Article ID: 1003-6326(2005)02-0468-05

Microstructure of explosively compacted

Nd-Fe-B magnet by TEM

AO Qi(敖 琪), LIU Wei(刘 薇),

CAO Li-jun(曹力军), WU Jian-sheng(吴建生)

(Key Laboratory for High Temperature Materials and Tests, Ministry of Education, Shanghai Jiaotong University, Shanghai 200030, China )

Abstract: The microstructure of an explosively compacted Nd-Fe-B permanent magnet(Nd-Fe-B) was investigated by means of TEM and XRD. It is shown that there are three kinds of phases: Nd2Fe14B matrix phase, O-rich phases and Nd-rich phase with different structures and compositions in the magnet. The hard magnetic phase Nd2Fe14B is tetragonal, which lattice parameters are determined to be a=0.88nm and c=1.22nm. The O-rich phase locates at the grain boundaries and the triple junctions has fcc structure whose lattice parameter is a=0.559nm. A dislocation is observed in this phase. It is also found that a large number of the block-shaped Nd-rich phases with hcp structure are embedded in the Nd2Fe14B matrix or at grain boundary. Their lattice parameters are determined to be a=0.395nm and c=0.628nm.

Key words: explosively compacted Nd-Fe-B; microstructure; boundary phase CLC number: TM273

Document code: A

1 INTRODUCTION

Permanent magnets based on the Nd-Fe-B system are typically prepared by melt spinning of a molten alloy[1-3], subsequent hot pressing[4] and powder metallurgy techniques followed by thermal treatments[5, 6]. Besides, explosive compacting process is one of the effective methods of the produce magnets for special applications[7]. Explosively compacted magnet has excellent properties such as rapid consolidation, simple technics, isotopic magnetic[7, 8]. It is well known that the hard magnetic properties of the magnets depend strongly on their microstructures, including the distribution, the composition, and the magnetic properties of the minority phases presented within the magnets[1-6, 9-15]. There have been several investigations aimed at explaining the structures features and magnetic properties observed in explosively compacted magnets[7, 15]. However, further clarification of the microstructures and compositions of the phases present is needed. Thus, the aim of this paper is to investigate some of the aspects by X-ray diffractometry and the transmission electron microscopy(TEM).

2 EXPERIMENTAL

The explosively compacted magnets were prepared by standard processing techniques, as described in Ref.[15]. The Nd-Fe-B magnet studied in this investigation has a nominal composition of Nd-15%, Fe-73% and B-1.1%(mass fraction). TEM thin film samples were prepared mechanically as thin as 50μm, followed by argon ion milling to electron transparency. The samples were examined using HITACH H—800 transmission electron microscope(TEM) at 200kV. The crystalline structure analysis was carried out using the X-ray diffraction system.

3 RESULTS AND DISCUSSION

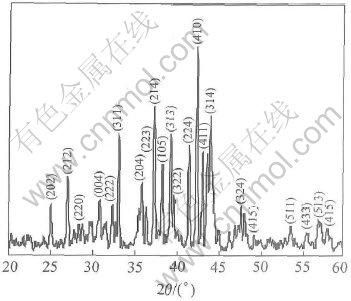

Fig.1 shows the X-ray diffraction pattern obtained from explosively compacted Nd-Fe-B. The peaks observed correspond to Nd2Fe14B phase. This confirms that the material is crystalline and contains predominantly the hard Nd2Fe14B phase. The amount of other possible phases is too little to be identified from the pattern.

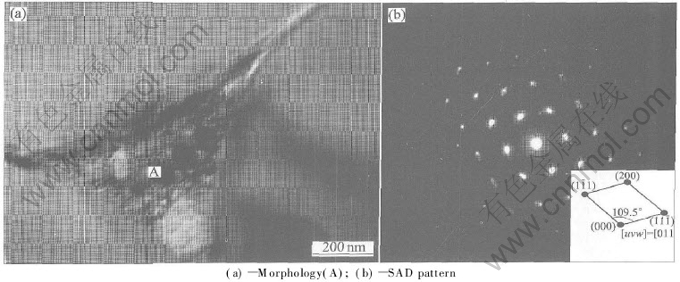

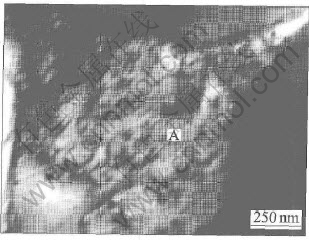

In the explosively compacted Nd-Fe-B permanent magnets, there co-exists three kinds of phases. Figs.2-5 show the microstructures and the selected area diffraction(SAD) patterns of the explosively compacted Nd-Fe-B permanent magnet. The composition analysis corresponding to the large-grains A and B in Fig.2(a) is listed in Table 1. Referring to the X-ray diffraction and the compositions analysis, the large-grains A and B are the matrix phases, the contents of Fe and Nd are about 70% and 25%(mole fraction), respectively. According to the SAD patterns, Nd2Fe14B phase is identified with tetragonal (Tetra.) structure, which can be indexed as [001]Tetra, with a lattice parameter of a=0.88nm and c=1.22nm.

