Characterization of refractory behaviour of complex gold/silver ore by diagnostic leaching

O. CELEP1, ?. ALP1, H. DEVEC?1, M. VICIL2

1. Mining Engineering Department, Karadeniz Technical University, 61080, Trabzon, Turkey;

2. Geology Engineering Department, Karadeniz Technical University, 61080, Trabzon, Turkey

Received 19 September 2008; accepted 11 November 2008

Abstract: The amenability of a refractory ore to the extraction of gold and silver by cyanide leaching was investigated. Diagnostic leaching tests were also performed to shed light on the refractory characteristics of ore. The leaching tests show that the extraction of gold and silver is consistently low, i.e. ≤47% and ≤19.2%, respectively, over a leaching period of 24 h. Even fine grinding (e.g. <38 ?m) does not improve the recovery of gold and silver. Diagnostic leaching approach provides information into the cause of the refractoriness of the ore. The findings suggest that the refractoriness is induced by the dissemination and encapsulation of the very fine gold and silver particles largely in the carbonates, oxides and sulfides and, to a small extent, with silicates present in the ore matrix. These findings highlight the practical importance of diagnostic leaching for the understanding of the refractory characteristic of such an ore and for the identification of possible pretreatment options to overcome its refractoriness prior to cyanide leaching.

Key words: gold and silver ores; refractoriness; characterization; diagnostic leach

1 Introduction

Generally, gold ores can be classified as “free milling” and “refractory” depending on their response to cyanide leaching[1]. While high gold recoveries (>90%) from free milling ores can be readily achieved, and refractory gold ores are often characterized by the low gold extractions (50%-80%) within a conventional cyanide leaching[2-3]. The refractoriness of gold ores can result primarily from the inherent mineralogical features with particular reference to the mode of presence and association of gold, and to the presence of carbonaceous matter[2].

A suitable pretreatment process is often required to overcome the refractoriness and render the gold accessible to the lixiviant action of cyanide and oxygen [4]. Roasting, pressure oxidation, biooxidation, ultrafine grinding and modified cyanidation are the pretreatment methods currently practiced for refractory gold ores and concentrates[5-6]. Ultrafine grinding is a physical method for the liberation of locked gold when efficient size reduction is achieved[7]. However, gold present as solid solution in host minerals such as arsenopyrite can only be effectively recovered if the mineral matrix is decomposed by some chemical or biological pretreatment methods[8]. Roasting, a simple stage process using a fluidized bed roaster at around 650 ℃, is one of the most common methods for the treatment of gold-bearing pyrite/arsenopyrite and pyrrhotite concentrates to produce porous calcine with the increased amenability to cyanidation[9-10]. Pressure oxidation and biooxidation methods have gained importance in recent years mainly due to the environmental problems (e.g. SO2 emissions) associated with roasting process[11-14].

Accurate characterization of an ore is essential to identify the mode and occurrence of gold and gold- bearing minerals and hence, to evaluate the refractory behaviour of gold in the traditional cyanidation process. With this information it is then possible to determine the amenability of an ore to different processing options [15-16]. The various techniques including optical microscopy, scanning electron microscopy(SEM), electron microprobe analysis(EMPA), proton X-ray emission(PIXE), dynamic secondary ion mass spectrometry (D-SIMS) are used for the characterization of gold ores[17-18]. Before the selection of a suitable process, diagnostic leaching has been also proved to be very useful as an analytical tool for establishing the distribution of gold within different mineral phases of an ore.

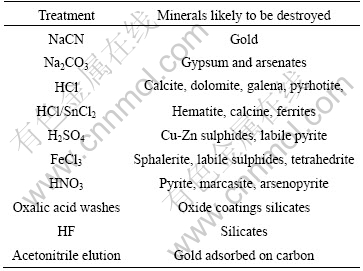

Diagnostic leaching procedure is achieved by selective leaching/destruction of minerals at stages followed by a cyanide leach step to recover gold available/liberated after each stage[19-20]. A set of guidelines for the design of a diagnostic leaching experiment were demonstrated by LORENZEN[21]. The procedure can be tailored to the mineralogical composition of the ore examined (Table 1).

