DOI:10.19476/j.ysxb.1004.0609.2018.08.12

等离子体辅助球磨对Al+C4H4N4合成超细AlN的影响机制

杨卓立1,廖海峰1, 2,孙 迪1, 2,戴乐阳1, 2,刘志杰3,王文春3

(1. 集美大学 轮机工程学院 福建省船舶与海洋工程重点实验室,厦门 361021;

2. 船舶检测与再制造福建省高校工程研究中心,厦门 361021;

3. 大连理工大学 材料改性教育部重点实验室,大连 116024)

摘 要:对铝(Al)和二氨基马来腈(C4H4N4)的混合物分别进行等离子体辅助球磨和普通球磨,研究等离子体辅助球磨活化对合成AlN的作用机制。结果表明:相对于普通球磨,等离子体辅助球磨更有利于Al粉的晶粒细化和晶格畸变,并有利于形成Al-C4H4N4纳米级的复合结构。辅助球磨中的等离子体促进C4H4N4的脱胺,使C4H4N4分解出更多的游离含N基团,加速与活化的Al合成AlN,辅助球磨14 h后AlN的转化率达到91%,远高于普通球磨合成AlN的产率83%。等离子体辅助球磨8 h的Al+C4H4N4前驱体发生氮化反应的激活能为353.46 kJ/mol,在Ar中于800 ℃保温1 h可以通过固-固反应机制全部转化为超细AlN,而普通球磨8 h的前驱体反应激活能高达441.21 kJ/mol,Al需熔化后才能进行氮化反应,导致部分C4H4N4先行受热分解蒸发,AlN产率仅为86%。辅助球磨促进AlN合成的主要原因是等离子体放电的高频脉冲轰击和瞬态“电火花”对粉体产生协同球磨作用。

关键词: 二氨基马来腈;AlN;等离子辅助球磨;固-固反应;活化

文章编号:1004-0609(2018)-08-1587-10 中图分类号:TG174 文献标志码:A

氮化铝(AlN)陶瓷具有高绝缘性、高热导率、耐高温、与硅相近的热膨胀系数及宽的禁带间隙等优良特性,可以作为大规模集成电路和大功率电子器件的理想散热基片和封装材料[1-2]。近年来研究还发现[3],纳米AlN粉末作为润滑油添加剂表现出良好的减摩抗磨能力。如何低成本、便捷制备高品质的超细AlN倍受人们关注。

工业上制备AlN粉末主要采用碳热还原法和直接氮化法[4-7],它们以气态含氮物质作为氮源(主要是N2或NH3),通过固-气反应模式合成AlN。但是固-气反应需要复杂的供气设备,并且粉体表面优先生成的AlN会阻碍气体向粉体内部扩散,导致其反应温度高(1600~1800 ℃)及合成时间长。虽然利用高能球磨活化粉体,在热力学上能够有效降低合成AlN的反应温度,但对改善固-气反应的动力学效果并不显著[8-9]。

与气态氮源相比,同等体积的固态氮源含氮量更多,采用固态含氮有机物作为氮源,通过固-固反应模式合成AlN[10]可望克服固-气反应的不足。而利用高能球磨的机械冲击和剪切作用可以激活粉体甚至诱发相变,这对降低AlN的合成温度以及在动力学方面促进合成AlN的固-固反应极为有利[11-13]。ZHANG等[12]以三聚氰胺(C3H6N6)为固态氮源和Al粉一起球磨,14 h后Al与C3H6N6才开始反应并快速生成AlN,该合成体系为瞬时强放热反应,容易诱发C3H6N6发生爆炸,存在较大的安全隐患。ROUNAGHI等[13]选择含氮量较高的廉价有机化合物二氨基马来腈(C4H4N4)与Al粉球磨,球磨7 h后开始出现AlN相,12 h后Al基本转变为AlN,因为C4H4N4分子结构上没有C3H6N6对称稳定的均三嗪环结构,其化学键更容易被破坏并与Al反应合成AlN,所以Al和C4H4N4之间表现为渐进性反应。但他们研究都发现[12-13],由于普通球磨对Al粉的细化和活化程度有限,球磨直接合成AlN的产率以及球磨前驱体后续退火合成AlN的产率都受到显著影响。

相比于单一机械能的普通球磨,介质阻挡放电等离子体辅助高能球磨具有更强的粉体细化和活化能力,对降低反应温度和促进反应完成非常有利,在新材料制备中显示出极大的优势[14]。作者研究发现,等离子体辅助球磨40 h的Al2O3在N2气中进行1400 ℃保温4 h 可以全部转变成AlN[15],而对Al2O3+C混合粉末只需等离子体辅助球磨30 h即可在同等条件下全部转化为AlN[16]。虽然C的润滑性能降低了球磨对混合粉体的机械作用,但等离子体辅助球磨仍可短时高效激活粉体,并使Al2O3与C之间形成均匀的精细复合结构,等离子体辅助球磨混合粉末反而在动力学上大大有利于Al2O3-C之间的扩散和碳热还原反应,促使后续氮化反应完成。

本文作者以Al+C4H4N4混合粉末为对象,通过对等离子体辅助球磨的特性进行观察诊断,然后对比等离子体辅助球磨与普通球磨过程中Al+C4H4N4混合粉末的相结构和官能团的变化,结合混合粉末的微观特征,研究以C4H4N4为固态氮源在球磨中合成AlN的机理;通过对不同方式球磨的Al+C4H4N4进行差热分析和反应激活能计算,分析Al+C4H4N4球磨前驱物受热合成AlN的动力学行为,并阐释等离子体辅助球磨对合成AlN的促进机制。

