度增大,其对压制的阻碍作用增加,从而导致压坯致密度下降。但是对于含1.00% 和3.19% Al2O3的合金粉末,二者的显微硬度接近,分别为165和161HV0.01(见表1),压坯致密度却相差较大,分别为96.2%和93.4%。这表明除了显微硬度之外,还有其他因素(如前述的加工硬化速率)会影响HVC成形Al2O3弥散铜合金粉末的压制效果。

综上所述,本研究中采用HVC成形含0.34% Al2O3的合金粉末获得了98%以上的压坯致密度,该成形效果与陈峰等[13]采用HVC方法成形纯Cu粉的效果相当,表明较低Al2O3含量不影响弥散铜合金粉末的HVC成形效果。

2.2 烧结性能

2.2.1 密度与微观组织

3种Al2O3弥散铜粉末压坯经1080℃烧结后,坯体的形状保持良好,没有出现鼓胀变形现象。通过检测密度发现,烧结体密度与压坯密度差异不大,即通过烧结并没有进一步提升致密度(见表1)。图4所示为3种压坯烧结后的SEM像。对比图3和4可以看出,烧结体中颗粒边界基本消失,颗粒之间由非冶金结合转变为冶金结合。但是烧结体中仍存有大量残余孔隙,而且孔隙数量及尺寸与烧结前相比没有显著变化。这是由于Al2O3弥散铜合金的烧结机理为固相烧结,弥散的Al2O3粒子提高了基体Cu扩散的起始位能,使体积扩散难以启动,阻碍了颗粒之间的空位流动,延缓了烧结颈的长大,从而对Cu粉的烧结有强烈的抑制作用[14]。虽然简单地提高烧结温度并不能促进Al2O3弥散铜合金的致密化,但可以提高烧结颈长大速率,改善颗粒间的界面结合状态,有利于获得更高的导电率。因此,本研究中选择在1080 ℃(0.996T,T为铜熔点温度)这一相对较高的温度进行烧结。

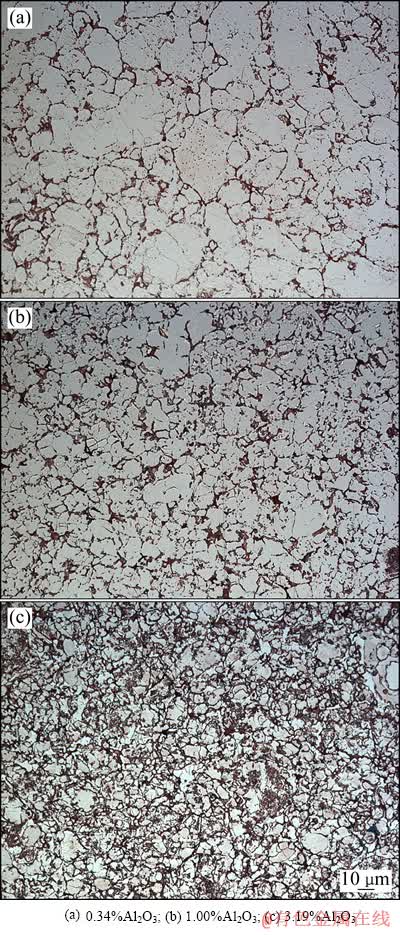

图5所示为烧结试样的金相组织。从图5可以看出,随Al2O3含量的增加,烧结体中的孔隙数量逐渐增加。这与密度检测结果及图4中的SEM结果是一致的。同时,随Al2O3含量的增加,晶粒尺寸明显减小。这应该与Al2O3粒子对Cu颗粒长大的抑制作用有关。而晶粒尺寸的减小意味着晶界数量的增加,对电子传递会造成更多的阻碍,从而影响合金的导电性能。此外还可以看出,随Al2O3含量的增加,烧结体的均匀性逐渐变差。这种不均匀性主要是以下两个原因造成的:一是添加的氧源Cu2O会被还原成未被Al2O3粒子强化的纯Cu颗粒。随原料粉末中Al含量的增 加,Cu2O的添加量也相应增加,使得更多的纯Cu颗粒混在了Al2O3弥散铜颗粒之间,导致了局部成分的不均匀程度增加;二是随Al含量的增加,内氧化时Al的逆扩散趋势增加,在粉末颗粒内部形成连续的氧化物壳,导致Al2O3弥散铜颗粒本身显微组织的不均匀程度增加。

