热拉伸和压缩条件下铸造和锻造Ni-42Cu合金的热加工性能

来源期刊:中国有色金属学报(英文版)2016年第6期

论文作者:M. ARJMAND S. M. ABBASI A. KARIMI TAHERI A. MOMENI

文章页码:1589 - 1597

关键词:Ni-Cu合金;热塑性;力学性能;动态再结晶;热压缩;变形性

Key words:Ni-Cu alloy; hot ductility; mechanical properties; dynamic recrystallization; hot compression; formability

摘 要:为了分析铸造和锻造条件下Ni-42Cu合金的流变行为和热加工性能,在温度为900~1150 °C、应变速率为0.001~1 s-1的条件下对合金进行热变形实验。拉伸实验结果表明,950 °C时铸造和锻造两种合金均出现“热塑性低谷”。因为慢速动态再结晶,铸造合金的热塑性降低更为明显。合金(特别是铸造合金)的热塑性降低、晶界开裂归因于枝晶原子向晶界的偏析。随应变速率的增大,锻造合金的热塑性得到提高,这与高应变速率下动态再结晶分数的增加有关。此结果验证了动态再结晶机理随应变速率而变化。计算得到锻造合金的应变速率敏感性和不稳定参数结果表明,此合金在低温如950~1050 °C和高应变速率(0.1和1 s-1)条件下易发生应变集中。根据拉伸和压缩实验结果,合金获得理想热加工性能的最佳温度为1050~1150 °C。

Abstract: In order to analyze the flow behavior and workability of Ni-42Cu in cast and wrought conditions, hot deformation tests were performed at temperatures and strain rates within the ranges of 900-1150 °C and 0.001-1 s-1, respectively. Tensile tests showed a “hot ductility trough” at 950 °C for both alloys. The drop in hot ductility was more considerable in the cast alloy because of the sluggish dynamic recrystallization. The hot ductility drop and grain boundary cracking, particularly in the cast alloy, were attributed to the segregation of detrimental atoms to the boundaries. It was shown that the hot ductility of the wrought alloy could be improved with increasing strain rate. It was associated with increasing the fraction of dynamic recrystallization at higher strain rates. This finding corroborated the change in the mechanism of dynamic recrystallization with strain rate. The strain rate sensitivity and instability parameters calculated for the wrought alloy showed that the material is prone to strain localization at low temperatures, i.e., 950-1050 °C, and high strain rates of 0.1 and 1 s-1. Based on the tensile and compression tests, the best temperature range for a desirable hot workability was introduced as 1050-1150 °C.

Trans. Nonferrous Met. Soc. China 26(2016) 1589-1597

M. ARJMAND1, S. M. ABBASI2, A. KARIMI TAHERI1, A. MOMENI3

1. Department of Materials Science and Technology, Sharif University of Technology, Tehran 11365-8639, Iran;

2. Metallic Materials Research Center, Maleke Ashtar University of Technology, Tehran 1774-15875, Iran;

3. Department of Materials Science and Engineering, Hamedan University of Technology, Hamedan 6516913733, Iran

Received 17 July 2015; accepted 31 January 2016

Abstract: In order to analyze the flow behavior and workability of Ni-42Cu in cast and wrought conditions, hot deformation tests were performed at temperatures and strain rates within the ranges of 900-1150 °C and 0.001-1 s-1, respectively. Tensile tests showed a “hot ductility trough” at 950 °C for both alloys. The drop in hot ductility was more considerable in the cast alloy because of the sluggish dynamic recrystallization. The hot ductility drop and grain boundary cracking, particularly in the cast alloy, were attributed to the segregation of detrimental atoms to the boundaries. It was shown that the hot ductility of the wrought alloy could be improved with increasing strain rate. It was associated with increasing the fraction of dynamic recrystallization at higher strain rates. This finding corroborated the change in the mechanism of dynamic recrystallization with strain rate. The strain rate sensitivity and instability parameters calculated for the wrought alloy showed that the material is prone to strain localization at low temperatures, i.e., 950-1050 °C, and high strain rates of 0.1 and 1 s-1. Based on the tensile and compression tests, the best temperature range for a desirable hot workability was introduced as 1050-1150 °C.

Key words: Ni-Cu alloy; hot ductility; mechanical properties; dynamic recrystallization; hot compression; formability

1 Introduction

Ni-Cu alloys, sometimes known as Monel, are generally introduced due to their good strength, toughness and excellent resistance against corrosion [1]. They are usually strengthened by solid solution, precipitation hardening, work hardening and grain refinement [2]. The precise control of processing route is therefore very crucial to achieve a refined microstructure and desirable mechanical properties.

