文章编号:1004-0609(2008)07-1311-06

铸铝件凝固过程三维瞬态温度场的数值模拟

隋大山,崔振山

(上海交通大学 国家模具CAD工程研究中心,上海 200030)

摘 要:采用有限元数值算法,针对一具体铝合金砂型铸造工艺,充分考虑材料和边界条件等参数的非线性特征,使用等价比热容法处理结晶潜热,对凝固过程进行了三维瞬态温度场的数值模拟。通过铸造测温实验,得到了不同位置的测温曲线,且每个位置的测温曲线与相应的计算温度曲线基本吻合,从而证明数值模拟的精度和有效性;对于各测温点的计算温度与测量温度的偏差情况,从测温误差和有限元模型两方面进行分析,提出降低热电偶测温误差和提高数值模拟精度的具体措施。

关键词:铝合金;凝固过程;三维热分析;瞬态温度场;有限元法;数值模拟

中图分类号:TG 146.2 文献标识码:A

Numerical simulation of 3D transient temperature field in

aluminum alloy solidification process

SUI Da-shan, CUI Zhen-shan

(National Die and Mould CAD Engineering Research Center, Shanghai Jiao Tong University, Shanghai 200030, China)

Abstract: The 3D transient temperature field was solved to the aluminum alloy solidification process by employing finite element method. The nonlinear feature of material properties and boundary condition was considered and the equivalent specific heat method was adopted to treat the latent heat. The temperature measurement experiment was done and the temperature measurement curves were acquired in different location, and the measurement temperatures were basically identical with the corresponding calculated ones. Thus, it verifies the accuracy and validity of numerical simulation. The errors between the measurement temperatures and the calculated ones were analyzed from the viewpoint on both the measurement error and the finite element model. Moreover, the detailed measurements were proposed to decrease the measurement errors and improve the simulation accuracy.

Key words: aluminum alloy; solidification process; 3D thermal analysis; transient temperature field; finite element method; numerical simulation

凝固过程温度场的数值模拟是铸造过程数值模拟技术的核心内容之一,是预测缩孔、缩松、热裂和宏观偏析等铸造缺陷的基础[1]。自20世纪60年代以来,各国学者对凝固过程温度场的数值模拟开展了一系列研究,主要包括材料参数、初始条件、边界条件和结晶潜热的处理方法,各种数值算法的具体实现等[2]。目前该技术已基本成熟,正逐渐成为铸造工艺设计和优化的主要工具。

对于凝固过程温度场的数值模拟,目前的研究重点是如何进一步提高模拟精度和计算效率[3]。许多学者对此进行了深入研究,如采用三维几何模型[4?5],考虑具体的铸造工艺特点[6?7],考虑材料参数的非线性特征[8?9],采用合适的方法处理结晶潜热[10?11],改进数值算法[12?13]等。

本文作者采用有限元数值算法,对一个具体的铝合金砂型铸造过程进行了三维瞬态温度场的数值模拟。模拟中充分考虑材料和边界条件等参数的非线性特征,使用等价比热容法处理结晶潜热。同时,对该铸造工艺进行了测温实验,测温曲线与相应的计算温度曲线基本吻合,从而证明了数值模拟的精度和有效性。针对计算温度与测量温度的偏差情况,从测量误差和计算模型两方面进行了分析,提出了降低热电偶测温误差和提高模拟精度的具体措施。

1 凝固过程数值模拟的数学模型

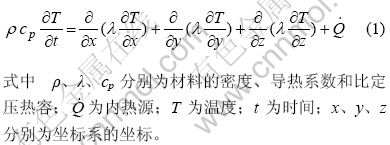

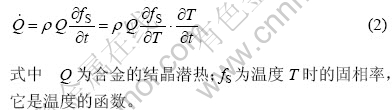

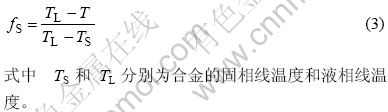

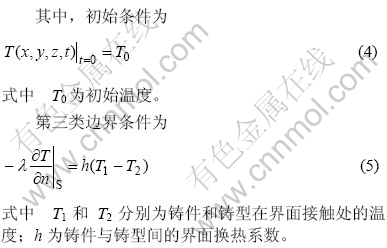

铸造凝固过程瞬态温度场的数值模拟就是求解Fourier导热微分方程,其数学模型为[2]:

