Trans. Nonferrous Met. Soc. China 24(2014) 3152-3157

Magnetocaloric effect in Ni-Mn-In-Co microwires prepared by Taylor-Ulitovsky method

Xue-xi ZHANG, Sheng-pei MIAO, Jian-fei SUN

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 30 October 2013; accepted 16 July 2014

Abstract: Ni-Mn-In-Co microwires with diameter of 30-100 μm are prepared by glass-coated metal filaments (Taylor–Ulitovsky) method. The effects of magnetic field on martensite transformation temperature in the as-prepared and annealed microwires are investigated using a physical property measurement system (PPMS). Magnetocaloric effect (MCE) attributed to field-induced austenite transformation in the as-prepared and annealed microwires is analyzed indirectly from the isothermal magnetization (M-B) curves. The as-prepared microwire has a 7-layer modulated martensite structure (7M) at room temperature. The changes of austenite starting temperature induced by an external magnetic field (ΔAs/ΔB) in the as-prepared and annealed microwires are -1.6 and -4 K/T, respectively. Inverse martensite to austenite transformation exists in annealed microwires when an external magnetic field is applied at temperatures near As. The entropy change (ΔS) obtained in the annealed microwires is 3.0 J/(kg·K), which is much larger than that in the as-prepared microwires 0.5 J/(kg·K). The large entropy change and low price make Ni-Mn-In-Co microwires a potential working material in magnetic refrigeration.

Key words: magnetic shape memory alloys; microwires; martensitic transformation; magnetocaloric effect; magnetization curve

1 Introduction

In recent years, Ni-Mn-X Heusler alloys have attracted particular attention due to their magnetic shape memory and magnetocaloric effects (MCE) [1]. As the temperature decreases, these alloys experience structural transformation from austenite to martensite associated with mutation of magnetization. In addition, martensitic transformation (MT) may occur by an external magnetic field due to the coupling between magnetic and structural ordering. These structural and magnetic transformations are likely to result in various interesting properties, such as magnetocaloric effect (MCE) [1], magnetoresistance [2] and electric polarization [3].

Ni-Mn-In-Co Heusler alloys exhibit a large magnetic field-induced strain (MFIS) of 3% [4] induced by magnetic-field-induced transformation, which are quite useful for sensor and actuator applications. Recent studies also revealed that large MCE can be obtained in Ni-Mn-In-Co alloy [5], which makes it a potential candidate for magnetic refrigerants. In addition, MT temperatures of these alloys are sensitive to composition [5], and thus large magnetic entropy change ΔS can be achieved in a wide temperature range through tuning the composition.

For technological applications, miniaturizing of actuators and sensors requires small size shape memory alloys like particles, wires, ribbons and films [6]. Recently, Ni-Mn-In-Co ribbons [7] and microwires [8] have been successfully fabricated by melt-extraction, during which a small amount of melting alloy was extracted using a rotating wheel and subsequently solidified to form ribbons or microwires. Great attention has also been paid to glass-coated metal filaments fabricated by Taylor–Ulitovsky method since it allows fabricating long, continuous, glass-coated microwires in a large quantity which cannot be achieved by melt-extraction [9]. The glass coating protects inner metallic filament against oxidation and fracture during solidification process after drawing. The rapid cooling rate during Taylor–Ulitovsky process creates microwires with fine granular and mixed amorphous-crystalline microstructure with improved MCE [10]. Glass-coated Ni-Mn-In [11] and Ni-Mn-Ga [12] microwires were successfully fabricated with a peak entropy change of 2.01 and 0.7 J/(kg·K) under 3 T field, respectively. However, both Ni-Mn-In and Ni-Mn-Ga microwires did not show a reversible martensitic transformation at a moderate magnetic field. In the present work, we investigated the MCE in Ni-Mn-In-Co microwires fabricated by Taylor–Ulitovsky method, and a large MCE attributed to inverse martensite to austenite transformation was revealed in the annealed microwires.