1 实验

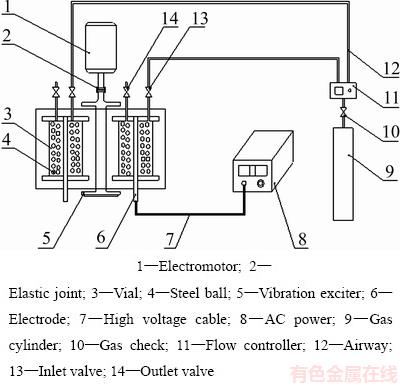

实验用Al粉为天津光复精细化工研究所出品,纯度>99.9%,C4H4N4为麦卡希试剂公司出品,纯度>98%。球磨在自制的等离子体辅助振动球磨装置[17]上进行,其结构如图1所示。所用球磨罐及磨球均为不锈钢材质,球磨机的振动频率为16 Hz,振幅为10 mm双振幅,球料质量比为60:1。等离子体辅助球磨 (Plasma assisted ball milling,简称辅助球磨,PM)时,等离子体电源放电参数为:放电电压37 kV,频率14 kHz。为了与普通球磨工艺对比,在其他球磨参数相同的情况下,关闭等离子体放电电源,进行没有等离子体辅助的普通球磨(Conventional ball milling,CM)。在手套箱中将Al粉与C4H4N4按摩尔比4:1混合装入球磨罐,手套箱中为0.1 MPa的高纯Ar,保证等离子体辅助球磨的放电气体为0.1 MPa的高纯Ar。为了减少高能球磨引入的铁污染,在试验前用普通球磨工艺预先球磨Al粉末10 h,使得球磨罐内壁和磨球上包覆一层Al。

图1 等离子体辅助球磨装置结构示意图

Fig. 1 Schematic illustration of PM

在手套箱中对球磨时间为4 h、8 h、10 h、12 h和14 h的粉末进行取样。采用Bruker D8衍射仪(XRD,Cu Kα)分析球磨中及热处理后粉末的物相构成,并利用Voigt方法计算球磨不同时间后Al的晶粒尺寸和晶格畸变,利用RIR参考强度对比法半定量计算AlN的转化率。采用Bruker Vertex 70傅里叶红外光谱(FT-IR)分析球磨不同时间后C4H4N4的官能团。采用Supra 55 Sapphire ZEISS场发射扫描电镜(SEM)对粉末进行形貌观察和元素分布表征。采用Mettler DSC 822/TGA/ SDTA851差热分析仪(DSC-TG)对球磨8 h的Al+ C4H4N4混合粉末进行差热-热重测试,测试时Ar气流量为100 mL/min,升温速率分别为10、15和20 K/min。采用Eltra ONH-2000 氧氮氢分析仪测试氮含量。

2 结果与讨论

2.1 等离子体辅助球磨诊断

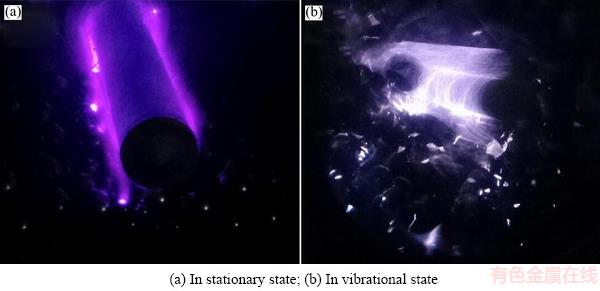

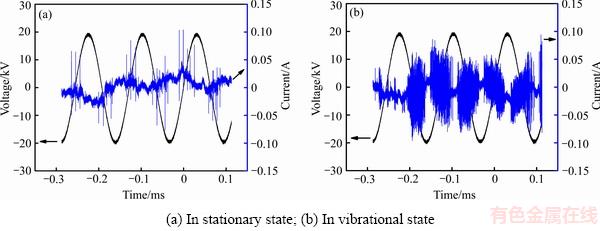

图1中的电极棒外面包覆一层绝缘介质,当外加的交流电电压足够高时,电极棒和钢球之间的气体被击穿,以流光放电机制形成介质阻挡放电等离子体[18]。对球磨罐内的等离子体放电情形进行观察,结果如图2所示。从图2(a)可见,当球磨机在静止状态时,钢球挨着的电极棒周围呈现明亮的紫红色辉光,但钢球之间并无放电;当球磨机处于运行状态后,电极棒周围转为耀眼的亮白辉光,钢球之间产生频繁的闪光,就像瞬态的“电火花”,如图2(b)所示。对两种状态的等离子体进行电学诊断,其电流和电压波形如图3所示。从图3(a)可见,当球磨机处于静止状态时,在电压的半个周期内,球磨罐内有许多无规则的丝状放电,其微放电通道的寿命为20~40 ns,且放电时强时弱并不十分均匀。这是因为介质阻挡交流放电由许多细微的快脉冲放电通道组成[19],在静止状态时只有在电极棒附近的钢球有放电现象产生,而其他距离较远的钢球放电效应极其微弱甚至没有。从图3(b)可见,当球磨机开始振动到运行状态后,球磨罐内的丝状放电频率变得非常密集,平均强度大大增加,微放电通道的寿命为50~60 ns。这是由于球磨机运转时,钢球围绕整个电极棒运动,钢球与电极棒的接触几率增多,放电通道迅速增加,钢球的相互碰撞也使得放电范围扩大到整个球磨罐内,因此电极棒周围的等离子体达到更强的准辉光放电状态[20],可以对粉体进行更均匀的处理。

