Flow stress and tribology size effects in scaled down cylinder compression

GUO Bin(郭 斌)1, 2, GONG Feng(龚 峰)1, WANG Chun-ju(王春举)1, 2, SHAN De-bin(单德彬)1, 2

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Key Laboratory of Micro-Systems and Micro-Structures Manufacturing, Ministry of Education,

Harbin Institute of Technology, Harbin 150080, China

Received 10 June 2009; accepted 15 August 2009

Abstract: Microforming is an effective method to manufacture small metal parts. However, macro forming can not be transferred to microforming directly because of size effects. Flow stress and tribology size effects were studied. Scaled down copper T2 cylinder compression was carried out with the lubrication of castor oil and without lubrication. The results show that the flow stress decreases with decreasing the initial specimen diameter in both lubrication conditions, and the flow stress decreases by 30 MPa with the initial specimen diameter decreasing from 8 mm to 1 mm. The friction factor increases obviously with decreasing the initial specimen diameter in the case of lubricating with castor oil, and the friction factor increases by 0.11 with the initial specimen diameter decreasing from 8 mm to 1 mm. However, the tribology size effect is not found in the case without lubrication. The reasons of the flow stress and tribology size effects were also discussed.

Key words: microforming; size effects; flow stress; friction factor; cylinder compression

1 Introduction

Microforming is a newly developed technology to produce parts or structures with at least two dimensions in sub-millimeter range using metal forming methods[1]. Because of its mass production, high efficiency, high precision, short duration, low cost and no pollution, microforming becomes one of the most popular ways to form miniature parts. Even though metal forming process is well understood and widely applied, it is not wise to transit metal forming to microforming directly because of size effects.

Although flow stress size effect becomes one of the research focuses in microforming in these years, most researches were concentrated in micro sheet metal forming. Size effect in micro sheet metal forming, which was widely investigated in tension[2-3], bending[4-5], and bulging processes[6-7], was well understood and quantitative description was almost available. However, only a few studies focused on massive micro forming. MESSENER et al[8] and CHEN et al[9] studied the flow stress size effect of Cu-Zn alloy by upsetting and micro hardness tests, respectively, and the results showed that the flow stress decreased with decreasing specimen dimension.

Compared with flow stress size effect, the research on tribology size effect was limited. MESSENER et al[8] first investigated the tribology size effect by ring compression test, and revealed that the friction coefficient increased with decreasing the initial specimen size. ENGEL et al [10-11] studied double cup extrusion and found that the friction factor dramatically increased under miniaturization with the lubrication of extrusion oil, but the friction factor kept constant without lubrication. However, KRISHNAN et al[12] found that the friction coefficient decreased with decreasing the size of the extrude pins in microextrusion without lubrication. VOLLERTSEN et al[13-14] studied macro and micro deep drawing and developed a new friction test method to study tribology size effect, and the results showed that the friction coefficient in micro forming was much greater than that in macro forming.

Cylinder compression is a common method to obtain the stress—strain curves, and it is also a simple method to determine the friction factor in metal forming. Scaled down cylinder compression was carried out to study the flow stress and tribology size effects in micro-forming in this work.

2 Experimental

2.1 Materials

Copper T2 was used in this study. The specified chemical compositions determined by the analysis of X-ray fluorescence were: Cu≥99.9%, impurity elements <0.1% (mass fraction).

To get the uniform material compositions and microstructures, the raw materials were first turned in an instrument lathe from strain-hardened rods of 10 mm in diameter. After turning, the specimens were annealed at 400 ℃ for 1 h in nitrogen atmosphere.

2.2 Specimens and experimental setup

Geometrically similar specimens with an initial diameter of 8, 4, 2 and 1 mm were used. The ratio of height to diameter h0/D0 was 1. The shape and dimension of the specimens were in accordance with China Standard GB/T 7314—2005, as shown in Fig.1.

Fig.1 Cylinder compression specimens

The experiments were carried out at room temperature with a universal testing machine INSTRON 5569. The strain rate  was 0.005 s-1, and the compression ratio was 50%. To study the influence of the lubrication condition on the tribology size effect, lubrication with castor oil and without lubrication were used.

was 0.005 s-1, and the compression ratio was 50%. To study the influence of the lubrication condition on the tribology size effect, lubrication with castor oil and without lubrication were used.

2.3 Stress, strain and friction determination method

A schematic of cylinder compression is shown in Fig.2.

The true strain and flow stress can be computed with the following equations:

(1)

(1)

(2)

(2)

where ε is the true strain, H0 is the initial height of cylinder, ΔH is the height reduction of cylinder after

Fig.2 Schematic of cylinder compression

deformation, σ is the flow stress, p is the pressure applied to cylinder and A0 is the initial area of the cross section of the cylinder.