Table 1 Diagnostic leaching procedure by selective destruction of gold ores[18]

LORENZEN and van DEVENTER[20] used diagnostic leaching to identify the refractory nature of gold ores with their findings and indicated that only 1.3% to 2.4% of the gold was leachable with direct cyanidation and approximately 95% of Au in ore was extracted by means of selective destruction of gold-bearing minerals with nitric and sulphuric acids. TEAGUE et al[22] studied diagnostic leaching of a refractory gold ore containing 5.9% pyrrhotite, 0.9% pyrite, 1.3% arsenopyrite and a bulk flotation concentrates. Based on the results of diagnostic leaching tests, CELEP et al[23] concluded that the refractoriness of a refractory gold ore was associated with the dissemination and encapsulation of the very fine gold particles largely within the carbonates, oxides and sulfides and, to a small extent, with silicates present in the ore matrix.

With a two-stage diagnostic approach, a refractory telluride ore is leached in dilute cyanide solutions (0.1% NaCN) at pH 9.5 for 24 h to dissolve native gold but not gold+silver tellurides (Stage 1) and the residue is then subjected to a second stage leaching using a strong cyanide solution (2% NaCN) at pH 12.5 for 96 h to dissolve gold+silver tellurides[24].

In this study, the amenability of a refractory gold/silver ore to cyanide leaching for the recovery of gold and silver was investigated. Diagnostic leaching of the ore was performed to distinguish the gold-bearing phases present and hence, to characterize its refractory behaviour. The mineralogical characteristics of the ore were also examined to aid the evaluation of the leaching behavior of gold and silver from the ore.

2 Materials and methods

2.1 Materials

In this study, high grade Akoluk (Ordu) refractory gold/silver ore was used. A total amount of 150 kg ore sample was obtained from the deposit. Hand-picked pieces of the ore were used to prepare the polished sections for mineralogical examination under an ore microscope (Leitz Wetzlar). The size distribution of gold particles in the polished sections examined was also determined based on particle counts. The sample was crushed down to <4 mm using jaw and roll crushers, and riffled to obtain 2 kg representative sub-samples. These were then ground (80% passing 38 mm) in a laboratory rod mill for diagnostic leaching tests and cyanidation.

The chemical composition of the ore sample (Table 2) and acid leach solutions was determined by wet chemical analysis methods using inductively coupled plasma-atomic emission spectroscopy(ICP-AES) and neutron activation analysis(NAA) after digestion in aqua regia. In Table 2, LOI is an abbreviation for “loss on ignition”. The XRD examination of ore was carried out by using a Rikagu D/max-IIIC X-ray diffractometer.

Table 2 Chemical composition of ore sample

2.2 Methods

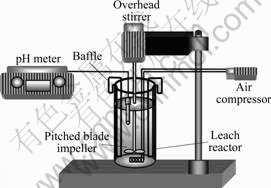

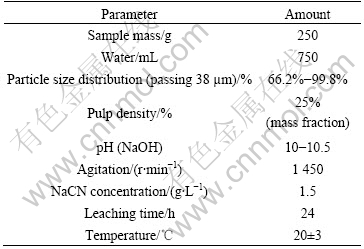

The cyanide leaching tests (24 h) were performed in a glass reactor equipped with a pitched-blade turbine impeller rotating at 1 450 r/min (Fig.1). Table 3 lists the conditions for cyanide leaching tests in which the concentration of cyanide was maintained at 1.5 g/L over the leaching period and the consumption of cyanide was recorded.

