Effects of deformation on microstructures and properties of

submicron crystalline Cu-5%Cr alloy

HE Wen-xiong(贺文雄), WANG Er-de(王尔德),

CHEN Hui(陈 晖), YU Yang(于 洋), LIU Jing-lei(刘京雷)

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 13 Jane 2006; accepted 27 December 2006

Abstract: Warm extrusion of submicron crystalline Cu-5%Cr from 100 ℃ to 600 ℃ was investigated. The effects of different extrusion ratios and different extrusion temperatures on microstructures and properties of submicron crystalline Cu-5%Cr were studied. The microstructures of the extruded Cu-5%Cr were characterized by backscattered electron images(BSE) and transmission electron microscopy(TEM). The mechanical properties of the extruded Cu-5%Cr were measured by means of microhardness and tension test. The results show that, the deformation, dynamic recovery and dynamic recrystallization of the extruded Cu-5%Cr are mainly produced in Cu matrix. The higher extrusion ratio leads to more uniform microstructure and finer Cu grains. When being extruded in the range of 100-600 ℃, dynamic recovery of Cu is the dominant process, and dynamic recrystallization of Cu occurred above 300 ℃ is far from end. The most part of microstructure of as-extruded Cu-5%Cr is subcrystallines produced by dynamic recovery, only a few recrystallines exist, and the average size of these grains is not larger than 400 nm. With extrusion temperature rising, the tensile strength and microhardness of Cu-5%Cr decrease, and elongation increases gradually.

Key words: Cu-Cr alloy; submicron crystalline; extrusion; dynamic recovery; dynamic recrystallization

1 Introduction

Cu-Cr composite material is a sort of functional material with wide applications due to the combination of high electrical conductivity and high temperature strength[1-4]. However, copper and chromium are immiscible, and the Cu-Cr alloys prepared by conventional melting method have coarse grains, which will lead to poor plasticity. So different preparation techniques of Cu-Cr alloys gain increasing interest, among which mechanical alloying is considered an important technique[5-11]. Mechanical alloying can solve the problem of difficulty to melt Cu-Cr alloys and maldistribution of chromium phase, which contributes to prepare chromium phase with fine dispersion granular or lamella particles and Cu matrix with very fine grains, and can also improve the coherence of Cu and Cr interface to get perfect strengthening effect[12-16].

By mechanical alloying, submicron grains and even nano-sized Cu-Cr composite powder can be prepared. By applying technical measures in the following solid state sintering, the growth of grains can be limited, and thus, the near compacted Cu-Cr billets with submicron grains can be fabricated[14-17]. However, little research has been done on the deformation mechanism in the process of plastic working and the evolution of its microstructures and properties, especially, the report on the dynamic recovery and dynamic recrystallization in the hot working, as well as the effects on its microstructures and properties. In present study, based on the near compacted Cu-5%Cr (mass fraction) composite material with submicron grains prepared by mechanical alloying and solid state sintering, further extrusion deformation has been performed in order to investigate its dynamic recovery, dynamic recrystallization and the evolution of its microstructures and properties at different extrusion ratios and different extrusion temperatures.

2 Experimental

The near compacted Cu-5%Cr composite material with submicron grains used in the present experiment was prepared by means of mechanical alloying and solid state sintering. Its technological process is as follows. Commercial copper and chromium elemental powers, with the purity of 99.9% and the average powder size of 74 μm, respectively, were used as the starting materials. Mechanical alloying of the powder mixture with composition of Cu-5%Cr (mass fraction) was performed for 7 h in a high-energy ball-attritor with a stirring speed of 400 r/min and a ball-to-powder mass ratio of 10?1. After cold compacting and sintering at 950 ℃ for 1 h in a vacuum furnace, the Cu-5%Cr composite powders prepared by mechanical alloying were then consolidated into d 40 mm×40 mm cylindrical billets with submicron grains, and its relative density can reach about 97%. Based on the above experiment, the sintered billets were finally extruded with an extrusion ratio of 5 and 20, respectively. The extrusion temperature of the billets was selected within the range of 100-600 ℃. The microstructures of the extruded Cu-5%Cr composite material samples were characterized by electron probe X-ray microanalysis (JCXA-733). The backscattered electron images were also taken. And the bright field images of Cu grains were obtained using a transmission electron microscopy (PHILIPS CM12). The mechanical properties of the as-extruded Cu-5%Cr composite material were measured by means of microhardness and tension test.

