DOI: 10.11817/j.issn.1672-7207.2018.12.004

淬火速率对6016铝合金显微组织及力学性能的影响

廖培1,唐建国1, 2,刘胜胆2,叶凌英2,涂文斌2,张勇2,黄元春1

(1. 中南大学 轻合金研究院,湖南 长沙,410083;

2. 中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:通过对试样进行部分水冷淬火处理,在同一试样不同位置进行取样,采用透射电镜分析、维氏硬度测试及室温拉伸实验等方法,研究淬火速率对6016铝合金薄板显微组织及力学性能的影响。研究结果表明:合金淬火速率越高,自然时效过程中晶内析出的Ⅰ型原子团簇越多,从而T4态的硬度及强度也越高;而在欠时效状态下(180 ℃×1 h),Ⅰ型原子团簇溶解后析出强化相β″,Ⅱ型团簇转化为强化相β″,淬火速率为875.8 ℃/s的材料强化效果最为明显,其他位置试验样品的强化效果则随着淬火速率的降低而降低。当淬火速率为875.8 ℃/s时,材料自然时效14 d后性能仍然稳定,具有良好的塑性及成形性能,其伸长率为36.2%,屈服强度小于140 MPa,应变硬化指数为0.245,人工时效后屈服强度为250.9 MPa,抗拉强度为299 MPa,时效硬化强度为116.7 MPa。

关键词:淬火速率;6016铝合金;自然时效;人工时效;Mg-Si团簇;析出相

中图分类号:TG146 文献标志码:A 文章编号:1672-7207(2018)12-2923-08

Effect of quenching rates on microstructure and mechanical properties on 6016 aluminum alloy

LIAO Pei1, TANG Jianguo1, 2, LIU Shengdan2, YE Lingying2,TU Wenbin2, ZHANG Yong2, HUANG Yuanchun1

(1. Light Alloy Research Institute, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: By means of partial water quenching and sampling at different positions in the same sheet, the effect of quenching rate on microstructure and mechanical properties of 6016 aluminum alloy was investigated with the aid of transmission electron microscopy(TEM), hardness test and tensile test. The results show that with the quenching rate increasing, the number of Mg-Si cluster(Ⅰ) and the hardness and strength of the samples increase during natural aging. After under aging (180 ℃×1 h), Mg-Si cluster(Ⅰ) dissolves and strengthening phase β″ precipitates and Mg-Si cluster(Ⅱ) transform into strengthening phase β″ particles. The sample whose quenching rate is 875.8 ℃/s shows the best artificial aging hardening response. When the quenching rate is 875.8 ℃/s, the hardness of that sample almost remains unchanged during natural aging for 14 d, the tensile test result shows good ductility and formability i.e, elongation δ is 36.2%, yield strength Rp,0.2<140 MPa, strain hardening exponent n is 0.245. After artificial aging, Rp,0.2 is 250.9 MPa, tensile strength Rm is 299 MPa, artificial aging response is 116.7 MPa.

Key words: quenching rate; 6016 alloy; natural aging; artificial aging; Mg-Si cluster; precipitated phase