In general, alloying elements that are routinely added to raise strength, often lead to degrading hot or cold workability. Therefore, an in-depth understanding of the underlying mechanisms of deformation under different processing conditions is essential to find the best processing regime. Hot workability is usually restricted by a set of reasons from either metallurgical or mechanical origins. The segregation of detrimental elements such as sulfur, phosphorous or even tin to grain boundaries has been found as the most serious metallurgical problem which limits hot workability [3]. The drastic decrease in the hot ductility of different steel grades termed as “hot ductility trough” has been attributed to the role of some detrimental elements, particularly sulfur [4-6]. In addition to these effects, some microstructural processes such as dynamic recovery (DRV) and dynamic recrystallization (DRX) play an important role in improving hot workability [7-9].

The concept of dynamic restoration processes (DRV and DRX) and their significance from the industrial and scientific points of view have been the topic of many investigations in the past decades [10-14]. The occurrence of DRX during hot working of pure Ni has been well documented, e.g., in the work done by SRINIVASAN and PRASAD [15]. However, for the case of Ni-Cu alloys, controversies over the mechanism of dynamic restoration have still remained unresolved. Although the processing map for Monel K500 has indicated a wide region of stable flow at low to medium strain rates associated with DRX [16], LI et al [17] reported that very high strain rates, in order of 105 s-1, are necessary to propel DRX in Monel 400 (Ni-30Cu) alloy.

More recently, EBRAHIMI et al [18] have shown that the mechanism of DRX in Monel 400 depended on the processing condition. These controversies intensify the concerns regarding the hot workability of Ni-Cu alloys and signify the necessity of more investigations into this topic. In this research, the hot workability of Ni-42Cu alloy and its safe processing regimes have been studied by conducting hot tensile and compression tests at different temperatures and strain rates. It has been tried to correlate the observed mechanical results with microstructural characterizations in different deformation regimes.

2 Experimental

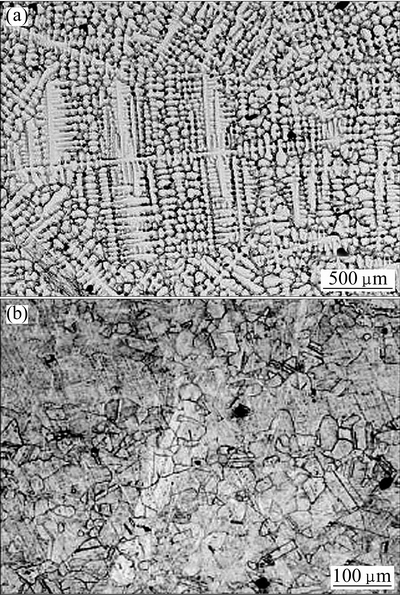

The Ni-42Cu alloy used in this investigation was prepared by sand casting with the chemical composition given in Table 1. After electro slag remelting and homogenization at 1000 °C for 3 h, some tensile samples were prepared to study the hot workability of the cast alloy at different temperatures. Based on the results of the hot tensile tests, the second part of the ingot was hot-rolled within the temperature range of 1100-1000 °C with a 70%-80% reduction to produce the as-rolled wrought material for further investigation. Figure 1 shows the starting microstructure of the cast and rolled samples before performing the designed testing procedure.

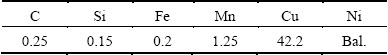

Table 1 Chemical composition of Ni-42Cu alloy (mass fraction, %)

The tensile test samples of the cast and rolled materials were prepared according to the ASTM E8 standard. Hot tensile tests were carried out on an Instron 8502 universal machine at temperatures of 800, 900, 950, 1000, 1050 and 1100 °C for both materials. In addition, some tests were conducted at 0.001, 0.01, 0.1 and 1 s-1 to study the effect of strain rate on the hot workability of the wrought alloy.

Some cylindrical compression samples, 10 mm in diameter and 15 mm in height, were also prepared from the wrought alloy, based on ASTM E209 standard, to further investigate the hot workability under hot compression testing. The hot compression tests were carried out on the same machine within the temperature range of 950-1150 °C and at the same four strain rates. In order to eliminate any temperature gradient in the samples, 10 min soaking was performed before each testing (tensile or compression). After the tests, the deformed samples were quenched in water to freeze the deformed microstructure for further microstructural investigations. For optical characterization of micro- structures, deformed samples were prepared by the standard metallographic techniques and then chemically etched in a reagent composed of 10 mL nitric acid and 10 mL acetic acid.