2 Experimental

A polycrystalline Ni45Mn37In13Co5 ingot was prepared by arc melting elemental Ni, Mn, In and Co (purity >99.9%) in the argon atmosphere. The ingot was sealed into a glass tube, evacuated and then heated by an acetylene-oxygen flame until the ingot was melted. The melting pool of the ingot heated the glass tube to the glassy state. Then, the softened glass tube was quickly stretched to form the resulting metal filament covered by a layer of glass. The as-prepared glass-coated microwires were annealed at 1023 K for 2 h, and then furnace-cooled to room temperature. Finally, the glass layer was removed in 10% HF solution. The microstructure of the wire was observed under a scanning electron microscope (Hitachi S4700) and the phase was determined by the x-ray diffraction (XRD) using Cu Kα radiation at room temperature. Magnetization versus temperature (M-T) and magnetization versus field (M-B) curves were measured using a physical property measurement system (Quantum Design PPMS-7T).

3 Results and discussion

3.1 Microstructure and magnetic properties of as- prepared microwires

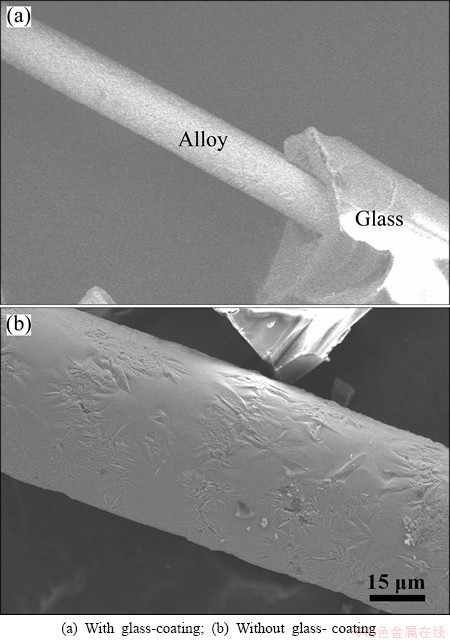

Figure 1 shows the morphology of the as-prepared microwires. Figure 1(a) shows the image of the metallic filament and glass coating. The diameter of the metal microwires is usually 30-100 μm and length about a few millimeters. Figure 1(b) shows a larger magnification micrograph of the metallic filament. Fine equi-axed grains with a size of 3-5 μm can be observed on the surface of the wire, which corresponds to the free solidification area. The other flat areas on the surface are formed due to the contact of glass layer with the solidifying melt. EDS results show that the actual composition of the ingot is Ni44.51Mn36.35In13.93Co5.2 (molar fraction, %), while the composition of as-prepared microwires is Ni45.26Mn36.83In12.82Co5.09, with some Ni, Mn increase and In, Co loss.

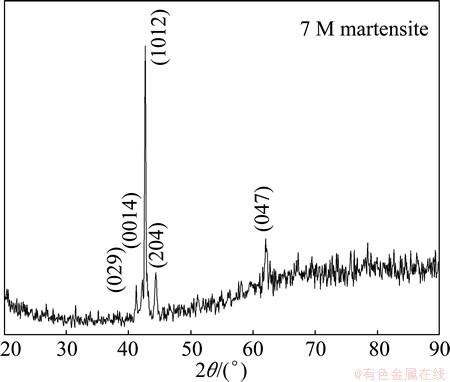

Figure 2 shows the X-ray diffraction (XRD) pattern of the as-prepared microwire at room temperature. The patterns can be indexed as a 7-layer modulated martensitic structure (7 M martensite) with space group I2/m. The same phase has also been found in bulk Ni45Mn37In13Co5 alloys [13].

Fig. 1 SEM micrographs of as-prepared Ni45.26Mn36.83In12.82- Co5.09 microwires

Fig. 2 XRD pattern of as-prepared Ni45.26Mn36.83In12.82Co5.09 microwires at room temperature