6xxx系Al-Mg-Si合金是中等强度铝合金,由于具有良好的成形性能、耐腐蚀性和较好的烤漆强化等特点[1],在交通运输和建筑行业有广泛应用[2]。该系铝合金有优良的综合性能,现主要应用在车盖、行李箱盖以及车门外覆盖件等[3-4],被认为是车身板中最具有前景的铝合金材料[5-6]。比如,在北美广泛采用的是6111和6022铝合金,欧洲广泛采用的则是6016铝合金[7]。当6xxx系铝合金应用于汽车车身板时,通常以T4态供货,要求材料有较低的屈服强度(Rp, 0.2<140 MPa)和较好的伸长率(δ>24%),保证合金有较高的成形性能;同时为了确保较好的抗凹性能,要求材料涂装烤漆后Rp, 0.2>200 MPa[8]。众所周知,材料的力学性能与显微组织有关,特别是与材料中形成的析出相种类、大小及密度有着密不可分的联系。6xxx系铝合金析出序列为SSS—Mg-Si团簇—GP区—β″—β′—β(Mg2Si)[8]。在强化相β″析出之前,Mg-Si团簇及GP区的形成是很复杂的过程。而在实际工业生产过程中,材料在出库到冲压加工成形之前,要经过一定时间的储存以及运输,会有明显的“停放效应”发生,即材料在固溶淬火之后的自然停放中,过饱和固溶体中Mg和Si溶质原子自发形成原子团簇,使得合金强度提升、塑性变差,对材料的冲压成形及烘烤硬化效应产生不利的影响,所以控制时效析出以及抑制自然时效带来的不良影响成为开发6xxx系车身板的研究重点[9]。为了探究该问题,国内外研究者展开了大量的工作。一方面是调整材料的合金成分,如添加Cu,Mn,Cr和Zr等元素[10-11];另一方面是调整处理材料的工艺制度,如预时效[8]、预拉伸[12]、温成形[13]等。淬火是热处理的重要环节,合适的淬火速率不但会影响合金的残余应力和残余应变,而且对合金强度、韧性有重要的影响[14-15]。刘星兴等[10]采取双级淬火方式(100 ℃×1 h)的工艺制度优化合金性能,但由于该制度耗时过长在工艺生产中不易实现。研究表明淬火冷却速率对Al-Mg-Si合金板材弯曲性能有一定的影响[14],但有关淬火速率对Al-Mg-Si合金自然时效和烤漆硬化性能研究较少。本文作者通过部分水冷淬火样品的不同位置取样,对同一材料取不同淬火速度样品,采用硬度测试、透射电镜分析、常温拉伸实验等方法研究淬火速率对6016铝合金的微观组织及力学性能的影响机理,以便为优化该合金热处理工艺提供一定的依据。

1 实验

1.1 实验材料

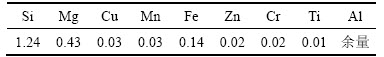

实验材料为某公司提供的冷轧态6016铝合金薄板,厚度为1 mm。按照ZJH735-2012电感耦合等离子体发射光谱法(ICP-AES)对采用的铝板进行化学成分分析,分析结果如表1所示。

表1 实验合金的化学成分(质量分数)

Table 1 Chemical composition of investigated alloy %

1.2 实验方法

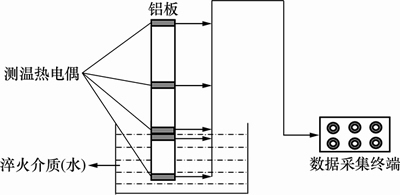

在SX-4-1型电阻炉中以540 ℃的温度进行30 min固溶处理,然后迅速将材料转移(转移时间控制5 s之内)到部分淬火装置上(见图1)进行淬火。淬火后试样在室温放14 d后标记为T4态,对T4态的材料进行180 ℃等温人工时效(AA,温度180 ℃,不同时间)。

图1 部分淬火实验装置图

Fig. 1 Partial water quenching experimental setup

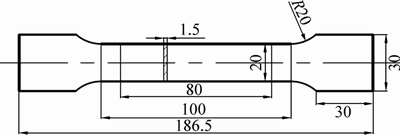

以部分淬火试样与水面的接触为参考,分别在是水面以下10 mm和90 mm,水面以上10,90和190 mm不同部位取样进行组织观察和力学性能测试。其中硬度测试在HV-10B维氏硬度试验机上进行,加载负荷和时间分别为3 kg和15 s,每个数据均测试5个点取平均值。室温拉伸性能测试以及合金的成形性指标n(应变硬化指数)均在MST-810材料试验机上进行,实验所用试样按照GB/T 228—2002进行加工,样品如图2所示,拉伸速率为2 mm/min,每个状态选3个平行样品测试取其平均值。透射电镜试验在MTP-1A电解双喷减薄仪进行制样,用30%硝酸+70%甲醇(体积分数)作为电解双喷液,在-20~-30 ℃(液氮冷却)双喷制样,双喷电压和电流分别为15~20 V和50~80 mA,双喷后制得的样品在Titan G2 60-300高分辨透射电镜上观察纳米析出相和相应的衍射花样。

图2 拉伸试样尺寸(单位:mm)

