文章编号: 1004-0609(2006)09-1641-06

铝电解槽用干防渗料的导热性与抗渗性

刘世英, 石忠宁, 任必军, 邱竹贤

(东北大学 材料与冶金学院, 沈阳 110004)

摘 要: 采用自制的沸腾平板导热仪测量防渗料在不同状态下的导热系数, 利用坩埚法测量防渗料的抗渗性能。 结果表明: 防渗料的导热系数随密度的增大而增加, 使用过的防渗料导热系数要比新的大一些; 防渗料的抗渗能力与堆积密度有关, 捣实状态下的抗渗能力比松散状态的好, 铝液能够使电解质向防渗料的渗透量增加, 在电解质中加入铝块后, 防渗料的抗渗能力减弱。

关键词: 铝电解槽; 干防渗料; 导热性; 抗渗性 中图分类号: TF821

文献标识码: A

Thermal conduction and anti-penetration of dry barrier

powder materials for aluminium electrolytic cells

LIU Shi-ying, SHI Zhong-ning, REN Bi-jun, QIU Zhu-xian

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: The thermal conduction coefficient of dry barrier powder materials was determined by home-made apparatus of thermal conduction coefficients by water boiling heat exchange method, and its anti-penetration was also determined by crucible method. The results show that the thermal conduction coefficients of dry barrier powder materials increase with increasing density. The thermal conduction coefficients of the used materials are bigger than that of the new one. The anti-penetration is relative to accumulative density, and the anti-penetration of compact materials is better than that of loosening materials. The anti-penetration of dry barrier powder materials is weakened under the same condition of an industrial cell.

Key words: aluminium electrolytic cells; dry barrier powder materials; thermal conduction; anti-penetration

铝电解生产中, 普遍采用冰晶石-氧化铝熔盐电解法, 在电解过程中, 电解质和钠蒸汽等具有很强的渗透腐蚀性, 能够渗透到阴极炭块下, 并逐步地侵蚀耐火砖层和保温层, 使电解槽底部的保温性能急剧下降, 破坏电解槽的热平衡, 增加热耗, 降低电解槽的使用寿命[1, 2]。 因此, 必须要阻止电解质和钠蒸汽等渗透到保温层中。 防渗料就具有这种功能。

以前的抗渗层大多采用氧化铝粉, 也有的加钢板, 用氧化镁粉、 镁砂等, 但效果不是很明显[3-6]。 直到20世纪90年代初, 国际上出现了干防渗料, 为铝电解工业的向前发展跨出了重要的一步[7-10]。 中国长城铝业公司于1995年引进干防渗料技术, 进行我国首例干防渗料工业应用的实验研究[11]。 经过近20年的发展, 目前市场上的干防渗料品种很多, 本文研究的是其中的一种。

防渗料是电解槽筑炉材料之一, 其导热系数是计算电解槽热平衡的一个重要数据。 对于防渗料导热系数的测定目前还没有统一完整的标准方法, 很多都是测定松散状态下的导热值, 这与实际应用情况不符, 因为导热系数与物质的密度、 孔隙度等很多因素有关。 因此, 要使数据准确, 就应尽可能地接近实际应用条件。

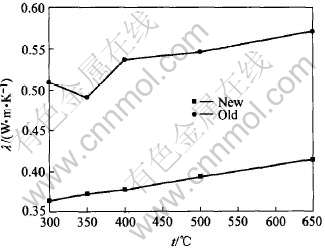

抗渗性能是防渗料的一个重要指标。 抗渗性不好, 起不到作用, 电解质等会破坏保温层, 减少槽寿命。 干防渗料能够同渗透下来的NaF反应, 生成霞石或钠长石, 能够阻止电解质等的继续渗透。 反应方程式可以写成[12]

本实验从导热性和抗渗性两个方面对防渗料进行了研究。

1 实验

1.1 实验原料

实验所用原料取自国内某大型铝厂的筑炉及刨炉材料。

干防渗料的性能指标如下: 捣实干料密度1920~2020kg/m3; 耐火度(PCE)31~35, 温度1683~1785℃; 110℃受热无变化, 816℃体积稳定。

表1 干防渗料的化学成分

Table 1 Chemical compositions of dry barrier powder materials (mass fraction, %)