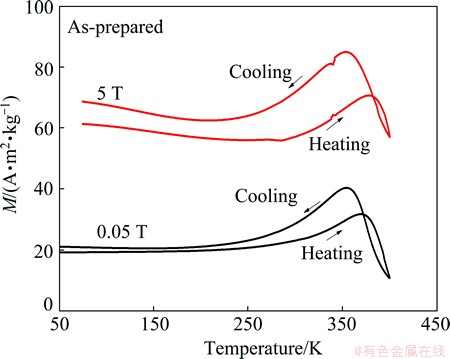

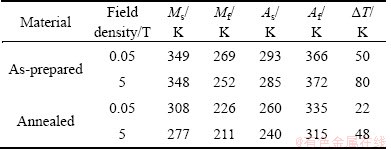

Figure 3 shows the effect of applied magnetic flux density on the magnetization response of as-prepared microwires as a function of temperature. A magnetic flux density of 0.05 T was applied at 50 K (75 K for as-prepared microwire at 5 T) and then the sample was heated to 400 K and cooled again to 50 K. The field density was subsequently increased to 5 T and the heating and cooling cycling of the same sample was repeated. The martensite transformation temperatures are listed in Table 1. It can be seen that M-T curve shifts leftward under a higher field of 5 T, implying austenite stabilization under a high magnetic field. In the cooling process, the austenite phase transforms from paramagnetic state to ferromagnetic state at the Curie point of austenite, accompanied by magnetization increasing during this process. The magnetization decreases below Ms, corresponding to martensite forward transformation to austenite, which is paramagnetic or antiferromagnetic [13], with a much lower magnetization compared to that of austenite phase. As shown in the M-T curves, the martensite starting temperature Ms, martensite finishing temperature Mf, austenite starting temperature As and austenite finishing temperature Af are 349, 269, 293 and 366 K for 0.05 T, respectively. However, under an external magnetic flux density of 5 T, Ms, Mf, As and Af change to 348, 252, 285 and 372 K, respectively. The magnetic field induced shift of As, ΔAs/ΔB, is -1.6 K/T. The decrease of As with increasing magnetic field is attributed to the stabilization of austenite phase which exhibits a higher saturation magnetization than that of martensite. Furthermore, the martensite transformation hysteresis increases from 50 K for 0.05 T, to 80 K for 5 T. This can be attributed to the high frictional resistance during martensitic transformation under low field [14].

Fig. 3 M-T curves of as-prepared Ni45.26Mn36.83In12.82Co5.09 microwires under magnetic flux density of 0.05 and 5 T

3.2 Magnetic properties of annealed microwires

During Taylor-Ulitovsky process, the liquid metal solidifies at a very high speed, which gives rise to an disequilibrium state such as composition inhomogeneity, internal stress and defects. The as-prepared wires were annealed at 1023 K for 2 h, following furnace cooling to room temperature. After annealing heat treatment, the composition of microwires is Ni45.35Mn36.81In12.97Co4.87, which changes little compared with that of the as-prepared microwires.

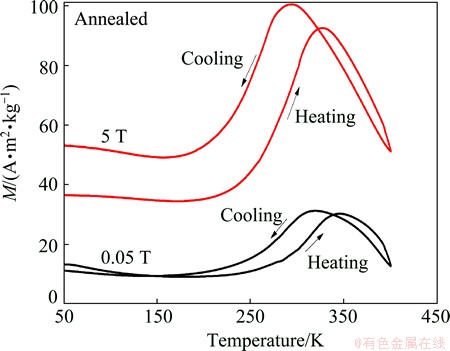

Figure 4 shows the M-T curves of the annealed microwires under magnetic flux density of 0.05 and 5 T. The characteristic transformation temperatures are listed in Table 1. It can be seen that all the transformation temperatures decrease after annealing. The decrease of transformation temperatures as well as hysteresis after annealing is due to the composition homogenization, reduction in defect density and internal stress. The magnetic field-induced shift of As, ΔAs/ΔB, is -4 K/T after annealing. This value (ΔAs/ΔB) is comparable to -4.4 K/T in Ni45Mn37In13Co5 ribbon [13] and -12.6 K/T in Ni45Mn36.5In13.5Co5 single crystal [15]. The larger ΔAs/ΔB change in the annealed microwires implies higher sensitivity of transformation temperature shift, and thus magnetic field induces reverse austenite formation under an external magnetic field, which may result in large MCE. The value of ΔAs/ΔB can be described by the Clausius–Clapeyron equation:

(1)

(1)

where ΔM and ΔS are differences of magnetization and entropy change between martensite and austenite. It can be seen from Fig. 4 that the ΔM in annealed microwires under 0.05 and 5 T is much larger than that in as-prepared wires, which contributes to a large ΔAs/ΔB in microwires after annealing.