图4 3种烧结试样的SEM像

Fig. 4 SEM images of three sintered samples

图5 3种烧结试样的金相组织

Fig. 5 Optical microstructures of three sintered samples

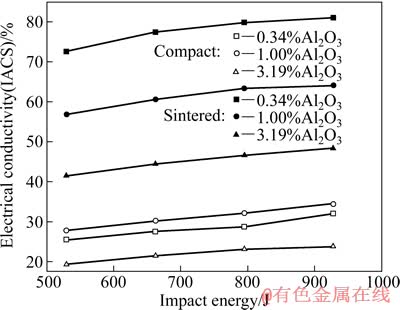

2.2.2 导电率

图6所示为3种压坯和烧结试样的导电率曲线。由图6可见,随冲击能量的增加,试样的电导率增大。含0.34%、1.00%和3.19% Al2O3的合金粉末在927.5J的冲击能量时,所成形压坯的导电率分别为32.0%(IACS)、34.4%(IACS)和23.8%(IACS),烧结后的导电率分别为81.0%(IACS)、64.1%(IACS)和48.3%(IACS),即烧结体的导电率比压坯的依次提高了153%、86%和103%。压坯经烧结后虽然致密度没有提高,但烧结体的导电率大幅度提高。这主要归因于烧结过程中粉末颗粒间发生了冶金结合。此外,随Al2O3含量的增加,烧结体的导电率显著下降,这主要与以下因素有关:1) 随Al2O3含量的增加,烧结体的致密度降低,因而降低了其导电率;2) 随Al2O3含量的增加,可导电金属Cu的体积分数下降,使导电率降低;3) Al2O3和铜热膨胀系数的差异造成的内应力会导致晶格畸变,导致电子波散射,使电阻率增加;4) Al2O3阻碍了晶粒长大,单位体积内的晶界数量增多,导致电子波散射增加,导电率下降[15]。

本研究所制备含0.34%Al2O3弥散铜合金的导电率最大,为81.0%(IACS),低于热挤压法制备的相同Al含量的弥散铜合金(ODS18)的水平(89.7% (IACS))[16],这主要是由于采用HVC方法制备的合金中仍存在一定的孔隙。而采用传统工艺制备Al2O3弥散强化铜合金时,通常需要借助多道次的热挤压+冷轧或拉拔等大变形方法实现致密化,最终材料基本可以达到全致密,因而,导电率更佳。但本研究中采用的工艺与传统工艺相比,流程明显缩短、材料利用率提高。同时,该合金的导电率与冷轧法制备的更低Al含量合金(0.15%Al)的导电率(80.8%(IACS))接近[12],与实际使用的高强高导铜合金(如铬青铜、铬锆青铜)的导电率相当。

图6 3种压坯和烧结试样的电导率

Fig. 6 Electrical conductivity of three compact and sintered samples

2.2.3 硬度

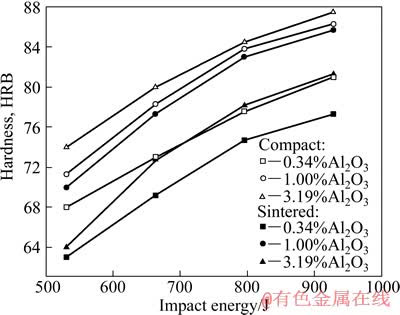

图7所示为3种压坯和烧结试样的硬度。由图7所示的硬度曲线可以看出,试样的硬度随冲击能量的增加而增大。就压坯而言,硬度随Al2O3含量的增加而增大,但1.00%和3.19%两种 Al2O3含量的粉末压坯硬度相差不大。与压坯相比,烧结体的硬度均有降低,但下降的幅度并不相同。含0.34%、1.00%和3.19% Al2O3的合金粉末在927.5J的冲击能量时,压坯的硬度分别为81.0、86.3和87.5 HRB,烧结后合金的硬度分别为77.3、85.7和81.3 HRB,依次下降了4.6%、0.7%和7.1%。

图7 3种压坯和烧结试样的硬度

Fig. 7 Hardness of three compact and sintered samples

致密度和Al2O3含量对Al2O3弥散强化铜合金的硬度有重要影响。随着冲击能量的增加,所成形试样的致密度增加,硬度随之增大。当Al2O3含量较低时,采用内氧化法制备的合金粉末中容易实现Al2O3粒子的均匀弥散分布。随Al2O3含量的提高,合金粉末的显微硬度增加,使得粉末压坯的硬度增加。但当Al2O3含量达到一定值时,内氧化法制备合金粉末已无法实现Al2O3粒子的均匀弥散分布,再增加Al2O3含量反而不利于提高材料的硬度,这也是1.00%和3.19%两种 Al2O3含量的合金粉末显微硬度和压坯硬度相差不大的原因。压坯经1080 ℃烧结后,由于坯体未发生进一步的致密化,同时成形过程中的加工硬化作用得以消除,使得合金的硬度反而低于压坯的硬度。

