Numerical simulation of iron/TiC ceramic tappet brazed with TiZrNiCu filler metal

来源期刊:中国有色金属学报(英文版)2003年第6期

论文作者:张丽霞 冯吉才 李卓然

文章页码:1367 - 1370

Key words:numerical simulation; TiC ceramic; iron; brazing

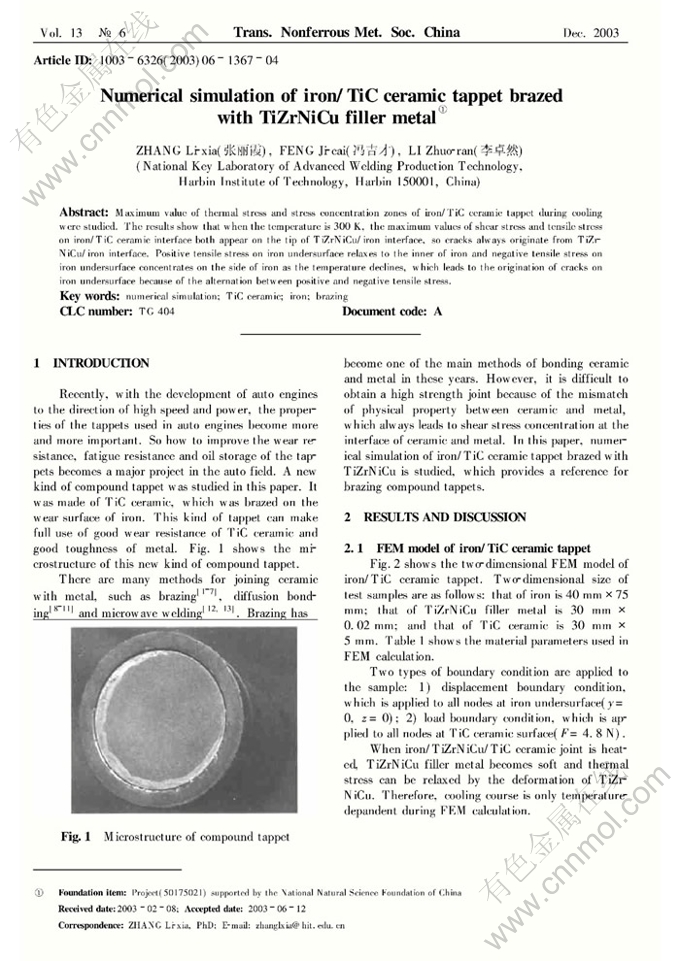

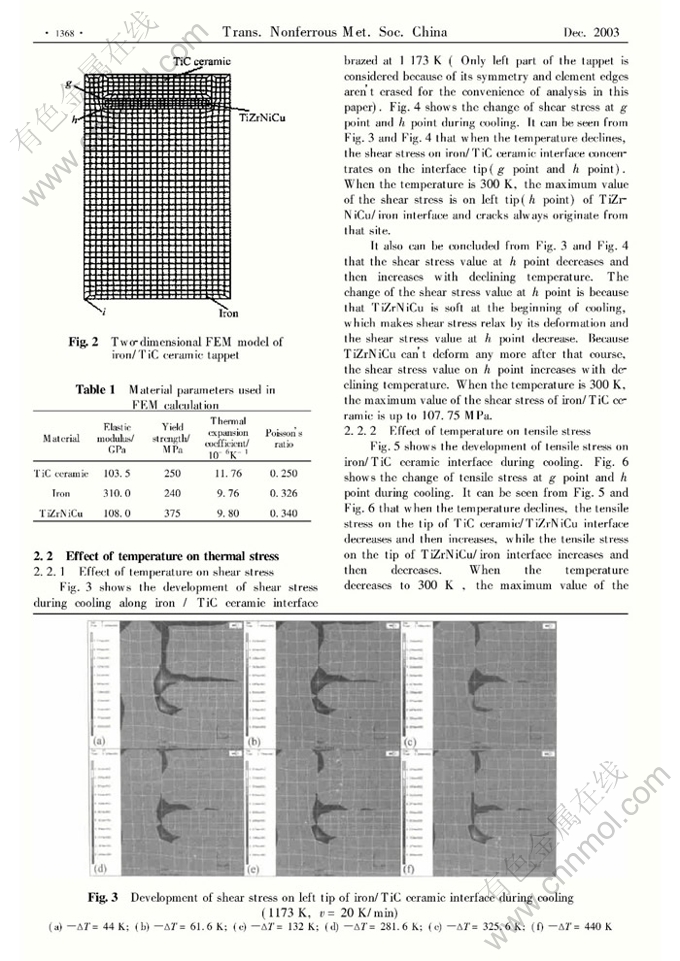

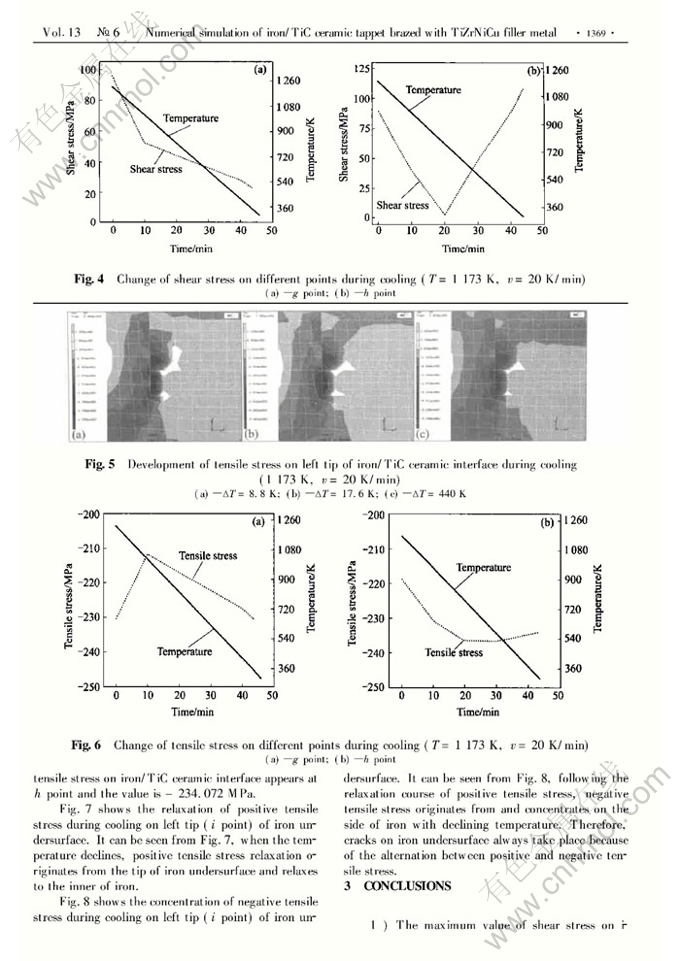

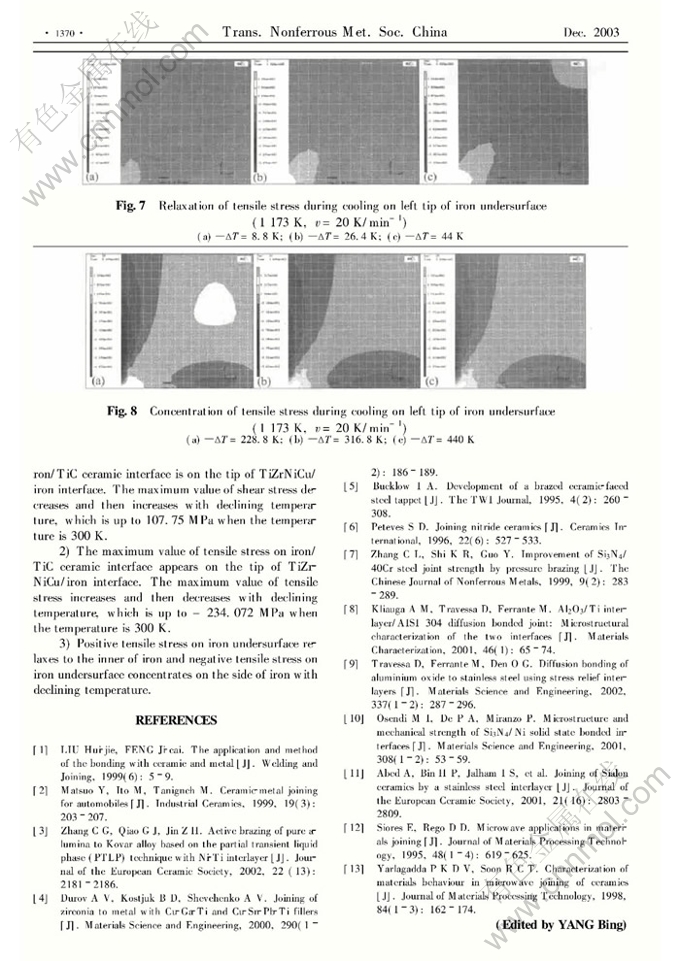

Abstract: Maximum value of thermal stress and stress concentration zones of iron/TiC ceramic tappet during cooling were studied. The results show that when the temperature is 300K, the maximum values of shear stress and tensile stress on iron/TiC ceramic interface both appear on the tip of TiZrNiCu/iron interface, so cracks always originate from TiZrNiCu/iron interface. Positive tensile stress on iron undersurface relaxes to the inner of iron and negative tensile stress on iron undersurface concentrates on the side of iron as the temperature declines, which leads to the origination of cracks on iron undersurface because of the alternation between positive and negative tensile stress.