热压反应合成 TiAl 合金的密度及孔隙分布

来源期刊:中南大学学报(自然科学版)1998年第5期

论文作者:刘咏 黄伯云 贺跃辉 王彬

文章页码:41 - 44

关键词:TiAl合金;粉末冶金;孔隙度

Key words:TiAl alloy; powder metallurgy; porosity

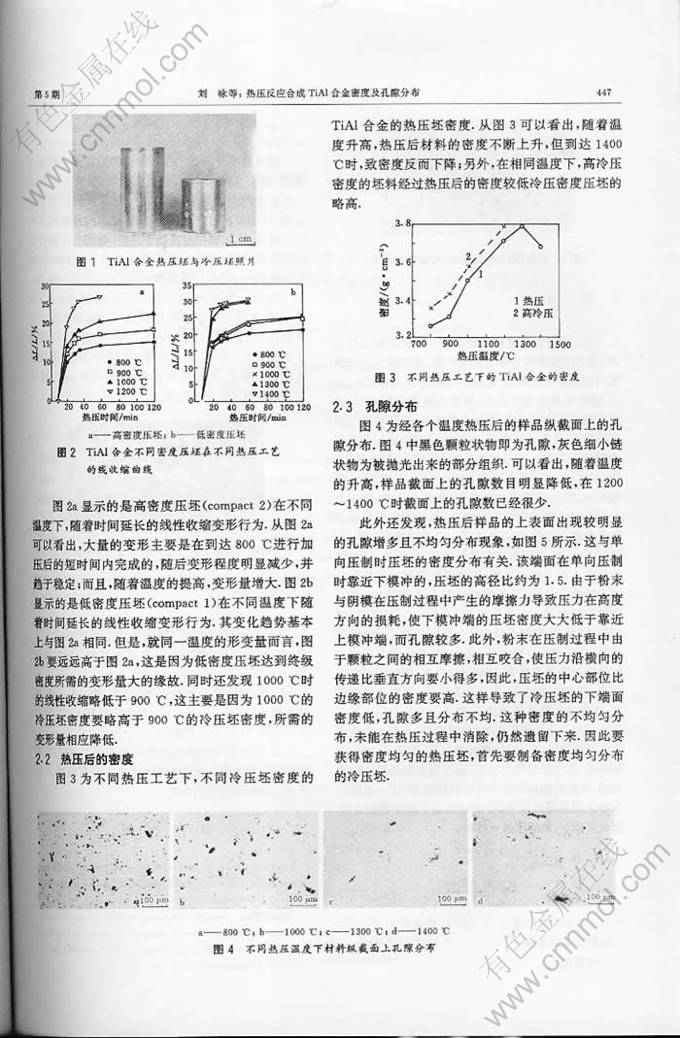

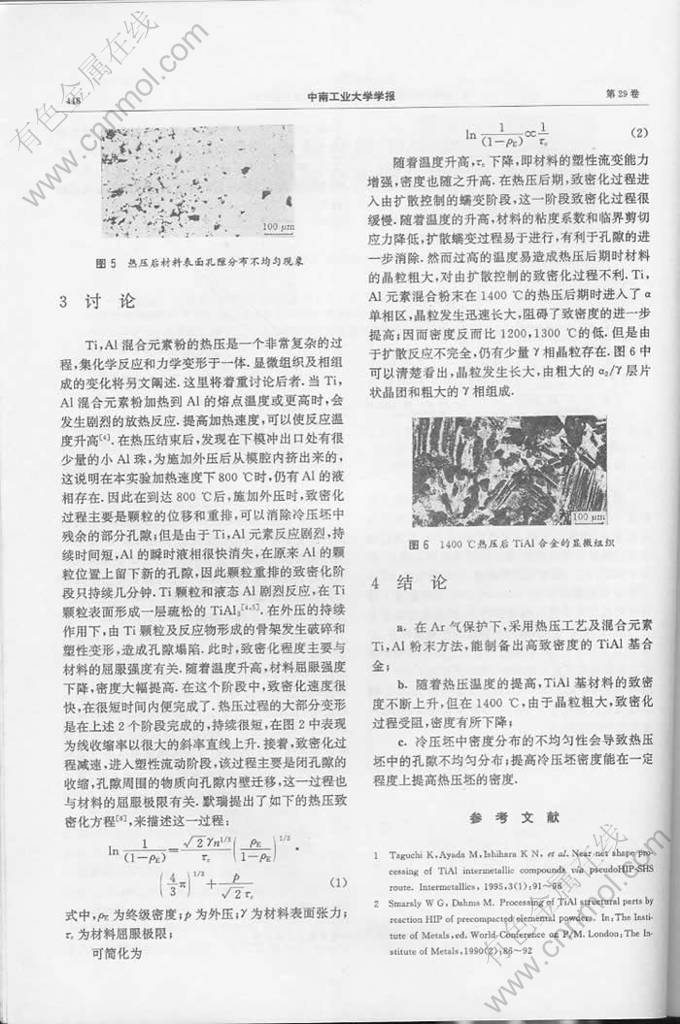

摘 要:采用Ti,AL混合元素粉,通过热压反应合成方法,研究了热压温度对Ti-48AL(原子数分数)致密化行为和孔隙分布的影响.结果表明:随着热压温度的升高,制备的材料致密度升高,而在1400℃下,由于晶粒粗大,导致材料的致密度难以继续提高,冷压坯上密度的不均匀性直接影响热压坯中材料的孔隙分布;提高冷压坯的密度,能在一定程度上使热压坯的密度升高.

Abstract: Blended elemental Ti 48Al(atom number fraction,%) powders were hot pressed at various temperatures, and their densification behavior and porosity distribution were discussed in this article. Results show that material density increases as the hot pressing temperature goes up, but the densification process is hindered at 1400 ℃,owing to the coarsening of grains. The inhomogeneity of density distribution in compacts will affect the porosity distribution in hot pressed samples; increasing the compact density will increase the density of hot pressed samples to a certain extent.