3 Results

3.1 Effect of deformation extent

The backscattered electron images of the Cu-5%Cr deformed with different extrusion ratios at 600 ℃ are shown in Fig.1. It can be seen that the deformation microstructure at extrusion ratio of 20 is much finer and more uniform than that at extrusion ratio of 5. It should be pointed out that the bright fibre-like areas in Fig.1 are not Cr phase, but Cu-rich areas. The most of Cr phase has been dissolved compulsively into Cu matrix in mechanical alloying, and then the Cr phase deposits from Cu matrix during the following sintering and extrusion. The particle size of deposited Cr phase is very small, and it distributes dispersively and uniformly in the gray areas in Fig.1.

Fig.1 Backscattered electron images of Cu-5%Cr extruded with different extrusion ratios at 600 ℃: (a) Longitudinal section, extrusion ratio of 5; (b) Transverse section, extrusion ratio of 5; (c) Longitudinal section, extrusion ratio of 20; (d) Transverse section, extrusion ratio of 20

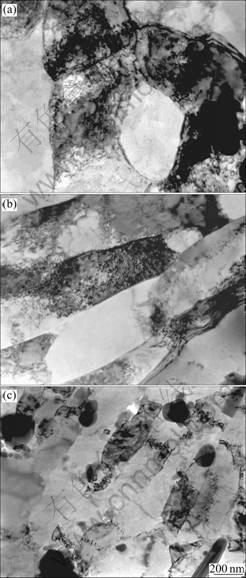

The TEM bright field images of Cu-5%Cr extruded at different extrusion ratios and that of original sample before extrusion as comparison are shown in Fig.2. Fig.2(a) shows that the average size of the original Cu grains is about 600 nm. Figs.2(b) and (c) show that, due to the extrusion deformation, the Cu grains are spindly and their average width is about 300 nm when the material is extruded at the extrusion ratio of 5. With the extrusion ratio up to 20, the average width of Cu grains reduces to about 150 nm. It can be seen that further refined Cu grains can be obtained in this way, and with the larger extrusion ratio, the extent of refining becomes larger. The precipitation of Cr particles can be observed in Fig.2(c), of which the size is about 150 nm with almost no deformation.

Fig.2 TEM bright field images of Cu-5%Cr alloy extruded at different extrusion ratios and original sample before extrusion: (a) Original microstructure; (b) Extrusion ratio of 5; (c) Extru- sion ratio of 20

The results of the microhardness tests show that, before extrusion, the microhardness value of the original microstructure is less than HV130, and it is about HV150 when the extrusion ratio is 5, and it is up to over HV160 when the extrusion ratio is 20.

3.1 Effect of deformation temperature

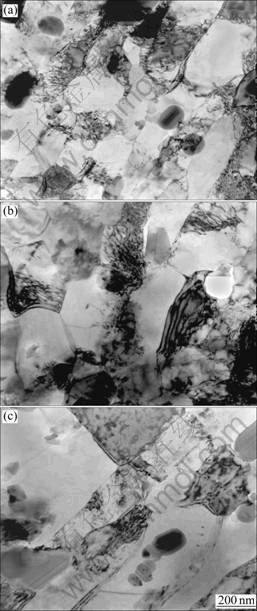

Fig.3 shows TEM bright field images of Cu-5%Cr extruded at different temperatures. The extrusion temperatures of Figs.3(a), (b) and (c) are 100, 300 and 500 ℃, respectively, and with the same extrusion ratio of 20. The deformation microstructure with more dislocations in Fig.3(a) begins to be polygonized, and to form subcrystallines. This shows the initial stage of dynamic recovery. The dislocations in Fig.3(b) decreases, and the polygonization formed subcrystallines are ongoing. This is in the process of dynamic recovery. Meanwhile, the nucleus of recrystallization can be seen in partial area in Fig.3(b), which means the beginning of dynamic recrystallization. The dislocations in Fig.3(c) decrease obviously, and lots of subcrystallines with low-angle-crystalline-boundries are formed. Meanwhile, there are recrystallines with high-angle-grain-boundry, but their number is very little, far from full equiaxed recrystallized microstructure. This means that dynamic recovery has almost finished and dynamic recrystallization has been far from fulfilling. The Cr particles deposited from Cu matrix that can be seen in Fig.3(a) and (c) are very small, with little deformation, like those in Fig.2(c), and their changes with extrusion temperature are not obvious.

