文章编号:1004-0609(2013)S1-s0505-07

Ti80合金时效过程中组织演变及其对力学性能的影响

郭爱红,吴义舟,陈庆磊,宁二宾

(中国船舶重工集团公司 第七二五研究所,洛阳 471039)

摘 要:对热锻态Ti80合金进行Tβ(30~50 ℃)淬火+(500~750 ℃)、(4~8 h)时效处理,测试了其拉伸和冲击性能,采用XRD、OM和TEM分析时效后的相结构及显微组织特征。结果表明:淬火态Ti80合金显微组织由棒状初生αp相+亚稳βt相+细小针状次生αs相(宽度小于0.1 μm)组成。经500 ℃时效,棒状初生αp相球化,亚稳βt相转变为细小针状次生αs相弥散析出,使强度、塑性和冲击韧性均升高;升高时效温度至550 ℃,细小针状次生αs弥散析出相含量增加,强度、塑性分别呈现小幅度升高和下降趋势,冲击韧性急速下降;继续升高时效温度,初生αp相与细小针状次生αs弥散析出相开始长大,使强度、塑性大幅度下降,冲击韧性显著升高。分析Ti80合金强度、塑性和冲击韧性-次生弥散αs析出相特征-时效处理制度之间的系统关系,指出次生αs弥散析出相含量及形貌特征变化是导致冲击韧性显著升高和下降的主要原因。

关键词:Ti80合金;时效;αs相;显微组织;力学性能

中图分类号:TG146.4 文献标志码:A

Microstructure evolution during ageing and its effect on mechanical properties of Ti80 alloy

GUO Ai-hong, WU Yi-zhou, CHEN Qing-lei, NING Er-bin

(Luoyang Ship Material Research Institute, Luoyang 471039, China)

Abstract: The (500-750 ℃), (4-8 h) aging treatments and then tensile and Charpy pendulum impact tests for quenched large Ti80 alloy were carried out. The microstructure was studied by XRD, OM and TEM. The results show that quenched metastable β phase transforms to fine acicular α phase and recovery happens in original α phase during aging. As a result, α grain is fine, the distribution of β phase between α grain becomes more uniformly, and the alloy obtains the higher match of strength-plasticity-toughness. However, when aging temperature increases and aging time is prolonged, α grain coarsens, which makes the toughness greatly increase, but the strength contrarily decreases. Finally, the relationship between microstructural evolution and the change of mechanical properties during aging is clarified.

Key words: Ti80 alloy; age; αs precipitates; microstructure; mechanical properties

Ti80合金是我国于20世纪70年代开发的一种近α型船用钛合金,Kβ为0.19,名义成分为Ti-6Al-3Nb- 2Zr-0.8Mo,具有中等室温强度、高塑韧性、良好的焊接性能、优异的抗海洋环境腐蚀能力。可用于深潜器耐压壳体、高压容器、船舶焊接结构件等的建造[1-8]。经过舰船钛合金应用研究单位40多年坚持不懈的研究开发与应用推广,Ti80合金现已在船舶管路系统、紧固件、海洋救生浮标耐压壳体等船舶构件及水中兵器上获得了一定量的应用。通常,Ti80合金在退火状态下使用,屈服强度等级为785 MPa,难以满足在更高强度要求结构件上使用的需求。截至目前,关于Ti80合金的研究主要集中在合金成分设计[7]、合金元素对力学性能的影响[9-11]、热处理温度对组织与力学性能影响[12]、锻造工艺对显微组织与力学性能影响[13]等方面。而关于Ti80合金固溶时效过程所发生的微观组织演变及力学性能变化规律的研究,至今尚未见文献报道。

强度、塑性和冲击韧性是衡量金属结构材料的主要性能指标,与合金相成分、结构、尺寸及含量等组织参量密切相关。但是,Ti80合金时效过程中的物相转变和组织演变以及与性能之间的内在关系规律至今尚未见文献报道。为此,本文作者系统研究了Ti80合金时效处理制度-相变-性能(强度、塑性和冲击韧性)三者之间相互依存的关系规律,揭示了该规律存在的内在机理。

1 实验

1.1 实验材料

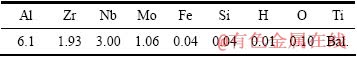

本研究所用试验材料为真空自耗电弧炉2次熔炼制备的铸锭,经β相区开坯,相变点以下20~30 ℃多火次锻造尺寸为90 mm×500 mm×600 mm热锻态Ti80锻件,其化学成分如表1所示。

表1 Ti80合金锻件化学成分

Table 1 Chemical composition of Ti80 forgings (mass fraction, %)