Fig. 1 Starting microstructures of Ni-42Cu alloy in cast (a) and wrought (b) conditions

3 Results and discussion

3.1 Hot workability of cast material in tensile tests

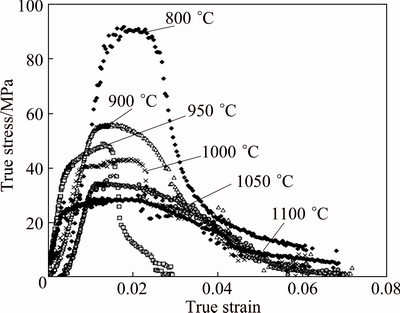

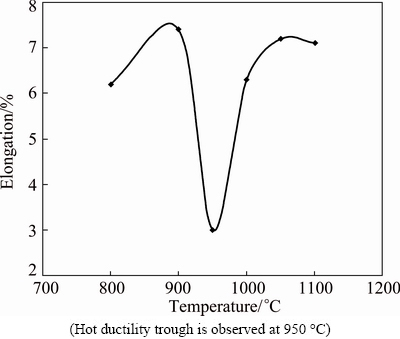

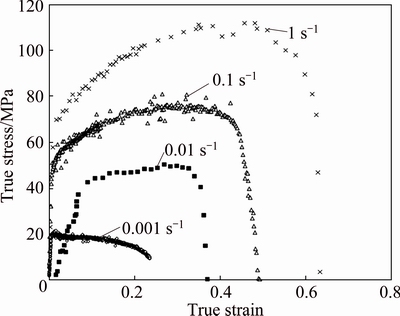

Figure 2 demonstrates the true stress-strain curves of the cast materials at different deformation temperatures and a strain rate of 0.01 s-1. The typical influence of temperature is clearly observed, so the flow stress level decreases as deformation temperature rises. However, the influence of temperature on the total strain to fracture (ef) is not as expected. It is observed that ef reaches the minimum of 0.03 at 950 °C and increases at lower or higher temperatures. It is therefore fair to say that the cast material exhibits better hot workability at 800 °C and 900 °C than at 950 °C. At temperatures beyond 950 °C, ef increases by about 30% from 0.06 at 1000 °C to 0.078 at 1100 °C. This in turn reflects better hot workability in the temperature range of 1000-1100 °C compared with lower temperatures (800-950 °C). The variation of total elongation with tensile temperature presented in Fig. 3 represents the pronounced hot ductility trough at 950 °C. The reason for such a degradation, based on our general knowledge, can be attributed to the segregation of S atoms to the grain boundaries, which leads to their weakening. The similar hot workability degradation has been reported in Cr-Mo steels, Fe-Ni-Co and Fe-Ni alloys due to the segregation of S and P atoms to the grain boundaries in critical temperature range of 1000-1050 °C [3,4,6]. The current results indicate that this detrimental effect cannot be eliminated even after refining by ESR. Therefore, the only way to avoid the hot ductility trough is to carry out hot working beyond the critical temperature. The comparison of current results with those reported in the literature for different steel grades [3,4,6] shows that hot ductility trough in Ni-Cu alloys is severer. The hot ductility trough for Fe-29Ni-17Co alloy has been reported [3] to be about 10% at 1050-1100 °C, while for current alloy, hot ductility drops by about 60% as temperature rises from 900 to 950 °C.

Fig. 2 True stress-strain curves of cast material at different temperatures and strain rate of 0.01 s-1

Fig. 3 Variation of total elongation with tensile temperature in cast alloy (Hot ductility trough is observed at 950 °C)

Although the difference strongly depends on the concentration of S in material, the tendency for segregation which is related to the grain boundary specific energy (γgb ) should not be neglected. There are some evidences which support that nickel has higher γgb than other FCC materials such as Ag, Al, Au, Cu and austenitic stainless steels [19]. In Ni-Al alloys, the segregation of Ni atoms to the grain boundaries increases γgb [20]. Some reports on Monel 400 [18], Ni-bearing steels [11,21] and some Ni-based superalloys [14] have stated that the high value of γgb even changes the mechanism of DRX.

According to the literature, it is reasonable to agree that the higher the grain boundary energy is, the greater the tendency for atomic segregation is. The drastic hot ductility drop in the current alloy can be therefore attributed to the great tendency of S atoms for the segregation to the high-energy grain boundaries of Ni.

