从湿法炼锌沉矾上清液中富集回收锗和铜

来源期刊:中国有色金属学报(英文版)2013年第5期

论文作者:周兆安 楚 广 甘红祥 杨天足 陈 霖

文章页码:1506 - 1511

关键词:回收;锗;铜;湿法炼锌;沉矾上清液;还原;铁粉

Key words:recovery; Ge; Cu; zinc hydrometallurgy; precipitating vitriol supernatant; cementation; Fe powder

摘 要:提出一种以铁粉为还原剂还原富集回收湿法炼锌沉矾上清液中锗和铜的新工艺。研究结果表明,反应时间、温度、搅拌强度、反应起始pH值、铁粉加入量对铜和锗的还原率有较大影响。得到的最佳工艺条件为:反应时间120 min,初始pH值1.5,铁粉用量4 g/L,搅拌速度600 r/min和反应温度80 °C。在此条件下,湿法炼锌沉矾上清液中锗的还原率大于96%,铜的还原率为100%。还原产物中锗的品位达到2.06%,实现了锗从硫酸锌溶液中的分离和富集。还原产物经过进一步的分离可得到品位更好的铜锗渣,其中锗和铜的品位可达到4.88%和56.75%。

Abstract: A novel technology using Fe powder as reducing agent for Ge and Cu recovery from precipitating vitriol supernatant in Zn hydrometallurgical plant was investigated. The results show that reaction time, temperature, agitation speed, initial pH value of solution and the amount of reducing Fe have significant effects on recovering Ge and Cu, and the optimum process operating parameters are established as follows: time 120 min, initial pH value 1.5, the dosage of reducing Fe powder 4 g/L, agitation speed 600 r/min and temperature 80 °C. Under these experimental conditions, the recovery ratios of Ge and Cu from precipitating vitriol supernatant in Zn hydrometallurgical plant can reach 96% and 100%, respectively. The content of Ge in the reduced residue reaches up to 2.06% (mass fraction), indicating that the separation and enrichment of Ge from the Zn sulfate solution is realized. The grade of Ge and Cu can reach up to 4.88% and 56.75%, respectively, when the reduced residue is further processed.

Trans. Nonferrous Met. Soc. China 23(2013) 1506-1511

Zhao-an ZHOU, Guang CHU, Hong-xiang GAN, Tian-zu YANG, Lin CHEN

School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China

Received 22 March 2012; accepted 8 November 2012

Abstract: A novel technology using Fe powder as reducing agent for Ge and Cu recovery from precipitating vitriol supernatant in Zn hydrometallurgical plant was investigated. The results show that reaction time, temperature, agitation speed, initial pH value of solution and the amount of reducing Fe have significant effects on recovering Ge and Cu, and the optimum process operating parameters are established as follows: time 120 min, initial pH value 1.5, the dosage of reducing Fe powder 4 g/L, agitation speed 600 r/min and temperature 80 °C. Under these experimental conditions, the recovery ratios of Ge and Cu from precipitating vitriol supernatant in Zn hydrometallurgical plant can reach 96% and 100%, respectively. The content of Ge in the reduced residue reaches up to 2.06% (mass fraction), indicating that the separation and enrichment of Ge from the Zn sulfate solution is realized. The grade of Ge and Cu can reach up to 4.88% and 56.75%, respectively, when the reduced residue is further processed.

Key words: recovery; Ge; Cu; zinc hydrometallurgy; precipitating vitriol supernatant; cementation; Fe powder

1 Introduction

The metallurgy of germanium (Ge) has profound impact on modern semiconductor technology. Ge is widely distributed in nature (6.7×10-4% worldwide average) [1]. It has been widely used in the electronics devices, optoelectronics, solar cells and catalysts, etc. There are only a few minerals like argyrodite, briartite, germanite and renierite that contain appreciable amounts of Ge. However, Ge is mostly produced via extraction from the final ore concentrate in some Zn-Cu-Pb ore bodies. In ore deposits Ge is commonly found substituting for zinc (Zn) in sphalerite framework structure [2], and other sulfide species [3]. The Zn ore has large and recoverable quantities of Ge, so nowadays Ge is mainly obtained as a byproduct of hydrometallurgical Zn processing operations [4]. In addition, around 30% of the Ge used in the world is obtained from recycled materials, particularly electronic devices [5].