1.2 实验仪器

本实验所用仪器主要有:厢式电阻加热炉;X射线衍射仪(ADVANCE D8);光学显微镜OM (OLYMPUS GX71);透射电镜TEM(Philips CM200);INSTRON万能试验机;JB300B冲击试验机。

1.3 实验方法

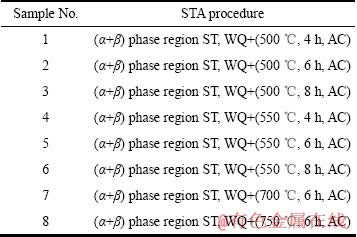

表2所示为Ti80合金固溶时效(STA)制度。从锻件上切取66 mm×60 mm×90 mm试块,按照表2所示的固溶时效制度进行处理。热处理后采用X射线衍射仪进行物相结构分析,采用金相显微镜(OM)和透射电镜(TEM)观察分析显微组织结构。在INSTRON万能试验机上测试室温拉伸性能,拉伸试样为标距段直径5 mm、长30 mm的国标试样。室温冲击试样为高和宽10 mm、长55 mm的V形缺口夏比冲击试样。

表2 Ti80合金固溶时效(STA)制度

Table 2 STA procedure of Ti80 alloy

2 结果与讨论

2.1 时效温度和时间对相组成的影响

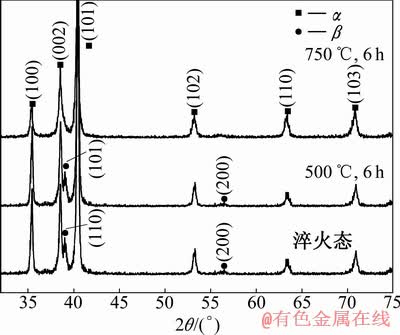

图1所示为Ti80合金不同温度6 h时效后XRD 谱。由图1可以看出:(α+β)相区固溶淬火Ti80合金进行时效处理后,β相含量减少;且随时效温度升高、时间延长,β相减少量增加;当时效温度升高至750 ℃、时效时间延长至8 h时,β相含量非常少(小于7%),XRD谱已经探测不到β相。这是因为Ti80合金(α+β)相区固溶后低温淬火时,β相中所含β稳定元素大于临界浓度,淬火后得过冷亚稳βt相[13-15];当较高温度(>550 ℃)时效时,过冷亚稳βt相发生如下转变:亚稳βt→αs+β,亚稳βt相分解,析出αs相。这可从透射电镜明场像形貌和电子衍射花样得到进一步证实。随时效温度升高和时效时间延长,亚稳βt相向弥散αs相转变分解更充分,使β相含量减少。当750 ℃、6 h时效后,β相含量已减少至7%以下。

图1 Ti80合金不同温度6 h时效后XRD谱

Fig. 1 XRD patterns of Ti80 alloy aged at different temperatures for 6 h

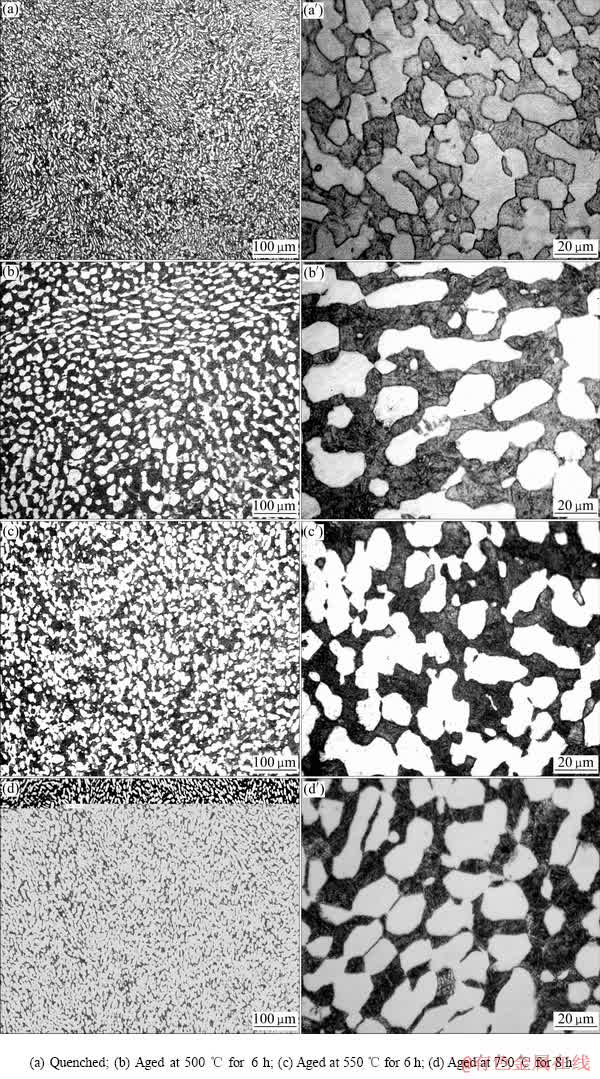

图2 Ti80合金不同温度时效不同时间后金相显微组织

Fig. 2 Optical microstructures of aged Ti80 alloy at different temperatures and time