图2 球磨罐中的等离子体放电情形

Fig. 2 Discharge images of plasma in milling vials

图3 球磨罐内等离子体放电的电压和电流波形图

Fig. 3 Waveforms of applied voltage and discharge current of plasma in milling vials

2.2 球磨过程中的物相演变

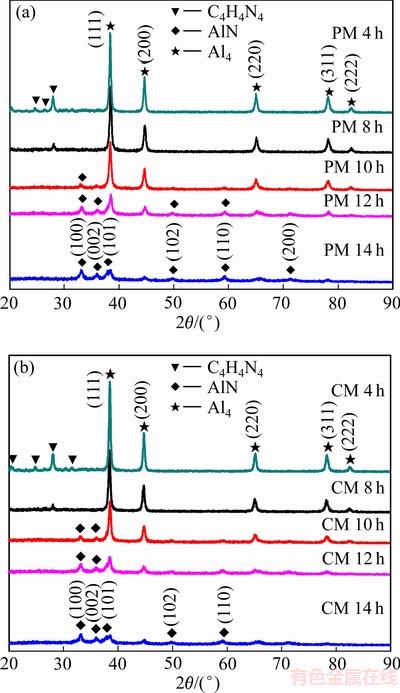

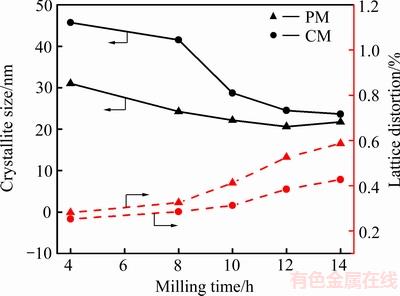

图4所示为辅助球磨和普通球磨不同时间后Al+C4H4N4混合物的XRD谱。从图4可见,随着球磨时间的增加,Al和C4H4N4的衍射峰均发生宽化和矮化。由于实验中都是在同等条件下完成,可以认为实验条件导致的衍射峰宽化相同,因此图4中各个衍射峰的宽化主要由晶粒细化,以及颗粒的微观畸变导致的结构缺陷和晶格应力造成。利用Voigt方法计算辅助球磨和普通球磨不同时间后Al的晶粒尺寸和晶格畸变,结果如图5所示。从图5可见,随着球磨时间的延长,两种球磨方式中Al的晶粒尺寸呈减小趋势、晶格畸变呈增大趋势,但辅助球磨中Al的晶粒细化和晶格畸变程度都明显更大。这是由于Al粉具有良好的塑性,普通球磨单一的机械力对Al粉的晶粒畸变和细化作用有限;在辅助球磨过程中,等离子体稳定而均匀的高频放电和瞬态“电火花”对粉体产生脉冲作用(见图1和图2),会大大增强Al粉的微区应力,进而增加晶格畸变并促进晶粒细化。辅助球磨8h后,Al粉的晶格畸变显著增加,大大增强了Al粉的反应活性。

图4 球磨不同时间后Al+C4H4N4粉末的XRD谱

Fig. 4 XRD patterns of Al+C4H4N4 powder milled for different times by PM(a) and CM(b)

图5 辅助球磨和普通球磨不同时间后Al相的晶粒尺寸和晶格畸变

Fig. 5 Crystallite size and lattice distortion of Al phase milled for different times by PM and CM

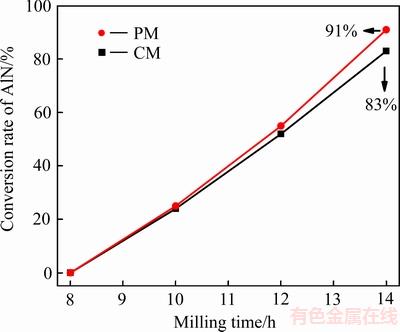

从图4还可见,辅助球磨8 h的混合粉末中开始有微弱的AlN衍射峰,而普通球磨中没有检测到新相的衍射峰;球磨到10 h时,两种球磨方式中都开始出现少量的AlN衍射峰,且随着球磨继续,AlN的衍射峰逐渐增多并明显增强;当球磨到14 h后,Al和C4H4N4的衍射峰均已基本消失,主要为AlN衍射峰。利用RIR参考强度比法对球磨中AlN的产率进行半定量计算,结果如图6所示。可见,随着球磨时间的延长,特别在球磨10 h之后,辅助球磨合成AlN的产率逐渐高于普通球磨,辅助球磨14 h的AlN产率为91%,而普通球磨14 h的产率只有83%。这是因为随着球磨的继续,普通球磨中Al粉的晶粒细化和晶粒长大容易达到动态平衡,粉体的激活程度有限;而辅助球磨时,Al粉体的细化进一步增加了粉末接受等离子体辐照的比表面积,使得等离子体的协同球磨效应在不断增强,当球磨一定时间后,Al粉的晶粒细化和晶格畸变程度开始远大于普通球磨Al粉的,粉末积蓄的反应活性也得以大大增强,辅助球磨合成AlN的产率明显增加。

图6 辅助球磨和普通球磨不同时间后Al+C4H4N4粉末的AlN转化率

Fig. 6 Conversion rate of AlN from Al+C4H4N4 powder milled for different times by PM and CM