烧结合金在氢气中经1080 ℃处理2 h后,其硬度基本保持不变(见表2)。而采用传统工艺制备的弥散铜合金在900~950 ℃以上温度处理1 h后,合金的硬度就会产生较大程度的降低。以秦晓冬[17]制得的1.0% Al2O3弥散强化铜合金为例,其室温硬度为82.9 HRB,经1000 ℃退火后,硬度仅为69.3 HRB。由此可以看出,高速压制法制备的Al2O3弥散铜合金在高温下基本不发生软化,具有优异的高温抗软化性能。整体而言,本研究中制备的含0.34% Al2O3的弥散铜合金具有良好的导电率、硬度和抗高温软化性能,可以满足点焊电极的使用要求,为短流程、低成本制备Al2O3弥散强化铜点焊电极提供了一种新方法。

表2 烧结合金及其在氢气中经1080 ℃处理2 h后的硬度

Table 2 Hardness of sintered alloys and treated in hydrogen at 1080 ℃ for 2 h

3 结论

1) HVC成形Al2O3弥散铜合金粉末时,压坯致密度随冲击能量的增加而缓慢增加,随Al2O3含量的增加有所降低。当冲击能量为927.5J时,HVC成形含0.34%、1.00%和3.19%的3种Al2O3含量的合金粉末所获得的压坯致密度分别为98.4%、96.2%和93.4%。

2) 弥散的Al2O3粒子强烈抑制Cu粉的烧结,使得HVC压坯在氢气中经1080 ℃烧结1h后,致密度没有提高,但烧结促进了颗粒之间的冶金结合,使导电率显著提高,同时烧结消除了HVC过程中的加工硬化,使硬度略有降低。

3) HVC方法制备的含0.34%、1.00%和3.19%的3种Al2O3含量的弥散强化铜合金的导电率分别为81.0%(IACS)、64.1%(IACS)和48.3%(IACS),硬度分别为77.3、85.7和81.3HRB。3种烧结合金经氢气中1080℃处理2h后,硬度基本保持不变。

4) 采用HVC方法制得的含0.34%Al2O3的弥散强化铜合金具有良好的导电率、硬度和抗高温软化等综合性能,可以满足点焊电极的实际应用需求。

REFERENCES

[1] BESTERCI M, KOHUTEK I, VELGOSOVA O. Microstructural parameters of dispersion strengthened Cu-Al2O3 materials[J]. Journal of Materials Science, 2008, 43(3): 900-905.

[2] 李美霞, 罗 骥, 郭志猛, 候 婷, 张云霞. 纳米Al2O3弥散强化铜复合材料的产业化制备及研究[J]. 材料导报, 2010, 24(1): 50-52.

LI Mei-xia, LUO Ji, GUO Zhi-meng, HOU Ting, ZHANG Yun-xia. Manufacture in industrialization and study on nano-Al2O3 dispersion strengthened copper composites[J]. Materials Review, 2010, 24(1): 50-52.

[3] DORE F, LAZZAROTTO L, BOURDIN S. High velocity compaction: overview of materials, applications and potential[J]. Materials Science Forum, 2007, 534/536: 293-296.

[4] 闫志巧, 蔡一湘. 高速压制技术的研究进展和发展趋势[J]. 材料研究与应用, 2010, 4(4): 495-499.

YAN Zhi-qiao, CAI Yi-xiang. Process and trend of high velocity compaction technology[J]. Materials Research and Application, 2010, 4(4): 495-499.

[5] BARENDVANDEN B, CHRISTER F, TOMAS L. Industrial implementation of high velocity compaction for improved properties[J]. Powder Metallurgy, 2006, 49(2): 107-109.

[6] 王建忠, 曲选辉, 尹海清, 周晟宇, 易明军. 电解铜粉高速压制成形[J].中国有色金属学报, 2008, 18(8): 1498-1503.

WANG Jian-zhong, QU Xuan-hui, YIN Hai-qing, ZHOU Sheng-yu, YI Ming-jun. High velocity compaction of electrolytic copper powder[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1498-1503.

[7] 何世文, 欧阳鸿武, 刘 咏, 汤慧萍, 黄愿平. 钛合金粉末温压成形行为[J]. 稀有金属材料与工程, 2005, 34(7): 1119-1122.