Many techniques have been used to separate Ge from other elements contained in leachates. The mainstream technology involves the precipitation with tannin [6], adsorption onto activated carbon [7], solvent extraction [8-11] and adsorption onto chelating exchange resins [12-14]. However, each of these methods can only be applied under restricted processing conditions and comes with a high cost of purification because of the lack of selectivity and capacity of extracting Ge.

Chemical precipitation method is used to treat the leach solution containing relatively low concentration of Ge [15], and most of Zn hydrometallurgical plant recover Ge from leaching liquor by its complexation with tannin. But too much tannin is consumed in the Ge-tannin complexation process, and 56-80 mol of tannin are needed to precipitated 1 mol of Ge, resulting in low concentration in the precipitation [16]. In addition, tannins in leaching liquor have an adverse effect upon Zn electrolysis.

The cementation technique has been used in industry for a long time in both hydrometallurgy and in the purification of process streams and wastewaters. The advantages of cementation process include its relative simplicity, ease of controlling the condition of process and its ability to recover valuable metals [17-19]. However, the consumption of sacrificial metals and the redox potentials of sacrificial metals limit the application of this process [20]. In the applied recovery process, more reactive metal (in the present case, Fe powder) is oxidized and Ge is reduced.

The objective of the present research is to develop a novel technology of extracting Ge from precipitating vitriol supernatant in Zn hydrometallurgy plant through a simple, cost-effective way. During the experiment, the technique of cementation was studied. Specifically, Fe powder acted as reducing agent for recovery of Ge from precipitating vitriol supernatant. This method yielded a higher recovery ratio of Ge up to 96%. This novel method was proved to be efficient, controllable and low consumption of sacrificial metals. Moreover, the influences of reaction time, temperature, agitation speed, initial pH value of solution and the dosage of Fe powder per liter of the solution were studied in detail.

2 Experimental

In this study, the more reactive and relatively cheap metal Fe powder was employed to extract Ge from precipitating vitriol supernatant in Zn hydrometallurgical plant via cementation. Fe was oxidized and Ge was reduced in the solution. Ge was precipitated by Fe powder and this precipitate called as reduced residue.

The standard reduction potentials of H2GeO3 and Fe are given as [21]:

=

= E=-0.182 V (1)

E=-0.182 V (1)

=

= , E=-0.447 V (2)

, E=-0.447 V (2)

The standard potential difference is calculated to be 0.265 V.

The overall reaction is expressed as

=

= (3)

(3)

The other important reactions are as follows:

2Fe3++Fe=3Fe2+ (4)

Cu2++Fe=Fe2++Cu (5)

2H++Fe=Fe2++H2↑ (6)

2.1 Materials

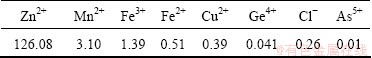

The composition of Zn sulfate solution used in this experiment was similar to the precipitating vitriol supernatant which was taken from a company, Hunan Province, China. Elemental analysis result of the solution is presented in Table 1. Analytical grade reagents were purchased in the local market, including basic Zn carbonate (AR, Sinopharm Chemical Reagent Co., Ltd.), reduced Fe power (AR, Tianjin Guangfu Fine Chemical Research Institute). All aqueous solutions were prepared using distilled water.

Table 1 Elemental analysis results of precipitating vitriol supernatant (g/L)

2.2 Method

The experiments of Ge recovery were conducted in a 500 mL round bottom flask. The solution was agitated by a three blade impeller driven by a variable speed motor. The round bottom flask was heated in a water bath. The temperature and agitation speed were measured through two PLD controllers.