2.2 时效处理对Ti80合金金相显微组织的影响

图2所示为Ti80合金淬火态和不同温度时效后的金相显微组织。由图2(a)可以看出:Ti80合金淬火态组织为长条状初生αp相+β相转内次生α相,光学显微镜下β转内次生α相模糊、不清晰,且α相和β相衬度差异不明显,黑白对比度小。500 ℃,6 h时效处理后,光学显微组织变清晰,α相和β相衬度差异增大,黑白对比强烈(图2(b))。初生αp相由长条状转变为球状,亚稳βt相在时效过程中发生分解,生成尺寸极细小次生α相,光学显微镜下已看不清其详细形貌特征。升高时效温度至550 ℃,初生αp相球化现象更明显,且αp相球尺寸变小,次生α相尺寸细小,光学显微镜下看不清其详细形貌特征。继续升高时效温度至750 ℃(图2(c)),延长时效时间至8 h,初生αp相长大成棒状,次生α相长大,尺寸增加,光学显微镜下隐约可见其细针状形貌。

2.3 时效处理对Ti80合金TEM组织的影响

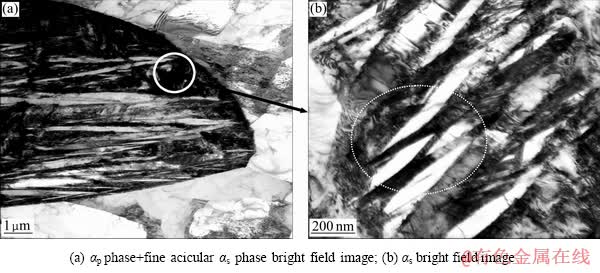

图3所示为Ti80合金淬火态TEM组织形貌明场像及αp相和βm相选区电子衍射花样。图3(a)表明:Ti80合金淬火态组织为“长条状初生αp相+βt内细针状次生αs相+βm相”,图3(b)选区电子衍射花样证实了βm相的存在。

图4所示为淬火Ti80合金500 ℃、6 h时效后的TEM组织明场像。在相同较小倍数放大情况下,500 ℃、6 h时效组织结构(图4(a))与淬火态Ti80合金组织结构(图3(a))相同,为长条状初生αp相+β转内细针状次生αs相+βm相。较高放大倍数下观察发现(图4(b)):时效态Ti80合金试样内,βm相含量减少,细针状次生αs相弥散分布,前端为针尖状,厚度尺寸约50~80 nm,淬火态试样内并未发现。说明这些纳米尺寸厚度的细针状次生αs相是在低温(500 ℃)时效过程中由过冷β亚稳相分解转变而来的,这一结果与X射线衍射分析结果是一致的。

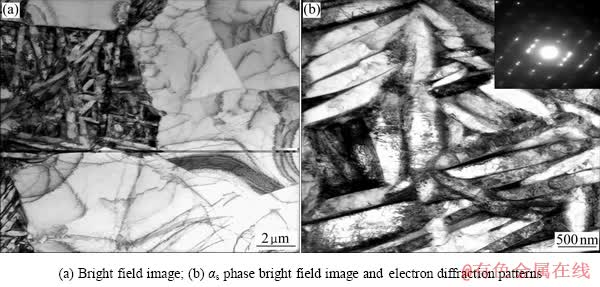

图5所示为Ti80合金750 ℃,8 h时效后TEM组织。图5表明:当时效温度和时间分别升高和延长至750 ℃,8 h时,次生αs相转变成尺寸较大的细棒状(直径100~200 nm),前端针尖消失,且棒状次生αs相总量增加,而过冷βm相含量则大大减少。这说明:此时过冷βm相已得到充分分解。