刨炉材料是在电解槽上使用过1000多天的防渗料。

抗渗实验所用的电解质成分是: 工业用冰晶石和氧化铝, 分析纯氟化钠。

1.2 实验方法

1.2.1 导热系数的测量

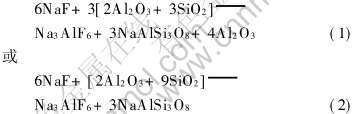

采用实验室自制的沸腾平板导热仪[13]测量导热系数, 测量的温度范围是300~650℃, 每个温度测量2次, 取平均值。 由于干防渗料是散料, 因此要在外面加套铁环, 铁环外面一定要包上耐火纤维, 减少试样向外散出的热量。 测量试样密实情况下的导热系数时, 采用逐层填料逐层捣打的形式。 所用实验装置如图1所示。

图1 测量导热系数的实验装置

Fig.1 Experimental apparatus of thermal conductivity coefficients

1.2.2 抗渗实验

从刨炉材料的分析可以看出, 渗入到阴极中的电解质呈碱性, 破损严重处的保温层中的电解质也呈碱性[14]。 因此本实验采用高分子比电解质(NaF与AlF3的摩尔比为5.0)。 将300g防渗料以逐层加入逐层捣打的形式放入坩埚内, 加入配比好的电解质100g, 加盖盖紧, 置于电炉内在960℃下恒温8h, 观察电解质的渗透情况。

2 结果与讨论

2.1 导热系数的测定结果与讨论

本实验测量了捣实后密度为1.985g/cm3试样的导热系数, 测量4个试样取其平均值, 并计算标准差, 其结果如表2所示。 从实验结果可以看出, 对于单次的测量值, 试样的导热系数值偏差较大, 这是由于干防渗料是松散料, 试样的粒径等级也不一样, 在制作试样时其分布不能达到均匀一致, 这是产生误差的重要原因。 因此, 要对试样进行多次测量取平均值。 干防渗料的导热系数基本上是随着温度的升高而增大。

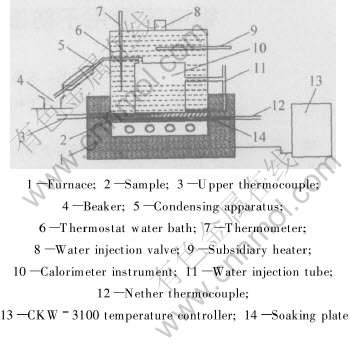

本实验分别测定了干防渗料在松散状态下(即自然堆积状态)ρ=1.514g/cm3和一般状态下ρ=1.726g/cm3的导热系数值, 并与捣实状态的一起进行对比, 结果如图2所示。 从实验结果可以看出, 试样的导热系数随着密度的增大而增加, 在松散状态下的导热值要比捣实的小很多。 在实际的电解槽中, 干防渗料都是捣实状态的, 实验中只是测量其在松散状态下的导热系数与实际使用的不相符。

表2 捣实下干防渗料的导热系数

Table 2 Thermal conductivity coefficients of compact dry barrier powder materials

图2 不同密度下试样的导热系数与温度的关系

Fig.2 Relation between thermal conductivity coefficients and temperature of samples of different densities

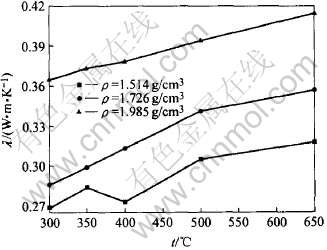

从刨炉情况可以看出, 阴极炭块下面的防渗料, 除几处破损严重外, 都形成了玻璃体状的霞石层, 此层下面的防渗料没有结壳。 本实验取霞石层下面的散状料做测试, 密度为1.992g/cm3, 实验结果如图3所示。 从图中可以看出, 使用过的干防渗料的导热系数值比新的大, 但比传统使用的耐火砖防渗层的导热系数小, 这可以减少槽底的热损失, 节省能量。 而且从刨炉情况能够看出, 防渗料下边的保温层没有被破坏, 在刨炉大修槽时保温层可以不动, 继续使用。

图3 新旧试样的导热系数与温度的关系

Fig.3 Relation between thermal conductivity coefficients and temperature of new and used samples

2.2 渗透实验结果与讨论

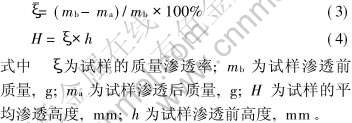

对于防渗料的抗渗性能, 有的以渗透高度计算[15,16], 即反应前的高度减去反应后的高度, 剩余高度就是防渗料的渗透高度。 这种方法是以测量面为基准, 从实验中可以看出, 反应后的高度不是一个平面, 用此种方法表示有一定的误差。 试样反应前、 后的质量比较好测量, 因此, 本实验中采用文献[17]中的方法, 以试样的质量渗透率来表示, 进而求出平均渗透高度, 此种方法能够反映试样的整体渗透情况。 计算公式为