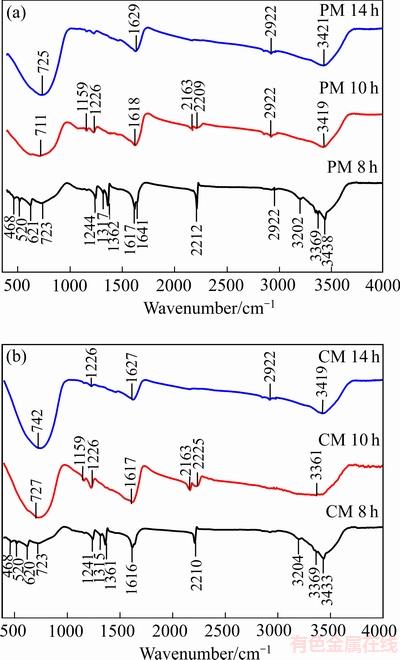

2.3 球磨过程中Al+C4H4N4混合粉末的红外光谱

图7所示为Al+C4H4N4混合粉末经过两种方式球磨8 h、10 h、14 h后的红外光谱。参照不同官能团峰值的特征频率[21-22],可见两种球磨中C4H4N4首先发生了脱胺,这是因为在C4H4N4分子中—NH2(胺基)的键能最弱(约为276 kJ/mol[13])。脱胺后的C4H4N4处于不稳定的活性状态,随球磨时间增长,N—H键(3200~3500 cm-1、1165~1300 cm-1与-750 cm-1)以及C=C键(1630~1690 cm-1与1610~1640 cm-1)的特征峰数目逐渐减少,且峰的形状由弱而尖锐转变为强而平缓。这是由于随着球磨的进行,C4H4N4发生缩聚,使几种不同振动形式的N—H基团缩聚成伯胺-伸缩振动(3200~3500 cm-1),而C=C基团缩聚成共轭-伸缩振动(1610~1640 cm-1)。从图7还可见,C≡N键(2100~2250 cm-1)和C—N键(1200~1365 cm-1)的特征峰强度也逐渐减弱,球磨到14 h时基本消失。这说明随着球磨的进行,C≡N和C—N等键发生断裂,整个球磨罐内充满≡N、—N=、N2等游离的不稳定含氮基团。同图4中的XRD结果相对应,随球磨时间的延长,红外光谱在723 cm-1位置出现Al≡N基伸缩振动的特征峰并逐渐增强,这说明球磨腔内游离的含氮基团与高活性的Al粒子发生反应生成AlN,并且随着球磨时间的增加,体系内合成AlN的转化率逐渐升高。

图7 不同球磨时间后Al+C4H4N4混合物的红外光谱

Fig. 7 FT-IR spectra of Al+C4H4N4 mixtures milled for different times by PM(a) and CM(b)

仔细比较图7(a)和(b)发现,球磨10 h时,辅助球磨的混合粉体在1200~1365 cm-1波段的C—N键和2100~2250 cm-1波段的C≡N键等基团的特征峰强度变化更为明显,其特征峰变弱甚至消失的速率也更快,且2922 cm-1处更早出现C4H4N4分子缩聚反应生成的C—H特征峰。这说明辅助球磨中,由于等离子体使高分子聚合物更容易发生断键和聚合作用[19, 23],因此C4H4N4中的C—N和C≡N键更容易发生断裂,使辅助球磨体系内处于高能活跃状态的含氮基团比普通球磨更多,从而有利于AlN的合成。另一方面,由于等离子体中的物质微粒具有极高的活性,吸附沉积在粉体表面后引起材料表面高能活化,提高粉体的扩散能力,进一步促进AlN的合成。实际上,辅助球磨8 h混合粉末的红外光谱中,在723 cm-1位置已经出现了微弱的Al≡N基伸缩振动峰。

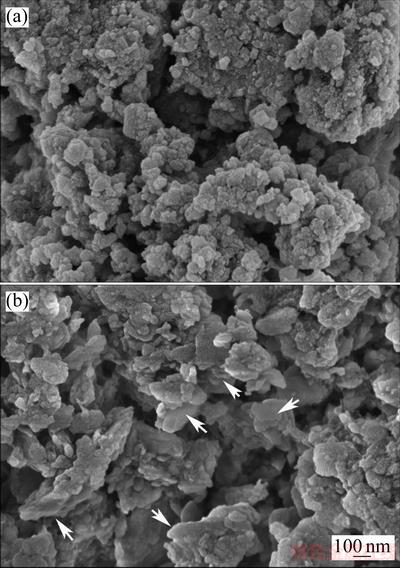

2.4 球磨后Al+C4H4N4粉末的形貌及元素分布

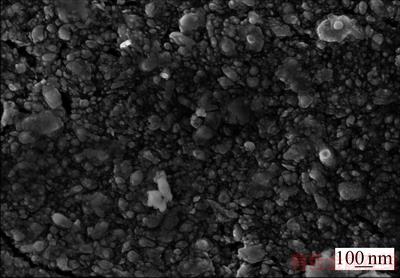

图8所示为两种方式球磨8 h的Al+C4H4N4混合粉末形貌。从图8(a)可见,辅助球磨中的Al粉都被细化为30 nm左右的微粒,并且Al和C4H4N4均匀混合,形成纳米复合团聚体;而普通球磨中的Al粉多数仍在100 nm左右,部分片状形态的Al粉互相冷焊在一起,没有和C4H4N4发生混合,如图8(b)中箭头所示。这是因为面心立方的Al粉质地软且具有优良的延展性,加上Al粉较低的熔点使其在球磨过程中极易发生冷焊成块,因此普通球磨中单一的机械冲击和剪切作用对Al粉的细化及分散作用有限。而辅助球磨时,等离子体的高能粒子脉冲轰击及温度效应使Al粉微区熔化并诱发“热爆”[14],加上钢球间的瞬态“电火花”作用,将大大促进Al粉和C4H4N4的细化和互溶,进而相互形成精细的纳米级复合结构。