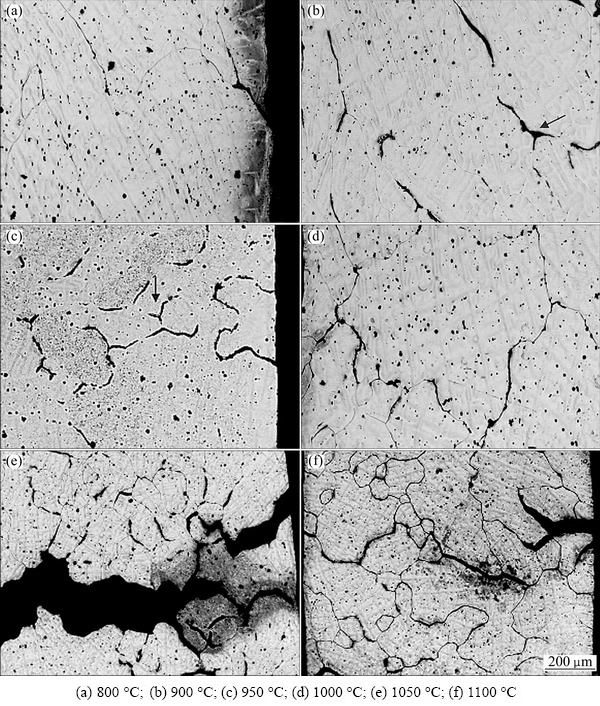

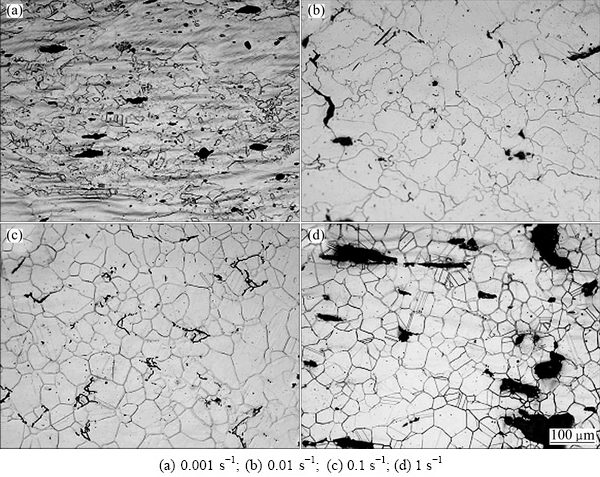

Figure 4 shows the microstructures of the hot tensile samples near the fractured surface. The micrographs help to correlate the tensile test results with the microstructural evolution. As seen, the starting dendritic microstructure of the cast material tends to undergo DRX when it is hot deformed. The micrographs clearly illustrate the increase of grain boundaries with the increase of tensile temperature which accelerates DRX. As it is clearly observed, Figs. 4(a) and (b) are characterized by large grains which should be associated with the initial cast structure. It is well-known that hot working favors homogenizing heat treatment to break down the dendritic microstructure to an equiaxed one. Therefore, it seems that dynamic homogenization is the predominant microstructural phenomenon at 800 and 900 °C. However, at 950 °C, the remarkable increase in the density of grain boundaries can be regarded as the assign to the occurrence of DRX. Due to the same reason, the segregation of S atoms to the newly formed grain boundaries gives rise to the observed drop in hot workability. The grain boundary cracks which seem to originate from the arrowed triple junctions are another reason for the grain boundary weakening.

3.2 Hot workability of wrought material in tensile tests

3.2.1 Effect of temperature

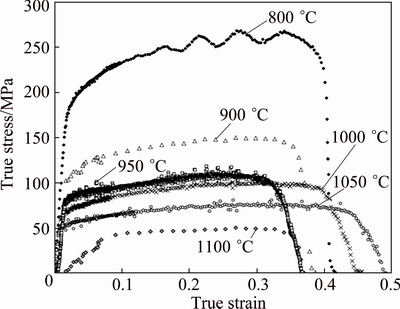

Figure 5 represents the true stress-strain curves of the wrought material at different deformation temperatures. At the first view, it is observed that the wrought material exhibits better hot workability, so that the ratio of ef,wrought/ef,cast lies in the range of 4-6 for the studied temperature range. This is easily attributed to the homogenous chemical composition and equiaxed grain structure (as seen in Fig. 1(b)) formed during previous hot rolling in the wrought alloy. The assessment of total elongation and reduction in area of the deformed samples in Fig. 6 shows that the wrought material suffers from hot ductility trough at the same temperature of 950 °C. Therefore, it is elicited that the hot workability degradation, due to the S atoms, mostly depends on temperature and not on the initial microstructure.

Fig. 4 Microstructures of hot tensile samples of cast material at strain rate of 0.01 s-1 and different tensile temperatures

Fig. 5 True stress-strain curves of wrought material at different temperatures and strain rate of 0.1 s-1

Fig. 6 Variation of total elongation and reduction in area for wrought alloy as function of tensile temperature showing same hot ductility trough at 950 °C

However, Figs. 3 and 6 clearly show that the intensity of hot ductility drop depends on the initial microstructure. Although the hot ductility drop for the cast material is about 60%, it is only about 40% for the wrought alloy. The better response of the wrought material to hot working at the critical temperatures, i.e., around 950 °C, can be ascribed to its finer grain structure which is capable of accommodating segregating atoms uniformly. Unlikely, in the cast material, the grain boundary network is not well-developed at low strains, leading to populating the detrimental atoms at some positions, such as the triple junctions, and thereby decreasing hot ductility drastically.