Fig. 4 M-T curves of annealed Ni45.35Mn36.81In12.97Co4.87 microwires under magnetic field of 0.05 and 5 T

Table 1 Characteristic transformation temperatures of as- prepared and annealed Ni-Mn-In-Co microwires

3.3 Magnetocaloric effect (MCE) in Ni-Mn-In-Co microwires

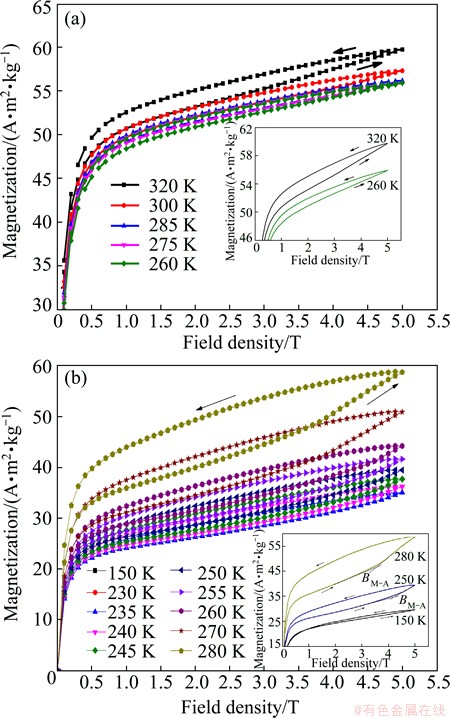

Figure 5 shows the isothermal M-B curves of as-prepared and annealed microwires up to 5 T near the reversible martensitic transformation temperatures. The samples were cooled from room temperature to 50 K, which was much lower than Mf and thus a complete transformation from austenite to martensite was achieved, then the sample was heated to various temperatures, kept at this temperature for 5 min and a M-B plot was recorded. Then, the sample was cooled to 50 K again following heating to a second temperature and another M-B curve was recorded. This process was repeated and finally M-B curves were obtained at 150, 260, 270, 275, 280, 285, 290, 295, 300, 310 and 320 K for the as-prepared microwires, and 150, 230, 235, 240, 245, 250, 255, 260, 270 and 280 K for annealed microwires. For clarity, only a part of M-B hysteresis loops are shown in Fig. 5.

Fig. 5 M-B curves at different temperatures for as-prepared (a) and annealed (b) Ni-Mn-In-Co microwires

From the M-B curves in Fig. 5, it can be seen that the as-prepared as well as the annealed microwires do not reach magnetic saturation up to 5 T at various temperatures. For as-prepared microwires (Fig. 5(a) and the inset), magnetization increases continuously with increasing external field intensity and there is no obvious magnetic field-induced phase transformation. However, for annealed microwires tested at 235-280 K, magnetization increases steadily with increasing field intensity following a sudden increase of magnetization which is a result of field- induced transformation from paramagnetic or antiferromagnetic martensite to ferromagnetic austenite phase. This phase transformation corresponds to a change from weak-magnetic martensite to strong- magnetic austenite phase, which contributes to the increase of magnetization after field-induced phase transformation. As shown in Fig. 5(b) and the inset, the field-induced martensite to austenite phase transformation occurs at a critical field BM-A in curves measured at 250 and 280 K. Similar magnetic field- induced martensite to austenite phase transformation has also been found in NiMnIn [16], NiCoMnIn [4] and NiCoMnSn [17] alloys when an external magnetic field was applied at their martensite state.