图8 球磨8 h后Al+C4H4N4混合粉末的SEM像

Fig. 8 SEM images of Al+C4H4N4 powder milled for 8 h by PM(a) and CM(b)

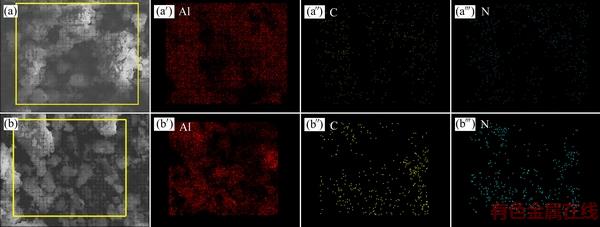

对球磨粉末进行Al、C、N的元素分布进行表征,结果如图9所示,可见同样经过8 h球磨时,辅助球磨中的Al、C、N元素分布更为均匀,尤其C和N元素的分布明显更为细微弥散。这种均匀互溶的纳米级复合结构对后续AlN的合成反应在动力学扩散上极为有利。

图9 球磨8 h后Al+C4H4N4混合粉末的背散射电子像及Al、C、N元素分布图

Fig. 9 Backscattering electron images and element mapping of Al, C and N of Al+C4H4N4 powder milled for 8 h by PM(a) and CM(b)

2.5 球磨后Al+C4H4N4混合粉末的差热分析

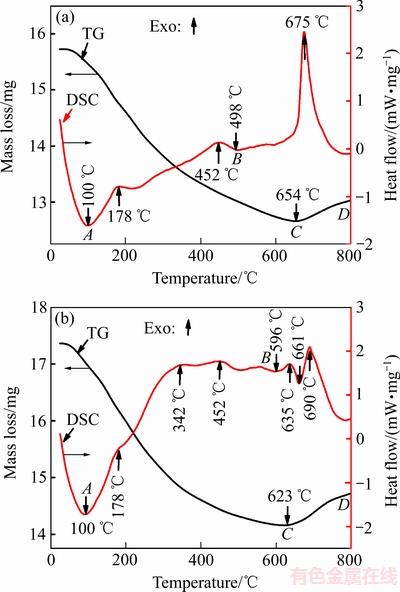

图10所示为两种方式球磨8 h的混合粉末的DSC-TG测试结果,升温速率为10 K/min。由图10(a)中的TG曲线可见,辅助球磨8 h的混合粉末在654 ℃之前一直处于质量损失状态。这首先是混合粉末中携带的少量水分蒸发所致,对应的DSC曲线于100 ℃处有一个吸热峰;随后的质量损失则是C4H4N4热分解所致,即C4H4N4中胺基的缩聚和腈基的缺失导致质量损失,因为有机物的聚合反应通常是放热反应且整个过程呈渐变状态[13],所以DSC曲线自178 ℃开始呈平缓的上升趋势,并在178 ℃和452 ℃出现两个较小的放热峰。从654 ℃至800 ℃,TG曲线显示混合粉末质量呈增加趋势,这是因为活化的Al和C4H4N4分解产生的游离N开始反应合成AlN,在DSC曲线上675 ℃处有一个与之对应的强放热峰。

与辅助球磨相似,普通球磨的混合粉末首先发生水分子的蒸发质量损失,随后到623 ℃一直发生C4H4N4的分解质量损失,在图10(b)中的DSC曲线上同样可以看到,在180、342和452 ℃等多处对应有C4H4N4逐级分解反应的放热峰。从178 ℃至623 ℃,粉末的质量损失率为14.1%,高于辅助球磨粉末的质量损失率12.4%。这是由于普通球磨中的Al粉自身冷焊团聚,与有机物C4H4N4的复合程度不如辅助球磨(见图8和图9),因此在加热过程中更多的C4H4N4容易分解蒸发。从623 ℃至800 ℃,普通球磨粉末同样由于生成AlN使得TG曲线呈质量增加趋势,但DSC曲线在635 ℃和690 ℃对应有一小一大两个放热峰,且在中间660 ℃有一个显著的吸热峰。660 ℃是Al的熔点,该吸热峰的存在说明普通球磨粉末在635 ℃时只有少部分Al的活性足以和C4H4N4分解的游离N发生反应,因此635 ℃是一个弱放热峰,对应TG曲线质量增加缓慢;绝大部分Al由于活性不够,只能在660 ℃熔化之后才能发生AlN的合成反应[24],由于合成AlN释放的热量大于Al熔化吸收的热量,因此在690 ℃处是一个强放热峰且对应显著的质量增加。

图10 球磨8 h后Al+C4H4N4混合物的DSC-TG曲线

Fig. 10 DSC-TG curves of mixture of Al+C4H4N4 milled for 8 h by PM(a) and CM(b)