图3 Ti80合金淬火态TEM像

Fig. 3 TEM images of quenched Ti80 alloy

图4 淬火态Ti80合金500 ℃、6 h时效TEM像

Fig. 4 TEM images of Ti80 alloy quenched and aged at 500 ℃ for 6 h

2.4 时效温度和时间对Ti80合金性能的影响

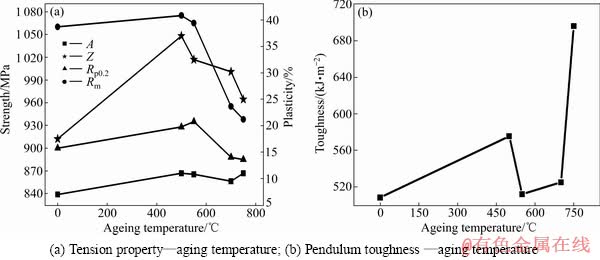

图6所示为Ti80合金拉伸性能和冲击韧性随时效温度变化曲线。图6(a)表明:500 ℃时效后,Ti80合金强度和冲击韧性均大幅度上升;升高时效温度至550 ℃,强度、塑性和冲击韧性均下降;继续升高时效温度至750 ℃,冲击韧性大幅度上升,强度和塑性显著下降。这是因为500 ℃时效后,过冷βm相分解转变成细小弥散分布的针状次生αs相,使得位错不能够轻易绕过α相,同时细小针状次生αs相弥散分布使得两相界面增多,造成第二相强化效应增强,从而强度升高。此外,淬火过程中产生的热应力释放,以及无序βm相向有序αs相的转变,使合金冲击韧性上升。升高时效温度至550 ℃,次生针状αs相长大,合金强度、塑性和冲击韧性均下降。继续升高时效温度至750 ℃,次生αs相长大,由细小针状长大到粗大棒状。由于弥散针状次生αs相的减少,合金中两相界面面积减少,第二相强化效果减弱,强度下降。同时,在冲击断裂过程裂纹形成阶段充当裂纹形核中心、在裂纹扩展阶段充当裂纹扩展通道的细小针状次生αs相长大到粗大棒状,提高了合金抵抗裂纹形成和扩展的能力,故冲击韧性显著提高。综合对比分析,500 ℃时效后,Ti80合金获得最佳“强度-塑性-冲击韧性”匹配。

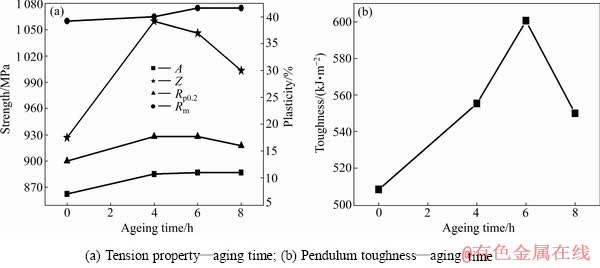

图7所示为500 ℃时效时时效时间对Ti80合金性能影响规律。图7表明:随时效时间延长,强度和塑性变化不大,冲击韧性先升高,6 h后开始下降。这表明,经500 ℃时效6 h时,Ti80合金淬火应力释放完毕,随时效时间延长,针状次生αs相析出量增加,冲击韧性开始下降。

图5 Ti80合金750 ℃、8 h时效后TEM像

Fig. 5 TEM images of Ti80 alloy quenched and aged at 750 ℃ for 8 h

图6 Ti80合金性能随时效温度变化曲线

Fig. 6 Curves of properties vs aging temperature for Ti80 alloy

图7 于500 ℃时效Ti80合金性能时间变化曲线

Fig. 7 Curves of properties vs aging temperature for Ti80 alloy

3 结论

1) Ti80合金低温时效过程中生成的细小针状次生αs相对合金具有强强化作用,但也导致冲击韧性下降。

2) 随时效温度升高,针状次生αs相长大至棒状,合金强化下降,冲击韧性上升。

3) 随时效时间延长,合金强度和塑性变化不大,冲击韧性先升高后降低。

REFERENCES

[1] 邵世单. 船用Ti6Al3Mo2Zr1Nb钛合金的应用[J]. 稀有金属材料与工程, 2005, 34(增刊3): 110-112.

SHAO Shi-dan. The application of Ti6Al3Mo2Zr1Nb titanium alloy [J]. Rare Metal Materials and Engineering, 2005, 34(Suppl 3): 110-112.

[2] 古 一, 戚延龄, 夏长清, 李学雄, 王志辉. 热暴露对 TC11 钛合金组织和力学性能的影响[J]. 中国有色金属学报, 2013, 13(4): 997-1004.

GU Yi, QI Yan-ling, XIA Chang-qing, LI Xue-xiong, WANG Zhi-hui. Effects of thermal exposure on microstructure and mechanical properties of TC11 titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2013, 13(4): 997-1004.

