Microstructure and properties of WE93 alloy

HE Lan-qiang1, LI Yong-jun1, LI Xing-gang1, MA Ming-long1,

ZHANG Kui1, WANG Xian-wen2, YAN Jian-ming2, LIN Hai-tao 2

1. State Key Laboratory of Nonferrous Metals and Processes,

Beijing General Research Institute for Nonferrous Metals, Beijing 100088, China;

2. Southwest Aluminum (Group) Co., Ltd, Chongqing 401326, China

Received 23 September 2010; accepted 25 December 2010

Abstract: The microstructure of WE93 alloy in different states and the mechanical properties at room temperature were investigated, and the creep behavior of the extruded and aged alloy at 200 °C and at stress of 100, 125 and 150 MPa was also discussed. The result shows that the microstructure of as-cast WE93 alloy consists of α-Mg, Mg12(MM) and Mg24Y5 with an average grain size of 45 μm. After being homogenized at 535 °C for 18 h, the Mg24Y5 phase is dissolved completely and there is only Mg12(MM) phase left around the grain boundaries. The grains do not grow up as prolonging the homogenization time. The extruded alloy has better mechanical properties than the as-cast alloy, especially the elongation increases to 12.5%. The extruded and aged alloy exhibits the highest yield strength and ultimate tensile strength of 315 and 385 MPa, respectively, however, the elongation decreases to 6.5%. The extruded and aged alloy exhibits good creep resistance at 200 °C and at stress of 100-150 MPa. The creep stress exponent n is 2.97, suggesting that grain boundary sliding plays a dominant role at the corresponding temperature and applied stresses.

Key words: rare-earth magnesium alloy; mish-metal; microstructure; temperature; stress; creep

1 Introduction

There has been a sharply growing interest in the development of magnesium alloys for the automotive, aerospace and 3C industries, especially the rare earth magnesium alloys[1-3]. It is crucial to improve the strength properties or the creep resistance of magnesium at elevated temperatures. Adding rare earth elements into magnesium alloys can efficiently reduce casting defects and change parameters so as to improve the oxidation resistance and heat resistance[4-8]. Many researchers investigated the high-temperature properties of Al-RE (AE), Y-RE (WE) cast alloys and so on, but the creep properties of extruded alloys containing mish-metal (Ce rich) have not been well studied. WE43 alloy now can be used stably under 250 °C for its mature research[9]. As the most important component of permanent magnet material, the consumption of Nd is speeding up, leading to the resource scarcity. In this study, Mg-Y-Zr alloy with the addition of mish-metal was prepared through hot-extrusion aiming to obtain high mechanical performance at room temperature and good creep resistance at high temperature. It also can reduce the cost of rare earth magnesium alloy, which has positive effect on balancing the use of domestic rare earth resource. This work investigated the microstructure of the WE93 alloy in different states and the mechanical properties at room temperature, and the creep behavior of the extruded and aged alloy was also investigated.

2 Experimental

2.1 Alloy preparation

The experimental alloy was melted in an intermediate frequency electromagnetic induction furnace, covered and protected by refining agent. Pure magnesium was melted in the crucible and added with pure yttrium and mish-metal (Ce rich) at 750 °C and Mg-30Zr master alloy at 850 °C. Mechanical stirring was applied during the melting process to ensure the alloying elements distribute uniformly. The samples were held for 15 min after they were melted completely in the crucible, then cast at 720 °C. The size of the ingots was d100 mm×400 mm. The outer epidermis and two ends were removed, then take samples from locations of R/2 of the ingot section as experimental materials. The composition of the WE93 is shown in Table 1.

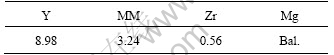

Table 1 Chemical composition of WE93 alloy (mass fraction, %)

2.2 Heat treatment and extrusion

The ingots were homogenized at 535 °C for 18 h and cooled in air. The ingots after homogenization were directly extruded at 420 °C at an extrusion speed of 2 mm/min and an extrusion ratio of 21. After extrusion, some of the specimens were isothermally aged according to the optimized parameters at 225 °C for 10 h in air.