2.6 球磨后Al+C4H4N4混合粉末的热动力学分析

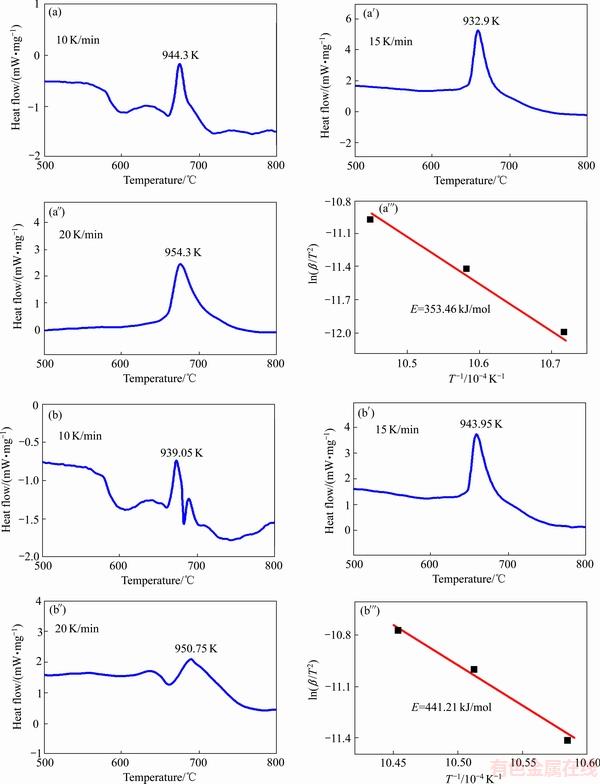

图11 利用Kissinger法计算球磨8 h的Al+ C4H4N4反应激活能

Fig. 11 Reaction activation energy calculated by Kissinger method of Al+C4H4N4 milled for 8 h by PM(a) and CM(b)

图11所示为不同升温速率下,两种方式球磨8 h的混合粉末的DSC测试结果,以及根据Kissinger法得到的ln (β/T2)-1/T的关系曲线,其中图11(a)中辅助球磨粉末对应的峰值温度T为(944.3 K、932.9 K、 954.3 K),图11(b)中普通球磨粉末对应的峰值温度T为(939.09 K、943.9 K、950.65 K),β为加热速率 (10 K/min、15 K/min、20 K/min),摩尔气体常数R取值为8.3145 J/(K·mol)。对ln (β/T2)-1/T的关系进行拟合得到一条直线,该直线的斜率即为反应的激活能。经计算,辅助球磨8 h后Al+C4H4N4合成AlN的反应激活能为353.46 kJ/mol,而普通球磨后粉末的反应激活能为441.21 kJ/mol,可见辅助球磨在热力学上也更大程度地降低了Al+C4H4N4合成AlN所需的反应激活能。

2.7 球磨后Al+C4H4N4混合粉末的热处理

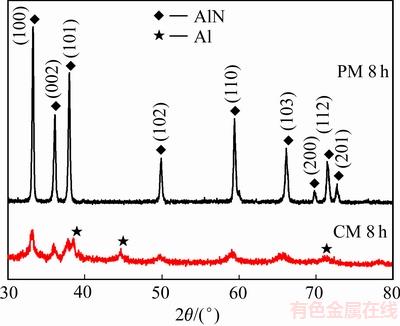

对两种方式球磨8 h的混合粉末在Ar中800 ℃保温1 h,其产物的XRD谱如图12所示。可见辅助球磨8 h的Al+C4H4N4混合粉末热处理后全部转变为AlN,而普通球磨的混合粉末还有Al相的残余,利用RIR参考强度比法进行半定量计算,AlN的产率只有86%。图13所示为辅助球磨8 h的Al+C4H4N4在800 ℃合成AlN的SEM像,可见合成的AlN粉末呈不规则粒状,多数颗粒的粒径在30 nm左右,部分颗粒达到100 nm。氮含量分析显示AlN的氮含量为33.58%,这表明辅助球磨8 h的Al+C4H4N4热处理后得到的AlN纯度达到98.34%。

综上分析可见,辅助球磨中等离子体放电的高频脉冲轰击和瞬态“电火花”对混合粉末产生协同球磨作用,既增大了Al粉的晶粒细化和晶格畸变程度,又有利于固态氮源C4H4N4的缩聚反应提供丰富的游离含氮基团,从而快速激活反应粉体,同时辅助球磨的Al+C4H4N4前驱体能够获得均匀互溶的纳米级复合结构,因此在热力学和动力学上均有利于后续热处理完成AlN的合成反应。而普通球磨8 h的前驱体中Al粉活性不足,需要熔化后才能与C4H4N4反应,并且部分Al微粒冷焊成块,与C4H4N4之间的互溶程度不好,使得一部分C4H4N4受热先行分解蒸发,影响了AlN的产率。

图12 球磨8 h的Al+C4H4N4在800 ℃热处理产物的XRD谱

Fig. 12 XRD patterns of production from PM and CM Al+C4H4N4 for 8 h after annealing at 800 ℃

图13 辅助球磨8 h的Al+C4H4N4在800 ℃合成AlN的SEM像

Fig. 13 SEM image of AlN gained from PM Al+C4H4N4 powder for 8 h after annealing at 800 ℃

3 结论

1) 对Al+C4H4N4混合物进行球磨,固态氮源C4H4N4发生脱胺和缩聚反应,产生大量的≡N、—N=、N2等游离含氮基团与活化的Al粉进行固-固反应生成AlN,但辅助球磨14 h时AlN的产率为91%,远高于普通球磨的83%。

2) 辅助球磨中等离子体放电的高频脉冲轰击和瞬态“电火花”对Al+C4H4N4产生协同球磨作用,增大了Al粉的晶粒细化和晶格畸变程度,同时又有利于C4H4N4的缩聚反应提供丰富的游离含氮基团,从而高效激活反应粉体并促进AlN合成。

3) 辅助球磨8 h的Al+C4H4N4前驱体经800 ℃热处理后全部转变为AlN,其纯度为98.34%,而普通球磨8 h粉末的AlN转变率只有87%,计算表明辅助球磨8 h的前驱体发生氮化反应的激活能为353.46 kJ/mol,远远低于普通球磨8 h粉末的激活能441.21 kJ/mol。

4) 辅助球磨的Al+C4H4N4前驱体激活程度高并形成了均匀互溶的纳米级复合结构,这对后续热处理合成AlN极为有利,而普通球磨的Al粉需要熔化后才能与C4H4N4反应,使得部分C4H4N4受热先行分解蒸发,影响了AlN的产率。

REFERENCES

[1] WANG X L, GONG H Y, ZHANG Y J, FENG Y R, Zhang L, ZHAO Y J. Effect of AlN content on properties of hot-press sintered Sialon ceramics[J]. Ceramics International, 2015, 41(3): 4308-4311.

