采用烧结法处理高铁赤泥回收氧化铝

周秋生,范旷生,李小斌,彭志宏,刘桂华

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘 要:利用氧化铝热力学数据库,对高铁赤泥炉料烧成过程中的相关化学反应进行热力学计算,并在此基础上,研究烧成温度、烧成时间、炉料配比等烧成工艺条件对高铁赤泥炉料烧成效果的影响。研究结果表明:赤泥炉料的配钙量可以在较宽的范围内变化,并且在烧成过程中可能生成不溶盐类,导致熟料中氧化铝的溶出率降低;延长烧成时间和增加配料铁酸钠含量均有利于烧结;高铁赤泥炉料的最佳配料是: 熟料中Na2O·Fe2O3 质量分数为10%~12%,钙铁摩尔比为1.0~1.2;烧成工艺条件是:温度为1 000~1 050 ℃,烧成时间为30~40 min。在最佳配料和烧成工艺条件下,当熟料中氧化铝含量为15%左右时,熟料中Al2O3回收率可达85%~90%。

关键词:高铁赤泥;烧结法;氧化铝;回收

中图分类号:TF802 文献标识码:A 文章编号:1672-7207(2008)01-0092-06

Alumina recovery from red mud with high iron by sintering process

ZHOU Qiu-sheng, FAN Kuang-sheng, LI Xiao-bin, PENG Zhi-hong, LIU Gui-hua

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: By employing the thermodynamic database of alumina production, relevant chemical reactions involved in the sintering process of red mud furnace charge with high iron were analyzed. Based on the thermodynamic analyses, influences of factors, such as sintering temperature, sintering duration time and prescription of red mud furnace charge on the sintering process were investigated. The results show that addition amount of calcium oxide can vary in a wide range, possible formation of indissoluble compound salts thermodynamically results in the decline of alumina recovery in the sinter, which prolongs sintering duration time and increases calculated sodium ferrite (Na2O·Fe2O3) mass fraction in the sintering process of red mud with high iron. The optimized prescription of red mud furnace charge with high iron and its suitable technological condition are as follows: the mass fraction of calculated sodium ferrite in sinter is 10%-12%, molar ratio of calcium oxide to ferric oxide is 1.0-1.2, sintering temperature is 1 000-1 050 ℃, and sintering duration time is 30-40 min. Under the optimal prescription of furnace charge and sintering technological conditions, alumina recovery can reach 85%-90% when mass fraction of alumina in sintering is 15%.

Key words: high iron red mud; sintering; alumina; recovery

在我国湖南、广西和山西等地有一定储量的高铁中等品位铝土矿,这种矿石适宜采用拜耳-烧结串联法来处理生产氧化铝[1-2]。即先利用简单、经济的拜耳法回收矿石中大部分Al2O3,拜耳法所产生的高铁赤泥再采用烧结法处理,进一步回收其中的Al2O3,回收铝后的富铁渣可用做炼铁的原料。但迄今为止,用烧结法处理拜耳法高铁赤泥仍存在技术难题。虽然人们对拜耳法厂高铁赤泥的综合利用方面开展了大量的研究,如用酸浸出赤泥制备聚合氯化铝铁、聚硅酸铁和聚硅酸铁铝等无机高效絮凝剂[3-5],用高铁赤泥煤基直接焙烧还原回收金属铁[6-9]以及用赤泥生产水泥等,但这些研究大都尚处于实验或半工业实验阶段,且主要着眼于回收其中的铁和其他稀有金属,而对采用烧结法[10-12]处理拜耳法高铁赤泥回收其中氧化铝的研究甚少。赤泥烧结块的特点是铁酸钠和铁酸钙的含量高,而铝酸钠的含量很低,倾向于形成易熔共晶体。对这样的炉料,其烧成温度范围较窄,熔化温度不高,造成烧成困难。同时,若采用传统的苏打-石灰炉料烧结时会生成难溶的含Al2O3和Na2O的三元化合物,降低碱和氧化铝的回收率[13]。所以,高铁赤泥炉料烧成时需要配入更多的石灰,使炉料中一部分氧化铁与石灰结合成铁酸钙(2CaO·Fe2O3或CaO·Fe2O3),另外的氧化铁与苏打生成铁酸钠。