2.3 Mechanical properties test

The microstructures of the as-cast, homogenized and extruded WE93 alloys were investigated by optical microscopy. The hardness was tested by Brinell hardness tester under a load of 30 kN. The room temperature tensile properties were tested along the tensile axis parallel to the extrusion direction at a stretching speed of 1 mm/min. Tensile creep tests under constant stress were conducted on the extruded-plus-aged materials along the stress axis parallel to the extrusion direction. Samples were tested in air at 200 °C and at stress of 100, 125 and 150 MPa, respectively.

3 Results and discussion

3.1 Microstructure

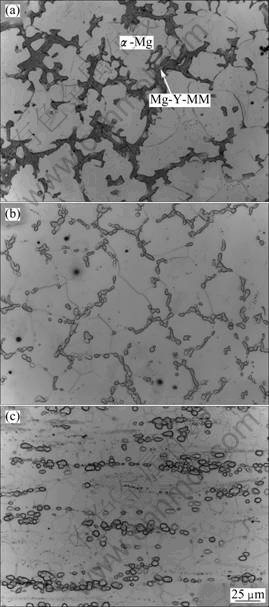

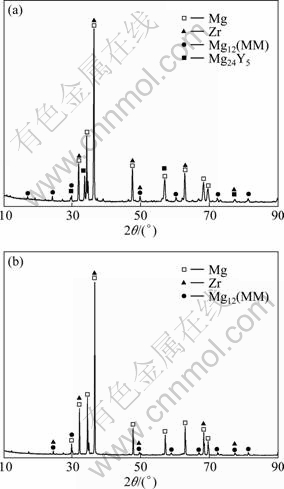

The microstructure of the as-cast Mg-9.0Y-3.0MM- 0.6Zr alloy is shown in Fig.1(a). There were three phases in the as-cast alloy: α-Mg, black bulk Mg24Y5 and stripy Mg12(MM) phase. The average grain size was about 45 μm. The eutectic around the grain boundaries was composed of the two latter phases. The structures of the homogenized WE93 alloy were more homogeneous, part of the eutectic phases were solutionized into the Mg matrix, and the black bulk Mg24Y5 phase disappeared, as shown in Fig.1(b). Fig.2(b) shows the XRD pattern of the homogenized WE93 alloy. No Mg24Y5 phase was found, which is consistent with the microstructures of the as-cast and homogenized alloys. After homogenization, Mg24Y5 phase was dissolved completely, and yttrium was solutionized into the Mg matrix, obtaining a good homogenization effect. The main second phase in the homogenized structure was Mg12(MM) around the grain boundaries and the grains did not grow significantly because Mg12(MM) phase has a good stability at high temperature[10-11], which can effectively inhibit the grain growth and enhance the high temperature performance of the alloy, as shown in Fig.1(b).

Fig.1 Microstructures of WE93 alloy in different states: (a) As-cast; (b) Homogenized at 535 °C for 18 h; (c) Extruded

The microstructure of the extruded Mg-9.0Y- 3.0MM-0.6Zr alloy is shown in Fig.1(c), which consist of fine equiaxed grains with a mean grain size of approximately 20 μm, suggesting that the dynamic recrystallization took place during the extrusion process at 420 °C. However, the grain size was not homogeneous and grains with different size distributed parallelly to the extrusion direction.

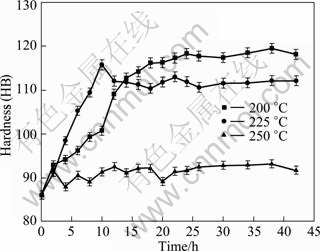

Figure 3 shows the hardness of the extruded WE93 alloy after aging treatment as a function of time at various aging temperatures. The hardness of the extruded alloy increased significantly after aging at 200 and 225 °C for different time. However, dynamic precipitates did not generate completely during aging process at 200 °C, while over aging phenomenon appeared at 250 °C and the hardness did not change obviously. The hardness of the alloy increased rapidly during aging at 225 °C in the first 10 h, presenting typical peak aging characteristics.

Fig.2 XRD patterns of WE93 alloy: (a) As-cast; (b) Homogenized at 535 °C for 18 h

Fig.3 Hardness of extruded WE93 alloy as function of time at various aging temperatures

3.2 Tensile properties

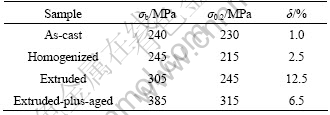

The tensile mechanical properties at room temperature are shown in Table 2 for the as-cast, homogenized, extruded and extruded-plus-aged WE93 alloys.