Fig. 2 Dimensional drawing of tensile sample

应变硬化指数n采用GB/T 5028—2008的标准在10%~20%塑性应变(均匀应变)的范围内按几何级数增加的方式取7个点,采用最小二乘法曲线拟合得到。

2 结果与讨论

2.1 部分水冷淬火试样取样位置对冷却曲线的影响

图3所示为淬火时距水面不同距离位置处的材料温度-时间曲线。由图3可见:以水面为界,水面以下离水面距离越远冷却速率越大,水面以上距离水面越远冷却速率越小。需要注意的是,在80~100 ℃的低温段,水面下以及水面上10 mm处的材料停留时间很短暂,但水面上90 mm以及190 mm材料停留时间较长。

图3 部分淬火6016铝合金板材不同位置的温度-时间曲线

Fig. 3 Temperature-time curves at different positions of partial quenched 6016 aluminum alloy sheet

对图3给出的板材不同位置处在200~400 ℃温度区间计算的平均淬火速率,结果如图4所示。由图4可见:在水面下,淬火速率很大,水面下90 mm和水面下10 mm淬火速率分别为931.1 ℃/s和875.8 ℃/s;在水面上淬火速率迅速降低,水面上10 mm处淬火速率为51.8 ℃/s,而水面上90 mm及190 mm处淬火速率仅为9.2 ℃/s和5.8 ℃/s。

2.2 淬火冷却速率对力学性能的影响

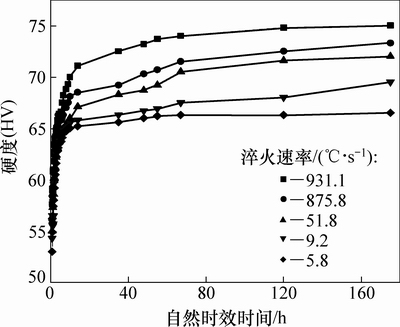

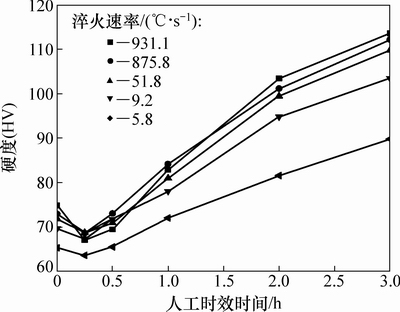

图5所示为不同淬火冷却速率样品自然时效的硬度-时间曲线。由图5可见:在自然时效初期,各淬火速率的样品硬度均快速上升,20 h后硬度上升速率逐渐放慢,40 h左右硬度趋于稳定。而伴随着淬火速率的升高,材料的硬度也有所提升,材料淬火速率最快和最慢的2组样品,硬度(HV)相差9.5。

图4 部分淬火6016铝合金板材不同位置处的淬火速率曲线

Fig. 4 Quenching rate curves at different positions of partial quenching 6016 aluminum alloy sheet

图5 不同淬火速率6016铝合金的自然时效硬化曲线

Fig. 5 Evolution of hardness during natural aging of aluminum alloy 6016 quenched with different cooling rates

图6所示为不同淬火速率样品自然时效14 d后的180 ℃人工时效硬度-时间曲线。由图6可见:在人工时效初期,各淬火速率样品都有硬度回归的现象出现,与已有研究结果[15]一致,可能是自然时效形成的原子团簇的溶解所造成的。在硬度回归期间,淬火速率越高,材料硬度下降越大。当人工时效15 min和30 min时,淬火速率最快的样品硬度仅为(HV)67.2和69.5,仅高于T4后硬度最低的材料,由于其硬度下降最多;直至人工时效1 h,淬火速率为931.1 ℃/s的材料硬度仍低于淬火速率为875.8 ℃/s的材料硬度;人工时效1 h后,随着时效时间的延长,淬火速率为931.1℃/s的材料硬度最高,材料的时效硬度随着淬火速率的降低而降低。

图6 不同淬火速率的6016铝合金自然时效14 d后的180 ℃人工时效硬化曲线

Fig. 6 Evolution of hardness during artificial aging (180 ℃) of aluminum alloy 6016 sheets quenched with different cooling rates and natural aged for 14 d