本文作者利用氧化铝热力学数据库,对高铁赤泥炉料烧成过程中相关反应进行了热力学计算,通过实验研究烧成温度、烧成时间、炉料配比等对高铁赤泥炉料烧成后所得熟料中氧化铝溶出率的影响,以期获得采用烧结法从高铁赤泥中回收氧化铝的最佳工艺 条件。

1 高铁熟料烧成的热力学分析

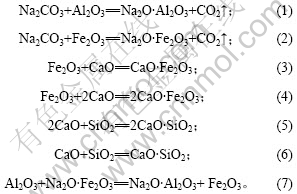

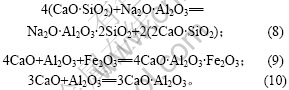

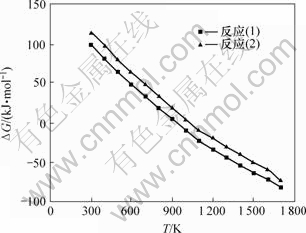

高铁赤泥烧成包含一系列化学反应,其中,主要反应有:

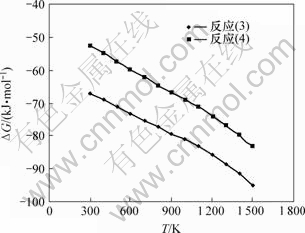

烧成过程中还会发生其他副反应,生成不溶盐,导致Al2O3溶出率降低,主要反应有[1, 13]:

利用氧化铝生产热力学数据[14-16],计算高铁赤泥炉料烧成过程中各反应的吉布斯自由能?G与温度T的关系,计算结果如图1~5 所示。

图1 反应(1)和(2)的?G-T关系

Fig.1 Relationship between ?G and T for reactions (1) and (2)

图2 反应(3)和(4)的?G-T关系

Fig.2 Relationship between ?G and T for reactions (3) and (4)

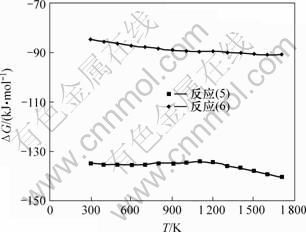

图3 反应(5)和(6)的?G-T关系

Fig.3 Relationship between ?G and T for reactions (5) and (6)

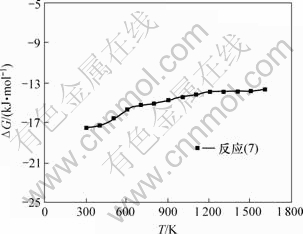

图4 反应(7)的?G-T关系

Fig.4 Relationship between ?G and T for reaction (7)

图5 反应(8)~(10)的?G-T关系

Fig.5 Relationship between ?G and T for reactions (8)-(10)

图1~4表明,反应(1)~(7)在所研究温度范围内均可能发生,并且在配钙量足够的情况下,CaO和SiO2反应的最终产物为2CaO·SiO2。CaO与Fe2O3反应可能生成CaO·Fe2O3和2CaO·Fe2O3,这就可以使与Fe2O3反应的那部分CaO的配钙比在1.0~2.0之间变化。这点很重要,因为在用拜耳-烧结串联法生产氧化铝时,除了铝土矿化学组成的变化影响赤泥组成外,拜耳法系统工艺条件的变化也会影响赤泥的组成。

从图5可以看出:在烧成条件下生成3CaO·Al2O3,Na2O·Al2O3·2SiO2和4CaO·Al2O3·Fe2O3反应的吉布斯自由能均为负值,其中产物4CaO·Al2O3·Fe2O3在热力学上最稳定,这说明在烧结过程中可能生成这些不溶盐类,从而降低高铁熟料中氧化铝、氧化钠的回收率。