Table 2 Tensile properties of WE93 alloy in different states

The mechanical properties did not significantly change after homogenization at 535 °C for 18 h, compared with the as-cast alloy. The extruded alloy shows higher tensile properties than the homogenized alloy. This is due to the grain refinement caused by dynamic recrystallization during the extrusion process, which can be explained by Hall-Petch formula[12]. After aging treatment, σ0.2 and σb significantly increased because of the dynamic precipitation. However, the elongation of the alloy after age treatment decreased to 6.5%. The extruded WE93 alloy after aging treatment showed the highest σb of 385 MPa.

3.3 Creep resistant properties

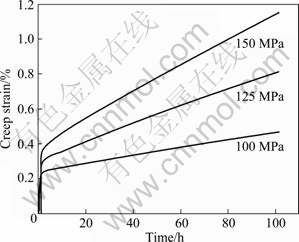

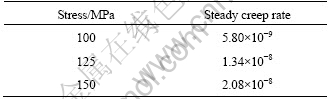

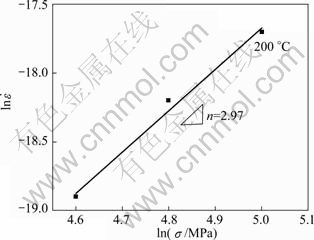

The creep curves of the extruded-plus-aged WE93 alloy at 200 °C and different stress are shown in Fig.4. The steady creep rates corresponding to the creep curves are presented in Table 3.  increased with increasing stress. The alloy exhibited good creep resistance at 200 °C and at stresses from 100 to 150 MPa. The creep deformation mainly took place in the steady creep stage and the creep curves did not show a third stage at 100 h at a small strain of 1.16% under 150 MPa, which suggested that the experimental alloy can be used stably at 200 °C under stress from 100 to 150 MPa. The relationship between the minimum creep rates and the applied stresses is plotted in a double logarithmic plot[13-14], as shown in Fig.5. The slope of the curve can be described as the creep stress exponent n, which is constant and equal to 2.97 at 200 °C.

increased with increasing stress. The alloy exhibited good creep resistance at 200 °C and at stresses from 100 to 150 MPa. The creep deformation mainly took place in the steady creep stage and the creep curves did not show a third stage at 100 h at a small strain of 1.16% under 150 MPa, which suggested that the experimental alloy can be used stably at 200 °C under stress from 100 to 150 MPa. The relationship between the minimum creep rates and the applied stresses is plotted in a double logarithmic plot[13-14], as shown in Fig.5. The slope of the curve can be described as the creep stress exponent n, which is constant and equal to 2.97 at 200 °C.

The value of the creep stress exponent n suggests that grain boundary sliding plays a dominant role when the alloy is crept at stress ranging from 100 to 150 MPa at 200 °C[15].

Fig.4 Creep curves of extruded-plus-aged Mg-9.0Y-3.0MM- 0.6Zr alloy at 200 °C and different stress

Table 3 Minimum creep rate of extruded-plus-aged WE93 alloy at 200 °C

Fig.5 Strain rate—stress curve of extruded-plus-aged WE93 alloy at 200 °C

4 Conclusions

1) The as-cast WE93 alloy consists of α-Mg, Mg12(MM) and Mg24Y5 with an average grain size of 45 μm. After homogenized at 535 °C for 18 h, the Mg24Y5 phase dissolved completely and there was only Mg12(MM) phase left around the grain boundaries. The grains did not grow up as prolonging the homogenization time.

2) The extruded alloy has better mechanical properties than the as-cast alloy, especially when the elongation increases to 12.5%. The extruded-plus-aged alloy exhibits the highest yield strength and ultimate tensile strength of 315 and 385 MPa, respectively, but the elongation decreases to 7.5%.

3) The extruded-plus-aged alloy exhibits good creep resistance at 200 °C and at stress of 100-150 MPa. The creep stress exponent n is 2.97, suggesting that grain boundary sliding plays a dominant role at the corresponding temperature and applied stresses.