Typically, 200 mL of the precipitating vitriol supernatant in Zn hydrometallurgical plant was poured into the round bottom flask slowly, which was then heated. When the water bath was heated to the required temperature, the solution was agitated. Then the initial pH value of the solution was adjusted by basic zinc carbonate or sulphuric acid. Finally, a certain amount of Fe powder was added into the 500 mL round bottom flask and mixed with the solution enough for a time. After reaction of cementation taking place, the residue containing Ge was filtered and thoroughly washed. The concentration of Ge ions in filtered solution was measured with inductively coupled plasma atomic emission spectroscopy (ICP) using Perkin Elmer Optical Emission Spectrometer Optima 2100 DV.

The composition of the solution shows that Fe is mainly consumed by Fe3+, Cu2+, H2GeO3 and sulphuric acid. Assuming the volume of solution is 1 L, then the theoretic Fe consumption can be calculate as follows:

(7)

(7)

If start pH value is 1.5 and end pH value is 4, then mFe≈2.0 g.

The extraction rate (η) was calculated by the following equation:

η=[(C0-Ct)/C0]×100 (8)

where C0 is the initial Ge or Cu concentration and Ct is the concentration after solid-liquid separation in the experiment.

3 Results and discussion

3.1 Cementation of Ge in precipitating vitriol supernatant by Fe powder

In order to obtain the optimal conditions, the effects of different variables on the recovery ratio of Ge were evaluated. The main variables include time, temperature, agitation speed, initial pH value of the precipitating vitriol supernatant and the amount of Fe powder added to the solution. The results obtained are summarized as the follows.

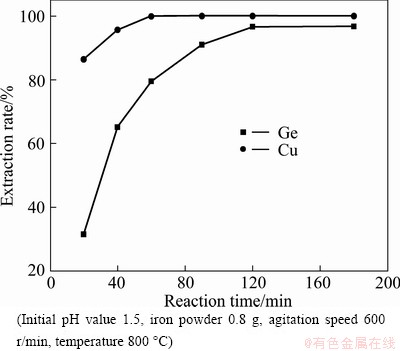

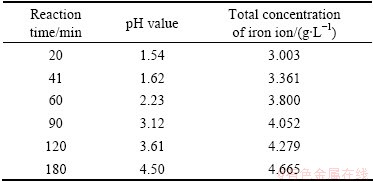

3.1.1. Effect of reaction time

The reaction time on Ge extraction was studied under the reaction initial pH value 1.5, the dosage of Fe powder 4.0 g/L, agitation speed 600 r/min and temperature 80 °C, and the results are presented in Fig. 1 and Table 2. It can be seen that the reaction time has no obvious effect on extraction ratio of Cu above 60 min, because Cu2+ was soon reduced by Fe powder. There was a rapid increase in the extraction ratio of Ge within 20 to 120 min. However, above 120 min the extraction ratio of Ge did not increase significantly. Prolonged reaction time had no help for the extraction ratio of Ge, but also might increase the consumption of Fe powder. Therefore, for subsequent experiments the reaction time was kept at 120 min.

Fig. 1 Effects of reaction time on extraction rates of Ge and Cu

Table 2 Effects of reaction time on reducing agent consumption

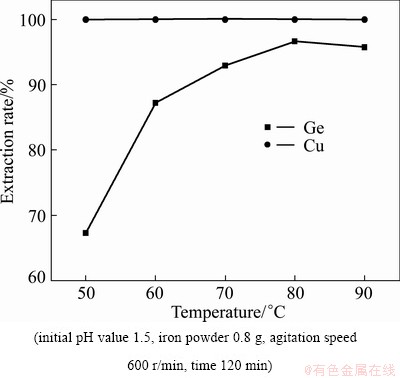

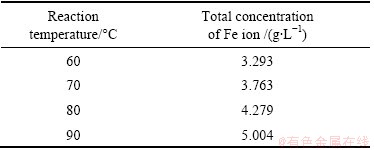

3.1.2 Effect of temperature

The extraction ratio of Ge is also affected by reaction temperature. High Ge extraction ratio may not be achieved in a short time at low temperatures whilst high temperatures have disadvantages such as higher energy consumption. So, the temperature in the range of 50 to 90 °C was selected and its effect on Ge extraction ratio was studied.

