Trans. Nonferrous Met. Soc. China 22(2012) 1412-1417

Microstructure characterization and thermal properties of hypereutectic Si-Al alloy for electronic packaging applications

YU Kun1, LI Shao-jun1, CHEN Li-san2, ZHAO Wei-shang2, LI Peng-fei2

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Zhuzhou Smelter Group Co., Ltd., Zhuzhou 412004, China

Received 7 June 2011; accepted 25 October 2011

Abstract: The rapid solidified process and hot press method were performed to produce three hypereutectic 55%Si-Al, 70%Si-Al and 90%Si-Al alloys for heat dissipation materials. The results show that the atomization is an effective rapid solidified method to produce the Si-Al alloy and the size of atomized Si-Al alloy powder is less than 50 μm. The rapid solidified Si-Al alloy powder were hot pressed at 550 ℃ with the pressure of 700 MPa to obtain the relative densities of 99.4%, 99.2% and 94.4% for 55%Si-Al, 70%Si-Al and 90%Si-Al alloys, respectively. The typical physical properties, such as the thermal conductivity, coefficient of thermal expansion (CTE) and electrical conductivity of rapid solidified Si-Al alloys are acceptable as a heat dissipation material for many semiconductor devices. The 55%Si-Al alloy changes greatly (CTE) with the increase of temperature but obtains a good thermal conductivity. The CTE of 90%Si-Al alloy matches with the silicon very well but its thermal conductivity value is less than 100 W/(m·K). Therefore, the 70%Si-Al alloy possesses the best comprehensive properties of CTE and thermal conductivity for using as the heat sink materials.

Key words: Si-Al alloy; rapid solidification; thermal properties; electronic packaging application

1 Introduction

Modern electronics demands efficient heat removal and dissipation during the operation of the components to prevent the failure of semiconductor devices [1]. The temperature increasing results in the dramatically failure rates of devices. The data indicate that with every 10 ℃ temperature raise, the lifetime of a GaAs or Si semiconductor device is reduced by one-third [2]. The heat dissipation is achieved by using heat sink or heat spreader packaging materials, such as W-Cu alloys, AlN ceramics [3]. Such alloys or ceramics are hard to meet the requirements of the electronics to manage the heat because their coefficient of thermal expansion (CTE) must match Si or GaAs with a value of (7-9)×10-6 ℃-1 [4]. And it also needs a high thermal conductivity more than 100 W/(m·K) and a low density less than 3 g/cm3. Hypereutectic Si-Al alloy with the content of Si over 50% occupies a combination of the physical properties for the thermal management [5,6]. Furthermore, the Si-Al alloy has a high specific stiffness and a platability with Au or Cu. So, it becomes an advanced electronic packaging material.

There are different manufacturing processes to produce the hypereutectic Si-Al alloy, including the conventional gravity casting (GC) and semi-solid casting. But those casting techniques cannot prepare the high quality Si-Al alloy for the heat dissipation because the size of primary silicon phase in as-cast alloy is too coarse to be acceptable [7]. The effective technique to produce Si-Al alloy with refined microstructure is rapid solidification technology. Spray deposition is one of the rapid solidification methods that can be used to fabricate the hypereutectic Si-Al alloys [4,8]. The controlled expansion Si-Al alloys with the contents of Si from 27% to 70% can be manufactured by using spray forming technology patented by Sandvik-Osprey Metals Ltd. [4]. Atomization is another rapid solidification technique to produce Si-Al alloy with refined microstructures. In order to develop a new method to obtain hypereutectic Si-Al alloys, the rapid solidification atomization is performed to produce three different compositions of Si-Al alloys to research their application properties and microstructure characterization in this investigation. The difference of properties and microstructures between the atomized Si-Al alloys and other as-cast or spray formed Si-Al alloys were provided and discussed.

2 Experimental

Three different hypereutectic Si-Al alloys were prepared with the compositions of 90%Si-10%Al, 70%Si-30%Al and 55%Si-45%Al, respectively. The pure polycrystalline silicon (99.9%) and pure aluminum (99.9%) were induction melted at 1400-1500 ℃. The melted alloy was poured into a pre-heated graphite tundish with a diameter of 4 mm. In atomization, a fine dispersion of droplets was formed when molten Si-Al alloy was impacted under a high energy nitrogen gas. The obtained Si-Al alloy powders were cold pressed at 200 MPa and then hot pressed in a pre-heated steel mould into fully dense billets under the pressure of 200-700 MPa in the temperature range of 200-550 ℃.