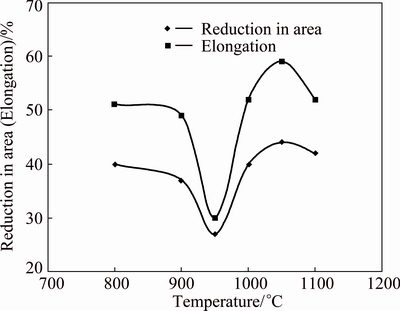

The microstructures of the tensile samples near the fracture surface, shown in Fig. 7, can be considered in view that how DRX progresses with increasing temperature. The micrograph at 800 °C (Fig. 7(a)) shows the early stages of DRX, in which some large elongated grains have been surrounded by irregular grain boundaries and some microcracks (dark regions). The micrographs of the tensile samples at 900 and 950 °C, shown in Figs. 7(b) and (c), are characterized by a large number of DRX new grains along with some preexisting deformed grains. It is worthy to note that due to the hot ductility drop at 950 °C, more microcracks can be observed near the fracture surface in Fig. 7(c). At 1000 °C and higher temperatures, i.e., Figs. 7(d)-(f), microstructures reflect complete DRX and increasing temperature only leads to larger grain size due to grain growth.

Fig. 7 Microstructure evolution in wrought material hot-deformed at strain rate of 0.1 s-1 and various temperatures

Fig. 8 True stress-strain curves of wrought material at 1050 °C and different strain rates

3.2.2 Effect of strain rate

The influence of strain rate on the hot ductility of the wrought alloy at 1050 °C is shown in Fig. 8. It is clearly seen that as strain rate rises, the hot ductility increases. The results of Fig. 8 are in contrast with our general knowledge that DRX is usually decelerated as strain rate rises. Indeed, this concept is not always true and may be overturned with a change in the mechanism of DRX. In addition, another source of this paradox arises from neglecting the effect of strain rate on the kinetics of void nucleation and growth. In order to assess the hot ductility under certain deformation condition, both DRX and void formation, which work concomitantly, should be considered. The nucleation of void is controlled by stress and its growth needs strain. Hence, at high strain rates, in which there is not enough time for voids to grow, fracture is actually controlled by void-nucleation. This means that at high strain rates, more voids with lower growth rate can coalesce and lead to fracture. For this to happen, larger strains are needed to form enough voids for fracture and this means better hot ductility. The improvement of hot ductility with increase in strain rate has also been reported in the literature for some steel grades [3,22,23]. On the contrary, at low strain rates, fracture is naturally strain-controlled, which means that fewer voids can grow to coalesce and lead to the final fracture. The influence of strain rate at tensile temperature of 1050 °C on the microstructural evolution of the wrought material is shown in Fig. 9. In contrary to our expectation, the micrographs show that increasing strain rate has a positive effect on the progress of DRX. EBRAHIMI et al [18], in their work on the hot deformation behavior of Monel 400 and some other researchers who studied Ni-rich alloys [11,14,21], claimed that the mechanism of dynamic softening changes from classical discontinuous DRX to a kind of continuous one (CDRX) as temperature rises or strain rate decreases. The current results confirm those reported in the literature and show that the improvement of hot workability in Fig. 8 should also be associated with more progressed DRX at higher strain rates.

Fig. 9 Microstructure evolution in wrought material hot-deformed at 1050 °C and different strain rates

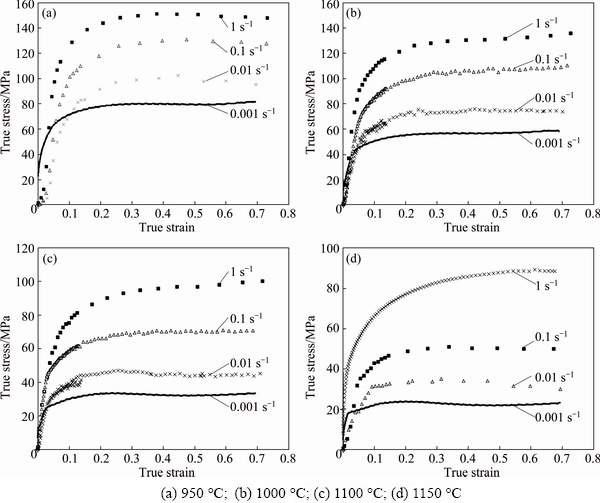

Fig. 10 Representative hot compression true stress-strain curves of wrought alloy at various strain rates and temperatures