Figure 2 and Table 3 show the effect of temperature on extraction of Ge and Cu under the conditions of initial pH value 1.5, Fe powder 4.0 g/L, agitation speed 600 r/min, and time 120 min. Cu reduction ratio was almost not affected by temperature. Ge extraction ratio increased from 66% to 96% when the temperature increased from 50 to 80 °C, and a further increase in temperature to 90 °C had no significant effect, but the consumption of Fe powder would increase. Therefore, the optimum temperature appeared to be 80 °C and all following experiments were carried out at this temperature.

Fig. 2 Effects of reaction temperature on extraction rates of Ge and Cu

Table 3 Effects of reaction temperature on reducing agent consumption

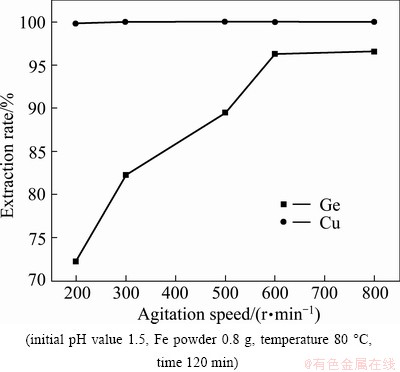

3.1.3 Effect of agitation

Agitation plays an important role in reducing Ge processes. The results of agitation, shown in Fig. 3, under optimum reaction conditions, indicate that Ge extraction ratio increased from 71% to 96% as the agitation speed increased from 200 to 600 r/min. A further increase in agitation speed up to 700 r/min had no significant effect on Ge extraction, so the agitation speed was maintained at 600 r/min, which was enough to suspend the Fe powders in the solution during the course of experiments. Cu is more easily reduced by Fe powder than Ge, and only need to have a certain stirring speed, Cu ions will soon be reduced completely.

Fig. 3 Effects of agitation speed on extraction rates of Ge and Cu

This increase in recovery ratio of Ge can be attributed to two factors. First, high stirring speed makes the particles collision become more frequent and effective, which strips the reduced products off the surface of Fe powder and thus strengthen the mass diffusion process in the particles (internal diffusion). Second, it is obvious that high speed can lead to suspension of the Fe powder in the solution and increase the diffusion velocity of products across the hydrodynamic boundary layer around the Fe powder.

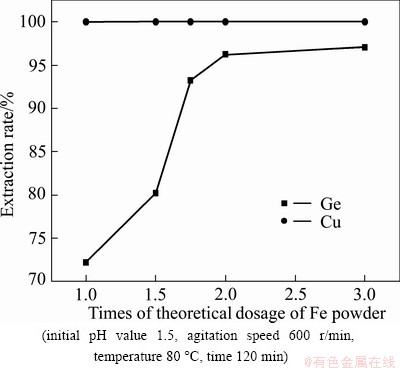

3.1.4 Effect of dosage of Fe powder

According to reaction (3), the dosage of Fe powder as reducing agent must affect Ge extraction. It can see from Eq. (7) that the theoretical consumption of Fe is nearly 2.0 g/L.

Fig. 4 Effects of dosage of Fe powder on extraction rates of Ge and Cu

In this study, the dosage of Fe powder ranging from 1.0 to 3.0 times of the theoretical dosage on Ge extraction rate was studied under optimum reaction conditions, and the results are shown in Fig. 4. The more the surplus dosage of Fe powder is, the higher the extraction rate of Ge is. But this has almost no effects on Cu extraction rate. Ge extraction rate increases from 72% to 96% when the dosage of Fe powder increased from 1.0 to 2.0 times of the theoretical dosage, and a further increase in the dosage of Fe powder has no significant effect.