2 实 验

2.1 实验原料与方法

先采用拜耳法在260 ℃高压溶出高铁中等品位一水硬铝石型铝土矿,获得高铁赤泥。然后,根据配料要求加入分析纯碳酸钠和石灰。配方为:Na2CO3的加入量按碱比NR=n(Na2O)/[n(Fe2O3)1+n(Al2O3)]=1加入(其中,n为物质的量,mol);CaO的总加入量 按赤泥中SiO2,Fe2O3和TiO2的含量加入,即CR1= n(CaO)1/n(SiO2)=2,CR2= n(CaO)2/n(Fe2O3)2=1.0~1.6,CR3=n(CaO)3/n(TiO2)=1。其中:n(Fe2O3)总=n(Fe2O3)1+ n(Fe2O3)2,n(CaO)总= n(CaO)1+n(CaO)2+n(CaO)3;若不考虑动力学因素,n(Fe2O3)1的铁全部按配料计算生成铁酸钠,控制其在熟料中的质量分数为8%~12%。根据以上配料计算原则,先准确称取高铁赤泥、Na2CO3和

按赤泥中SiO2,Fe2O3和TiO2的含量加入,即CR1= n(CaO)1/n(SiO2)=2,CR2= n(CaO)2/n(Fe2O3)2=1.0~1.6,CR3=n(CaO)3/n(TiO2)=1。其中:n(Fe2O3)总=n(Fe2O3)1+ n(Fe2O3)2,n(CaO)总= n(CaO)1+n(CaO)2+n(CaO)3;若不考虑动力学因素,n(Fe2O3)1的铁全部按配料计算生成铁酸钠,控制其在熟料中的质量分数为8%~12%。根据以上配料计算原则,先准确称取高铁赤泥、Na2CO3和 ,并使三者均匀混合,然后称取一定量的混匀料至刚玉坩埚中,先置于马弗炉中,在700 ℃恒温15 min,然后转移到高温马弗炉中,炉料在设定温度下烧结预定时间后,取出坩埚冷却至室温,冷却后的熟料经称重、磨细后置于磨口瓶中备用。

,并使三者均匀混合,然后称取一定量的混匀料至刚玉坩埚中,先置于马弗炉中,在700 ℃恒温15 min,然后转移到高温马弗炉中,炉料在设定温度下烧结预定时间后,取出坩埚冷却至室温,冷却后的熟料经称重、磨细后置于磨口瓶中备用。

按熟料添加量为160 g/L称取熟料,移取一定体积的调整液(调整液成分为:Na2Ok 60.12 g/L,Na2Oc 5 g/L,ak=1.51),一起加入100 mL的钢弹中,然后,放入低压群釜中,于80 ℃溶出15 min,溶出浆液经过滤、3次热水洗涤后获得滤液和渣相。采用容量法测定滤液中Al2O3和Na2Ok的浓度,渣相烘干后进行物相分析。

表1 拜耳法赤泥的化学成分

Table 1 Chemical composition of red mud from Bayer process w/%

2.2 实验设备

实验设备为:SX2-5-12型马弗炉(长沙华信合金机电有限公司制造);DY-8型低压群釜装置(中南工业大学机械厂制造)。采用电加热,以甘油为加热介质,温度控制精度为±1 ℃。

3 结果与讨论

3.1 烧成温度对高铁赤泥炉料烧成的影响

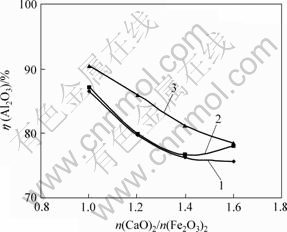

实验在烧成温度为1 000~1 200 ℃,烧成时间为20 min,按配料计算所得的熟料中Na2O·Fe2O3质量分数为8%,n(CaO)2/n(Fe2O3)2为1.0~1.6的条件下,考察烧成温度对烧成熟料中Al2O3溶出率的影响,结果如图6所示。

温度/℃: 1—1 000; 2—1 050; 3—1 100

图 6 烧成温度对高铁赤泥熟料中氧化铝溶出率η的影响

Fig.6 Influence of sintering temperature on alumina recovery of sinter obtained from red mud furnace charge with high iron