Fig.3 TEM bright field images of Cu-5%Cr extruded at different temperatures with extrusion ratio of 20: (a) Extruded at 100 ℃; (b) Extruded at 300 ℃; (c) Extruded at 500 ℃

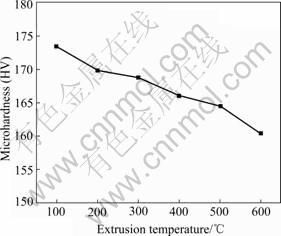

Fig.4 shows the variation of microhardness of Cu-5%Cr with extrusion temperature. It can be seen that the microhardness decreases gradually with extrusion temperature rising. This is the result mainly caused by dynamic recovery. There are also some effects of dynamic recrystallization while being extruded at higher temperature, but it is not sufficient because there is no obvious decrease of microhardness.

Fig.4 Variation of microhardness of Cu-5%Cr with extrusion temperature

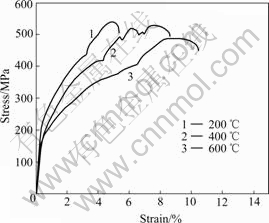

Fig.5 shows the room-temperature stress—strain curves of Cu-5%Cr extruded at different temperatures. The curves 1, 2 and 3 correspond to extrusion temperatures of 200, 400 and 600 ℃, and they correspond to tensile strengths of 542, 528 and 487 MPa, and tensile elongations of 5.2%, 8.4% and 10.4%, respectively. It can be seen that the tensile strength of Cu-5%Cr decreases and the elongation increases gradually with extrusion temperature rising. The evolution trend of strength is consistent with that of microhardness of Cu-5%Cr with extrusion temperature rising. It is also caused mainly by dynamic recovery. As stated previously, while being extruded at higher temperature, though the dynamic recrystallization exists, it is not fulfilled. This can also be seen from the phenomenon that the tensile elongation is still relatively low (only 10.4%) when being extruded at 600 ℃.

Fig.5 Room-temperature stress—strain curves of Cu-5%Cr extruded at different temperatures

4 Discussion

The deformation of Cu-5%Cr produced during extrusion is mostly produced in Cu phase. As stated previously, the particle size of deposited Cr phase is very small, about 150 nm, and the Cr particles distribute dispersively and uniformly. On the other hand, the strength and hardness of Cr are higher than those of Cu matrix. Therefore it is very difficult for Cr particles to produce large deformation during extrusion, and only very small deformation can be produced in Cr phase. That is to say, the deformation is mainly produced in Cu matrix, and the refinement of crystallines produced by extrusion is mostly involved in Cu crystallines.

The effects of extrusion temperature on microstructures and properties of Cu-5%Cr are mainly embodied in Cu matrix. Because the recovery temperature and recrystallization temperature of Cr are higher than those of Cu, and the extrusion temperatures utilized in this paper are mostly lower than the recovery temperature and recrystallization temperature of Cr, the possibility of recovery and recrystallization of Cr phase is very small. However, the recovery temperature and recrystallization temperature of Cu are very low, so the dynamic recovery and dynamic recrystallization of Cu-5%Cr produced during extrusion are mostly produced in Cu matrix.

In present study, the extrusion temperatures are not beyond 600 ℃, and the extruding time is very short, not more than 10 s, and then cooled to room temperature rapidly. Therefore, though the dynamic recrystallization of Cu begins to occur during extrusion above 300 ℃, it is far from end. It is mainly the dynamic recovery of Cu that affects the microstructures and properties of Cu-5%Cr when extrusion temperatures are lower than 600 ℃. Because the dynamic recrystallization is not fulfilled, only a few recrystallized grains exist in the microstructure of Cu-5%Cr. The main part of the microstructure of Cu-5%Cr is subcrystallines produced by dynamic recovery, and the average size of these grains is not larger than 400 nm.

5 Conclusions

1) The deformation of Cu-5%Cr produced in extrusion is mainly produced in Cu matrix, and the dynamic recovery and dynamic recrystallization are also mostly produced in Cu matrix.

2) Because of the larger deformation produced in Cu-5%Cr, the finer and more uniform microstructure can be obtained. The grains of Cu can be refined by extrusion, and the higher the extrusion ratio, the larger the extent of refinement of Cu grains.