2.2.1 防渗料的堆积密度与抗渗性的关系

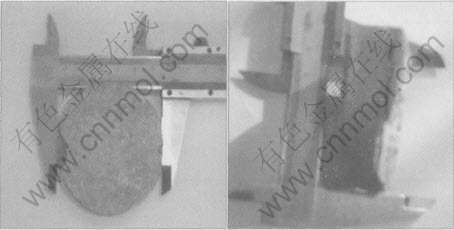

捣实试样(密度为2.023g/cm3)的渗透情况如图4所示。 可见, 防渗料与电解质接触的部分已经形成了一个薄层, 此薄层下的防渗料成灰白色的松散状, 电解质没有渗透下来。 防渗料的结壳与电解质层的界面清晰, 结壳比较密实、 规整。 松散料的渗透情况如图5所示。 将完全松散的防渗料200g [CM(22]放在石墨坩埚中, 测量试样高度, 然后加入100g 高分子比电解质, 放在电炉中在960℃下恒温8h。 从实验结果可以看出, 防渗料不但与接触的电解质反应, 还沿着坩埚边部的缝隙渗透。渗透层很疏松, 厚度也不均匀。

图4 捣实的防渗料渗透照片

Fig.4 Photographs showing penetration of compact dry barrier powder materials

图5 松散的防渗料渗透照片

Fig.5 Photographs showing penetration of loose dry barrier powder materials

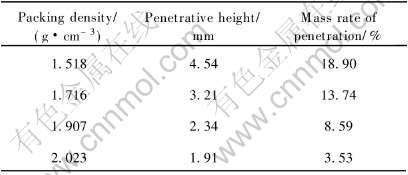

从实验结果(表3)可以看出, 随着防渗料密度的增大, 电解质的质量渗透率逐渐减小。 捣实试样在960 ℃下经过8h的高分子比电解质渗透后, 防[CM(22]渗料的质量渗透率是3.53%, 平均的渗透高度是[CM)]

表3 防渗料的堆积密度与抗渗性的关系

Table 3 Relation between anti-penetration and packing density of barrier powder materials

1.91mm, 而松散试样的质量渗透率达到了18.9%, 平均渗透高度是4.54mm, 平均渗透高度是捣实状态下的2.38倍。 因此, 堆积密度是一个重要的抗渗指标。 在实际使用中, 一定要将防渗料捣实压平, 尤其是边部与槽壳的接触部位, 否则电解质等熔体会顺着缝隙渗透下来。

2.2.2 铝液对抗渗性的影响

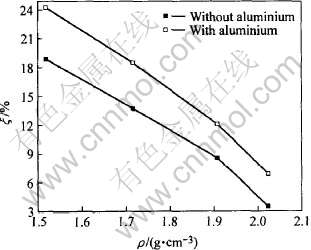

在实际生产中, 铝液会沿着阴极炭块渗透到防渗层。 为了研究铝液是否对电解质的渗透起作用, 实验中将防渗料按照实验需要的密度加入石墨坩埚中, 在上面放入30g铝块, 再加入高分子比的电解质, 密封坩埚, 放入电炉中在960℃下恒温8h。 观察不同密度下电解质的渗透情况, 并与没有加入铝液的对比, 结果如图6所示。 可以明显看出有无铝液时渗透的对比情况。 在加入铝块时电解质的渗透量比没有加入铝块的明显增多, 对防渗料的密度小于1.907g/cm3的试样, 电解质的渗透很深, 而且渗透层也不规则; 在防渗料的密度为2.023g/cm3时, 渗透层中可以看到白色的电解质, 结壳非常规整、 致密, 此结壳下面的防渗料成松散状, 未发生渗透。 加入铝块后的渗透能力要比没加的强, 是因为铝液使电解质对防渗料的湿润性得到改善, 有助于电解质自然渗透到防渗料中, 使渗透量增多。

图6 铝液对防渗料渗透性的影响

Fig.6 Effect of aluminium on penetration of barrier powder materials

3 结论

1) 干防渗料的导热系数随着堆积密度的增大而增加, 要测得接近实际使用情况下的导热值, 必须将防渗料捣实。 并且使用过的防渗料的导热系数要比新的大。

2) 随着堆积密度的增大, 防渗料的抗渗性能也增大。 在工业生产中, 必须将防渗料捣实才能发挥其良好的抗渗作用。

3) 铝液能够加大电解质的渗透量, 在防渗料的上部加入铝块后, 电解质的渗透量明显增加。

REFERENCES

[1]Weibel R, Juhl L F, Mikkelsen J, et al. Ageing of cathode refractory materials in aluminium reduction cells[A]. Light Metals[C]. Warrendale: TMS, 2002: 425-431.

