文章编号:1004-0609(2009)08-1468-05

反应烧结制备多孔TiB2-TiC复相陶瓷

谢继峰,曹顺华,张秀芳,李文超

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:通过反应烧结制备TiB2-TiC多孔复合材料。采用XRD和SEM分析该多孔复合材料的相组成和微观结构,并采用气体透过法测定多孔复合材料的相对透气系数和最大孔径。结果表明:制备的TiB2-TiC陶瓷复合材料中存在大量的连通孔隙,随烧结温度的升高,烧结体的密度增大、抗弯强度增强,而孔隙度、透气性和最大孔径均逐渐减小;当烧结温度为1 700 ℃时,所制备的多孔复合材料孔隙度为30.9%,相对透气系数达到0.7 mm/(Pa·s),最大孔径达到5 μm。

关键词:TiB2-TiC复相陶瓷;反应烧结;孔隙度

中图分类号:TB 332 文献标识码: A

Preparation of porous TiB2-TiC multiphase ceramics by reactive sintering

XIE Ji-feng, CAO Shun-hua, ZHANG Xiu-fang, LI Wen-chao

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The reactive sintering was used to synthesize the porous TiB2-TiC multiphase ceramics. The phase composition and microstructure of the porous TiB2-TiC multiphase ceramics were analyzed by XRD and SEM. The gas permeability and maximum aperture of porous ceramics were tested by gas permeation. The results show that a large number of pores exist in the prepared TiB2-TiC multiphase ceramics. With increasing sintering temperature, the density and transverse rupture strength of all the specimens increase, whereas the open porosity, maximum pore size and gas permeability decrease gradually. When the specimens are sintered at 1 700 ℃, the open porosity, gas permeability and maximum pore size of the specimens are 30.9%, 0.7 mm/(Pa?s) and 5 μm, respectively.

Key words: TiB2-TiC multiphase ceramics; reactive sintering; porosity

钛化物陶瓷碳化钛、硼化钛,由于具有硬度大、化学稳定性优良、质轻、耐高温、耐磨、高导电性等优点,可以作为切削工具、喷沙嘴材料,还可以用做核反应堆的保护材料、航天推进系统和热防护材料 等[1]。REMBERG等[2]的研究结果表明,高纯细晶的TiB2在高温时具有较好的抗塑性变形能力。而TiC 材料则相反,在1 000~1 500 ℃时可以发生塑性变形,通过加入一定量的B,产生TiB2,因此,TiC 会产生沉淀硬化[3]。由于TiB2陶瓷材料的局部氧化和烧结过程中金属与B的偏析导致脆性,延缓了TiB2 陶瓷材料的发展[4]。近年来,许多研究者成功制备了TiC和TiB2两相复合陶瓷材料[5?9]。与单相陶瓷材料相比,含有TiC和TiB2两相复合陶瓷材料的总体性能提高较大。鉴于TiB2-TiC良好的高温性能,多孔TiB2-TiC是一种很有应用背景的高温过滤材料。

在不添加助烧剂的条件下,以TiB2和TiC为原材料难以制备TiB2-TiC复合材料。SPIVAK等[10]的研究表明,在10 MPa的压力条件下,要获得大于95%的理论密度,烧结温度需高达2 200 ℃。与其它工艺相比较,反应烧结合成是放热过程,具有工艺简单、烧结温度低,以及烧结体晶粒细小等优点,在经济和技术上更可行。本文作者采用反应烧结法制备多孔TiB2-TiC陶瓷基复合材料,并对其性能进行研究。

1 实验

1.1 实验原理

高温下金属Ti能够与B4C发生化学反应,同时生成TiB2和TiC两相[11],反应式如下:

式(1)为放热反应,Ti与B4C 发生剧烈反应的温度高达1 100 ℃[12],且随着温度的升高,反应焓增加,反应放出的热量有利于反应的进行。

1.2 实验方法

实验所采用的原材料主要为:Ti粉(平均粒径小于45 ?m,纯度为99%)、B4C粉(平均粒径小于75 ?m,纯度为97%)。按式(1)的配比称量Ti粉和B4C粉,采用丙酮作为球磨介质进行球磨,球料质量比为3?1球磨时间24 h。球磨后的粉末于55 ℃真空干燥冷却后,添加6%的成形剂并制粒,采用模压成形,压坯的相对密度为50%,压坯尺寸为d32 mm×5 mm和5 mm×5 mm×35 mm,压坯放入真空炉中分别在1 000、 1 100、1 200、1 300、1 400、1 500、1 600和1 700 ℃等温度下烧结,保温时间均为1 h,真空度为1.4×10?3Pa。

