文章编号: 1004-0609(2005)03-0415-08

低频电磁场对半连铸高强Al合金组织结构的影响

颜 莹1, 张彩碚1, 崔晶磊1, 崔建忠2

(1. 东北大学 理学院, 沈阳 110004;

2. 东北大学 材料电磁过程研究教育部重点实验室, 沈阳 110004)

摘 要: 利用光学显微镜、 X射线衍射仪和透射电镜, 研究了在不同电流和频率作用下, 半连铸d100mm高强高韧Al合金铸锭组织结构的变化。 结果表明: 在电磁场频率为25Hz时, 当电流从60A增大到100A时, 电流越大, 晶粒细化越明显; 在电流为100A时, 晶粒细化的最佳频率为25Hz; 与常规铸锭相比, 随电流增大, 铸锭内沿[311]方向产生的织构逐渐消失, 并且铸锭边缘和中心部位的点阵常数逐渐趋于一致, 这表明溶质元素的分布更加均匀; 在电流和频率分别为100A和25Hz时, 晶界附近无析出带宽度变窄, 约为100nm。 此时, 无论是在晶内还是沿晶界, 析出相的尺寸明显减小, 并且有亚稳相, 形态近似为颗粒状。

关键词: 金属材料; 组织结构; 低频电磁场铸造; 高强Al合金 中图分类号: TG146.2; TG249.7

文献标识码: A

Influence of low frequency electromagnetic field on microstructures of semi-continuously cast high-strength Al alloy

YAN Ying1, ZHANG Cai-bei1, CUI Jing-lei1, CUI Jian-zhong2

(1. College of Science, Northeastern University, Shenyang 110004, China;

2. The Key Laboratory of Electromagnetic Processing of Materials,

Ministery of Education, Northeastern University, Shenyang 110004, China)

Abstract: Microstructures of semi-continuously cast d100mm Al alloy ingot at different current intensities and frequencies were studied in details by optical microscope, X-ray diffraction and TEM to investigate the effect of electromagnetic field on microstructures of ingot. When current increases from 60 to 100A at 25Hz, the grains are gradually refined; When current is 100A, the optimum frequency of grain refinement is 25Hz. In contrast to the as-cast ingot, with the increase of current, texture produced along [311] direction gradually eliminates, and lattice constants at the center and edge of the ingot are more and more close, which shows that the distribution of solute atoms is more uniform. At current of 100A and frequency of 25Hz, width of precipitate-free zones on both sides of grain boundary becomes narrower and is about 100nm, the size of precipitates deposited both inside grains and along grain boundaries becomes smaller, and there exists metastable phase, with basically granular shapes.

Key words: metallic materials; microstructure; low frequency electromagnetic casting; high-strength Al alloy

作为航空、 航天一些器件主要结构材料的超高强铝合金,因其强度和韧性很难协调, 制约了其更为广泛的应用。 采用特殊的工艺, 加入更多的强化合金元素来提高合金的强度, 又不降低合金的韧性, 已成为研究开发超高强高韧铝合金的热点[1]。 在凝固过程中降低晶界偏析(即提高晶内合金元素含量、 降低晶界处共晶相和化合物的数量和尺寸)、 细化晶粒, 是提高超高强高韧Al-Zn-Mg-Cu合金强度和断裂韧性的有效方法。 电磁细晶铸造[2, 3], 加上较低的频率[4, 5], 不但可以细化晶粒[6-9], 增加溶质元素在基体中的含量[10, 11], 而且还可以增强锭坯的抗裂纹能力, 减小宏观偏析[12, 13], 以为后续工序获得高强高韧Al合金打了良好的基础。 低频电磁场对合金元素含量较高的Al-Zn-Mg-Cu合金铸锭组织结构的影响, 尤其是对析出相尺寸、 形态、 种类及晶界附近无析出带宽度等的影响, 目前尚未见详细报道。

本文作者主要采用低频半连续铸造工艺, 制备了d100mm Al-Zn-Mg-Cu合金铸锭, 利用光学显微镜、 X射线衍射仪和透射电镜, 研究在低频电磁场作用下, 高强高韧Al合金铸锭组织结构的变化, 以便为电磁场理论在材料铸造过程中的应用提供一些参考数据。