The microstructures of the Si-Al alloy specimens were observed by using optical microscope (OM) and JEOL JSM-5600Lv scanning electron microscope (SEM). The densities of Si-Al alloy specimens were measured by Archimedes method at the ambient temperature. The thermal physical properties were measured with a JR-3 tester. The thermal diffusion ratio was tested by laser flash method, and then the thermal conductivity of alloy specimen was calculated by K=αρc, where α is the thermal diffusion ratio, ρ is the density, and c is the specific heat capacity. And the CTE was measured in a differential thermal analysis apparatus from 25 to 400 ℃ with a heating speed of 150 ℃ /h. For all testing, three samples were performed per each measurement to acquire the average value.

3 Results and discussion

The cooling rate (ε) of molten alloy droplets during the atomization process could be as a function of droplet size as follows [9]:

(1)

(1)

where TP and TC are the temperatures of the molten droplets and the environment, respectively; αΣ is the heat transmission coefficient of the surface; c is the specific heat capacity of Si-Al alloy; and r is the radius of droplet. The atomized Si-Al alloy powders are shown in Fig. 1(a). The measured average diameter of the alloy powders is less than 50 μm. So, the estimated cooling rate of Si-Al alloy droplets in this experiment is 104-105 ℃/s. Such a rapid cooling rate is benefit to refine the primary Si phase and modify the morphology of eutectic Si-Al phase [10].

Fig. 1 Morphologies of atomized Si-Al alloy powders (a) and hot pressed Si-Al alloy billet (b)

Hot pressed billet of the atomized Si-Al alloy powders is shown in Fig. 1(b). The diameter of the billet is 76.2 mm and the thickness is 6 mm. All specimens in this investigation were cut from the billet. Both the pressure and the temperature play important roles in the density of the billet during the hot press process. Figure 2 shows the effects of pressure and temperature on the relative densities of the experimental billets. With the high pressures of 400 or 700 MPa, the relative densities of three experimental alloy billets all exceed 90%. And the billets obtained the relative densities over 90% at the temperature of 500 ℃. But when the temperature exceeded 550 ℃, the billet became sticky and soldered on the steel mold even with the lubricant. And the billet would crack under a high pressure over 700 MPa. Therefore, in order to obtain the relative densities as high as possible, the billets were pressed at 550 ℃ under the pressure of 700 MPa. The obtained relative densities for three experimental billets were 99.4%, 99.2% and 94.4% for 55%Si-Al, 70%Si-Al and 90%Si-Al alloys, respectively.

Microstructures of the ordinary gravity cast hypereutectic 70%Si-Al alloy and three rapid solidified Si-Al alloy billets are shown in Fig. 3. The gravity cast Si-Al alloys exhibit the coarse flake primary Si phase with the size of 2-3 mm and needle-like Si-Al lamellar eutectic (Fig. 3(a)). And many pore defects can be observed even by naked eyes in the as-cast specimen. But the microstructure of rapid solidified Si-Al alloys consists of refined primary Si phase with the size of 40-60 μm. It also exhibits no Al-Si lamellar eutectic phases and consists of an interpenetrating secondary Al-rich phase only. With the increase of Si content from 55% to 90%, the primary Si phase changes from discontinuous distribution to continuous morphology.

Fig. 2 Effects of pressure (a) and temperature (b) on relative density of Si-Al alloy billets

Fig. 3 Microstructures of Si-Al alloys: (a) Gravity cast 70%Si-Al alloy; (b) Hot pressed rapid solidified 55%Si-Al alloy; (c) Hot pressed rapid solidified 70%Si-Al alloy; (d) Hot pressed rapid solidified 90%Si-Al alloy

The X-ray phase identification shows that only Si and Al phases exist in the rapid solidified alloys with different contents (Fig. 4). In order to confirm the precise microstructures of rapid solidified Si-Al alloy during the atomization process, the SEM observation and EDX analysis of interpenetrating Al-rich phase were performed and compared with ordinary gravity cast alloy, as shown in Fig. 5.