从图6可看出:在1 000~1 100 ℃烧成温度范围内,所得熟料Al2O3溶出率都小于70%;于1 050 ℃烧成得到的熟料中Al2O3溶出率比于1 000 ℃和1 100 ℃烧成所得熟料中Al2O3溶出率要稍高。这主要是因为:当温度达1 050 ℃后,4CaO·Al2O3·Fe2O3与Na2O? (Al2O3, Fe2O3)的固溶体相互反应,4CaO·Al2O3·Fe2O3中的氧化铁被还原成磁铁矿,游离出来的氧化钙与Na2O·Al2O3·2SiO2作用形成2CaO·SiO2, 从而提高Al2O3溶出率[7]。在实验过程中发现,在1 000~1 100 ℃温度范围内烧成所得熟料形成了部分液相,收缩率为10%左右;进一步提高烧成温度到1 200 ℃,炉料烧成过程中形成了大量液相,熟料收缩率大于40%,烧成熟料致密,且Al2O3溶出率很低。这说明高铁赤泥炉料烧成不宜采用过高的烧成温度。

3.2 烧成时间对高铁赤泥炉料烧成的影响

在烧成温度为1 000 ℃,所计算的熟料中Na2O·Fe2O3含量为12%,n(CaO)2/n(Fe2O3)2为1.0~1.6的条件下,考察烧成时间对熟料中Al2O3溶出率的影响,结果见图7。从图7可知,在实验条件范围内,延长烧成时间,熟料中氧化铝溶出率升高,最高可达99%。虽然热力学计算结果表明,在同样反应温度下铝酸钠比铁酸钠更稳定,但由于受动力学因素的影 响[12],实际上生成Na2O·Fe2O3的反应速率比生成Na2O·Al2O3的反应速率要快,因此,若烧成时间过短,含铝化合物将不能完全转化为Na2O·Al2O3,而且还可能生成铁铝酸四钙(4CaO·Al2O3·Fe2O3)和铝硅酸钠(Na2O·Al2O3·2SiO2)[7]等不溶三元化合物。随着烧成时间的延长,熟料中铝酸钠含量增加,结合成不溶化合物的氧化铝和碱所占比例减少,从而熟料中Al2O3溶出率升高。

烧成时间/min: 1—10; 2—20; 3—30; 4—40

图7 烧成时间对高铁赤泥熟料中氧化铝溶出率η的影响

Fig.7 Influence of sintering duration time on alumina recovery of sinter obtained from red mud furnace charge with high iron

3.3 铁酸钠含量对高铁赤泥炉料烧成的影响

在烧成温度为1 050 ℃,烧成时间为30 min的条件下,考察配料计算所得熟料中Na2O·Fe2O3的质量分数对烧成后所得熟料中Al2O3溶出率的影响,结果如图8所示。

w(Na2O?Fe2O3)/%: 1—8; 2—10; 3—12

图 8 铁酸钠含量对高铁赤泥熟料中氧化铝溶出率η的影响

Fig.8 Influence of calculated Na2O·Fe2O3 content on alumina recovery of sinter obtained from red mud furnace charge with high iron

从图8可知,n(CaO)2/n(Fe2O3)2为1.0~1.6时,熟料中Al2O3溶出率随配料计算所得Na2O·Fe2O3含量的增加而升高。其原因可能是,随着配料Na2O·Fe2O3含量的增加,有利于反应式(7)向右进行,使Al2O3置换Na2O·Fe2O3中的Fe2O3生成Na2O·Al2O3的反应更快地进行,从而提高所得熟料中Al2O3溶出率。

3.4 n(CaO)2/n(Fe2O3)2对高铁赤泥炉料烧成的影响

从图 7和图8 可以看出,氧化铝溶出率随n(CaO)2/n(Fe2O3)2的降低而升高,n(CaO)2/ n(Fe2O3)2为1.0时,熟料中Al2O3溶出率最高,超出此范围,溶出率有所下降。这是由于Al2O3溶出率与n(CaO)2/ n(Fe2O3)2有关:n(CaO)2/ n(Fe2O3)2=1.0~1.2,低于此值,炉料不饱和,形成Na2O·n(Al2O3, Fe2O3)2O3型固溶体,造成Al2O3溶出率降低;而高于此值,由热力学分析可知,可能生成不溶性的铝酸三钙(3CaO·Al2O3)以及铁铝酸四钙(4CaO·Al2O3·Fe2O3),从而造成Al2O3溶出不完全。