表2所示为T4态样品在180 ℃×1 h人工时效前后的力学性能,其中人工时效硬化效应(AAR,artificial aging response)由材料人工时效180 ℃×1 h前后材料屈服强度增值表征。由表2可知:淬火速率为51.8 ℃/s样品的硬度指数最高,其伸长率也最大。淬火速率为875.8 ℃/s的样品人工时效硬化效应最好,达到了116.7 MPa,淬火速率最快的931.1 ℃/s的材料次之,为101.7 MPa,其他3组样品的人工时效硬化效应则随着淬火速率的降低而降低,这与图6的人工时效硬度结果一致。

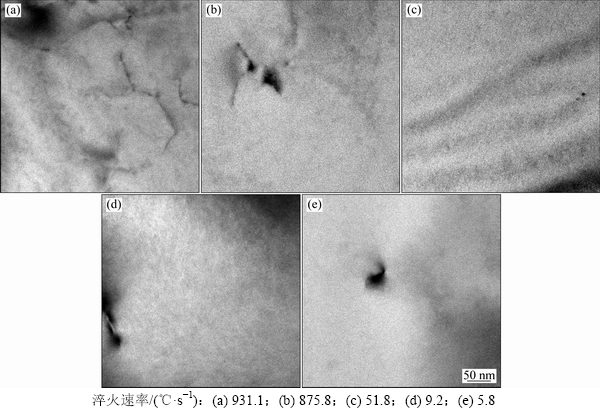

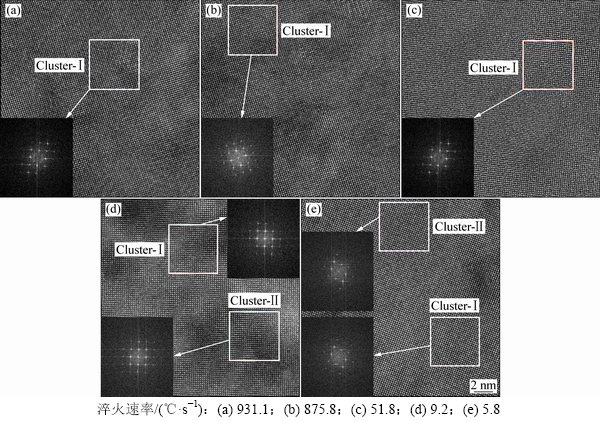

2.3 淬火冷却速率对不同时效状态析出相的影响

力学性能的差异是由微观组织结构的不同造成的,不同淬火速率将影响微观组织的形态,进而造成材料力学性能的不同[15-16],因此,从微观组织入手,结合力学性能分析淬火速率对6016铝合金的微观组织以及力学性能的影响。图7所示为不同淬火速率处理后T4态[001]Al方向6016铝合金试验样品的TEM组织。由图7可见:各状态均没有明显第二相衬度,这说明样品中没有明显沉淀相析出。图8所示为对样品进行[001]Al方向的HRTEM组织和FTT斑点。由图8可见:各试样均析出了与Al基体完全共格没有明显错配的原子团簇。其中淬火速率分别为931.1,875.8和51.8 ℃/s的样品中只有一种粒径约为2 nm的团簇,小于烤漆温度下β″相的形核临界粒径[17],应为Ⅰ型Mg-Si团簇。而淬火速率分别为9.2 ℃/s和5.8 ℃/s的样品中,则有2种不同的衍射斑点,一种为Ⅰ型Mg-Si团簇,另一种则原子间距略大,与基体错配度也较大,原子团簇粒径在4 nm左右,应为Ⅱ型Mg-Si型团簇。根据相关文献[10],Ⅰ型团簇主要是在低于50 ℃的条件下形成,Ⅱ型团簇则是在80 ℃附近形成,因此,淬火速率分别为931.1,875.8和51.8 ℃/s的3组样品在80 ℃附近停留时间较短,析出Ⅱ型团簇条件不足,仅在自然停放过程中析出Ⅰ型团簇,从而在T4态样品中仅观察到一种团簇;而淬火速率分别为9.2 ℃/s和5.8 ℃/s的样品在80 ℃左右停留的时间较长,有足够的条件析出Ⅱ型团簇,当温度降低后,则继续析出Ⅰ型团簇,故该淬火速率下T4态样品中观察到2种团簇。但是因为这2种团簇粒径比较小,它们引起的晶格畸变也小,所以在自然时效中即使有这些团簇的析出,也并不能引起明显的应变场衬度变化[18]。在自然停放过程中溶质原子富集形成的Ⅰ型团簇有强化作用,不利于材料后期加工,并且这些团簇形成过程中消耗大量空位,使原子扩散能严重降低[18],因此,淬火速率越高的样品,材料中溶质原子和空位浓度越高,形成Ⅰ型团簇越多,自然时效后硬度越高,这与图4的实验结果相符合。