Fig.1 Experimental set-up for diagnostic leaching of ore

Table 3 Experimental conditions for cyanide leaching of ore

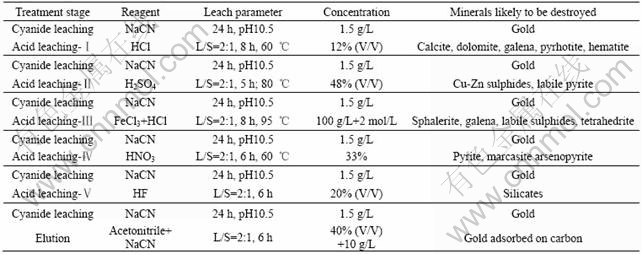

Diagnostic leach tests involved a series of acid leaching stages aimed to destroy specific minerals (Table 4), followed by cyanidation of the residue from each stage. The decomposition of some mineral phases in different leaching stages may be represented by the chemical reactions below[17, 25]:

CaCO3+2HCl→CaCl2+H2O+CO2 (1)

MS+H2SO4→MSO4+H2S (M=Zn, Cu, Pb, etc.) (2)

Cu12Sb4S13+44Fe3+→12Cu2++4Sb5++13S0+44Fe2+ (3)

2FeS2+10HNO3→2Fe3++2H++4SO42-+10NO+4H2O (4)

SiO2+6HF→H2SiF6+2H2O (5)

Table 4 Conditions of diagnostic leaching of ore sample (D80<38 ?m)

Analysis of gold and silver in the samples removed at predetermined intervals was carried out using atomic absorption spectrometry(AAS). Leach residues at the end of each stage were also analyzed for gold and silver to establish a mass balance and to determine the metal recovery. Free CN- concentration was determined by titration with silver nitrate using p-dimethylaminobenza- lrhodanine (0.02%, mass fraction in acetone) as the indicator.

3 Results and discussion

3.1 Mineralogical characteristics of ore

The Akoluk ore deposit is located in the southwest of Ordu, Turkey and in the western part of the Eastern Pontides which consists mainly of volcanic-sedimentary rock units. The gold deposition was indicated to be of an epithermal origin[26-27]. The ore deposit was reported to contain a variety of sulphide and oxide minerals as well as native gold[28]. Total reserves of Akoluk ore are estimated to be about 10 Mt[29]. Gold was claimed to be mostly associated with zinkenite (PbSb2S4) as inclusions [30].

The chemical and mineralogical analysis of the ore sample indicated that the ore consisted of predominantly quartz/clay (52.2% SiO2) and barite (17.1% Ba), and to a less extent, sulphide minerals such as pyrite, antimonite, sphalerite, fahlerz (e.g. tetrahedrite) and zinkenite (Table 2 and Fig.2). The XRD results confirmed the presence of quartz, illite, barite and sulphide minerals (Fig.3).

Fig.2 Presence and association of gold in ore (Au—Gold; Py—Pyrite; Sp—Sphalerite; Qz—Quartz; Cn—Cinnabar; Ant—Antimonite; Fh—Fahlerz): (a) Au particles with cinnabar in quartz matrix; (b) Au with antimonite in quartz; (c) Au within pyrite and fahlerz; (d) Au with sphalerite; (e) Au particles within fahlerz; (f) Gold particle along pyrite fracture

The ore sample was found to contain 15 g/t Au and 220 g/t Ag. Gold was present in native form and associated with sulphide minerals and quartz as particles of 1-88 ?m in size (Figs.3(a)-(d)). The half of the gold particles visible under microscope appeared to be smaller than 3 μm in size (Fig.4). Although the ore appeared to be rich in silver (220 g Ag/t), no silver minerals were identified in the samples examined under the microscope. It could be present as occlusions in potential silver-bearing minerals such as fahlerz, antimonite and zinkenite[30].