3.5 熟料中主要成分分析

图9所示为高铁赤泥炉料烧成后所得熟料的X 射线衍射图谱。结果表明,熟料中的主要物相有Na2O·Al2O3,Na2O·Fe2O3,2CaO·SiO2,CaO·Fe2O3和CaO·TiO2等。这说明炉料的烧成反应是按照式(1),(2),(3),(5)和(7)进行,因此,也证明了采用烧结法回收高铁赤泥中的氧化铝是可行的。

1—Na2O·Al2O3;2—2CaO·SiO2;3—Na2O· Fe2O3;4—CaO·TiO2;5—CaO·Fe2O3

图9 赤泥炉料烧成熟料的X射线衍射图谱

Fig.9 X-ray diffraction pattern of sinter obtained from red mud furnace charge with high iron

4 结 论

a. 用烧结法处理高铁赤泥回收其中的Al2O3,适宜的炉料配方是:熟料中配料计算Na2O·Fe2O3 质量分数控制在10%~12%,n(CaO)2/n(Fe2O3)2为1.0左右。高铁赤泥炉料适宜的烧成温度为1 000~1 050 ℃,烧成时间为 30~40 min。

b. 最佳炉料配比和烧成工艺条件下获得的高铁熟料在80 ℃溶出15 min,熟料中Al2O3回收率可达85%~90%。

c. 烧成熟料中主要物相有Na2O·Al2O3,Na2O·Fe2O3,2CaO·SiO2和CaO·Fe2O3等。

参考文献:

[1] 杨重愚. 轻金属冶金学[M]. 北京: 冶金工业出版社, 1991: 74.

YANG Zhong-yu. Light metals metallurgy[M]. Beijing: Metallurgical Industry Press, 1991: 74.

[2] 马里茨H C. 串联法生产氧化铝的新进展[M]. 陈恒芳, 杨贵忠, 译. 北京: 中国科学技术社, 1991.

Marici H C. The new progresses of alumina production by series combination process[M]. CHEN Heng-fang, YANG Gui-zhong, trans. Beijing: Science and Technology Press of China, 1991.

[3] 王海峰, 毛小浩, 赵平源. 工业废酸与高铁赤泥制取聚合氯化铝铁的实验研究[J]. 贵州大学学报: 自然科学版, 2006, 23(3): 323-325.

WANG Hai-feng, MAO Xiao-hao, ZHAO Ping-yuan. Research of application of polymerized aluminum ferrum chloride producing with high-iron red mud and discard the hydrochloric acid[J]. Journal of Guizhou University: Natural Science, 2006, 23(3): 323-325.

[4] 罗道成, 刘俊峰. 铝厂赤泥制备无机高分子絮凝剂聚硅酸铁及应用[J]. 无机盐工业, 2005, 37(6): 27-32.

LUO Dao-cheng, LIU Jun-feng. Preparation and application of inorganic high molecular flocculant polyferric silicate from red mud in alumina plant[J]. Inorganic Salt Industry, 2005, 37(6): 27-32.

[5] 罗道成, 易平贵, 陈安国, 等. 用氧化铝厂赤泥制备高效混凝剂聚硅酸铁铝[J]. 环境污染治理技术, 2002, 3(8): 33-35.

LUO Dao-cheng, YI Ping-gui, CHEN An-guo, et al. Preparation of high efficient coagulant of polysilicate aluminum ferrite using red mud in a alumina plant[J]. Techniques and Equipment for Environment Pollution Control, 2002, 3(8): 33-35.

[6] 梅贤恭, 袁明亮, 左文亮, 等. 高铁赤泥煤基直接还原中铁晶粒成核及晶核长大特性[J]. 中南工业大学学报: 自然科学版, 1994, 25(6): 696-700.