1 实验

以工业纯Al(质量分数为99.7%)、 Zn、 Mg、 Cu为原料, 以复合锆盐的形式加入微量Zr, 在2RZ30倾斜式熔化电阻炉内熔炼, 其熔炼温度为760℃。 合金熔体经除气、 扒渣、 精炼后转入电阻静置炉内。 当静置炉内合金熔体温度降到710℃、 保温15min后, 在710℃进行低频电磁场铸造。 电磁铸造条件为: 电流为100A、 频率分别为15、 25、 35Hz; 频率为25Hz、 电流分别为60、 80、 100A。 铸锭化学成分(质量分数)为: 10%Zn、 2.5%Mg、 2.5%Cu, 其余为Al。 在铸锭垂直横截面的边部和中部截取试样。

借助光学显微镜、 X射线衍射仪和透射电镜观察不同电流强度和频率作用下, 半连铸d100mm Al合金铸锭的显微组织结构, 探讨在电磁场作用下合金组织结构的变化特点。

2 结果及讨论

2.1 晶粒尺寸的变化

2.1.1 电流的影响

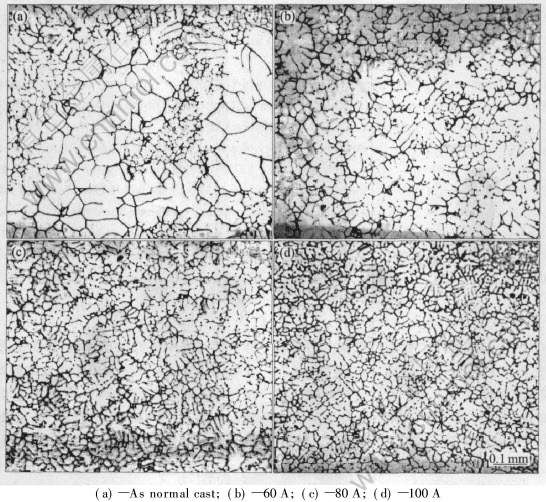

常规铸锭和电流频率为25Hz、 电流分别为60、 80和100A时, 铸锭边缘部位和中心部位晶粒尺寸的变化见图1和图2。

常规铸锭的晶粒比较粗大, 并且大小不均。 在电磁场作用下, 晶粒发生了细化。 随电流增大, 晶粒细化明显, 并且晶粒由树枝状逐渐转变为等轴状。

图1 铸锭边缘部位晶粒尺寸随电流的变化

Fig.1 Evolutions of grain size with current at edge of ingot

图2 铸锭中心部位晶粒尺寸随电流的变化

Fig.2 Evolutions of grain size with current at center of ingot

随电流增大, 铸锭中心部位等轴晶数目增多, 晶粒细化。 但与边缘部位相比, 随电流增大, 晶粒细化程度减小。

在电磁场作用下, 晶粒细化和等轴晶的形成主要是: 熔体在电磁力作用下产生受迫振动, 打碎了树枝晶, 增加晶核数目; 另外, 电磁搅拌也使液-固混合物保持流动, 并在生长的枝晶上产生机械剪切作用, 使枝晶上脱落下来的碎块漂浮在熔体中, 枝晶碎块之间以及它们与液体之间的碰撞、 摩擦和冲刷, 也会增加晶核数目; 其次, 强制对流, 降低了熔体温度梯度和液固界面处的成分过冷, 使晶粒处于一个相对均匀的生长环境中, 消弱了枝晶的生长条件。 综合作用, 导致在电磁场下铸锭组织细化。 电流越大, 对流、 机械搅拌及剪切作用越大, 晶粒细化越明显, 并且等轴晶数目增多。

铸锭边缘部位晶粒细化比中心部位明显, 这是因为: 电磁场作用虽然使熔体内的传热和传质速度增加, 加快了内部熔体温度的降低。 但相对铸锭中心而言, 由于边缘部位冷却快, 对流作用和机械剪切作用又强, 导致晶核数目增多, 长大时间缩短, 从而晶粒较细小。

2.1.2 电流频率的影响

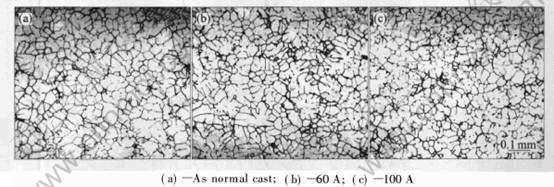

常规铸锭和电流为100A、 频率分别为15、 25和35Hz时, 铸锭边缘部位晶粒尺寸的变化如图3所示。

与常规铸锭相比,电流频率为15Hz时,晶粒尺寸有所减小,并且等轴晶数目增多; 当频率为25Hz时, 晶粒细化最明显; 随频率继续增大,晶粒尺寸又有所增大。 这主要是因为: 磁感应强度在熔体内衰减的情况由集肤深度δ来表征:

δ=1/(πσμf)

式中 σ和μ分别为熔体的电导率和磁导率; f为电磁场频率。

从上式可见, 当电磁场频率较高时,电磁场的集肤深度很小, 电磁力主要集中于熔体的表面, 对熔体的搅拌和对流作用相对较弱; 随电磁场频率的降低, 电磁场渗透深度增加, 其磁力线相对于铸锭对称轴产生明显的偏转[4], 导致电磁力有旋分量增加, 对熔体的搅拌和对流作用增强; 当频率进一步降低, 电磁场渗透深度继续增加, 磁感应强度在熔体内的衰减率逐渐下降, 导致电磁场分布渐趋均匀, 对熔体的搅拌和对流作用减弱。 因而, 对晶粒的细化存在一最佳频率, 在本研究中为25Hz。

2.2 基体Al衍射峰及点阵常数的变化

2.2.1 基体Al衍射峰的变化

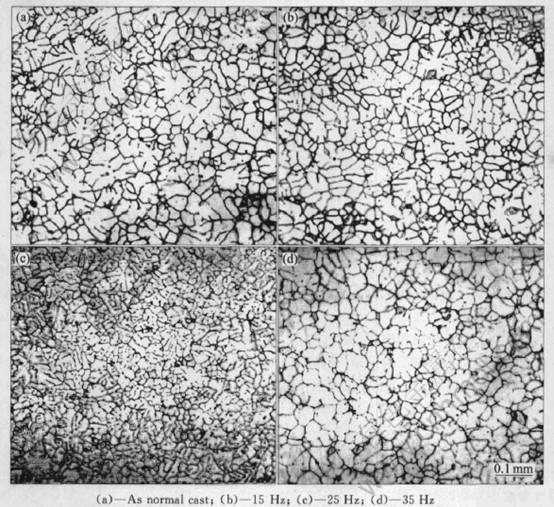

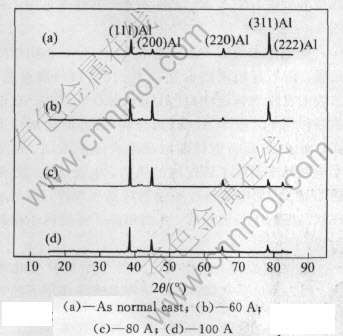

对常规铸锭和不同电流作用下铸锭边缘及中心部位分别进行了X射线衍射分析, 其结果见图4和图5。

从图4(a)可以发现, 基体Al的(311)面衍射峰最强, 而不是粉末衍射强度最大的(111)面最强, 这表明在常规铸锭中沿[311]方向存在织构。 在电磁场作用下, 基体Al的(111)和(200)面衍射峰增强, 而(311)面衍射峰随电流增大逐渐减弱。 这表明电磁铸造消除了铸锭内的织构, 电流越大, 效果越明显。 因为电磁铸造的强制对流和搅拌, 抑制了柱状晶区的生长或形成, 从而消除了铸锭内织构的形成。

铸锭中心部位基体Al的各个衍射峰变化不大。 因为无论是常规铸锭还是在电磁场作用下的铸锭, 中心部位都是随机取向的等轴晶。

2.2.2 基体Al点阵常数的变化

依据图4和图5, 对所有样品均取同样的最高角度区, 并选取相同的θ和h、 k、 l值, 利用公式: a=(λ/2sinθ)(h2+k2+l2)1/2, 得到基体Al的点阵常数, 列于表1。

图3 晶粒尺寸随电流频率的变化

Fig.3 Evolutions of grain size with current frequency

图4 不同电流作用下铸锭边缘部位的X射线衍射谱

Fig.4 XRD patterns at edge of cast at different currents

图5 不同电流作用下铸锭中心部位的X射线衍射谱

Fig.5 XRD patterns at center of cast at different currents

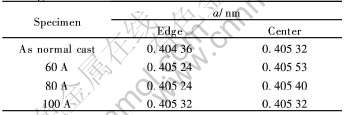

表1 铸锭中心部位与边缘部位基体Al的点阵常数

Table 1 Point lattice constants of matrix Al at edge and center of cast at different currents