Fig.1 XRD pattern of explosively compacted Nb-Fe-B magnet

Table 1 Composition of explosively compacted Nd-Fe-B magnet

Fig.2 Matrix phase of explosively compacted Nd-Fe-B magnet

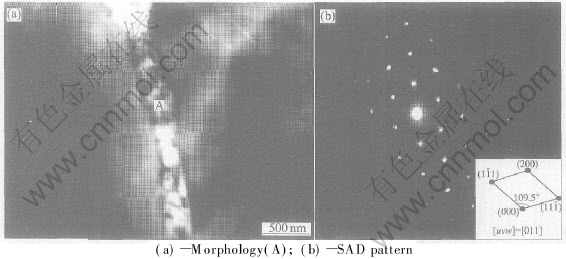

Fig.3 O-rich phase at three-grain junction of explosively compacted Nd-Fe-B

Fig.4 O-rich phase at two-grain boundary of explosively compacted Nd-Fe-B magnet

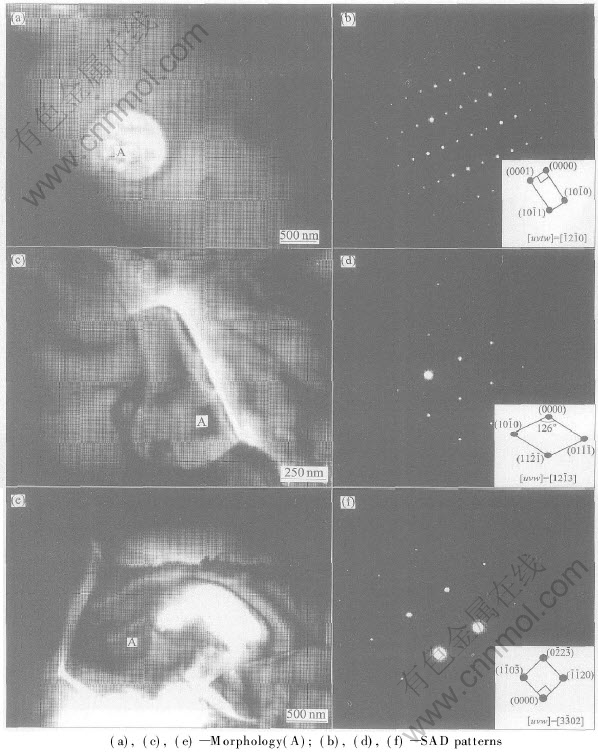

Fig.5 Block-shaped Nd-rich phases of explosively compacted Nd-Fe-B magnet

Table 1 shows the result of the composition analysis of the three-grain junction (A) and two-grain boundary (B) in Figs.3 and 4. Based on the composition analysis, the three-grain junction and two-grain boundary belong to the compound Nd-Fe-O, and contents of O, Nd and Fe are 56%, 22% and 21%(mole fraction), respectively. Since content of O is higher than that of Nd in the three-grain junction and two-grain boundary, it can be called as O-rich phase. Figs.3(b) and 4(b) show the microdiffraction patterns at the three-grain junctions and two-grain boundaries.

Based on the SAD patterns, the O-rich phase was identified to be face-centered cubic (fcc) structure that is indexed as [011]fcc, which is similar to the results of sintered magnet. However, the phase at two-grain boundary of explosively compacted sample is about 30-300nm in width about 10 times larger than the boundary width of sintered sample. The content of O also increases about 10 times higher than that of sintered sample[7]. It is one of the reasons why the coercivity and energy product of explosively compacted magnets are lower than that of sintered magnets.

Fig.5 shows the cases in which different shaped Nd-rich phases exist as an independent grain at the grain boundary or in the matrix grain. According to the composition analysis, the different block-shaped phases belong to the compound Nd-O, and contents of Nd and Fe are about 85% and 12%(mole fraction), respectively. Based on the SAD patterns (see Figs.5 (b), (d) and (f)), the Nd-rich phase is identified as a hexagonal close packed (hcp) structure. It is determined that the lattice parameters of this phase are a=0.395nm and c=0.628nm. Fig.6 shows a few dislocations formed in the Nd-rich phase. The reason is conjectured as that the high pressure resulted from powders collisions at the crashed point on the surface of powder transmits into the inner as the shock wave which causes the mass dislocations.