表2 不同淬火速率的6016铝合金板材T4态样品人工时效前后的力学性能

Table 2 Tensile properties before and after artificial aging of 6016 aluminum alloy sheet quenched with different cooling rate

图7 不同淬火速率6016铝合金T4态样品[001]Al向TEM照片

Fig. 7 TEM images ([001]) of aluminum alloy 6016-T4 quenched with different cooling rates

图8 不同淬火速率6016铝合金T4态样品[001]Al向HRTEM分析结果

Fig. 8 HRTEM images ([001]) of aluminum alloy 6016-T4 quenched with different cooling rates

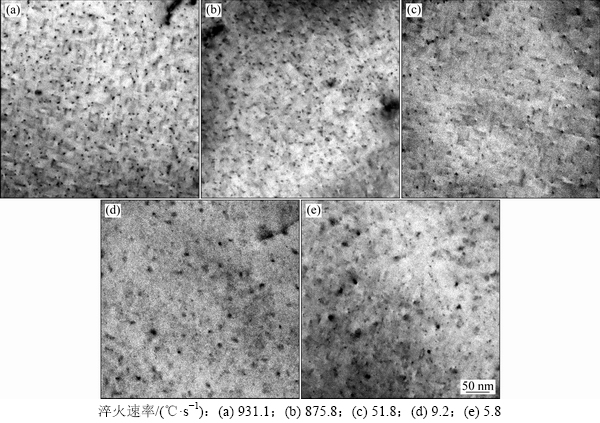

图9所示为不同淬火速率处理T4态[001]Al向6016样品经过180 ℃×1 h人工时效的TEM组织。由图9可见:析出相为针状颗粒,分别沿着Al基体的3个<100>Al方向排列分布的针状相,其中沿[100]及[010]方向的针状析出相投影像为长条状,平均长度为20 nm左右,沿[001]方向则是针状析出相的点状横截面,这与文献报道的起主要强化作用的β″相的形貌一致[19]。结合图4和图5可知:淬火速率越高,自然时效期间形成的Ⅰ型原子团簇就越多,而I型团簇在人工时效初期会回溶到基体中,延缓析出相形核,故淬火速率越快的样品回归时效硬度的下降幅度也就越大,这一点与图5实验结果一致。当人工时效15 min时,样品硬度下降幅度随淬火速率的升高而增大。当时效时间为1 h时,由于回归时效淬火速率最快的样品I型团簇最多硬度下降幅度最大,所以在回归时效结束后的短时间内,虽然材料的硬度有较大的增长,但还是比淬火速率次之的样品的硬度小。

对人工时效1 h样品中点状析出相颗粒进行HRTEM观察以及FFT斑点分析,结果见图10。由图10可见:析出相在尺寸上有明显区别,淬火速率较快、在80 ℃左右停留时间较短的3组样品的点状析出相粒径较小为3 nm;淬火速率较慢在80 ℃左右停留时间较长的2组样品的点状析出相分别为3 nm和8 nm。3 nm左右的尺寸小数目多的析出相为Ⅰ型团簇在人工时效初期回溶到Al基体内的溶质原子重新形成析出β″相,故析出相尺寸较小数目较多,8 nm尺寸大数目少的析出相为Ⅱ型团簇在人工时效期间直接转化成的强化相即β″相[7]。人工时效前要求材料强度较低便于冲压成形;在人工时效后则要求材料强度较高满足抗凹性要求,综合两者要求,淬火速率为875.8 ℃/s的材料性能表现较优秀,这是因为该速率下材料中溶质原子过饱和度以及空位浓度略低,自然停放过程中析出的原子团簇数目适中,所以T4态材料的硬度和强度较低,而在人工时效期间,由于材料回溶后溶质原子以及空位数目适中,形成析出相密度高且分布弥散,材料成形性能较好能够满足要求。