采用RIGAKUD/MAX?3A型X射线衍射仪,Cu靶,扫描速度为4 (?)/min,对样品的相组成进行分析。采用JSM?6360LV型扫描电子显微镜观察材料的微观结构。采用ARCHIMEDES排水法测定开孔隙度。采用BPT?Ⅲ多孔材料性能检测仪测试烧结样品的相对透气系数和最大孔径。

2 结果与分析

2.1 反应产物的XRD分析

图1所示为不同温度下3Ti-B4C系统真空烧结后的XRD谱。由图1可知,于1 000 ℃烧结后,反应产物的XRD谱中除含有Ti和B4C相的衍射峰外,还出现TiC、TiB和TiB2等相的衍射峰,说明此时体系反应已经开始进行,生成TiC、TiB和TiB2。从1 100和1 200 ℃烧结后样品的XRD谱可以看出,烧结样品中不仅存在TiC、TiB和TiB2等相的衍射峰,而且出现Ti3B4相的衍射峰。烧结温度高于1 300 ℃以后,由烧结样品的XRD谱看出,产物中只有TiC和TiB2相存在,发现未反应的Ti和B4C,也没有TiB和Ti3B4等中间相存在。唐建新等[5, 13]和李世波等[14]的研究认为,Ti-B4C反应体系最终没有Ti3B4相的存在,并且认为Ti3B4为中间过渡相,这与本研究结果一致。

从图1还可以看出,TiB相从反应开始进行到反应结束在比较宽的温度范围内一直都存在;而Ti3B4相的存在是比较短暂的,只在中间过渡相向最终相转变之前比较窄的温度范围内,即1 100~1 200 ℃范围内存在;当温度达到1 300 ℃以后,TiB和Ti3B4两相均消失。ZHAO和CHENG[15]研究认为,Ti-B4C反应体系是分两种路径进行的。当温度低于1 300 ℃时,反应烧结将沿着路径1进行;当温度高于1 300 ℃后,路径2成为主导反应过程,此时由于B原子的扩散速率增大,直接与Ti结合而没有出现Ti3B4相。这与本实验结论相符合。

t≤1 300 ℃,反应按路径1进行,即

t>1 300 ℃,反应按路径2,即

图1 不同温度下3Ti-B4C系统经真空烧结后的XRD谱

Fig.1 XRD patterns of 3Ti-B4C system after vacuum sintered at different temperatures

与实验中计算Ti与B4C摩尔比为3?1时,体系可能发生的反应在不同温度下的吉布斯自由能随温度变化的曲线如图2所示。由图2可知,在计算温度范围内,自由能都为负值,说明在热力学上,反应都能自发进行。

图2 3Ti-B4C 系统反应吉布斯自由能随温度的变化

Fig.2 Variation of Gibbs free energy calculated for 3Ti-B4C system with temperature

2.2 TiB2-TiC陶瓷的显微结构

烧结样品表面的SEM像如图3所示。从图3可以看出,在反应初期,粉末颗粒变化不是很明显。基本保持原来的形貌,颗粒间结合较松散(见图3(a));样品于1 300 ℃烧结并保温1 h后颗粒间的结合则发生了明显的变化,小颗粒与大颗粒结合较为紧密,体系出现轻微的烧结现象(见图3(b))。样品经1 700 ℃烧结并保温1 h后,随着烧结温度的升高,样品发生明显的烧结现象(见图3(c)),烧结体主要发生孔隙结构变化,颗粒间的结合进一步加强,孔隙收缩,形成了刚性骨架结构。

图3 3Ti-B4C系统经真空烧结后的SEM像

Fig.3 SEM images of 3Ti-B4C system after vacuum sintered under different conditions: (a) Before reaction; (b) 1 300 ℃, 1 h; (c) 1 700 ℃, 1 h

2.3 TiB2-TiC陶瓷的孔隙结构

孔隙的形成原因主要有以下两点:1) 压坯本身的密度不高,相对密度只有50%,压坯本身存在大量的孔隙。SPIVAK等[10]的研究表明,要获得大于95%的理论密度,在10 MPa的压力条件下,烧结温度高达2 200 ℃,而本实验是在真空条件下烧结合成的,烧结温度仅为1 700 ℃,因此,烧结体中不可避免地存在孔隙;2) 由于3Ti-B4C原料系统反应前的密度低于反应后的密度(B4C、TiB2和TiC的密度分别为2.5、4.5和4.9 g/cm3)引起烧结体收缩,而试验的压坯经过烧结后形成刚性骨架,几乎没有收缩,因而烧结体内部存在孔隙。体系是否存在柯肯德尔(Kirkendall)效应而产生微孔还需要进一步证实。