[2] CAO C W, FENG Y B, QIU T, YANG J, LI X Y, LIANG T, LI J. Effects of isothermal annealing on the oxidation behavior, mechanical and thermal properties of AlN ceramics[J]. Ceramics International, 2017, 43(12): 9334-9342.

[3] TAO Y, TAO Y X, WANG B B, TAI Y L. Preparation and investigation of nano-AlN lubricant with high performance[J]. Materials Chemistry and Physics, 2014, 147(1/2): 28-34.

[4] PATHAK L C, RAY A K, DAS S, SIVARAMAKRISHNAN C S, RAMACHANDRARAO P. Carbothermal synthesis of nanocrystalline aluminum nitride powders[J]. Journal of the American Ceramic Society, 1999, 82(1): 257-260.

[5] HE Q, QIN M L, HUANG M, CHU A M, LU H F, CHEN P Q, WANG H, QU X H. Mechanism and kinetics of combustion-carbothermal synthesis of AlN nanopowders[J]. Ceramics International, 2017, 43(12): 8755-8762.

[6] KAMESHIMA Y, IRIE M, YASUMORI A, OKADA K. Mechanochemical effect on low temperature synthesis of AlN by direct nitridation method[J]. Solid State Ionics, 2004, 172(1): 185-190.

[7] JIA L, KONDOH K, IMAI H, ONISHI M, CHEN B, LI S F. Nano-scale AlN powders and AlN/Al composites by full and partial direct nitridation of aluminum in solid-state[J]. Journal of Alloys and Compounds, 2015, 629: 184-187.

[8] 刘新宽, 马明亮, 席生歧, 周敬恩, 王渠东, 丁文江. 氧化铝碳热还原反应机制及其热力学[J]. 中国有色金属学报, 2000, 10(S1): s46-s49.

LIU Xin-kuan, MA Ming-liang, XI Sheng-qi, ZHOU Jing-en, WANG Qu-dong, DING Wen-jiang. Mechanism and thermodynamics of carbothermal reduction of alumina[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(S1): s46-s49.

[9] CABALLERO E S, CINTAS J, CUEVAS F G, MONTES J M, TERNERO F, REINA F J V. Synthesis and characterization of in situ-reinforced Al–AlN composites produced by mechanical alloying[J]. Journal of Alloys and Compounds, 2017, 728: 640-644.

[10] DU Y X, LEI M, YANG H. Facile solid-state synthesis route to metal nitride nanoparticles[J]. Journal of Materials Science & Technology, 2008, 24(5): 737-741.

[11] 李鹏亮, 周敬恩, 席生歧. 高能球磨制备立方AlN及其高温相变[J]. 无机材料学报, 2006, 21(4): 821-827.

LI Peng-liang, ZHOU Jing-en, XI Sheng-qi. Cubic AlN synthesized by high energy ball milling and its phase conversion at high temperature[J]. Journal of Inorganic Materials, 2006, 21(4): 821-827.

[12] ZHANG W L, LI Z Q, ZHANG D. Synthesizing AlN powder by mechanochemical reaction between aluminum and melamine[J]. Journal of Materials Research, 2010, 25(3): 464-470.

[13] ROUNAGHI S A, ESHGHI H, KIANI RASHID A R, VAHDATI KHAKI J, SAMADI KHOSHKHOO M, SCUDINO S, ECKERT J. Synthesis of nanostructured AlN by solid state reaction of Al and diaminomaleonitrile[J]. Journal of Solid State Chemistry, 2013, 198: 542-547.

[14] 朱 敏, 鲁忠臣, 胡仁宗, 欧阳柳章. 介质阻挡放电等离子体辅助球磨及其在材料制备中的应用[J]. 金属学报, 2016, 52(10): 1239-1248.

ZHU Min, LU Zhong-chen, HU Ren-zong, OUYANG Liu-zhang. Dielectric barrier discharge plasma assisted ball milling technology and its applications in materials fabrication[J]. Acta Metallurgica Sinica, 2016, 52(10): 1239-1248.

[15] 戴乐阳, 张宝剑, 林少芬, 刘志杰, 王文春. 等离子体辅助球磨活化Al2O3合成AlN[J]. 中国有色金属学报, 2015, 25(1): 171-178.

DAI Le-yang, ZHANG Bao-jian, LIN Shao-fen, LIU Zhi-jie, WANG Wen-chun. Synthesis of AlN from Al2O3 activated by plasma assisted ball milling[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 171-178.

[16] 戴乐阳, 郭学平, 闫 锦, 张宝剑, 刘志杰, 王文春. 等离子体辅助球磨活化对Al2O3+C合成AlN固-固反应的影响机制[J]. 功能材料, 2016, 47(3): 03109-03114.