金属凝固过程释放结晶潜热是其显著特点。对于结晶潜热的处理,常用的方法有等价比热容法、温度回升法和热焓法等[2]。本文作者采用等价比热容法处理结晶潜热,即有

假定结晶潜热在凝固区间均匀释放,合金的固相率与温度呈线性关系,则有

求解Fourier导热微分方程的定解条件还包括初始条件和边界条件。

综合以上数学模型,就可求解凝固过程铸件与铸型内的三维瞬态温度场。本文作者采用有限单元 法,在通用CAE软件ABAQUS平台上经二次开发以求解瞬态温度场。

2 具体工艺方案和测温实验

对一个壁厚为25 mm的工字型铸件的凝固过程进行了三维瞬态温度场的数值模拟。该铸造工艺采用两箱造型,铸件材料是ZL102,铸型为石英干砂型,铸造工艺示意图及结构尺寸如图1所示。图中TC1、TC2和TC3为定义的3个热电偶位置,以o点为坐标原点(x、y、z方向如图1所示),这3个热电偶的坐标分别为TC1(100, 40, 50)、TC2(77.5, 37.5, 50.0)和TC3(60.0, 27.5, 50.0),采用K型热电偶分别测量3个位置的温度变化曲线,测温数据每隔0.225 s记录一次,K型热电偶的公差等级为二级,时间常数约为45 ms。

图1 铸造工艺示意图

Fig.1 Schematic diagram of casting process (mm)

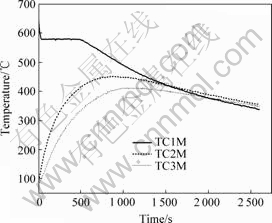

开始浇注时,砂型的初始温度为80.0 ℃,ZL102的浇注温度为690.0 ℃,3个热电偶的测量温度分别为TC1M、TC2M和TC3M,曲线如图2所示。

图2 3个热电偶的测温曲线

Fig.2 Measurement temperature curves for 3 thermocouples

3 三维瞬态温度场的数值模拟

3.1 有限元模型和已知条件

根据该铸造工艺对称的结构特点,取模型的四分之一进行模拟,对称面作为绝热面处理。有限元模型采用六面体单元。其中,铸件部分共生成4 282个节点和3 180个单元;砂型部分共生成8 235个节点和6 890个单元。铸件的有限元模型(整个铸件的四分之一)如图3所示。

图3 工字型铸件的有限元模型

Fig.3 Finite element model of 工-shape casting

为保证模拟精度,充分考虑材料参数的非线性特征,根据文献[14],ZL102和干砂型的热物性参数如表1所列。ZL102的固相线温度θS=574.0 ℃,液相线温度θL=580.0 ℃,结晶潜热Q=480.0 kJ/kg。另外,砂型表面与外界空气的对流换热系数为15.0 W/(m2?K)。

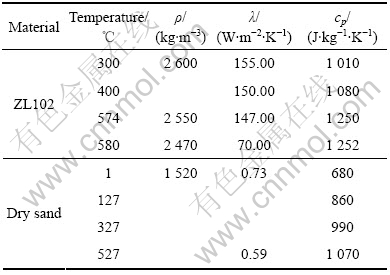

表1 ZL102和干砂型的热物性参数

Table 1 Material property parameters of ZL102 and dry sand

作为边界条件的铸件与铸型间界面换热系数,通过采用文献[15]介绍的Tikhonov正则化方法求解热传导反问题来确定。求解热传导反问题的依据是使用上述相同的合金和铸型材料(即ZL102和干砂型)的圆柱体铸件的测温数据,求得的界面换热系数表达式为:

3.2 三维瞬态温度场的模拟结果

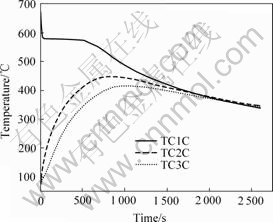

根据上述已知条件,在通用CAE软件ABAQUS平台上经两次开发即可求解铸件和铸型内的三维瞬态温度场。3个热电偶位置对应的计算温度(分别为TC1C、TC2C和TC3C),曲线如图4所示。

图4 3个热电偶的计算温度曲线

Fig.4 Calculation temperature curves for 3 thermocouples

4 结果及分析

4.1 模拟结果分析

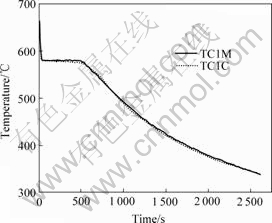

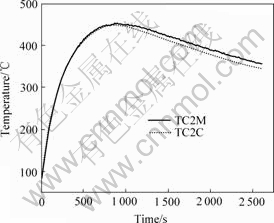

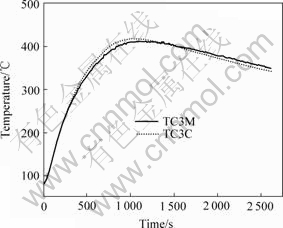

根据图2和4,将每个热电偶位置的测量温度曲线和计算温度曲线放在同一坐标系内(见图5~7),TC1点位于铸件内。由图5知,该点的测量温度曲线与计算温度曲线基本重合。TC2点和TC3点位于砂型内。由图6和7可知,这两点的测量温度曲线与计算温度曲线在某些时刻存在明显的偏离。

图5 TC1点的计算温度和测量温度的对比

Fig.5 Comparison of measurement temperature and calculation temperature at TC1 point

图6 TC2点的计算温度和测量温度的对比

Fig.6 Comparison of measurement temperature and calculation temperature at TC2 point

图7 TC3点的计算温度和测量温度的对比

Fig.7 Comparison of measurement temperature and calculation temperature at TC3 point

为进一步了解每个测温点位置的计算温度与测量温度的偏离情况,设温度偏差 (i = 1, 2, 3),

(i = 1, 2, 3), 为计算温度,

为计算温度, 为测量温度,则各点的偏差曲线如图8所示。

为测量温度,则各点的偏差曲线如图8所示。

图8 3个热电偶位置对应的温度偏差曲线

Fig.8 Temperature deflection curves for 3 thermocouples

从总体看,TC1点的温度偏差波动范围为?8.2~ 4.9 ℃;TC2点的波动范围为?14.3~6.7 ℃;TC3点的波动范围为?10.0~13.9 ℃。

具体看来,TC1点的最大温度偏差为 = ?8.2 ℃,对应的时间为t = 27 s,

= ?8.2 ℃,对应的时间为t = 27 s, = 586.8 ℃,

= 586.8 ℃, = 595.0 ℃,此时的误差为1.38%。TC2点的最大温度偏差为

= 595.0 ℃,此时的误差为1.38%。TC2点的最大温度偏差为 = ?14.3 ℃,对应的时间为t = 2 151 s,

= ?14.3 ℃,对应的时间为t = 2 151 s, = 368.7 ℃,

= 368.7 ℃, = 383.0 ℃,此时的误差为3.73%。TC3点的最大温度偏差为

= 383.0 ℃,此时的误差为3.73%。TC3点的最大温度偏差为 = 13.9 ℃,对应的时间为t = 675 s,

= 13.9 ℃,对应的时间为t = 675 s, = 385.3 ℃,

= 385.3 ℃, = 371.4 ℃,此时的误差为3.74%。综合以上分析,铸件内的TC1点的温度偏差较小,而砂型内的TC2点和TC3点的偏差较大。

= 371.4 ℃,此时的误差为3.74%。综合以上分析,铸件内的TC1点的温度偏差较小,而砂型内的TC2点和TC3点的偏差较大。

4.2 误差分析

针对计算温度与相应测量温度的偏差情况,可从测温误差和有限元模型两方面进行分析。

1) 从测温误差方面分析,误差主要来自3个方面。

①热电偶本身的误差。根据资料介绍[16],公差等级为二级的标准K型热电偶在?40~1 200 ℃范围内的测温误差一般为±2.5 ℃或0.75%θ(θ为测量温度值),这从图8中每条曲线的波动情况得以体现。