常规铸造时中心部位与边缘部位的点阵常数差别较大, 这主要是溶质元素分布不均造成的。 在电磁场作用下, 点阵常数差别不大, 尤其是100A时, 基本一致。 这表明随电流增大, 溶质元素的分布更加均匀。 因为电流增大, 电磁搅拌和对流传输作用越强, 导致溶质元素在基体当中分布更均匀。

2.3 析出相尺寸、 形态及种类

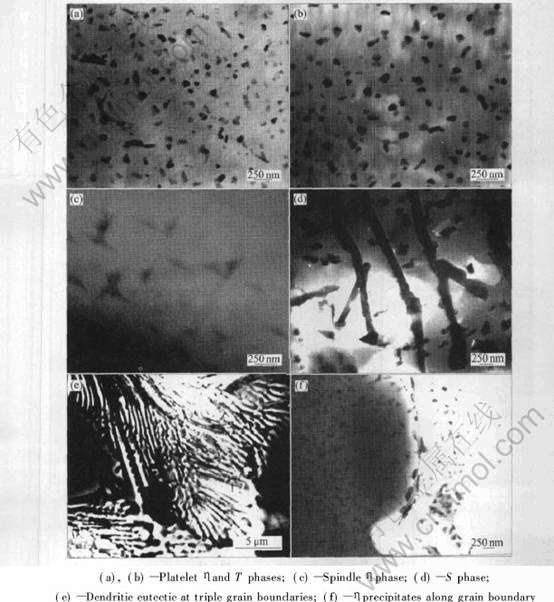

图6所示为常规铸锭不同析出相的尺寸、 形态及晶界附近的特点。 在常规铸锭中, 析出相的尺寸较大; η相和T相主要为片状(图6(a)、 6(b)), 在有些区域还发现了纺锤体状的η相(图6(c)), S相为粗大片状, 连接在一起就像竹节(图6(d)); 由于晶界处粗大树枝状共晶组织增多, 晶界明显宽化(图6(e)); 晶界两侧无析出带的宽度约为3~5μm, 沿晶界析出的沉淀相主要为板条状的η相(图6(f))。

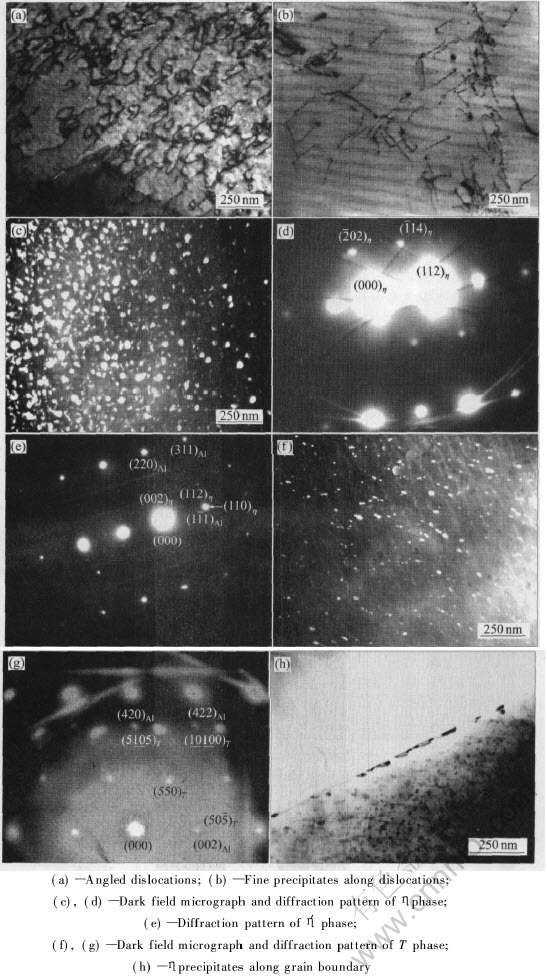

经电磁场处理后, 晶界处粗大树枝状共晶组织明显减少, 晶内析出相除了有η和T稳定相外, 还出现了亚稳相η′, 这些析出相的尺寸都较小, 并且与基体存在一定的取向关系。 图7所示为100A、 25Hz电磁场作用下Al合金铸锭的TEM组织。 此