References

[1] LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Theory of basis and application of magnesium matrix light alloy [M]. Beijing: China Machine Press, 2002: 16-35. (in Chinese)

[2] LIU Chu-ming, QIU Cong-zhang, CHANG Ya-zhe, LI Hui-zhong, WANG Meng-jun, WANG RONGF. Mechanical properties and damping capacity of cast Mg-Zr-Er-Zn alloy [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1602-1606. (in Chinese)

[3] ALVES H, KOSTER U, AGHION E. Environmental behavior of magnesium and magnesium alloys [J]. Materials Technology, 2001, 16(2): 110-126.

[4] JAIN Chao-chi, KOO Chun-hao. Creep and corrosion properties of the extruded magnesium alloy containing rare earth [J]. Materials Transactions, 2007, 48(2): 265-272.

[5] SHEPELVA L, BAMBERGER M. Microstructure of high pressure die cast AZ91D modified with Ca and Ce [J]. Materials Science and Engineering A, 2006, 15(6): 312-318.

[6] BRADAI D, KDAI-HNAIFI M. The kinetics of the discontinuous precipitation and dissolution in Mg-rich Al alloys [J]. Journal of Materials Science, 1999, 34(1): 5331-5336.

[7] ZHANG Kui, LI Xing-gang, LI Yong-jun, MA Ming-long. Effect of Gd content on microstructure and mechanical properties of Mg-Y-RE-Zr alloys [J]. Transactions of Nonferrous Metal Society of China, 2008, 18(s1): s12-s16.

[8] MORDIKE B L. Magnesium properties applications potential [J]. Mater Sci Eng A, 2001, 302: 37-45.

[9] DING Wen-jiang. Magnesium alloy science and technology [M]. Beijing: Science Press, 2007: 127. (in Chinese)

[10] GU Wen-quan, GUO Guang-ping, ZHANG Ming-jun, YU Yun-feng, XUE Tao. Effect of MM on microstructure and mechanical properties of ZM5 alloy [J]. Special Casting and Nonferrous Alloys, 2008, 28(8): 643-645. (in Chinese)

[11] POWELL R B. Creep-resistant magnesium alloys for powertrains [J]. Advanced Materials, 2001, 6: 46-47.

[12] LIU Zhi-en. Material science [M]. Xi’an: Northwestern Polytechnical University Press, 2003. 226-227.

[13] SHA Gui-ying, XU Yong-bo, HAN En-hon. Microstructure and creep behavior of a cast Mg-RE alloy [J]. Chinese Journal of Materials Research, 2003, 17(6): 603-606. (in Chinese)

[14] WEI Xiao-wei, SHEN Bao-luo, YI Yong. Compressive creep behaviors of as-cast ZA27 alloy [J]. The Chinese Journal of Nonferrous Metals. 2003, 13(5): 1171-1174. (in Chinese)

[15] CHEN Zhen-hua. Heat resisting magnesium alloy [M]. Beijing: Chemical Industry Press, 2007: 185-189. (in Chinese)

WE93合金的组织与性能

何兰强1, 李永军1, 李兴刚1, 马鸣龙1, 张 奎1, 王献文2, 鄢建明2, 林海涛2

1. 北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088;

2. 西南铝业(集团)有限责任公司,重庆 401326

摘 要:研究不同状态WE93合金的组织与室温力学性能,以及时效态合金在温度200 °C,应力100、125和150 MPa条件下的蠕变性能。 结果表明:WE93合金铸态组织由α-Mg、Mg12(MM) 及 Mg24Y5相组成,其平均晶粒尺寸为45 μm。铸态合金经535 °C保温18 h均匀化处理后,Mg24Y5 相基本完全分解,晶界周围仅残留MM相,晶粒尺寸随着保温时间的延长未见明显长大。挤压态合金较铸态合金具有更好的力学性能,尤其是其延伸率达到12.5%。经过时效处理的挤压态合金的屈服强度及断裂强度最高,分别为 315和385 MPa,但延伸率降至6.5%。经时效处理后的挤压态合金在200 °C,应力100-150 MPa条件下具有较好的抗蠕变性能,应力指数为2.97,说明在相应的温度及应力条件下晶界滑移为该合金的主要蠕变机制。

关键词:稀土镁合金;混合稀土;组织;温度;应力;蠕变

(Edited by FANG Jing-hua)

Foundation item: Projects (2007CB613704, 2007CB613705) supported by the National Basic Research Program of China

Corresponding author: ZHANG Kui; Tel: +86-10-82241168; E-mail: zhkui@grinm.com

DOI: 10.1016/S1003-6326(11)60782-6