②热电偶的位置精度导致的误差。热电偶安放位置的波动也会产生一定的测温误差,特别是砂型中的热电偶,由于砂型的热阻大,位置波动会带来较大误差。

③热电偶的延迟效应和衰减效应产生的误差。砂型铸造中,由于砂型的热阻远大于铸件热阻和界面热阻,使得热电偶在砂型中的延迟效应和衰减效应更加突出,测温误差也更大。这是导致TC2点和TC3点产生较大温度偏差的主要原因之一。因此,在放置热电偶时应尽量使其靠近界面,以减小热阻并削弱延迟效应和衰减效应对测温误差的影响。

2) 从有限元模型方面分析,为提高温度场的模拟精度,应在3个方面做进一步研究工作。

①进一步考虑材料参数、初始条件和边界条件等参数的非线性特征,加密有限元网格等。

②凝固模拟前,应进行充型过程数值模拟,以便为凝固模拟提供一个更准确的初始温度场。

③应考虑铸件和铸型的热膨胀性质,对凝固过程进行热结构耦合分析,以提高模拟精度。

5 结论

1) 凝固过程温度场的数值模拟是铸造过程数值模拟的核心内容之一,它是预测缩孔、缩松、热裂和宏观偏析等铸造缺陷的基础。本文作者利用有限元算法,充分考虑材料和边界条件等参数的非线性特征,采用等价比热容法处理结晶潜热,在通用CAE软件ABAQUS平台上经二次开发求解了ZL102砂型铸造中铸件和铸型内的三维瞬态温度场。

2) 对ZL102砂型铸造工艺进行了测温实验,分别得到了铸件和砂型内的测温曲线。测量温度与相应计算温度基本吻合,从而证明了数值模拟的精度和有效性。从3个热电偶位置的计算温度与测量温度的偏差看,铸件内的TC1点的温度偏差较小,而砂型内的TC2点和TC3点的偏差较大。

3) 针对计算温度与相应测量温度的偏差情况,从测量误差和有限元模型两方面进行了分析。一方面,应尽量避免热电偶的位置波动,且在砂型内放置热电偶时应尽量使其靠近界面,以减小热阻并削弱延迟效应和衰减效应对测温误差的影响;另一方面,为提高模拟精度,应充分考虑材料参数、初始条件和边界条件等参数的非线性特征。通过充型过程数值模拟为凝固过程模拟提供一个准确的初始温度场。考虑铸件和铸型的热膨胀性质,对凝固过程进行热结构耦合分析等。

REFERENCES

[1] 荆 涛. 凝固过程数值模拟[M]. 北京: 电子工业出版社, 2002.

JING Tao. Numerical simulation of solidification process[M]. Beijing: Electronics Industry Press, 2002.

[2] 熊守美, 许庆彦, 康进武. 铸造过程模拟仿真技术[M]. 北京: 机械工业出版社, 2004.

XIONG Shou-mei, XU Qing-yan, KANG Jin-wu. Casting process simulation technology[M]. Beijing: China Machine Press, 2004.

[3] 王君卿, 孙 逊. MCSP6-2004国际会议概况和铸造过程数值模拟技术发展动向[J]. 铸造, 2005, 54(4): 307?313.

WANG Jun-qing, SUN Xun. Survey of MCSP6-2004 international conference and new development for numerical simulation of casting process[J]. Foundry, 2005, 54(4): 307?313.

[4] BERMUDEZ A, OTERO M V. Numerical solution of a three-dimensional solidification problem in aluminium casting[J]. Finite Elements in Analysis and Design, 2004, 40: 1885?1906.