Fig. 4 XRD patterns of Si-Al alloys

The morphology of Al-rich phase has no lamellar eutectic which always appears in inter-Si regions in conventional as-cast hypereutectic Si-Al alloy. The EDX analysis shows that only Al can be detected in the inter-Si regions. According to the Al-Si binary phase diagram, the expected eutectic lamellar phases would form in the pre-existing Si phase during conventional solidification [11]. But with a high content of Si and rapid solidification rate, Si will arise on the earlier nucleation of primary Si which forms first in the droplets. This leads to the fully divorced eutectic and the resulting inter-Si regions are free of lamellar eutectic as reported previously for hypereutectic Al-Si alloys [12,13].

Obviously, such different microstructures between the ordinary gravity cast and rapid solidified hypereutectic Si-Al alloys will result in a total difference of properties of the alloy. The as-cast Si-Al alloy with coarse primary Si phase and the serious casting defects can hardly provide necessary properties for the application requirements. The physical properties of experimental rapid solidified Si-Al alloy specimens compared with other typical heat treated materials are shown in Table 1.

The properties of three rapid solidified Si-Al alloys in this experiment were compared with those of other metal, alloy, ceramics and metal matrix composite materials, as shown in Table 1. The Si-Al alloys were the lightest thermal treatment materials compared with all the other materials so that they were benefit to be used in the modern electronic equipments or in aerospace and space applications [14,15]. The Si-Al alloys are 3-6 times lighter than the established packaging and base plate materials used in the products such as Kovar?, copper-molybdenum and copper-tungsten. At the same time, the Si-Al alloys offer greatly superior thermal conductivity compared with Kovar? alloy [1]. Therefore, Si-Al alloys can meet the increased power loading of the latest generation of devices which produce a lot of heat during operation. Compared with AlN, the Si-Al alloys possess the equivalent physical properties. Furthermore, Si-Al alloys acquire good mechanical properties, such as the bend strength and elastic modulus. And they are not unduly hard so that they are amenable to stand on machining operations, such as milling and drilling, and are machined easy by electron discharge machining as the same as other metals.

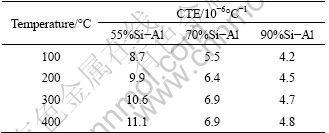

The properties of three experimental Si-Al alloys are different but are suitable to use for different requirements. The typical coefficients of thermal expansion of three experimental Si-Al alloys at different temperatures are shown in Table 2. The 55%Si-Al alloy in CTE changes greatly with the increase of temperature but obtains a good thermal conductivity. The CTE of 90%Si-Al alloy matches with the silicon very well but the thermal conductivity value is less than 100 W/(m·K) which is a threshold level for thermal management materials. Therefore, the 70%Si-Al alloy possesses the best comprehensive properties as the heat sink materials.

Fig. 5 Morphologies (a, b) and EDX analyses (c, d) of different phases in 70%Si-Al alloys: (a) Gravity cast alloy; (b), (c), (d) Rapid solidified alloy

Table 1 Typical properties of rapid solidified Si-Al alloy and other heat treated materials

Table 2 Coefficients of thermal expansion of Si-Al alloys at different temperatures

4 Conclusions

1) The atomization is an effective rapid solidified method to produce Si-Al alloy with the powder size less than 50 μm.

2) The rapid solidified Si-Al alloy powder are cold pressed and then hot pressed at 550 ℃ with the pressure of 700 MPa to obtain the relative densities of 99.4%, 99.2% and 94.4% for 55%Si-Al, 70%Si-Al and 90%Si-Al alloys, respectively.

3) The typical physical properties, such as the thermal conductivity, coefficient of thermal expansion and electrical conductivity, of rapid solidified Si-Al alloy are acceptable as a heat dissipation material for many semiconductor devices. The 55%Si-Al alloy changes greatly in CTE with the increase of temperature but obtains a good thermal conductivity. The CTE of 90%Si-Al alloy matches with the silicon very well but the thermal conductivity value is less than 100 W/(m·K). Therefore, the 70%Si-Al alloy possesses the best comprehensive properties for using as the heat sink materials.

References

[1] HARPER C A. Electronic materials and processes handbook [M]. 3rd ed. New York: McGraw-Hill Companies, Inc, 2004: 404-432.

[2] GAN W P, CHEN Z K, YANG F L, ZHOU Z F. Research states and development of high silicon aluminum alloy for light weight electronic package materials [J]. Materials Review, 2004, 18: 79-82.

[3] LIN F, FENG X, LI S C, REN X J, JIA X S. Research on high performance navel electronic packaging materials of Si-based aluminum [J]. Materials Review, 2006, 20: 107-110.