3.3 Hot workability of wrought material in compression tests

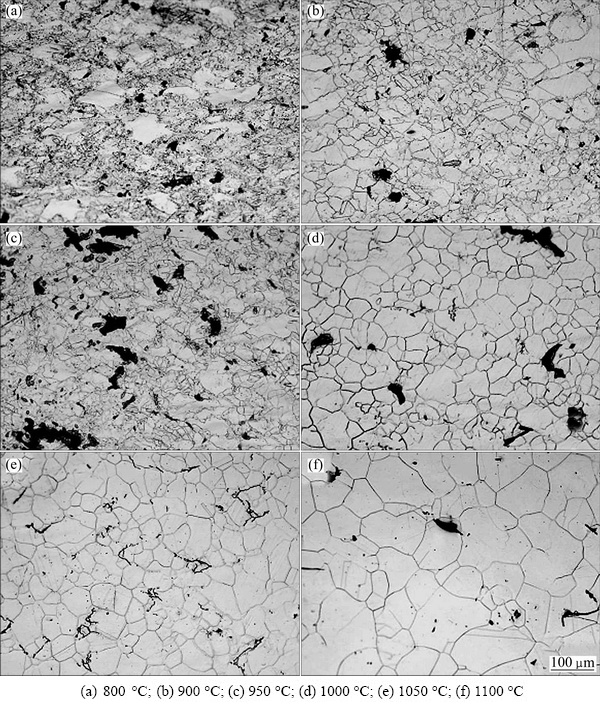

Figure 10 shows the representative true stress-strain curves of the wrought material at different temperatures and strain rates. As observed, the flow curves, unless those pertaining to strain rate of 1 s-1, indicate a nearly long steady state condition after work hardening. As the feasibility of DRX was confirmed through hot tensile tests, the slow work hardening rate or steady state flow behavior in the flow curves of Fig. 10 can be associated with DRX. However, as EBRAHIMI et al [18] reported in their work, its mechanism has not been well understood. The absence of pronounced flow softening, as observed in other materials prone to DDRX, is a source of concerns regarding the hot workability of the material under the some deformation conditions. The strain rate sensitivity parameter (m) can be used as an index to assess hot workability in various deformation regimes. It is often defined as the variation of flow stress with strain rate, based on the viscoplastic power-law equation, given by

(1)

(1)

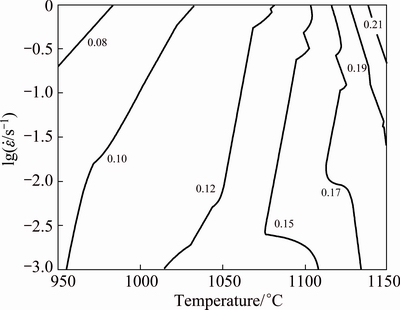

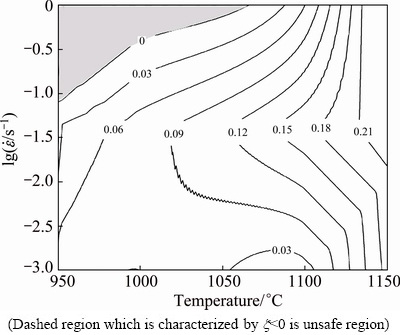

By adopting a typical strain of 0.4, the values of m were determined at various deformation temperatures and strain rates. The developed window for m in Fig. 11 shows the regions having the smallest m value at 950 and 1000 °C, particularly at high strain rates. Although m value often reflects the resistance of material to flow localization, these results confirm previous findings, suggesting the risk of insufficient workability or premature fracture by hot deformation at about 950 °C.

Fig. 11 Strain rate-temperature map of strain rate sensitivity parameter (m) representing iso-m contours in different deformation regimes and strain of 0.4

Another criterion, which was proposed by ZIEGLER [24], considered the stability condition of deformation in a given material via the dynamic material model approach and proposed that stable flow is ensured if following inequality satisfies

(2)

(2)

The variation of instability parameter  in the window of temperature and strain rate yields a map in which instability regions are characterized by negative

in the window of temperature and strain rate yields a map in which instability regions are characterized by negative  . Figure 12 demonstrates the iso-stability contours of instability map for the wrought material. Consistent with the m-window, shown in Fig. 11, x-window also predicts the possibility of plastic instability at low temperatures, in particular, between 950 and 1050 °C and at high strain rates. This mode of instability is often due to the flow localization and introduces the dashed region as an unsafe range of processing. It is often observed that the flow localization happens in conditions which are characterized by low m values. This is because when m is high, the material withstands against flow localization. The direct relationship between the value of m and resistance to flow localization is inferred from Eq. (1). Under a high-m condition, when flow localization happens, the strain rate increases locally. According to Eq. (1), flow stress increases considerably and leads to suppressing further flow in the localized region. This therefore leads to a self-consistent mechanism of flow transition to other regions of the material, which finally results in a more uniform deformation. Based on all the mechanical and microstructural investigations on the wrought and cast Ni-42Cu alloys, temperatures in the range of 1050-1150 °C can be introduced as the safest range of hot working.