图6 Al合金常规铸锭的TEM组织

Fig.6 TEM microstructures of as normal ingot of Al alloy

图7 电流100A、 频率25Hz电磁场作用下Al合金铸锭的TEM组织

Fig.7 TEM microstructures of Al alloy cast at 100A current and 25Hz frequency

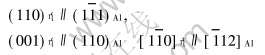

时晶内位错密度较高, 并发生缠结(图7(a))。 缺陷浓度的提高表明电磁铸造促进了熔体的非平衡凝固过程; 在有些区域可以观察到, 沿位错线析出的细小沉淀相(图7(b)), 这也说明析出相可能主要是在位错处形核; η相近似为颗粒状, 其暗场相和电子衍射花样见图7(c)和7(d)。 在晶内还发现了颗粒状的η′相, 其衍射花样见图7(e), 与基体的取向关系为

T相仍为小片状, 其暗场相和电子衍射花样见图7(f)和7(g), 与基体的取向关系为

沿晶界析出的沉淀相仍为板条状η相, 晶界两侧无析出带宽度变窄, 约为100nm左右(图7(h))。

在电磁场作用下, 铸锭析出相的尺寸、 形态和种类发生了明显改变。 在电磁场作用下, 大量位错缺陷的形成, 增加了析出相的形核部位, 而电磁的搅拌又提供了能量, 导致析出相更易形核。 溶质元素在基体中固溶度的增加[1]和凝固速度的加快, 使析出相来不及长大, 导致细小沉淀相的形成。 一般, 在Al-Zn-Mg(或加Cu)合金中, 稳定相η的形成遵循以下的时效次序: α→球状GP区→η′(MgZn2)→η(MgZn2)[14]。 在电磁场作用下, 由于铸锭快速凝固, 观察到了η′相的存在。

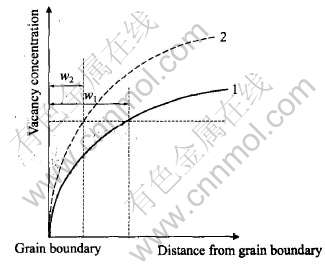

晶界附近无析出带的形成: 一是溶质原子很容易扩散到晶界处形成尺寸较大的粒子, 导致晶界附近溶质原子的贫乏; 二是空位浓度低于析出相形核所需要的临界空位浓度, 导致晶界附近析出相不能形核[15]。

在电磁场作用下, 晶界附近无析出带宽度变窄, 主要是凝固速度的加快, 提高了空位浓度(图8中的曲线2), 从而导致在析出相形核所需要临界空位浓度不变的条件下, 晶界附近无析出带宽度由w1变成w2(见图8), 即无析出带宽度变窄。

图8 淬火合金中晶界附近空位浓度的变化

Fig.8 Representation of profiles of vacancy concentration adjacent to a grain boundary in quenched alloys

(Curves 1 and 2 show distribution of critical

vacancy concentration needed to assist

with nucleation of precipitates near grain

boundaries at the particular temperature, and

of vacancy concentration near grain boundaries under

non-equilibrium condition, respectively.)

3 结论

1) 在电磁场作用下, 晶粒细化。 电流增大, 晶粒细化明显, 晶粒由树枝状逐渐转变为等轴状。 电流频率为25Hz时, 晶粒细化最明显。

2) 在电磁场作用下, 随电流增大, 铸锭内部织构逐渐消失, 溶质元素分布更加均匀。

3) 常规铸锭晶界宽化, 晶界两侧无析出带宽度约为3~5μm, 晶内析出相尺寸较大, 主要为片状和纺锤体状的η相, 及片状的T相和粗大片状的S相。

4) 电流为100A、 频率为25Hz时, 半连铸铸锭内, 晶界两侧无析出带宽度为100nm左右, 晶内位错密度较高, 沉淀相尺寸较小, 析出相主要为颗粒状的η′和η相, 及小片状的T相。

REFERENCES

[1]董杰. 超高强铝合金低频电磁半连续铸造工艺及理论研究 [D]. 沈阳: 东北大学, 2004.

DONG Jie. Study on semi-continuously casting process of super-high strength Al alloys under low-frequency electromagnetic field and its theory [D]. Shenyang: Northeastern University, 2004.

[2]Vives C. Effects of forced electromagnetic vibrations during the solidification of aluminum alloys (Ⅱ)—solidification in the presence of collinear variable and stationary magnetic fields[J]. Metall Mater Trans B, 1996, 7B: 457-464.

[3]Vives C. Electromagnetic refining of aluminum alloys by the CREM process(Ⅰ)—working principle and metallurgical results[J]. Metall Trans B, 1989, 20B: 623-629.