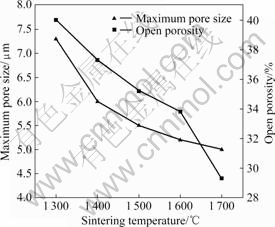

图4所示为烧结样品的最大孔径及开孔率随烧结温度的变化。由图4可以看出,反应完成以后,随着烧结温度的升高,烧结体的最大孔径值逐渐减小,当烧结温度达到1 700 ℃时,烧结体的最大孔径仅为5 μm。致密化过程大孔隙的存在给气体排出提供了主要通道,小孔隙则为反应的进行提供了场所[13]。随着烧结温度的升高,致密化速度加快。因而造成烧结颈长大、孔隙收缩以及孔径减小。

图4 烧结样品的最大孔径及开孔率随烧结温度的变化

Fig.4 Variation of maximum pore size and open porosity with sintering temperature

流体透过多孔材料的透过性能是多孔材料设计、制备和使用的重要参考依据。在测定多孔材料的透过性时,多数情况下均选用气体作为试样流体,即以多孔体的透气系数来表征(由于液体作为实验流体会带来许多困难,其原因参见文献[16])。透气系数测量的理论依据是达尔西公式,在工程测量中通常使用简化的达尔西公式,即

图5所示为相对透气系数与烧结温度的关系。由图5可看出,随着烧结温度的升高,材料的相对透气系数逐步减小。透气性与开孔隙度具有紧密的联系,开孔隙度越高,材料透过性能越好。当烧结温度较低时,原子的迁移速率较慢,颗粒间的结合还不紧密,存在大量连通孔隙,材料的相对透气系数较高;随着烧结温度的提高,烧结致密化程度逐渐增大,颗粒接触地方的物质加速迁移,孔隙数量减少,一部分连通孔被封闭,相对透气系数随之减小。

图5 相对透气系数与烧结温度的关系

Fig.5 Relationship between gas permeability and sintering temperature

2.4 TiB2-TiC多孔陶瓷的力学性能

图6所示为系统经不同温度烧结后烧结样品的密度与烧结温度的关系。由图6可以看出,反应完成以后,随着烧结温度的升高,烧结体的密度逐渐增加。1 700 ℃时,烧结体的密度达到3.2 g/cm。温度的升高导致生成物中TiC的塑性增大,同时新的生成物加速扩散,因此,密度有所增加。

图6 烧结样品的密度与烧结温度的关系

Fig.6 Relationship between density and temperature of sintered sample

图7所示为3Ti-B4C原料系统经不同温度烧结并保温1 h后烧结样品的抗弯强度与烧结温度的关系曲线。由图7可以看出,随着温度的升高,烧结体的抗弯强度逐渐增加。这是因为随着烧结温度升高,致密化程度增加,烧结体的密度增大,颗粒间的结合更为紧密,烧结体形成了刚性骨架结构,抗弯强度有所增加。当烧结温度达到1 700 ℃,材料的抗弯强度大有幅度提高,达到120 MPa。抗弯强度与密度及温度未成线性关系,这主要是孔隙球化和孔隙表面光滑化提高了颗粒间的结合强度,说明提高烧结温度有利于提高材料的力学性能。

图7 烧结样品抗弯强度与烧结温度的关系

Fig.7 Relationship between transverse rupture strength and sintering temperature of sintered sample

3 结论

1) 以Ti粉末和B4C粉末为原料通过真空烧结可以制备出多孔TiB2-TiC复相陶瓷。

2) 反应烧结合成的烧结产物比较纯净,只有TiB2和TiC两相,而没有TiB和Ti3B4中间过渡相存在。

3) 反应烧结合成的烧结体的密度和抗弯强度均随烧结温度的升高而提高,透气性、最大孔径和开孔隙度则是呈现逐步降低的现象。当烧结温度为1 700 ℃时,所制备出的复相陶瓷材料的密度为3.2g/cm3,抗弯强度达到了120 MPa,最大孔径为5 ?m,相对透气系数达到0.7×10 mm/(Pa·s)。

REFERENCES

[1] YUTAKA O, MICHAEL J P, GUNTER P. Sintering of in-situ synthesized SiC-TiB2 composites with improved fracture toughness[J]. Journal of the American Ceramic Society, 1992, 75(9): 247?2483.