HE Shi-wen, OU YANG Hong-wu, LIU Yong, TANG Hui-ping, HUANG Yuan-ping. Study of warm compaction behavior for titanium alloy powder[J]. Rare Metal Materials and Engineering, 2005, 34(7): 1119-1122.

[8] ABKOWITZ S, ABKOWITZ S M, FISHER H, SCHWARTZ P J. CermeTi discontinuously reinforced Ti-matrix composites: Manufacturing, properties, and applications[J]. JOM, 2004, 56(5): 37-41.

discontinuously reinforced Ti-matrix composites: Manufacturing, properties, and applications[J]. JOM, 2004, 56(5): 37-41.

[9] 闫志巧, 陈 峰, 蔡一湘. 不同粒径Ti粉的高速压制行为和烧结性能[J]. 金属学报, 2012, 48(3): 379-384.

YAN Zhi-qiao, CHEN Feng, CAI Yi-xiang. High velocity compaction behavior and sintered properties of Ti powders with different particle sizes[J]. Acta Metallurgica Sinica, 2012, 48(3): 379-384.

[10] KHAN D F, YIN H Q, LI H, ABIDEEN Z, ULLAH A, QU X H, ELLAHI M. Effect of impact force on Ti-10Mo alloy powder compaction by high velocity compaction technique[J]. Materials & Design, 2014, 54: 149-153.

[11] YAN Z Q, CHEN F, CAI Y X, YIN J, ZHENG Y K. Preparation and properties of Ti-4.5Al-6.8Mo-1.5Fe-alloy by high-velocity compaction[J]. Powder Technology, 2013, 246: 345-350.

[12] 高 翔, 罗丰华, 谭永菊, 付晓虎, 陈春辉, 崔建民. 内氧化-冷轧制备Al2O3弥散强化铜合金的组织与性能[J]. 中国有色金属学报, 2010, 20(10): 2019-2024.

GAO Xiang, LUO Feng-hua, TAN Yong-ju, FU Xiao-hu, CHEN Chun-hui, CUI Jian-min. Microstructure and properties of Al2O3 dispersion strengthened copper alloys prepared by internal oxidation and cold rolling[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 2019-2024.

[13] 陈 峰, 闫志巧, 蔡一湘, 郑玉凯. 压制方式对电解Cu粉高速压制成形特征的影响[J]. 粉末冶金材料科学与工程, 2014, 19(1): 116-122.

CHEN Feng, YAN Zhi-qiao, CAI Yi-xiang, ZHENG Yu-kai. Effect of high-velocity compaction methods on characteristics of electrolytic copper powder[J]. Materials Science and Engineering of Powder Metallurgy, 2014, 19(1): 116-122.

[14] 肖广志, 肖平安, 周 威, 雷 豹, 张小虎. 球磨时间和氧化铝含量对氧化铝弥散增强铜基复合材料组织与性能的影响[J]. 机械工程材料, 2011, 35(1): 40-42, 52.

XIAO Guang-zhi, XIAO Ping-an, ZHOU Wei, LEI Bao, ZHANG Xiao-hu. Effects of ball milling time and alumina content on microstructure and properties of alumina dispersion reinforced copper based composites[J]. Materials for Mechanical Engineering, 2011, 35(1): 40-42, 52.

[15] HUSSAIN Z, KIT L C. Properties and spot welding behavior of copper-alumina composites through ball milling and mechanical alloying[J]. Materials & Design, 2008, 29(7): 1311-1315.

[16] LEE J, KIM Y C, LEE S, KIM N J, AHN S. Correlation of the microstructure and mechanical properties of oxide-dispersion- strengthened coppers fabricated by internal oxidation[J]. Metallurgical and Materials Transactions A, 2004, 35(2): 493-502.

[17] 秦晓冬. Cu-5wt.%Al2O3复合材料微观结构及高温性能研究[D]. 长沙: 中南大学, 2013: 54-57.

QIN Xiao-dong. Microstructure and high-temperature properties of Cu-5wt%Al2O3 composites[D]. Changsha: Central South University, 2013: 54-57.

(编辑 李艳红)

基金项目:广州市珠江科技新星专项基金资助项目(2012J2200096);科技部科研院所技术开发研究专项基金资助项目(2012EG215025);国家自然科学基金资助项目(51004040)

收稿日期:2014-05-28;修订日期:2014-12-22

通信作者:闫志巧,高级工程师,博士;电话:020-61086627;E-mail:zhiqiaoyan@163.com