The magnetic entropy change ΔS as a function of temperature and magnetic flux density was calculated from magnetization curves in Fig. 5 using the Maxwell relation:

(2)

(2)

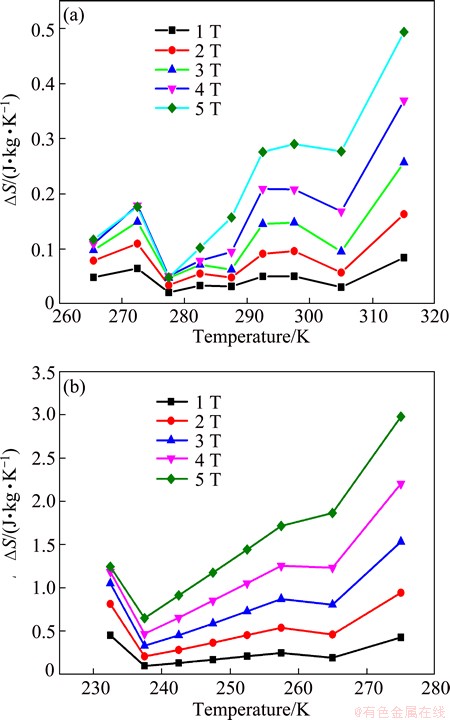

The calculated temperature dependence of ΔS for as-prepared and annealed microwires is given in Figs. 6(a) and (b), respectively. The entropy change ΔS of as-prepared microwire is small at low temperature, then tends to increase with the increase of temperature. In addition, the entropy change increases significantly under high external field. For example, ΔS is 0.5 J/(kg·K) at 315 K under a field of 5 T, which is much higher than that of 0.08 J/(kg·K) at 1 T.

Compared to the as-prepared microwires, the annealed microwires exhibit a much higher entropy change ΔS, as shown in Fig. 6(b). A maximum entropy change of 3.0 J/(kg·K) was realized at 275 K under a magnetic field of 5 T. This improved entropy change is consistent with the M-B results in Fig. 5, in which magnetic field-induced martensite to austenite phase transformation is prone to occur in annealed microwires rather than in the as-prepared state. The occurrence of field-induced phase transformation and thus the improved MCE property is attributed to the composition homogenization, reduction in internal stress and defects after annealing. Furthermore, the Ni45.35Mn36.81In12.97- Co4.87 microwire studied here does not reach its peak entropy change near As temperature, which is different to common magnetic alloys such as Ni-Mn-In-Co ribbons that show their peak ΔS below or near their As point [14]. It is expected that Ni45.35Mn36.81In12.97Co4.87 microwires may have a peak ΔS value at a temperature higher than As. Further research works are required to reveal the phenomena and mechanisms of the entropy change in annealed Ni45.35Mn36.81In12.97Co4.87 microwires at temperatures higher than As.

Fig. 6 Temperature dependence of magnetic entropy change ΔS for as-prepared (a) and annealed (b) Ni-Mn-In-Co microwires in magnetic fields of 1-5 T

4 Conclusions

1) Composition change during Taylor-Ulitovsky process and annealing is only ~1% and thus the composition of the resulting microwires may be tailored.

2) An external magnetic field may induce martensite to austenite phase transformation at temperatures around As in the annealed microwires. The change of As induced by an magnetic field (ΔAs/ΔB) is -4 K/T for annealed microwire and -1.6 K/T for as-prepared microwire.

3) MCE of the microwires is significantly improved after annealing. A large magnetic entropy change ΔS of 3.0 J/(kg·K) is obtained in the annealed microwires, compared to the low ΔS of 0.5 J/(kg·K) in the as-prepared microwires.

References

[1] KRENKE T, DUMAN E, ACET M, WASSERMANN E F, MOYA X, MANOSA L, PLANES A. Inverse magnetocaloric effect in ferromagnetic Ni-Mn-Sn alloys [J]. Nature Materials, 2005, 4: 450-454.

[2] CHERNENKO V A, OHTSUKA M, KOHL M, KHOVAILO V V, TAKAGI T. Transformation behavior of Ni-Mn-Ga thin films [J]. Smart Materials & Structures, 2005, 14(S): s245-s252.

[3] HAMMERSLEY A P, SVENSSON S O, HANFLAND M, FITCH A N, HAUSERMANN D. Two-dimensional detector software: From real detector to idealised image or two-theta scan [J]. High Pressure Research, 1996, 14: 235-248.