Therefore, the optimum dosage of Fe powder as reducing agent appears to be 4.0 g/L and all following experiments were carried out at this dosage.

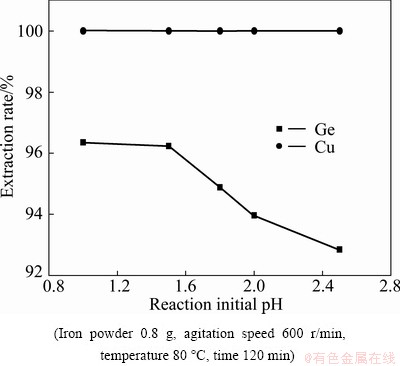

3.1.5 Effect of initial pH value of solution

The optimum extraction of Ge is also affected by initial pH value of solution. In our present study, an initial pH value ranging from 1.0 to 2.5 was selected and its effect on Ge extraction rate was studied. Figure 5 shows the effect of initial pH value on the extraction rate of Ge and Cu under the conditions of Fe powder 4.0 g/L, agitation speed 600 r/min, temperature 80 °C, time 120 min. Cu reduction rate was 100% under all reaction conditions. Ge extraction rate decreased from 96.45% to 92.84% when the initial pH value increased from 1.0 to 2.5, and a further increase in initial pH value will result in Fe hydroxide emerges. At the same time, Ge extraction rate had no significant increase when the initial pH value decreased from 1.5 down to 1.0, but high concentration of sulfuric acid will increase the consumption of Fe and may produce arsine in experiment. So the optimum initial pH value appeared to be about 1.5.

Fig. 5 Effects of reaction initial pH value on extraction rates of Ge and Cu

3.2 Possibility of arsine generation

Under a high acid and strong reducing condition, arsenate may be reduced to arsine. As we all know that arsine is an extremely toxic gas. In order to investigate the safety of this process, we had monitored whether there was arsine generation in experiments by the silver nitrate paper. Fortunately, the result shows that as theoretical analysis, there was no any arsine. In addition, MO [22] indicated that this reaction system won't produce any arsine. So it is a safe and reliable method for Ge recovery from precipitating vitriol supernatant in Zn hydrometallurgical plant.

3.3 Analysis of reduced residue containing Ge

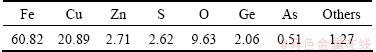

The optical spectrum analyses result of reduced residue containing Ge via cementation by Fe powder is shown in Table 4, which shows that the content of Ge reaches up to 2.06%. But there is a lot of Fe powders that did not participate in chemical reactions, because the dosage of Fe powder is 2.0 times of the theoretical dosage. Therefore, the separation of Fe powder from the reduced residue will be required in order to increase the grade of Ge.

Table 4 Chemical composition of reduced residue containing Ge (mass fraction, %)

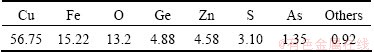

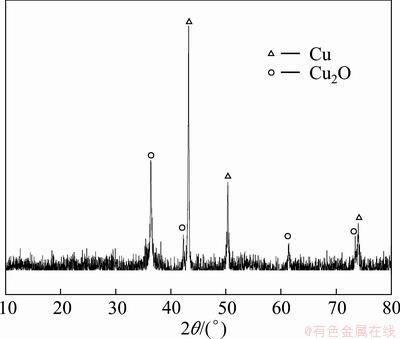

The reduced residue was dried ground, sieved and separated, then Ge-rich Cu residue was got. Its chemical composition is shown in Table 5. The XRD pattern of this kind of Ge-rich Cu residue is shown in Fig. 6, which reveals that the major crystalline mineral phases are Cu and Cu2O in the residue. The grade of Ge and Cu are 4.88% and 56.75%, respectively. This kind of high value-added Ge-rich Cu concentrate can be used for preparation of germanium tetrachloride by the chlorination distillation process.