Fig.3 XRD pattern of Ordu-Akoluk ore

Fig.4 Size distribution of visible gold particle in polished sections of ore

3.2 Cyanide leaching of ore

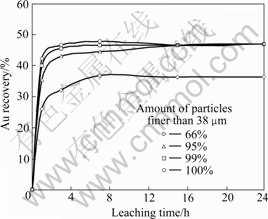

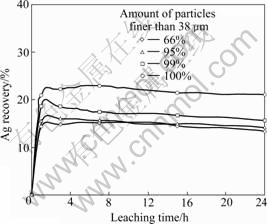

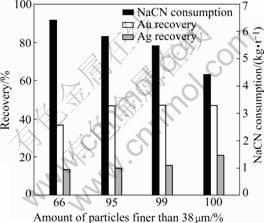

Figs.5-6 show that even fine grinding (e.g. 100% finer than 38 ?m) produces no desired effect on the extractions of gold and silver, which are limited to≤47% and ≤19.2%, respectively. Dissolution of gold and silver is observed to occur largely over an initial period of 1.5-2 h. Following these initial periods, the dissolution process appears to be almost ceased off. The consumption of cyanide is determined to be 4.4-6.4 kg NaCN per ton of the ore with its tendency to decrease as the particle size decreased (Fig.7). These findings indicate the gold and silver contents of the ore available to direct cyanide leaching and confirm highly refractory nature of the ore. It can be also inferred that a suitable pretreatment method should be developed to achieve high gold and silver extractions in the subsequent cyanide leaching stage. However, the determination of the reason(s) for the refractoriness is required for the development and/or application of the most effective pretreatment method.

Fig.5 Effect of particle size on extraction of gold from ore in cyanide solutions (1.5 g/L NaCN) over a period of 24 h

Fig.6 Effect of particle size on extraction of silver from ore in cyanide solutions (1.5 g/L NaCN) over a period of 24 h

Fig.7 Effect of particle size on final extraction of gold and silver, and consumption of cyanide over 24 h leaching period

3.3 Diagnostic leaching tests

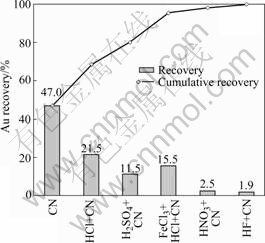

Fig.8 illustrates the results of the diagnostic leaching of the ore, which involves stepwise acid treatment followed by standard cyanide leaching after each stage for gold recovery. Initial cyanide leaching of untreated ore resulted in a gold extraction of 47%, indicating the cyanide recoverable gold consistent with the findings reported above. The remaining portion of the gold appeared to be refractory in character presumably is due to the inaccessibility of gold particles to the action of cyanide. A sequence of acid treatment (HCl, H2SO4, FeCl3+HCl, HNO3, HF) improves the extraction of gold to 100%. Based on the diagnostic leaching data (Table 4) the refractoriness of the ore can be ascribed to fine dissemination and association of gold with carbonates and oxides (about 21%), silicates (about 1.9%) and sulphides (29.5%, i.e., a total gold extraction in H2SO4, FeCl3+HCl, HNO3 treatments). The results of acetonitrile elution stage suggest no preg-robbing activity in the ore.

Fig.8 Extraction of gold following each stage of acid treatments with diagnostic leaching of ore

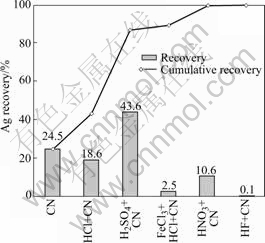

The recoveries of silver in cyanide leaching after each treatment stage of diagnostic leaching are also given in Fig.9. Silver extraction is determined to increase from 24.5% (in direct cyanidation) to complete in a sequence of acid treatments (HCl, H2SO4, FeCl3+HCl, HNO3, HF). The contribution of the treatments performed for the destruction of sulphides to silver extraction is the most significant (i.e., by about 56.5%) whilst only negligible portion silver (about 0.1%) is associated with silicates.

Fig.9 Extraction of silver following each stage of acid treatments in diagnostic leaching of ore

It was reported that a sequential acid leaching treatment using HCl, H2SO4, FeCl3+HCl, HNO3, and HF would destroy a variety of mineral phases[21]. However, it is extremely difficult to quantify the decomposed phases and hence draw firm conclusion from the data due to the non-selective nature of acid treatment expected, i.e., partial removal of some sulfides by HCl and H2SO4 prior to FeCl3+HCl and HNO3 treatments. Further detailed studies are required to distinguish the minerals decomposed following each stage of acid treatment. Notwithstanding this, the extensive dissolution of sulphides is confirmed by the chemical analysis of the residues after HNO3 treatment (Fig.10) and at this stage, the extraction of gold and silver is recorded to be 98% and 99.5%, respectively.