[4]张勤, 崔建忠, 张北江. CREM法半连铸铝合金过程中最佳电磁场频率范围的确定[J]. 铸造, 2004, 53(1): 41-45.

ZHANG Qin, CUI Jian-zhong, ZHANG Bei-jiang. Determination of optimal frequency on the process of semicontinuous casting of aluminum alloy by CERM[J]. Foundry, 2004, 53(1): 41-45.

[5]张北江, 崔建中, 路贵民, 等. 电磁场频率对电磁铸造7075铝合金微观组织的影响[J]. 金属学报, 2002, 38(2): 215-218.

ZHANG Bei-jiang, CUI Jian-zhong, LU Gui-min, et al. Effect of frequency on microstructures of electromagnetic casting 7075 aluminum alloy [J]. Acta Metallurgica Sinica, 2002, 38(2): 215-218.

[6]董杰, 崔建忠, 刘晓涛, 等. 7A60超高强铝合金的低频电磁铸造(Ⅰ)—直径0.2m锭坯的铸态组织[J]. 中国有色金属学报, 2003, 13(6): 1494-1499.

DONG Jie, CUI Jian-zhong, LIU Xiao-tao, et al. Super-high strength 7A60 Al alloy by low frequency electromagnetic cast(Ⅰ)—As-cast structures of billets with diameter of 0.2m[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1494-1499.

[7]ZHANG B J, CUI J Z, LU G M. Effect of electromagnetic frequency on microstructures of continuous casting aluminum alloys[J]. Journal of Materials Science and Technology, 2002, 18(5): 1-3.

[8]董杰, 崔建中, 刘晓涛, 等. 低频电磁场参数对Al-10Zn-2.5Mg-2.5Cu-0.15Zr合金铸态组织和性能的影响[J]. 金属学报, 2003, 39(5): 482-485.

DONG Jie, CUI Jian-zhong, LIU Xiao-tao, et al. Effect of low frequency electromagnetic parameters on the as-cast microstructures and mechanical properties of an Al-10Zn-2.5Mg-2.5Cu-0.15Zr alloy[J]. Acta Metallurgica Sinica, 2003, 39(5): 482-485.

[9]Boettinger W J, Coriell S R, Greer A L, et al. Solidification microstructures: recent developments, future directions[J]. Acta Mater, 2000, 48(1): 43-70.

[10]张勤, 崔建忠. 7075铝合金CREM法半连铸坯中溶质元素的宏观分布[J]. 金属学报, 2003, 39(12): 1264-1268.

ZHANG Qin, CUI Jian-zhong. Macro-distribution of solute elements in 7075 aluminum alloy ingots produced by CREM process[J]. Acta Metallurgica Sinica, 2003, 39(12): 1264-1268.

[11]张勤, 崔建忠, 路贵民, 等. 电磁振荡法半连铸7075合金的微观组织及溶质元素分布[J]. 中国有色金属学报, 2003, 13(5): 1184-1191.

ZHANG Qin, CUI Jian-zhong, LU Gui-min, et al. Microstructure and solute distribution of 7075 alloy produced by semi continuous casting under electromagnetic vibration[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1184-1191.

[12]ZHANG Bei-jiang, CUI Jian-zhong, LU Gui-min. Effect of electromagnetic field on macrosegregation of continuous casting 7075 aluminum alloy [J]. Transa Nonferrous Met Soc China, 2002, 12(4): 545-548.

[13]张北江, 崔建忠, 路贵民, 等. 外加电磁场对半连续铸造7075铝合金宏观偏析规律的影响[J]. 东北大学学报, 2002, 23(10): 63-65.

ZHANG Bei-jiang, CUI Jian-zhong, LU Gui-min, et al. Effect of electromagnetic field on macrosegregations of continou casting 7075 aluminum alloy[J]. Journal of Northeastern University, 2002, 23(10): 63-65.

[14]Park J K, Ardell A J. Microstructures of the commercial 7075 Al alloy in the T651 and T7 tempers[J]. Metall Trans A, 1983, 14A: 1957-1965.

[15]Polmear I J. Light Alloys[M]. New York: Edward Arnold, 1989. 24-25.

(编辑陈爱华)

基金项目: 国家重点基础研究发展规划资助项目(G199906490501)

收稿日期: 2004-07-20; 修订日期: 2005-01-06

作者简介: 颜 莹(1966-), 女, 副教授, 博士.

通讯作者: 颜 莹, 副教授; 电话: 024-83688088; E-mail:yy-neu01@163.com