Table 5 Contents of Ge-rich Cu residue analyzed by X-ray fluorescence spectrometer (mass fraction, %)

Fig. 6 XRD pattern of Ge-rich Cu residue

4 Conclusions

1) An effective technique of extracting Ge from precipitating vitriol supernatant in Zn hydrometallurgical plant via cementation was established using Fe powder as reducing agent.

2) The optimum operating parameters were as follows: time 120 min, initial pH value 1.5, the dosage of reducing Fe powder 4.0 g/L, agitation speed 600 r/min and temperature 80 °C. Under these experimental conditions, the recovery rates of Ge and Cu from the supernatant can reach 96% and 100%, respectively.

3) The content of Ge in the reduced residue reached up to 2.06%, and the separation and enrichment of Ge from the Zn sulfate solution was realized.

4) The grade of Ge and Cu were 4.88% and 56.75%, respectively, in Ge-rich Cu residue. This kind of high value-added Ge-rich Cu concentrate can be used for preparation of germanium tetrachloride by the chlorination distillation process.

References

[1] SCOYER J, GUISLANIN H, WOLF H U. Germanium and Germanium compounds [M]// Ullmann’S Encyclopedia of Industrial Chemistry. Vol. 15. Weinheim: Wiley-VCH Verlag GmbH & Co., 1987: 523.

[2] LEVISON A A. Introduction to exploration geochemistry [M]. Wilmette: Applied Publishing Ltd, 1980: 924.

[3] ADAMS J H. Germanium and Germanium compounds. ASM metals handbook [M]. 10th Ed. Ohio: ASM International, 1990: 733-738.

[4] VOJKOVIC V, JURANOVIC I, TAMHINA B. Extraction and separation of Germanium (IV) with 4-Pyridone derivatives [J]. Croatica Chemica Acta, 2001, 74(2): 467-477.

[5] BUTTERMAN W C, JORGENSON J D. Germanium [R]. USGS Open-File Report 2004-1218. 2005: 19. (http://pubs.usgs.gov/of/ 2004/1218/ 2004-1218.pdf).

[6] MOSKALYK R R. Review of Germanium processing worldwide [J]. Minerals Engineering, 2004, 17(3): 393-402.

[7] MARCO-LOZAR J P,  D, LINARES- SOLANO A. A new strategy for Germanium adsorption on activated carbon by complex formation [J]. Carbon, 2007, 45(13): 2519-2528.

D, LINARES- SOLANO A. A new strategy for Germanium adsorption on activated carbon by complex formation [J]. Carbon, 2007, 45(13): 2519-2528.

[8] MENENDEZ F J, MENENDEZ F M, de la CUADRA HERRERA A, TAMARGO F A, LORENZO L P, VALCARCEL M R, FERNANDEZ V A. Process for the recovery of Germanium from solutions that contain it: US, 4886648 [P]. 1989-12-12.

[9] TORRALVO F A,  C. Recovery of Germanium from real fly ash leachates by ion-exchange extraction [J]. Minerals Engineering, 2011, 24(1): 35-41.

C. Recovery of Germanium from real fly ash leachates by ion-exchange extraction [J]. Minerals Engineering, 2011, 24(1): 35-41.

[10] LIN Jiang-shun, WANG Hai-bei, GAO Ying-jian, ZHAO Lei, ZHANG Lei. Preparation and application of a novel extractant for Ga and Ge [J]. Nonferrous Metals, 2009, 61(2): 84-87. (in Chinese)

[11] CHU Guang, ZHOU Zhao-an, YANG Tian-zu, WU Jiang-hua. Study on the Germanium (IV) extraction from the acid leach liquor after jarosite process in Zn hydrometallurgy by G8315 [J]. Mining and Metallurgical Engineering, 2011, 31(5): 69-72. (in Chinese)

[12] HARADA A, TARUTANI T, YOSHIMURA K. Spectrophotometric determination of Ge in rocks after selective adsorption on Sephadex gel [J]. Analityca Chimica Acta, 1988, 209: 333-388.