Because of the friction over the die, the cylinder barreled after deformation. The friction factor can be calculated with the following equations based on the upper bound theorem[15]:

(3)

(3)

(4)

(4)

(5)

(5)

(6)

(6)

where m is the friction factor, R is the average radius of cylinder after deformation, H is the height of cylinder after deformation, b is the barrel parameter, ΔR is the difference between maximum and top radius, R0 is the initial radius of cylinder, RM and RT are the maximum and top radii of cylinder after deformation, respectively.

According to Eqs.(3)-(6), if R0, H0, RM and H are exactly measured, the friction factor can be calculated. A tool microscope and a laser scanning confocal microscope(LSCM) were used to measure these parameters in this work.

3 Results and discussion

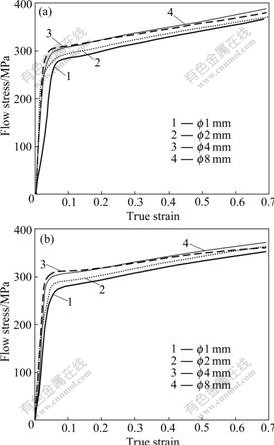

3.1 Flow stress size effect

The flow stress—true strain curves of different specimens are shown in Fig.3. The flow stresses decreased with the miniaturization of the initial specimen diameter. The yield strength of the specimens can be determined according to the flow stress—true strain curves. The yield strength decreased by 30 MPa as the initial specimen diameter decreased from 8 mm to 1 mm in both lubrication conditions. This meant that the flow stress size effect occurred with the miniaturization of the initial specimen diameter whether with lubrication or not.

Fig.3 Flow stress—true strain curves: (a) Without lubrication; (b) Lubricated with castor oil

The flow stress size effect has correlation with dislocations in the specimens. The grains in the surface are less restricted than the grains in the volume. Dislocations move through the grains in the volume and pile up at the grain boundaries but not at the grains in the surface during the forming process. This leads to the hardening and resistance against deformation of the grains in the surface less than the grains in the volume, and results in less flow stress of the grains in the surface than that in the volume. With miniaturization of the initial specimen size, the ratio of the grains in the surface to the grains in the volume becomes large, resulting in lower yield strength.

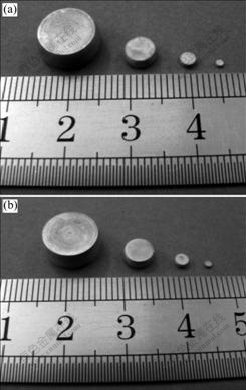

3.2 Tribology size effect

The specimens after deformation are shown in Fig.4. As can be observed, the degree of the barreling lubricated with castor oil was different from that without lubrication.

Fig.4 Specimens after deformation: (a) Without lubrication; (b) Lubricated with castor oil

The friction factor of different specimens under different lubrication conditions can be determined with Eqs.(3)-(6), as shown in Fig.5. It is clear that the friction factor increased in the case of lubrication with castor oil with miniaturization. The friction factor increased by about 0.11 with miniaturization. However, in the case without lubrication, the friction factor seems to keep constant. The maximum difference is only about 0.02. According to the above analysis, tribology size effect occurred with the lubrication of castor oil, but did not occur without lubrication.

Fig.5 Friction factors of different specimens

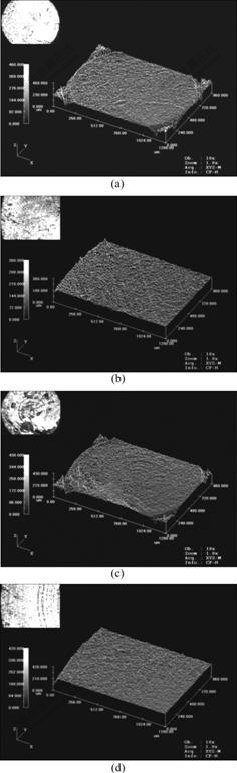

The LSCM images of surface topography of the 1 mm and 4 mm diameter specimens after deformation can be seen in Fig.6.

Fig.6 LSCM images of surface topography: (a) 1 mm, without lubrication; (b) 4 mm, without lubrication; (c) 1 mm, lubricated with castor oil; (d) 4 mm, lubricated with castor oil

It is clear from Figs.6(a) and (b) that, the asperities of the specimens were severely deformed and the topography almost flattened for both 4 mm and 1 mm diameter specimens deformed without lubrication. Moreover, it is also clear from Figs.6(c) and (d), only the asperities in the edge were severely deformed as the specimens were deformed without lubrication. However, the deformed degree of the asperities in the inner part was much lower than that in the edge for both 4 mm and 1 mm diameter specimens with the lubrication of castor oil.