Fig.10 Au and Ag recovery based on some element dissolution after total sulphide matrix destruction

4 Conclusions

1) The reasons for the low gold and silver recoveries from the refractory Akoluk (Ordu) ore were investigated by adopting a diagnostic approach. Mineralogical analysis of the ore indicates the presence of native gold and a variety of sulphide minerals; but, quartz, barite and clay minerals are the most abundant minerals present in the ore.

2) The direct cyanidation tests with low gold and silver recoveries of 47% and 20% even after fine grinding (<38 ?m) reveal the degree of refractoriness of the ore.

3) Diagnostic leaching tests demonstrate that the refractoriness of the ore is caused by fine dissemination and association of gold and silver mainly with sulphide minerals since the decomposition of sulphides increases the extraction of gold and silver by about 29.5% and about 56.7%, respectively.

4) Although diagnostic leaching proves an invaluable tool for the assessment of the ore, further detailed tests may be required to distinguish gold/silver-bearing sulphides so that the most effective pretreatment method can be selected or developed.

Acknowledgements

The authors would like to express their sincere thanks and appreciation to the Research Foundation of Karadeniz Technical University (Project No: 2004.112.008.2) for the financial support, to the General Directorate of Mineral Research and Exploration of Turkey and Gür?elik Mining Trading Ind. Ltd. for kindly providing the ore samples.

References

[1] la BROOY S R, LINGE H G, WALKER G S. Review of gold extraction from ores [J]. Minerals Engineering, 1994, 7(10): 1213-1241.

[2] RUBISOV D H, PAPENGELAKIS V G, KONDOS P D. Fundamental kinetic models for gold ore cyanide leaching [J]. Canadian Metallurgical Quarterly, 1996, 35(4): 353-361.

[3] ADAMS M D. Advances in gold ore processing, developments in mineral processing [M]. Amsterdam: Elsevier, 2005.

[4] UBALDINI S, MASSIDDA R, ABBRUZZESE C. Factorial experiments in the study of a biooxidative pretreatment for a conventional cyanidation of a Turkey arsenical gold ore [C]// Proceedings of the 5th Int Mineral Processing Symposium. Cappadocia: Turkish Mining Development Foundation, 1994: 403- 410.

[5] SINADINOVIC D, KAMBEROVIC Z, VAKANJAC B. Refractory gold ores, characteristics and methods of their procession [C]// Proceedings of 8th Balkan Mineral Processing Conference. Belgrade, Yugoslavia, 1999: 411-418.

[6] IGLESIAS N, CARRANZA F. Refractory gold-bearing ore: A review of treatment methods and recent advances in biotechnological techniques [J]. Hydrometallurgy, 1994, 34: 383-395.

[7] BROWNER R E, LEE K H.. Effect of pyrrhotite reactivity on cyanidation of pyrrhotite produced by pyrolysis of a sulphide ore [J]. Minerals Engineering, 1998, 11(9): 813-820.

[8] LEHMAN M N, OLEARY S, DUNN J G. An evaluation of pretreatments to increase gold recovery from a refractory ore containing arsenopyrite and pyrrhotite [J]. Minerals Engineering, 2000, 13(1): 1-18.

[9] ROSHAN B B. Hydrometallurgical processing of precious metal ores [J]. Mineral Processing and Extractive Metallurgy Review, 1990, 6: 67-80.

[10] DUNN J G, CHAMBERLAIN A C. The recovery of gold from refractory arsenopyrite concentrates by pyrolysis-oxidation [J]. Minerals Engineering, 1997, 10(9): 919-928.

[11] COSTA M C. Hydrometallurgy of gold: New perspectives and treatment of refractory sulphide ores [J]. Fizykochemiczne Problemy Mineralurgü, 1997(63): 63-72.

[12] GUNYANGA F P, MAHLANGU T, ROMAN R J, MUNGOSHI J, MBEVE K. An acidic pressure oxidation pre-treatment of refractory gold concentrates from the Kwekwe Roasting Plant-Zimbabwe [J]. Minerals Engineering, 1999, 12(8): 863-875.

[13] WEI Y, ZHONGS K, ADAMOVT E V, SMITH R W. Semi-continuous biooxidation of the Chongyang Refractory Gold Ore [J]. Minerals Engineering, 1997, 10(6): 517-583.