快速淬火时,T4态6016铝合金内析出Ⅰ型Mg-Si团簇,硬度、强度较高,人工时效(180 ℃×1 h)后,由于Ⅰ型Mg-Si团簇回溶后空位释放形核点增多,材料硬度、强度较高。慢速淬火时,T4态6016铝合金内有80 ℃附近析出的Ⅱ型Mg-Si团簇及Ⅰ型Mg-Si团簇,材料硬度、强度较低,人工时效(180 ℃×1 h)后,由于空位浓度低形核点较少,材料硬度和强度较低。在本实验的各组淬火速率样品中,淬火速率为875.8 ℃/s的样品性能最佳,能同时满足人工时效前硬度、强度较低以及人工时效后材料硬化效果明显的双重要求。

图9 不同淬火速率6016铝合金180 ℃人工时效1 h样品[001]Al向TEM照片

Fig. 9 TEM images ([001]) of artificial aged (180 ℃ for 1 h) aluminum alloy 6016 quenched with different cooling rates

图10 不同淬火速率6016铝合金180 ℃人工时效1 h样品[001]Al向HRTEM分析结果

Fig. 10 HRTEM images ([001]) of artificial aged (180 ℃ for 1 h) aluminum alloy 6016 quenched with different cooling rates

3 结论

1) 淬火冷却速率对6016铝合金板材的自然时效行为有重要的影响,随着淬火速率的增加,T4态的硬度和强度增大,但合金板材的自然时效的稳定性随冷却速率的增加后降低,冷却速率为875.8 ℃/s时的自然时效稳定性较好,自然时效14 d后δ为36.2%,n为0.245。

2) 180 ℃人工时效的初期有一个软化过程,随着淬火速率的增加软化程度增加;在随后1 h内的快速硬化阶段,硬化曲线随淬火冷却速率的增加先增加后减少,875.8 ℃/s淬火速率试样1 h内的硬化速率最快,淬火1 h后的试样的Rp,0.2为250.9 MPa,时效后的强度增加了 116.7 MPa。

3) 淬火冷却速率对人工时效的影响可能与自然时效的析出有关,快速冷却速率试样中,只有一种粒径约为2 nm的析出物,而速率较慢的样品有2种不同粒径的析出相。

参考文献:

[1] 孙顺平, 易丹青, 陈振湘, 等. Er在Al-Mg-Si合金中的存在形式及其热力学分析[J]. 材料热处理学报, 2011, 32(1): 138-143.

SUN Shunping, YI Danqing, CHEN Zhenxiang, et al. The existing form and thermodynamic analysis of Er in Al-Mg-Si alloy [J]. Journal of Heat Treatment, 2011, 32(1): 138-143.

[2] RODRIGUE S P, ALVES C F A, CAVALEIIRO A, et al. Water and oil wettability of anodized 6016 aluminum alloy surface[J]. Applied Surface Science, 2017, 422: 430-442.

[3] 王祝堂, 张新华. 汽车用铝合金[J]. 轻合金加工技术, 2011, 39(2): 1-14.

WANG Zhutang, ZHANG Xinhua. The processing technology of aluminum alloy[J]. Light Alloy for Automobile, 2011, 39(2): 1-14.

[4] 贾志宏, 丁立鹏, 吴赛楠, 等. 汽车车身用6000系铝合金板材微观组织与热处理工艺的研究进展[J]. 材料工程, 2014(12): 104-113.

JIA Zhihong, DING Lipeng, WU Sainan, et al. Research progress in microstructure and heat treatment process of 6000 series aluminum alloy sheet for automobile body[J]. Materials Engineering, 2014(12): 104-113.

[5] BIROL Y. Precipitation during homogenization cooling in Al-Mg-Si alloys[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 1875-1881.

[6] SUHUDDIN U F H R, S. MIRONOY S, SATO Y S, et al. Grain structure and texture evolution during friction stir welding of thin 6016 aluminum alloy sheets[J]. Materials Science and Engineering A, 2010, 527(7/8): 1962-1969.

[7] MILLER W S, ZHUANG L, BOTTEMA J, et al. Recent development in aluminum alloys for the automotive industry[J]. Materials Science and Engineering A, 2000, 280(1): 37-49.

[8] BIROL Y. Pre-aging to improve bake hardening in a twin-roll cast Al-Mg-Si alloy[J]. Materials Science and Engineering A, 2005, 391(1/2): 175-180.