When a forming load is applied to the surface of the lubricated workpiece, the lubricant in the edge escapes and cannot be able to transmit the forming load. The forming load can only apply on the asperities and results in a higher fraction of real contact area. On the contrary, the lubricant in the inner part can transmit part of the forming load and result in a lower fraction of real contact area. Because the width of the edge is constant, with miniaturization, the fraction of the edge increases, which results in higher real contact area and higher friction. If there is no lubricant, the forming load can only apply on the asperities and do not affect the fraction of real contact area, thus the tribology size effect is not found in the case of without lubrication.

4 Conclusions

1) Flow stress size effect occurred in scaled down cylinder compression whether use a lubricant or not. The yield strength decreased by about 30 MPa as the specimen size decreased from 8 mm to 1 mm. This can be explained by the dislocations in the specimens.

2) Tribology size effect occurred in scaled down cylinder compression in the case of lubrication with castor oil. The friction factor increased by about 0.11 as the specimen size decreased from 8 mm to 1 mm. However, tribology size effect is not found in the case of without lubrication. This can be explained by the fraction of real contact area under deformation.

References

[1] GEIGER M, KLEINER M, ECKSTEIN R, TIESLER N, ENGEL U. Microforming [J]. Annals of the CIRP, 2001, 50(2): 445-462.

[2] KALS T A, ECKSTEIN R. Miniaturization in sheet metal working [J]. Journal of Materials Processing Technology, 2000, 103(1): 95-101.

[3] RAULEA L V, GOIJAERTS A M, GOVAERT L E, BAAIJENS F P T. Size effects in the processing of thin metal sheets [J]. Journal of Materials Processing Technology, 2001, 115(1): 44-48.

[4] MICHEL J F, PICART P. Size effects on the constitutive behaviour for brass in sheet metal forming [J]. Journal of Materials Processing Technology, 2003, 141(3): 439-446.

[5] GAU J T, PRINCIPE C, WANG J. An experimental study on size effects on flow stress and formability of aluminum and brass for microforming [J]. Journal of Materials Processing Technology, 2007, 184(1/3): 42-46.

[6] PICART P, MICHEL J F. Effect of size and texture on the constitutive behaviour for very small components in sheet metal forming [C]// Proceedings of the 6th International Conference on Technology of Plasticity. Nuremberg, 1999: 895-900.

[7] MAHABUNPHACHAI S, KO? M. Investigation of size effects on material behavior of thin sheet metals using hydraulic bulge testing at micro/meso-scales [J]. International Journal of Machine Tools and Manufacture, 2008, 48(9): 1014-1029.

[8] MESSNER A, ENGEL U, KALS R, VOLLERTSEN F. Size effect in the FE-simulation of micro-forming process [J]. Journal of Materials Processing Technology, 1994, 45(1/4): 371-176.

[9] CHEN F K, TSAI J W. A study of size effect in micro-forming with micro-hardness tests [J]. Journal of Materials Processing Technology, 2006, 177(1/3): 146-149.

[10] TIESLER N, ENGEL U. Microforming—Effects of miniaturization [C]// Metal Forming 2000. Rotterdam, 2000: 355-360.

[11] ENGEL U, ECKSTEIN R. Microforming-from basic research to its realization [J]. Journal of Materials Processing Technology, 2002, 125/126: 35-44.

[12] KRISHNAN N, CAN J, DOHDA K. Study of the size effects on friction conditions in microextrusion (part 1): microextrusion experiments and analysis [J]. Journal of Manufacturing Science and Engineering, 2007, 129(4): 669-676.

[13] VOLLERTSEN F, HU Z, NIEHOFF H S. State of the art in micro forming and investigations into micro deep drawing [J]. Journal of Materials Processing Technology, 2004, 151(1/3): 70-79.

[14] VOLLERTSEN F, HU Z. Tribology size effects in sheet metal forming measured by a strip drawing test [J]. Annals of the CIRP, 2006, 55(1): 291-294.

[15] EBRAHIMI R, NAJAFIZADEH A. A new method for evaluation of friction in bulk metal forming [J]. Journal of Materials Processing Technology, 2004, 152(2): 136-143.

(Edited by YUAN Sai-qian)

Foundation item: Project(2006AA04Z316) supported by the High-tech Research and Development Program of China; Project(JC-05-11) supported by the Science Foundation for Distinguished Young Scholars of Heilongjiang Province, China; Project(HIT.NSRIF.2008.36) supported by the Natural Scientific Research Innovation Foundation in Harbin Institute of Technology, China

Corresponding author: GUO Bin; Tel: +86-451-86416218; E-mail: bguo@hit.edu.cn