[4] HOGG S C, LAMBOURNE A, OGILVY A. Microstructural characterisation of spray formed Si-30Al for thermal management applications [J]. Scripta Mater, 2006, 55: 111-114.

[5] WANG Feng, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, WEI Yang-guang. Microstructure, thermo-physical and mechanical properties of spray-deposited Si-30Al alloy for electronic packaging application [J]. Materials Characterization, 2008, 59: 1455-1457.

[6] YU Kun, LI Chao, WANG Ri-chu, YANG Jun. Production and properties of a spray formed 70%Si-Al alloy for electronic packaging applications [J]. Materials Transactions, 2008, 49(3): 685-687.

[7] CHIEN C W, LEE L S, LIN J C. Effects of Sip size and volume fraction on properties of Al/Sip composites[J]. Materials Letters, 2002, 52: 334-341.

[8] WEI Yan-guang, XIONG Bai-qing, ZHANG Yong-an, LIU Hong-wei, WANG Feng, ZHU Bao-hong. Property measurements on spray formed Si-Al alloys [J]. Transactions Nonferrous Metals Society of China, 2007, 17(2): 368-372.

[9] CUI C, SCHULZA A, SCHIMANSKIA K, ZOCHA H W. Spray forming of hypereutectic Al–Si alloys [J]. Journal of Materials Processing Technology, 2009, 209: 5220-5228.

[10] YOSHIKAWA T, MORITA K. Refining of silicon during its solidification from a Si-Al melt [J]. Journal of Crystal Growth, 2009, 311: 776-779.

[11] OGRIS E, WAHLEN A, LUCHINGER H, UGGOWITZER P J. On the silicon spheroidization in Al–Si alloys [J]. Journal of Light Metals, 2002, 2: 263-269.

[12] KIM W J, YEON J H, LEE J C. Superplastic deformation behavior of spray-deposited hyper-eutectic Al-25Si alloy [J]. Journal of Alloys and Compounds, 2000, 308: 237-243.

[13] OTT R D, BLUE C A, SANTELLA M L, BLAU P J. The influence of a heat treatment on the tribological performance of a high wear resistant high Si Al–Si alloy weld overlay [J]. Wear, 2001, 251: 868-874.

[14] ARPON R, MOLINA J M, SARAVANANR A, GARCIA- CORDOVILLA C, LOUIS E, NARCISO J. Thermal expansion behaviour of aluminium/SiC composites with bimodal particle distributions [J]. Acta Materialia, 2003, 51: 3145-3156.

[15] HUBER T, DEGISCHER H P, LEFRANC G, SCHMITT T. Thermal expansion studies on aluminium-matrix composites with different reinforcement architecture of SiC particles [J]. Composites Science and Technology, 2006, 66: 2206-2217.

电子封装材料过共晶硅-铝合金的组织特征和热性能

余 琨1,李少君1,陈立三2,赵为上2,李鹏飞2

1. 中南大学 材料科学与工程学院,长沙 410083;

2. 株洲冶炼集团股份有限公司,株洲 412004

摘 要:采用快速凝固制粉技术和粉末热压烧结技术制备55%Si-Al,70%Si-Al和90%Si-Al 3种过共晶含量的硅铝合金。结果表明:雾化沉积是制备过共晶硅铝合金的有效的快速凝固工艺,采用该工艺获得的快速凝固硅铝合金粉末的尺寸小于50 μm。快速凝固的硅铝合金粉末经过550 ℃和700 MPa热压后,获得3种不同成分合金试样的相对密度分别为99.4%,99.2%和94.4%。作为电子封装材料,3种试样的热导率、热膨胀系数和电导率都可以满足应用要求。55%Si-Al合金的热膨胀系数随温度的变化最剧烈,但是该合金具有较好的热导率。90%Si-Al合金的热膨胀系数较小,但是其热导率最差,小于100 W/(m·K)。70%Si-Al合金具备热沉材料所应具备的优良的热导率和热膨胀系数的综合性能。

关键词:硅铝合金;快速凝固;热性能;电子封装材料

(Edited by LI Xiang-qun)

Foundation item: Project (2011) supported by the Hunan Nonferrous Research Funding of Hunan Nonferrous Metals Holding Group Co., Ltd., China

Corresponding author: YU Kun; Tel: +86-731-88879341; Fax: +86-731-88876692; E-mail: kunyugroup@163.com

DOI: 10.1016/S1003-6326(11)61334-4