[5] 杨 刚, 李宝宽, 于 洋, 齐凤升. 薄板坯连铸结晶器铜板的三维传热分析[J]. 金属学报, 2007, 43(3): 332?336.

YANG Gang, LI Bao-kuan, YU Yang, QI Feng-sheng. Three dimensional heat transfer of cooling copper plate of thin slab continuous casting mold[J]. Acta Metallurgica Sinica, 2007, 43(3): 332?336.

[6] RADOVIC Z, LALOVIC M. Numerical simulation of steel ingot solidification process[J]. Journal of Materials Processing Technology, 2005, 160(2): 156?159.

[7] VIJAYARAM T R, SULAIMAN S, HAMOUDA A M S, AHMAD M H M. Numerical simulation of casting solidification in permanent metallic molds[J]. Journal of Materials Processing Technology, 2006, 178(1/3): 29?33.

[8] 于彦东, 雷 黎, 蒋海燕, 付彭怀, 翟春泉, 丁文江. 基于数值模拟的镁合金真空压铸浇注系统设计与优化[J]. 中国有色金属学报, 2005, 15(12): 1903?1909.

YU Yan-dong, LEI Li, JIANG Hai-yan, FU Peng-huai, ZHAI Chun-quan, DING Wen-jiang. Design and optimization of runner and gating systems for vacuum die casting of magnesium through numerical simulation[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(12): 1903?1909.

[9] DIOSZEGI A, SVENSSON I L. On the problems of thermal analysis of solidification[J]. Materials Science and Engineering A, 2005, 413/414: 474?479.

[10] 李东辉, 高云宝, 辛启斌, 邱以清, 刘相华, 王国栋. 铸件凝固潜热的处理方法与应用研究[J]. 铸造, 2004, 53(12): 1005?1007

LI Dong-hui, GAO Yun-bao, XIN Qi-bin, QIU Yi-qing, LIU Xiang-hua, WANG Guo-dong. The processing method and application study for latent heat releases in alloy castings[J]. Foundry, 2004, 53(12): 1005?1007.

[11] 李金山, 梅金娜, 陈忠伟, 胡 锐, 寇宏超. 铜薄板连铸过程中的数值模拟[J]. 中国有色金属学报, 2005, 15(3): 338?343.

LI Jin-shan, MEI Jin-na, CHEN Zhong-wei, HU Rui, KOU Hong-chao. Numerical simulation of temperature field in continuous casting of copper thin-slab[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 338?343.

[12] ZHANG X P, XIONG S M, XU O Y. Numerical methods to improve the computational efficiency of solidification simulation for the investment casting process[J]. Journal of Materials Processing Technology, 2006, 173(1): 70?74.

[13] 郭 鹏, 张兴国, 郝 海, 金俊泽. AZ31镁合金圆锭连铸温度场的数值模拟[J]. 中国有色金属学报, 2006, 16(9): 1570?1576.

GUO Peng, ZHANG Xing-guo, HAO Hai, JIN Jun-ze. Temperature simulation of direct chill casting of AZ31 magnesium alloy billets[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1570?1576.

[14] 杨 全, 张 真. 金属凝固与铸造过程数值模拟[M]. 杭州: 浙江大学出版社, 1996.

YANG Quan, ZHANG Zhen. Metal solidification and numerical simulation of casting process[M]. Hangzhou: Zhejiang University Press, 1996.

[15] SUI Da-shan, CUI Zhen-shan. Regularization method to the parameter identification of interfacial heat transfer coefficient and properties during casting solidification[J]. Journal of Shanghai Jiao Tong University: Science, 2007, E-12(4): 511?516.

[16] 杨泽宽, 王魁汉. 热工测试技术[M]. 辽宁: 东北工学院出版社, 1987.

YANG Ze-kuan, WANG Kui-han. Thermal measurement technology[M]. Liaoning: Northeast Technical College Press, 1987.

收稿日期:2007-06-27;修订日期:2008-04-02

通讯作者:崔振山,教授,博士;电话:021-62827605;E-mail: cuizs@sjtu.edu.cn

(编辑 李艳红)