MEI Xian-gong, YUAN Ming-liang, ZUO Wen-lian, et al. Studies on the nucleation and grain growth characteristics of metallic phase in direction reduction of high iron red mud with coal base[J]. Journal of Central South University of Technology: Natural Science, 1994, 25(6): 696-700.

[7] 刘永康, 梅贤功. 高铁赤泥煤基直接还原的研究[J]. 烧结球团, 1995, 20(2): 5-9.

LIU Yong-kang, MEI Xian-gong. Study on coal-based direct reduction of high-iron-content red mud[J]. Sintering and Pelletizing, 1995, 20(2): 5-9.

[8] 邱冠周, 刘永康, 梅贤功. 添加剂对高铁赤泥煤基的直接还原行为[J]. 中南工业大学学报: 自然科学版, 1995, 26(6): 734-738.

QIU Guan-zhou, LIU Yong-kang, MEI Xian-gong. Research on the influence of additives on the coal based direct reduction of high-iron-content red mud[J]. Journal of Central South University of Technology: Natural Science, 1995, 26(6): 734-738.

[9] 梅贤恭, 袁明亮, 左文亮, 等. 高铁赤泥煤基直接还原中铁晶粒成核及晶核长大动力学[J]. 中南工业大学学报: 自然科学版, 1996, 27(2): 159-163.

MEI Xian-gong, YUAN Ming-liang, ZUO Wen-liang, et al. Kinetics of the nucleation and grain growth of metallic phase in direct reduction of high-iron red mud with coal base[J]. Journal of Central South University of Technology: Natural Science, 1996, 27(2): 159-163.

[10] Mishra B, Staley A, Kirkpatrick D. Recovery and utilization of iron from red-mud[C]//Light Metals: Proceedings of Sessions, TMS Annual Meeting. Warrendale: TMS, 2001: 149-156.

[11] Mishra B, Slavik M, Kirkpatrick D. Recycling of red mud by recovery of value-added products[C]//Global Symposium on Recycling, Waste Treatment and Clean Technology (REWAS 1999). San Sebastian, 1999, 1: 251-260.

[12] 阳春华, 杨旭坤, 王雅琳, 等. 一种用于氧化铝生料浆优化调配的改进遗传算法[J]. 中南大学学报: 自然科学版, 2006, 37(4): 775-779.

YANG Chun-hua, YANG Xiu-kun, WANG Ya-lin, et al. An improved genetic algorithm for raw slurry optimal arrangement in alumina process[J]. Journal of Central South University: Science and Technology, 2006, 37(4): 775-779.\

[13] 阿不拉莫夫В Я. 碱法综合处理含铝原料的物理化学原理[M]. 陈谦德, 译. 长沙: 中南工业大学出版社, 1988: 152-165.

Ablamoff B R. Physical and chemical principles of comprehensive treatment of aluminum-containing raw materials by basic process[M]. CHEN Qian-de, trans. Changsha: Press of Central South University of Technology, 1988: 152-165.

[14] 孟 芸. 氧化铝生产热力学数据库的优化与应用[D]. 长沙: 中南大学冶金科学与工程学院, 2004.

MENG Yun. Optimization and application of thermodynamic database for alumina production[D]. Changsha: School of Metallurgical Science and Technology, Central South University, 2004.

[15] LI Xiao-bin, L? Wei-jun, LIU Gui-hua, et al. The applicability of Debye-Hückel model in NaAl(OH)4-NaOH-H2O system[J]. Journal of Processing Engineering, 2005, 5(5): 525-528.

[16] LI Xiao-bin, L? Wei-jun, LIU Gui-hua, et al. An activity coefficients calculation model for NaAl(OH)4-NaOH-H2O system[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(4): 908-912.

收稿日期:2007-03-28;修回日期:2007-05-10

基金项目:国家重点基础研究发展规划项目 (2005CB6237-02)

作者简介:周秋生(1972-),男,湖南涟源人,副教授,博士后,从事氧化铝生产工艺、理论及特种陶瓷粉体材料研究

通信作者:周秋生,男,副教授,博士后;电话:0731-8830453; E-mail: qszhou@mail.csu.edu.cn