[13] ARROYO TORRALVO F,  M C. Recovery of Germanium from aqueous solutions by ion-exchange extraction of its catechol complex [J]. Industrial & Engineering Chemistry Research, 2010, 49(10): 4817-4823.

M C. Recovery of Germanium from aqueous solutions by ion-exchange extraction of its catechol complex [J]. Industrial & Engineering Chemistry Research, 2010, 49(10): 4817-4823.

[14] INUKAIA Y, CHINENB T, MATSUDAB T, KAIDAA Y, I YASUDA S. Selective separation of Germanium (IV) by 2,3-dihydroxypropyl chitosan resin [J]. Analityca Chimica Acta, 1998, 371(1-2): 187-193.

[15] SEIFULLINA I I, POZHARITSKII A F, SKRYLEV L D, BELOUSOVA E, CHISTOV A S. Isolation of Germanium tannate and gallate complexes by the flotation method [J]. Russian Journal of Applied Chemistry, 1973, 39: 2077-2079. (in Russian)

[16] LIANG Duo-qiang, WANG Ji-kun, WANG Yun-hua, WANG Fan, JIANG Ji-bao. Behavior of tannins in Germanium recovery by tannin process [J]. Hydrometallurgy, 2008, 93(3-4): 140-142.

[17] HABASHI F. A short history of hydrometallurgy [J]. Hydrometallurgy, 2005, 79(1-2): 15-22.

[18] DOYLE F M. Teaching and learning environmental hydrometallurgy [J]. Hydrometallurgy, 2005, 79(1-2): 1-14.

[19] NOSIER S A, SALLAM S A. Removal of lead ions from wastewater by cementation on a gas-sparged zinc cylinder [J]. Sep Purif Technol, 2000, 18(2): 93-101.

[20] PARK J C. Purification and recovery of rhodium metal by the formation of intermetallic compounds [J]. Bull Korean Chem Soc, 2008, 29(9): 1787-1789.

[21] LI Meng-long. Concise handbook of chemical data [M]. Beijing: Chemical Industry Press, 2003: 170-171. (in Chinese)

[22] MO Ding-cheng. The method of silicon removal from silicic-rich acidic solution [J]. Nonferrous Metals: Extractive Metallurgy, 1995, (3): 7-9. (in Chinese).

周兆安, 楚 广, 甘红祥, 杨天足, 陈 霖

中南大学 冶金科学与工程学院,长沙 410083

摘 要:提出一种以铁粉为还原剂还原富集回收湿法炼锌沉矾上清液中锗和铜的新工艺。研究结果表明,反应时间、温度、搅拌强度、反应起始pH值、铁粉加入量对铜和锗的还原率有较大影响。得到的最佳工艺条件为:反应时间120 min,初始pH值1.5,铁粉用量4 g/L,搅拌速度600 r/min和反应温度80 °C。在此条件下,湿法炼锌沉矾上清液中锗的还原率大于96%,铜的还原率为100%。还原产物中锗的品位达到2.06%,实现了锗从硫酸锌溶液中的分离和富集。还原产物经过进一步的分离可得到品位更好的铜锗渣,其中锗和铜的品位可达到4.88%和56.75%。

关键词:回收;锗;铜;湿法炼锌;沉矾上清液;还原;铁粉

(Edited by Chao WANG)

Foundation item: Project (2011TT2057) supported by Science & Technology Department of Hunan Province, China

Corresponding author: Guang CHU; Tel/Fax: +86-731-85201576; E-mail: chuguang2006@163.com

DOI: 10.1016/S1003-6326(13)62623-0