[2] REMBERG J, WOLFE C, WILLIAMS W. Resistance of TiB2 to high temperature yielding[J]. Journal of the American Ceramic Society, 1985, 68(3): 78?79.

[3] BARSOUM M W. The transient plastic processing of ceramic-ceramic composites[J]. JOM, 1995, 47(11): 52?55.

[4] BALK S, PAUL F B. Effect of oxygen contamination on densification of TiB2[J]. Journal of the American Ceramic Society, 1987, 70(8): 527?530.

[5] 唐建新, 曾照强, 胡晓清, 苗赫濯. 原位合成TiB2-TiC陶瓷基复合材料[J]. 材料工程, 2001(2): 19?21.TANG Jian-xin, ZENG Zhao-qiang, HU Xiao-qin, MIAO He-zhuo. TiB2-TiC ceramics matrix composites prepared by in-situ technique[J]. Journal Material Engineering, 2001(2): 19?21.

[6] GOTMAN I, TRAVITZKY N A, GUTMANAS E Y. Dense in situ TiB2/TiN and TiB2/TiC ceramic matrix composites: reactive synthesis and properties[J]. Mater Sci Eng, 1998, 244(1): 127?137.

[7] SONG I, WANG L, WIXOM M. Self-propagating high temperature synthesis and dynamic compaction of titanium diboride/titanium carbide composites[J]. Journal of Materials Science, 2000, 35(10): 2611?2617.

[8] CIRAKOGLU M, PENG Z X, STEPHENS R R. Estimation of mechanical properties of titanium boride based composites produced by reactive hot pressing[J]. Ceramic Engineering and Science, 2000, 21(3): 737?744.

[9] ZHAO Kun-yu, ZHU Xin-kun. Synthesis of TiB2-TiC by mechanical alloying[J]. Trans Nonferrous Met Soc China, 2001, 11(1): 135?137.

[10] SPIVAK I I, ANDRIEVSKII R A, KLIMENKO V V, LAZARENKO V D. Creep in the binary system TiB2-TiC, ZrB2-ZrN[J]. Soviet Powder Metallurgy and Metal Ceramics, 1974, 137: 617?620.

[11] 唐建新, 左开芬, 胡晓清. 过渡塑性相工艺制造Ti-B-C复合陶瓷材料[J]. 清华大学学报, 1998, 38(12): 73?75.TANG Jian-xin, ZUO Kai-fen, HU Xiao-qin. Transient plastic phase processing of Ti-B-C composites[J]. Journal of Tsinghua University, 1998, 38(12): 73?75.

[12] 唐建新. 过渡塑性相工艺制备Ti-B-C复合陶瓷材料的机理研究[D]. 北京: 清华大学, 1999.TANG Jian-xin. Study on the principle of transient plastic phase processing of Ti-B-C composites[D]. Beijing: Tsinghua University, 1999.

[13] 唐建新, 程继红, 曾照强, 苗赫濯. Ti-B4C反应机理和扩散路径的研究[J]. 无机材料学报, 2000, 15(5): 886?887.TANG Jian-xin, CHENG Ji-hong, ZENG Zhao-qiang, MIAO He-zhuo. Analysis of reaction mechanism and reaction path between Ti and B4C[J]. Journal of Inorganic Materials, 2000, 15(5): 886?887.

[14] 李世波, 温广武, 张宝生. 原位生成棒晶增强Ti-B-C复相陶瓷的研究[J]. 无机材料学报, 2001, 16(6): 1247?1249.LI Shi-bo, WEN Guang-wu, ZHANG Bao-sheng. Study of in situ formation of rod-like phases reinforced Ti-B-C ceramics[J]. Journal of Inorganic Materials, 2001, 16(6): 1247?1249.

[15] ZHAO Hong, CHENG Yi-bing. Formation of TiB2-TiC composites by reactive sintering[J]. Ceramics International, 1999, 25(4): 353?358.

[16] 刘培生, 杨权成, 周茂奇. 多孔材料透过性能的表征[J]. 钛工业进展, 2006, 23(4): 12?16.LIU Pei-sheng, YANG Quan-cheng, ZHOU Mao-qi. Expression of permeation property of porous materials[J]. Titanium Industry Progress, 2006, 23(4): 12?16.

收稿日期:2008-10-08;修订日期:2009-03-05

通讯作者:曹顺华,教授,博士;电话:0731-88830724;E-mail: shuacao@163.com

(编辑 龙怀中)