[14] UBALDINI S, VEGLIO F, TORO L, ABBRUZZESE C. Biooxidation of arsenopyrite to improve gold cyanidation: Study of some parameters and comparison with grinding [J]. Int J Miner Process, 1997, 52: 65-80.

[15] GOODALL W R, SCALES P J, BUTCHER A R. The use of QEMSCAN and diagnostic leaching in the characterization of visible gold in complex ores [J]. Minerals Engineering, 2005, 18: 877-886.

[16] GOODALL W R, SCALES P J, RYAN C G. Applications of PIXE and diagnostic leaching in the characterization of complex gold ores [J]. Minerals Engineering, 2005, 18: 1010-1019.

[17] MARSDEN J O, HOUSE C L. The chemistry of gold extraction [M]. USA, Society for Mining Metallurgy and Exploration, 2006.

[18] PAKTUN? D, KINGSTON D, PRATT A. Distribution of gold in pyrite and in products of its transformation resulting from roasting of refractory gold ore [J]. The Canadian Mineralogist, 2006, 44: 213-227.

[19] LORENZEN L, TUMILTY J A. Diagnostic leaching as an analytical tool for evaluating the effect of reagents on the performance of a gold plant [J]. Minerals Engineering, 1992, 5(3): 503-512.

[20] LORENZEN L, van DEVENTER J S J. The identification of refractoriness in gold ores by the selective destruction of minerals [J]. Minerals Engineering, 1993, 5(3): 1013-1023.

[21] LORENZEN L. Some guidelines to the design of a diagnostic leaching experiment [J]. Minerals Engineering, 1995, 8(3): 247-256.

[22] TEAGUE A J, SWAMINATHAN C, van DEVENTER J S J. The behaviour of gold bearing minerals during froth flotation as determined by diagnostic leaching [J]. Minerals Engineering, 1998, 11(6): 523-533.

[23] CELEP O, ALP ?, DEVEC? H, YILMAZ T. Characterisation of refractory behaviour of Kaleta? (Turkey) gold ore by ultrafine grinding and diagnostic leaching [C]// International Conference of Modern Management of Mine Producing, Geology and Environmental Protection-SGEM. Bulgaria: International Scientific Conference SGEM, 2005: 169-176.

[24] HENLEY K J, CLARKE N C, SAUTER P. Evaluation of a diagnostic leaching technique for gold in native gold and gold+silver tellurides [J]. Minerals Engineering, 2000, 14(1): 1-12.

[25] GUPTA C K, MUKHERJEE T K. Hydrometallurgy in extraction processes [M]. Volume I. Boston: CRC Press, 2000.

[26] CELEP O, ALP ?, DEVEC? H, YILMAZ T. The investigation of gold and silver recovery from Akoluk (Ordu-Turkey) ore [C]// International Conference of Modern Management of Mine Producing, Geology and Environmental Protection-SGEM. Bulgaria: International Scientific Conference SGEM, 2006: 251-258.

[27] T?YS?Z N, AK?AY M. A comparative anatomy of the gold occurences in the eastern black sea region [C]// Earth Sciences and Mining Congress of 75. Republic Anniversary. General Directorate of Mineral Research and Exploration, 2000: 625-645.

[28] YAYLALI G. Geology, geochemistry and hydrothermal alteration of Akoluk (Ulubey-Ordu) epithermal gold mineralization [D]. Trabzon, Turkey: Karadeniz Technical University, 2000: 150 (in Turkish)

[29] MTA, 1993. Gold and Silver Inventory of Turkey, No:198 [K]. Ankara: General Directorate of Mineral Research and Exploration in Turkey. (in Turkish)

[30] ASLANER G, OTTEMANN J. Native gold appearance occurred in Toktam?? zinkenite veins [R]. Ankara: General Directorate of Mineral Research and Exploration, 1971.

Corresponding author: O. CELEP; Tel: +90-462-3774118; Fax: +90-462-3257405; E-mail: ocelep@ktu.edu.tr

DOI: 10.1016/S1003-6326(08)60337-4

(Edited by YANG Hua)