[3] ZHANG X D, WIEZOREK J M K, BAESTACK W A. Precipition of ordered α2 phase in Ti-62222 alloy [J]. Acta Mater, 1998, 46: 4485-4495.

[4] ZENG L, BIELER T R. Effects of working heat treatment and aging on microstructural evolution and crystallgraphic texture of α, α′, α″ and β phase in Ti-6Al-4V wire [J]. Materials Science and Engineering A, 2005, 392: 403-414.

[5] LUTJERING G, WILLIAMS J C. Titanium [M]. Germany: Springer, 2003: 33-39.

[6] LENYENS C, PETERS M. Titanium and titanium alloys [M]. Weinheim: Wiley-VCH Verlag Gmbh & Co. KGaA, 2003: 33- 39.

[7] 曹振新, 张必强, 毛彭龄. Ti80船用钛合金的研究[J]. 钛工业进展, 2005, 20(6): 22-25.

CAO Zhen-xin, ZHANG Bi-qiang, MAO Peng-ling. The research of Ti80 titanium alloy for ship building [J]. Titanium Industry Progress, 2005, 20(6): 22-25.

[8] 蒋 鹏, 孟宪亮, 刘茵琪. Ti80合金锻造工艺对显微组织和性能的影响[J]. 稀有金属材料与工程, 2005, 34(增刊3): 286-288.

JIANG Peng, MENG Xian-liang, LIU Yin-qi. The effects of forging process on microstructure and properties of Ti80 alloy [J]. Rare Metal Material and Engineering, 2005, 34(Suppl3): 286-288.

[9] 毛彭龄, 曹振新. STi80钛合金中合金元素对力学性能的影响[J]. 上海钢研, 2001, 4: 10-13.

MAO Peng-ling, CAO Zhen-xin. A study of effect of compositions on mechanical properties of titanium alloy STi80 [J]. Shanghai Steel Research, 2001, 4: 10-13.

[10] 李赛毅, 文 浩, 雷力明, 张慧儒. TC11 合金两相区退火对微观组织与微观织构的影响[J]. 中国有色金属学报, 2012, 22(11): 3022-3028.

LI Sai-yi, WEN Hao, LEI Li-ming, ZHANG Hui-ru. Effect of annealing in two phase field on microstructure and microtexture of TC11 alloy [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3022-3028.

[11] 李士凯, 惠松骁, 叶文君, 于 洋, 熊柏青. 微观组织对TA15 ELI钛合金损伤容限性能的影响[J]. 中国有色金属学报, 2007, 17(7): 1119-1123.

LI Shi-kai, HUI Song-xiao, YE Wen-jun, YU Yang, XIONG Bai-qing. Effects of microstructure on damage tolerance properties of TA15 ELI titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1119-1123.

[12] 文志刚, 王韦琪, 王小翔. 热处理温度对Ti-6Al-3Nb-2Zr-1Mo 合金板材显微组织和性能的影响[J]. 中国有色金属学报, 2010, 20(增刊1): s647-s649.

WEN Zhi-gang, WANG Wei-qi, WANG Xiao-xiang. Effects of heat treatment temperature on microstructure and mechanical properties of Ti-6Al-3Nb-2Zr-1Mo alloy plate [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(Suppl 1): s647-s649.

[13] 张 奕, 虞高峰, 雷锦文. 锻造工艺对Ti6321合金棒材显微组织与力学性能的影响[J]. 钛工业进展, 2010, 27(6): 34-35.

ZHANG Yi, YU Gao-feng, LEI Jin-wen. The effects of forging process on microstructure and mechanical properties of Ti6321 stick [J]. Titanium Industry Progress, 2010, 27(6): 34-35.

[14] 张喜燕, 赵永庆, 白晨光. 钛合金及应用[M]. 北京: 化学工业出版社, 2005: 98-99.

ZHANG Xi-yan, ZHAO Yong-qing, BAI Chen-guang. Titanium alloy and application [M]. Beijing: Chemical Industry Press, 2005: 98-99.

[15] 张尧武, 曾卫东, 史春玲, 康 超, 彭雯雯. 真空去应力退火对TC18钛合金残余应力及组织性能的影响[J]. 中国有色金属学报, 2011, 21(11): 2780-2785.

ZHANG Yao-wu, ZENG Wei-dong, SHI Chun-ling, KANG Chao, PENG Wen-wen. Influence of vacuum stress relieving annealing on residual stress and microstructure properties of TC18 titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2780-2785.

(编辑 陈爱华)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:郭爱红,博士,高工;电话: 0379-67256964; E-mail: aihonggg@sina.com