Fig.6 Dislocation of boundary phase in explosively compacted Nd-Fe-B magnet

Analytical TEM observation shows the Nd-rich phase with different shapes and compositions. It can be easily seen that the fourth element is oxygen which enters the alloy in the process of the explosive compacting. At the beginning of the explosive compaction, the temperature of the powders surface increases sharply, which accelerates the oxidation reaction at the surface of the powders. So the oxide is formed as the block-shaped phase during the subsequent consolidating process between the matrix phases in the explosively compacted Nd-Fe-B alloy.

4 CONCLUSIONS

Matrix of the explosively compacted Nd-Fe-B magnets is predominantly the hard Nd2Fe14B phase with lattice parameters of a=0.88nm and c=1.22nm. The O-rich phase presents at the two-grain boundaries and three-grain junctions, with fcc structures, and lattice parameter is a=0.559nm. A large number of the different block-shaped Nd-rich phases are considered to be Nd-O compounds and distributed in the Nd2Fe14B phases, with hcp structure and lattice parameters of a=0.395nm and c=0.628nm. In the O-rich phase, contents of O, Nd and Fe are 56%, 22% and 21%, respectively. The rich-Nd phase is considered to be Nd-O compound with the contents of 85%Nd and 12%O.

REFERENCES

[1]Croat J, Herbst J F, Lee R W, et al. Pr-Fe and Nd-Fe-based materials: a new class of high-performance permanent magnets(invited) [J]. J Appl Phys, 1984, 55: 2078-2082.

[2]Baker J J. Rapidly quenched metals for permanent magnet materials(invited) [J]. J Appl Phys, 1984, 55: 2067-2072.

[3]LIU Wei, JIANG Jian-hua, WU Jian-sheng, et al. Magnetic force microscope study on anisotropic NdFeB permanent magnets [J]. Trans Nonferrous Met Soc China, 2003, 13: 1410-1414.

[4]Lee R W. Hot-pressed meodymium-iron-boron magnets [J]. Appl Phys Lett, 1985, 46: 790-791.

[5]Sagawa M, Fujimura S, Togawa N, et al. New material for permanent magnets on a base of Nd and Fe(invited) [J]. Appl Phys, 1984, 55: 2083-2087.

[6]Narasimhan K S V L. Iron-based rare-earth magnets(invited) [J]. J Appl Phys, 1985, 57: 4081-4085.

[7]Guruswamy S, McCarter M K, Shield J E. Explosive compaction of magnequench Nd-Fe-B magnetic powders [J]. J Appl Phys, 1996, 79(8): 4851-4853.

[8]Ando S, Mine Y, Takashima K, et al. Explosive compaction of Nd-Fe-B powder [J]. J Mater Proc Tech, 1999, 85:142-147.

[9]Ramesh R, Chen J K, Thomas G. On the grain-boundary phase in iron rare-earth boron magnets [J]. J ApplL Phys, 1987, 61(8): 2993-2998.

[10]TANG Wei-zhong, ZHOU Shou-zeng, WANG Run. An investigation of the Nd-rich phases in the Nd-Fe-B system [J]. J Appl Phys, 1988, 64(10): 5116-5118.

[11]MIshra R K, Chen J K, Thomas G. Effect of annealing on the microstructure of sintered Nd-Fe-B magnets [J]. J Appl Phys, 1986, 59(6): 2244-2246.

[12]Hiraga K, Hirabyashi M, Sagawa M, et al. A study of microstructure of grain boundaries in sintered Fe77Nd15B8 permanent magnet by high-resolution electron microscopy [J]. J Appl Phys, 1985, 24(6): 699-703.

[13]Makita K, Yamashita O. Phase boundary structure in Nd-Fe-B sintered magnets [J]. Appl Phys Lett, 1999, 74(14): 2056-2058.

[14]Liu W, Zhang Z D. Structure and magnetic properties of N-containing Nd-Fe-B alloys prepared by mechanical alloying [J]. J Appl Phys, 2000, 87: 5332-5334.

[15]LIU Wei, CAO Li-jun, WU Jian-sheng, et al. Characterization of melt-spun NdFeB magnets prepared by explosive compaction [J]. Mater Trans, 2003, 44(10): 2094-2098 .

Foundation item: Project(50071035) supported by the National Natural Science Foundation of China; Project(02ZE14054) supported by the Natural Science Foundation of Shanghai, China

Received date: 2004-11-22; Accepted date: 2005-01-18

Correspondence: AO Qi, PhD; Tel: +86-21-62932440; Fax: +86-21-629322440; E-mail: aq2002sjtu.edu.cn

(Edited by LI Xiang-qun)