3) When being extruded in the range of 100-600 ℃, dynamic recovery of Cu is the dominant process, and dynamic recrystallization of Cu that occurs above 300 ℃ is far from end.

4) After being extruded, the most part of microstructure of Cu-5%Cr is subcrystallines produced by dynamic recovery, and only a few recrystallines exist. The average size of these grains is not larger than 400 nm.

5) With extrusion temperature rising, the tensile strength and microhardness of Cu-5%Cr decrease, and elongation increases gradually.

References

[1] ZHEN Yan-jun, YAO Jia-xin, LI Guo-jun. The present situation and future prospect of the research on high-strength high-conductivity copper-based alloys [J]. Materials Review, 1997, 11(6): 52-55. (in Chinese)

[2] KANG S K, PURUSHOTHAMAN S. Development of conducting adhesive materials for microelectronic applications [J]. J Electronic Mater, 1999, 28: 1314-1318.

[3] GHOSH G, MIYAKE J, FINE M E. The systems-based design of high-strength, high-conductivity alloys [J]. JOM, 1997, 49(3): 56-60.

[4] JIN Y, ADACHI K, TAKEUCHI T, SUZUKI H G. Correlation between the cold-working and aging treatments in a Cu-15 wt. pct. Cr in situ composite [J]. Metall Mater Trans, 1998, 29A: 2195-2203.

[5] BENGHALEM A, MORRIS D G. Milling and mechanical alloying of copper and some solution alloys seen as a thermomechanical process [J]. Acta Metall Mater, 1994, 42(12): 4071-4081.

[6] GAFFET E, LOUISON C, HARMELIN M, FAUDOT F. Metastable phase transformation induced by ball-milling in the Cu-W system [J]. Mater Sci Eng, 1991, A134: 1380-1384.

[7] TAN L K, LI Y, NG S C, LU L. Structure, properties and responses to heat treatment of Cu-Y alloys prepared by mechanical alloying [J]. J Alloys Comp, 1998, 278: 201-208.

[8] WU Jian-jun, LI Guo-bin, ZHANG Yun. Copper matrix composites reinforced with nanometer alumina particles [J]. J Mater Sci Tech, 1999(2): 143-146.

[9] PATEL A N, DIAMOND S. Effects of non-equilibrium processing in the development of copper alloys [J]. Mater Sci Eng, 1988, 98: 329-334.

[10] MURTY B S, RANGANATHAN S. Novel materials synthesis by mechanical alloying/milling [J]. Int Mater Rev, 1998, 43(3): 101-141.

[11] MORRIS D G, MORRIS M A. Rapid solidification and mechanical alloying techniques applied to Cu-Cr alloys [J]. Mater Sci Eng, 1988, 104A: 201-213.

[12] MORRIS M A, MORRIS D G. Microstructural refinement and associated strength of copper alloys obtained by mechanical alloying [J]. Mater Sci Eng, 1989, A111: 115-127.

[13] RAGHU T, SUNDARESAN R, RAMAKRISHNAN P, RAMAMOHAN T R. Synthesis of nanocrystalline copper-tungsten alloys by mechanical alloying [J]. Mater Sci Eng A, 2001, A304/306: 438-441.

[14] HU Lian-xi, WANG Er-de. Fabrication of high strength conductivity submicron crystalline Cu-5% Cr alloy by mechanical alloying [J]. Trans Nonferrous Met Soc China, 2000, 10(2): 209-212.

[15] LIU Jing-lei, LIU Zu-yan, WANG Er-de, XIAN Heng-ze. Structures, properties and responses to heat treatment of deformation processed Cu-15wt %Cr composite powders prepared by mechanical milling [J]. Trans Nonferrous Met Soc China, 2002, 12(6): 837-840.

[16] LIU Jing-lei, WANG Er-de, LIU Zu-yan. Phases interface in deformation processed Cu-15 wt.%Cr composite prepared by elemental powders [J]. Mater Sci Eng A, 2004, A382: 301-304.

[17] LIU Jing-lei, LIU Zu-yan, WANG Er-de. Densification of Cu- 15wt%Cr composite powders prepared by mechanical milling [J]. Materials Science and Technology, 2003, 11(12): 136-139. (in Chinese)

Corresponding author: HE Wen-xiong; Tel: +86-631-5687267; E-mail: hewell@sina.com

(Edited by YANG Bing)