. Figure 12 demonstrates the iso-stability contours of instability map for the wrought material. Consistent with the m-window, shown in Fig. 11, x-window also predicts the possibility of plastic instability at low temperatures, in particular, between 950 and 1050 °C and at high strain rates. This mode of instability is often due to the flow localization and introduces the dashed region as an unsafe range of processing. It is often observed that the flow localization happens in conditions which are characterized by low m values. This is because when m is high, the material withstands against flow localization. The direct relationship between the value of m and resistance to flow localization is inferred from Eq. (1). Under a high-m condition, when flow localization happens, the strain rate increases locally. According to Eq. (1), flow stress increases considerably and leads to suppressing further flow in the localized region. This therefore leads to a self-consistent mechanism of flow transition to other regions of the material, which finally results in a more uniform deformation. Based on all the mechanical and microstructural investigations on the wrought and cast Ni-42Cu alloys, temperatures in the range of 1050-1150 °C can be introduced as the safest range of hot working.

Fig. 12 Strain rate-temperature map of instability parameter (x) representing iso-stability contours at different deformation regimes and strain of 0.4

4 Conclusions

1) The cast and wrought Ni-42Cu alloys subjected to the hot tensile tests showed a “hot ductility trough” at about 950 °C. The drop in hot ductility was severer in the cast alloy due to more sluggish DRX.

2) The hot ductility drop and extensive grain boundary cracking were attributed to the segregation of detrimental atoms which led to the boundary weakening.

3) It was found that increasing strain rate has a positive influence on the hot ductility of the alloy. This was attributed to the change in the mechanism of DRX which could lead to the increase of recrystallization fraction with increasing strain rate.

4) The strain rate sensitivity and instability windows, developed from the hot compression tests, showed that the material is prone to strain localization at low temperatures, i.e., 950-1050 °C, and high strain rates of 0.1 and 1 s-1.

5) Based on the hot tensile and compression tests, the best temperature range for a desirable hot workability was found as 1050-1150 °C.

References

[1] GHOSH S K, DEY G K, DUSANE R O, GROVER A K. Improved pitting corrosion behavior of electrodeposited nanocrystalline Ni-Cu alloys in 3.0wt.% NaCl solution [J]. Journal of Alloys and Compounds, 2006, 426: 235-243.

[2] GRAY G T, CHEN S R, VECCHIO K S. Influence of grain size on the constitutive response and substructure evolution of Monel 400 [J]. Metallurgical and Materials Transactions A, 1999, 30: 1235-1247.

[3] YAZDANI M, ABBASI S M, MOMENI A, KARIMI TAHERI A. Hot ductility of a Fe–Ni–Co alloy in cast and wrought conditions [J]. Materials and Design, 2011, 32: 2956-2962.

[4] BEN MOSTEFA L, SAINDRENAN G, SOLIGNAC M P, COLIN J P. Effect of interfacial sulfur segregation on the hot ductility drop of Fe-36Ni alloy [J]. Acta Metallurgica et Materialia, 1991, 39: 3111-3118.

[5] YU Yan-chong, CHEN Wei-qing, ZHENG Hong-guang. Effects of Ti-Ce refiners on solidification structure and hot ductility of Fe-36Ni invar alloy [J]. Journal of Rare Earths, 2013, 31: 927-932.

[6] CHEN X M, SONG S H, SUN Z C, LIU S J, WENG L Q, YUAN Z X. Effect of microstructural features on the hot ductility of 2.25Cr-1Mo steel [J]. Materials Science and Engineering A, 2010, 527: 2725-2732.

[7] MOHAMMADI SHORE F, MORAKABATI M, ABBASI S M, MOMENI A. Hot deformation of Incoloy 901 through hot tensile testing [J]. Journal of Materials Engineering and Performance, 2014, 23: 1424-1433.

[8] EBRAHIMI G R, KESHMIRI H, MALDAR A R, MOMENI A. Dynamic recrystallization behavior of 13% Cr martensitic stainless steel under hot working condition [J]. Journal of Materials Science and Technology, 2012, 28: 467-473.

[9] MOHAMMADI SHORE F, MORAKABATI M, ABBASI S M, MOMENI A, MAHDAVI R. Hot ductility of Incoloy 901 produced by vacuum arc remelting [J]. ISIJ International, 2014, 54: 1353-1360.