[9] CHANG C S T, BANHART J. Low-temperature differential scanning calorimetry of an Al-Mg-Si alloy[J]. Metallurgical and Materials Transactions A, 2011, 42(7): 1960-1964.

[10] 刘星兴, 唐建国, 张新明, 等. 双级淬火对车身板用6016铝合金烤漆硬化效应的影响[J]. 中国有色金属学报, 2014, 24(5): 1186-1193.

LIU Xingxing, TANG Jianguo, ZHANG Xinming, et al. Influence of interrupted quenching on paint-bake response of AA6016 Al alloy sheet[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1186-1193.

[11] 刘亚妮, 陈江华, 尹美杰, 等. 自然时效和Cu含量对AlMgSi(Cu)合金时效硬化行为的影响[J]. 电子显微学报, 2010, 29(3): 280-286.

LIU Yani, CHEN Jianghua, YIN Meijie, et al. The effect of natural aging and Cu content on aging hardening behavior of AlMgSi (Cu) alloy[J]. Journal of Chinese Electron Microscopy Society, 2010, 29(3): 280-286.

[12] BIROL Y. Pre-straining to improve the bake hardening response of a twin-roll cast Al-Mg-Si alloy[J]. Scripta Materilia, 2005, 52(3): 169-173.

[13] 李翔, 唐建国, 张新明, 等. 温变形对汽车车身用6061铝合金自然时效及力学性能的影响[J]. 中国有色金属学报, 2016, 26(1): 1-6.

LI Xiang, TANG Jianguo, ZHANG Xinming, et al. Effects of warm deformation on natural aging and mechanical properties of 6061 aluminum alloy for automobile body[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 1-6.

[14] 李丹. 淬火速率和人工时效对汽车车身板AA6016铝合金组织与性能影响的研究[D]. 重庆: 重庆大学材料科学与工程学院, 2016: 58-59.

LI Dan. Effect of quench rate and artificial aging on the microstructure and properties of AA6016 aluminum alloy[D]. Chongqing: Chongqing University. College of Material Science and Engineering, 2016: 58-59.

[15] 姜云, 梁益龙, 徐军, 等. 淬火速度对高强度弹簧钢组织与力学性能的影响[J]. 中南大学学报(自然科学版), 2017, 48(3): 617-624.

JIANG Yun, LIANG Yilong, XU Jun, et al. Effect of quenching rate on microstructure and mechanical properties of high strength spring steel[J]. Journal of Central South University (Science and Technology), 2017, 48(3): 617-624.

[16] SERIZAWA A, HIROSAWA S, SATO T. Three-dimensional atom probe characterization of nanoclusters responsible for multistep aging behavior of an Al-Mg-Si alloy[J]. Metallurgical and Materials Transactions A, 2008, 39(2): 243-251.

[17] 梅霖. 6016铝合金低温形变热处理行为的研究[D]. 重庆: 重庆大学材料科学与工程学院, 2015: 65-68.

MEI Lin. Study of cryogenic thermo-mechanical treatment behavior of 6016 aluminnium alloy[D]. Chongqing: Chongqing University. College of Material Science and Engineering, 2015: 65-68.

[18] CHEN J H, COSTAN E, van HUIS M A, et al. Atomic pillar-based nanoprecipitates strengthen AlMgSi alloys[J]. Science, 2006, 312: 416-419.

[19] 陈江华, 刘春辉. AlMgSi(Cu)合金中纳米析出相的结构演变[J]. 中国有色金属学报, 2011, 21(10): 2352-2360.

CHEN Jianghua, LIU Chunhui. Microstructure evolution of precipitates in AlMgSi(Cu) alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2352-2360.

(编辑 赵俊)

收稿日期:2017-12-17;修回日期:2018-03-12

基金项目(Foundation item):国家自然科学基金资助项目(51474240,51475162);湖南省重大科技计划项目(2016KG1004);Projects(51474240, 51475162) supported by the National Natural Science Foundation of China; Project(2016KG1004) supported by the Key Science and Technology Program of Hunan Province)

通信作者:唐建国,博士,副教授,从事铝合金材料加工制备技术研究;E-mail:jgtang@csu.edu.cn