DAI Le-yang, GUO Xue-ping, YAN Jin, ZHANG Bao-jian, LIU Zhi-jie, WANG Wen-chun. Mechanism for the effect on synthesis of AlN from Al2O3+C activated by plasma assisted ball milling during solid-state reaction[J]. Journal of Functional Materials, 2016, 47(3): 03109-03114.

[17] 朱 敏, 戴乐阳, 曹 彪, 曾美琴, 欧阳柳章, 童燕青, 李 北. 一种等离子体辅助高能球磨方法: 中国发明专利ZL200510036231.9[P]. 授权日期: 2007-08-29.

ZHU Min, DAI Le-yang, CAO Biao, ZENG Mei-qin, OUYANG Liu-zhang, TONG Yan-qing, LI Bei. A method of high-energy ball milling assisted by plasma: Chinese patent ZL200510036231.9[P]. 2007-08-29.

[18] 徐学基, 楮定昌. 气体放电物理[M]. 上海: 复旦大学出版社, 1996.

XU Xue-ji, CHU Ding-chang. Gas discharge physics[M]. Shanghai: Fudan University Press, 1996.

[19] VENAULT A, WEI T C, SHIH H L, YEH C C, CHINNATHAMBI A, ALHARBI S A, CARRETIER S, AIMAR P, LAI J Y, CHANG Y. Antifouling pseudo-zwitterionic poly (vinylidene fluoride) membranes with efficient mixed-charge surface grafting via glow dielectric barrier discharge plasma-induced copolymerization[J]. Journal of Membrane Science, 2016, 516: 13-25.

[20] LIU Z J, YANG D Z, WANG W C, DAI L Y, SHAIBO J. Effect of different precursors on synthesized AlN by plasma-assisted ball milling[J]. Materials and Manufacturing Processes, 2016, 31(12): 1583-1588.

[21] GFIFFITH P R, HASETH J A D. Fourier transform infrared spectrometry[M]. 2nd ed. New York: John Wiley & Sons, 2007.

[22] FINCH A. Chemical application of far infrared spectroscopy[M]. New York: Academic Press, 1970.

[23] MOREIRA P W P, RANGEL A L R, CONEJO L S, BATISTA N L, DEUS R C, NISHIME T M C, KODAIRA F V P, CAMPOS K A, SIQUEIRA M B, KOSTOV K G, MOTA R P. Acetylene plasma polymer treated by atmospheric dielectric barrier discharge[J]. Vacuum, 2014, 107(3): 195-198.

[24] COTTON F A, WILKINSON G, MURILLO C A, BOCHMANN M. Advanced inorganic chemistry[M]. 6th ed. New York: Wiley, 2000.

Effect mechanism of plasma assisted ball milling on synthesis of ultrafine AlN from Al+C4H4N4

YANG Zhuo-li1, LIAO Hai-feng1, 2, SUN Di1, 2, DAI Le-yang1, 2, LIU Zhi-jie3, WANG Wen-chun3

(1. Fujian Provincial Key Laboratory of Naval Architecture and Ocean Engineering, Institute of Marine Engineering, Jimei University, Xiamen 361021, China;

2. Fujian Engineering Research Center of Ship Detecting and Remanufacturing, Xiamen 361021, China;

3. Key Lab of Materials Modification, Ministry of Education, Dalian University of Technology, Dalian 116024, China)

Abstract: The synthesis mechanism of AlN from diaminomaleonitrile (C4H4N4) and aluminum (Al) by using plasma assisted ball milling (PM) was investigated, in which the conventional ball milling (CM) was also used under the same conditions for comparison. The results indicate that PM is much more favorable for the grain refinement and lattice distortion of Al, as compared with that of CM, which promotes the synthesis of nanocomposite structure between Al and C4H4N4. During the process, the plasma formed in PM can promote the deammoniation of C4H4N4 to decompose much more free N-containing groups than that of the CM, which accelerates to react with the activated Al powders. After 14 h milling, the conversion rate of AlN by using PM method is up to 91%, which is much higher than the value of 83% in CM process. Furthermore, a lower nitriding reaction activation energy (353.46 kJ/mol) was obtained in the Al+C4H4N4 precursors by 8 h-PM process, which could achieve a full conversion temperature is about 800 ℃, but for the 8 h-CM process, a higher nitriding reaction activation energy (441.21 kJ/mol) needs a higher nitriding temperature in the Al+C4H4N4 precursors, leading to the melting of Al phase and evaporation of part of C4H4N4, and obviously reducing the conversion rate to 86%. The main synthesis mechanisms of AlN through the plasma assisted ball milling is a synergistic effect between high frequency pulse bombardment and transient “spark” on the powders by plasma discharge.

Key words: diaminomaleonitrile; AlN; plasma assisted ball milling; solid-solid reaction; activation

Foundation item: Projects(51177008,51779103) supported by the National Natural Science Foundation of China; Project(2018H0026) supported by the Science and Technology Plan of Fujian Province, China; Project(2016) supported by the Science and Technology (Culture) Plan for Military of Fujian Province, China; Project(3502Z20173031) supported by the Science and Technology Plan of Xiamen, China

Received date: 2017-10-09; Accepted date: 2018-03-20

Corresponding author: DAI Le-yang; Tel: +86-13850065983; E-mail: daileyang@jmu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51177008,51779103);福建省科技计划项目(2018H0026):福建省科技(文化)拥军项目(2016);厦门市科技计划项目(3502Z20173031)

收稿日期:2017-10-09;修订日期:2018-03-20

通信作者:戴乐阳,教授,博士;电话:13850065983;E-mail: daileyang@jmu.edu.cn