[10] LIN Y C, CHEN M S, ZHONG J. Effect of temperature and strain rate on the compressive deformation behavior of 42CrMo steel [J]. Journal of Materials Processing Technology, 2008, 205: 308-315.

[11] YAZDANI M, ABBASI S M, KARIMI TAHERI A, MOMENI A. Hot deformation behavior of Fe-29Ni-17Co alloy [J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3271-3279.

[12] ETAATI A, DEHGHANI K. A study on hot deformation behavior of Ni-42.5Ti-7.5Cu alloy [J]. Materials Chemistry and Physics, 2013, 140: 208-215.

[13] KHAMEI A A, DEHGHANI K. A study on the mechanical behavior and microstructural evolution of Ni60wt%–Ti40wt% (60 Nitinol) intermetallic compound during hot deformation [J]. Materials Chemistry and Physics, 2010, 123: 269-277.

[14] MOMENI A, ABBASI S M, MORAKABATI M, BADRI H, WANG X. Dynamic recrystallization behavior and constitutive analysis of Incoloy 901 under hot working condition [J]. Materials Science and Engineering A, 2014, 615: 51-60.

[15] SRINIVASAN N, PRASAD Y V R K. Characterization of dynamic recrystallisation in nickel using processing map for hot deformation [J]. Materials Science and Technology, 1992, 8: 206-212.

[16] PRASAD Y V R K, SASIDHARA S. Hot working guide: A compendium of processing maps [M]. Ohio: ASM International, 1997: 435-436.

[17] LI Q, XU Y B, LAI Z X, SHEN L T, BAI Y L. Dynamic recrystallization induced by plastic deformation at high strain rate in a Monel alloy [J]. Materials Science and Engineering A, 2000, 276: 250-256.

[18] EBRAHIMI G R, MOMENI A, ABBASI S M, MONAJATIZADEH H. Constitutive analysis and processing map for hot working of a Ni-Cu alloy [J]. Metals and Materials International, 2013, 19: 11-17.

[19] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena [M]. 2nd ed. Amsterdam: Elsevier, 2004.

[20] NAJAFABADI R, WANG H Y, SROLOVITZ D J, LESAR R. The effects of segregation on grain boundary cohesive energies in Ni3-xAIl+x [J]. Scripta Metallurgica, 1991, 25: 2497-2502.

[21] ABBASI S M, MOMENI A. Hot working behavior of Fe-29Ni-17Co analyzed by mechanical testing and processing map [J]. Materials Science and Engineering A, 2012, 552: 330-335.

[22] CEPEDAJ L E, RODRIQUEZ IBABE M, UROCOLA J J. Influence of composition and thermal history on the dynamic recrystallisation and subsequent hot ductility of mild steels [J]. ISIJ International, 1993, 33: 799-806.

[23] HURTADO-DELGADO E, MORALES R D. Hot ductility and fracture mechanisms of a C-Mn-Nb-Al steel [J]. Metallurgical and Materials Transactions B, 2011, 32: 919-927.

[24] ZIEGLER H. Progress in solid mechanics [M]//New York: John Wiley and Sons, 1963: 63-193.

M. ARJMAND1, S. M. ABBASI2, A. KARIMI TAHERI1, A. MOMENI3

1. Department of Materials Science and Technology, Sharif University of Technology, Tehran 11365-8639, Iran;

2. Metallic Materials Research Center, Maleke Ashtar University of Technology, Tehran 1774-15875, Iran;

3. Department of Materials Science and Engineering, Hamedan University of Technology, Hamedan 6516913733, Iran

摘 要:为了分析铸造和锻造条件下Ni-42Cu合金的流变行为和热加工性能,在温度为900~1150 °C、应变速率为0.001~1 s-1的条件下对合金进行热变形实验。拉伸实验结果表明,950 °C时铸造和锻造两种合金均出现“热塑性低谷”。因为慢速动态再结晶,铸造合金的热塑性降低更为明显。合金(特别是铸造合金)的热塑性降低、晶界开裂归因于枝晶原子向晶界的偏析。随应变速率的增大,锻造合金的热塑性得到提高,这与高应变速率下动态再结晶分数的增加有关。此结果验证了动态再结晶机理随应变速率而变化。计算得到锻造合金的应变速率敏感性和不稳定参数结果表明,此合金在低温如950~1050 °C和高应变速率(0.1和1 s-1)条件下易发生应变集中。根据拉伸和压缩实验结果,合金获得理想热加工性能的最佳温度为1050~1150 °C。

关键词:Ni-Cu合金;热塑性;力学性能;动态再结晶;热压缩;变形性

(Edited by Wei-ping CHEN)

Corresponding author: A. MOMENI; E-mail: ammomeni@aut.ac.ir

DOI: 10.1016/S1003-6326(16)64264-4