电磁搅拌法连铸半固态铝合金及其凝固组织分析

来源期刊:中国有色金属学报2000年第1期

论文作者:张奎 刘国钧 徐骏 石力开

文章页码:47 - 50

关键词:连续铸造;凝固组织;半固态合金;转变机制

Key words:continuous casting; solidification microstructure; semi-solid alloys; transform mechanism

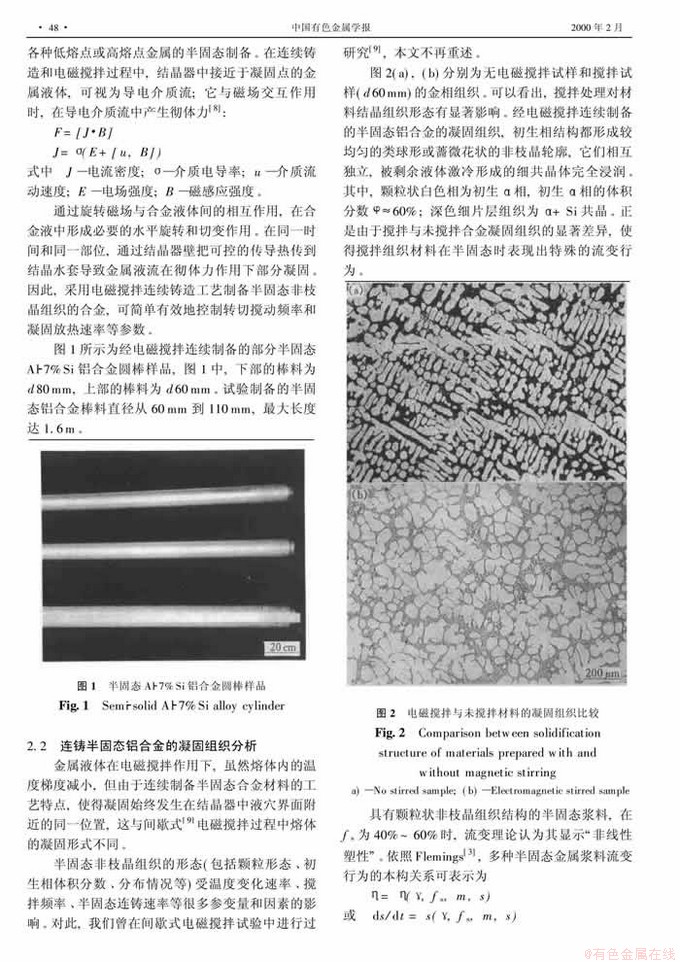

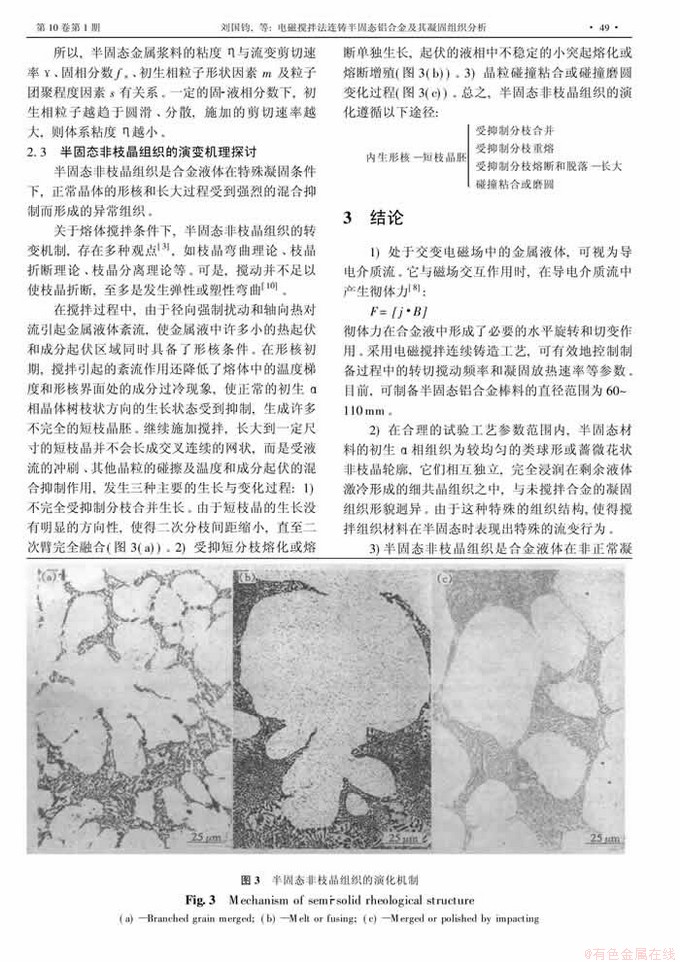

摘 要:采用电磁搅拌连续铸造装置,制备具有触变性非枝晶组织的半固态铝合金圆棒。棒料内部组织形貌为具有类圆形轮廓的初生相晶粒浸润在细共晶体中,与传统的凝固枝晶组织有显著差异。对半固态非枝晶组织的演化机理进行了探讨,结果表明处于交变电磁场中的金属液体,可视为导电介质流,它与磁场交互作用,在导电介质流中产生彻体力。半固态非枝晶组织是在晶体正常的形核和长大过程中,受彻体力强烈的混合抑制作用而形成的。

Abstract: Experiments on semi-solid slurry forming were carried out by practical electromagnetic stirring-continuous casting method. Through optimizing the processing parameters, semi-solid Al-7%Si alloy cylinders with thixotropic non-dentritic structures were successfully produced. The diameter of the cylinder is in the range of 60~110mm. The original phase crystalline grains with roundish configuration are merged in fine eutetic-crystal, and this kind of microstructure is apparently different from conventional solidification crystal structure. The forming mechanism of the semi-solid rheological non-dentritic structures was discussed, the results show that the semi-solid non-dendritic structures are resulted from the strong restraint of normal crystal nucleation and growth in the semi-solid process.