[2]李贺松, 梅炽. 铝电解槽热电场的有限元分析[J]. 中国有色金属学报, 2004, 14(5): 854-859.

LI He-song, MEI Chi. Finite element analysis of thermo-electric coupled field in aluminum reduction cell[J]. The Chinese Journal of Nonferrous Metal,2004,14(5):854-859.

[3]Sorlie M, Oye H A. Deterioration of carbon linings in aluminium reduction cells[J]. Metall, 1984, 38(2):109-115.

[4]Allaire C. Efficiency of steel plate barriers in aluminium reduction cell potlining refractories[J]. Canadian Ceramics Quarterly, 1994, 63(2): 128-131.

[5]YAO Guang-chun, ZHU Wang-xi, QIU Zhu-xian, et al. On the MgO-C composite refractory diffusion barriers in alumina reduction cell cathodes[A]. Light Metals[C]. Warrendale: TMS, 1993. 349-351.

[6]Harris D, Oprea G. Cryolite penetration studies on barrier refractories for aluminum electrolytic cells[A]. Light Metals[C]. Warrendale: TMS, 2000: 419-427.

[7]Ebacher V, Pelletier R, Allaire C. Experimental investigation on stress-corrosion of refractories exposed to liquid aluminum[A]. Light Metals[C]. Warrendale: TMS, 2005: 905-908.

[8]Hagni A M. The mineralogical characterization of dry-powder barriers in al reduction cells[J]. JOM, 1998, 50(2): 24-28.

[9]Allaire C, Pelletier R, Siljan O J, et al. An improved corrosion test for potlining refractories[A]. Light Metals[C]. Warrendale: TMS, 2001: 245-249.

[10]Schoning C, Grande T, Siljan O J. Cathode refractory materials for aluminum reduction cells[A]. Light Metals[C]. Warrendale: TMS, 1999: 231-238.

[11]成庚, 吕增旭, 王醒钟. 进口干式防渗料在75kA预焙槽上的工业应用试验研究[J]. 轻金属, 2000(10): 31-33.

CHENG Geng, L Zeng-xu, WANG Xing-zhong. Experimental investigation of imported dry barrier for 75KA prebaked cell[J]. Light Metals, 2000(10): 31-33.

[12]Siljan O J, Slagnes S, Sekkingstad A, et al. Olivine-based refractories in potlinings of aluminium electrolysis cells[A]. Light Metals[C]. Warrendale: TMS, 2004: 405-411.

[13]刘世英, 于亚鑫, 邱竹贤. 耐火保温材料导热系数的测定[J]. 东北大学学报(自然科学版), 2006, 27(2): 196-198.

LIU Shi-ying, YU Ya-xin, QIU Zhu-xian. Determination of thermal conduction coefficient of refractory and thermal insulation materials[J]. Journal of Northeastern University(Natural Science), 2006, 27(2): 196-198.

[14]邱竹贤, 张明杰, 姚广春, 等. 铝电解中的界面现象及界面反应[M]. 沈阳: 东北工学院出版社, 1986. 156-200.

QIU Zhu-xian, ZHANG Ming-jie, YAO Guang-chun, et al. Interfacial Phenomenon and Interface Reaction for Aluminum Electrolysis[M]. Shenyang: Northeastern Engineering College Press, 1986. 156-200.

[15]张宏, 干益人. 铝电解槽用干式防渗保温料的研制和应用[A]. 第三届国际耐火材料学术会议[C]. 北京: 中国金属学会, 1998. 180-185.

ZHANG Hong, GAN Yi-ren. Development and application of insulating dry barrier for aluminum electrolytic cell[A]. The Third International Refractory Materials Academic Conference[C]. Beijing: The Chinese Society for Metals, 1998: 180-185.

[16]Tabereaux A T, Windfeld M. Evaluation and performance of powder dry-barrier refractories for use in aluminum cell cathodes[A]. Light Metals[C]. Warrendale: TMS, 1995. 471-477.

[17]赵建立. 铝电解槽用干式防渗料检测方法的研究[D]. 西安: 西安建筑科技大学, 2003. 39-44.

ZHAO Jian-li. Studies on Inspeeting Technique for Dri-barrier Mix Using in Aluminium Electrobath[D]. Xian: Xian University of Architecture & Technology, 2003. 39-44.

基金项目: 国家重点基础研究发展计划资助项目(2001AA335010); 国家自然科学基金重点资助项目(50334030)

收稿日期: 2005-12-22; 修订日期: 2006-07-19

通讯作者: 刘世英; 电话: 024-83680245; E-mail: neulsy@163.com

(编辑龙怀中)