[4] KAINUMA R, IMANO Y, ITO W, SUTOU Y, MORITO H, OKAMOTO S, KITAKAMI O, OIKAWA K, FUJITA A, KANOMATA T, ISHIDA K. Magnetic-field-induced shape recovery by reverse phase transformation [J]. Nature, 2006, 439: 957-960.

[5] ITO W, IMANO Y, KAINUMA R, SUTOU Y, OIKAWA K, ISHIDA K. Martensitic and magnetic transformation behaviors in heusler-type nimnln and nicomnln metamagnetic shape memory alloys [J]. Metallurgical and Materials Transactions A—Physical Metallurgy and Materials Science A, 2007, 38: 759-766.

[6] DUNAND D C, MULLNER P. Size effects on magnetic actuation in Ni-Mn-Ga shape-memory alloys [J]. Advanced Materials, 2011, 23: 216-232.

[7] LIU J, WOODCOCK T G, SCHEERBAUM N, GUTFLEISCH O. Influence of annealing on magnetic field-induced structural transformation and magnetocaloric effect in Ni-Mn-In-Co ribbons [J]. Acta Materialia, 2009, 57: 4911-4920.

[8] JI Y Z, NIE Z H, CHEN Z, LIU D M, WANG Y D, WANG G, ZUO L, XING D W, SUN J F. Flexible bamboo-structured nicomnin microfibers with magnetic-field-induced reverse martensite transformation [J]. Metallurgical and Materials Transactions A—Physical Metallurgy and Materials Science A, 2011, 42: 3581-3584.

[9] DONALD I W, METCALFE B L. The preparation, properties and applications of some glass-coated metal filaments prepared by the taylor-wire process [J]. Journal of Materials Science, 1996, 31(5): 1139-1149.

[10] ZHUKOV A, GONZALEZ J, ZHUKOVA V. Magneto resistance in thin wires with granular structure [J]. Journal of Magnetism and Magnetic Materials, 2005, 294: 165-173.

[11] VEGA V, GONZALEZ L, GARCIA J, ROSA W O, SERANTES D, PRIDA V M, BADINI G, VARGA R, SUNOL J J, HERNANDO B. Ni59.0Mn23.5In17.5 Heusler alloy as the core of glass-coated microwires: Magnetic properties and magnetocaloric effect [J]. Journal of Applied Physics, 2012, 112: 033905.

[12] VARGA R, RYBA T, VARGOVA Z, SAKSL K, ZHUKOVA V, ZHUKOV A. Magnetic and structural properties of Ni-Mn-Ga heusler-type microwires [J]. Scripta Materialia, 2011, 65: 703-706.

[13] LIU J, SCHEERBAUM N, HINZ D, GUTFLEISCH O. Magnetostructural transformation in Ni-Mn-In-Co ribbons [J]. Applied Physics Letters, 2008, 92: 162509.

[14] LIU J, SCHEERBAUM N, LYUBINA J, GUTFLEISCH O. Reversibility of magnetostructural transition and associated magnetocaloric effect in Ni-Mn-In-Co [J]. Applied Physics Letters, 2008, 93: 102512.

[15] KARACA H E, KARAMAN I, BASARAN B, REN Y, CHUMLYAKOV Y I, MAIER H J. Magnetic field-induced phase transformation in NiMnColn magnetic shape-memory alloys—A new actuation mechanism with large work output [J]. Advanced Functional Materials, 2009, 19: 983-998.

[16] OIKAWA K, ITO W, IMANO Y, SUTOU Y, KAINUMA R, ISHIDA K, OKAMOTO S, KITAKAMI O, KANOMATA T. Effect of magnetic field on martensitic transition of Ni46Mn41In13 heusler alloy [J]. Applied Physics Letters, 2006, 88: 122507.

[17] KAINUMA R, IMANO Y, ITO W, MORITO H, SUTOU Y, OIKAWA K, FUJITA A, ISHIDA K, OKAMOTO S, KITAKAMI O, KANOMATA T. Magnetic shape memory effect in a Heusler-type Ni43Co7Mn39Sn11 polycrystalline alloy [J]. Applied Physics Letters, 2006, 88: 192513.

泰勒法制备的Ni-Mn-In-Co合金纤维的磁热效应

张学习,苗生沛,孙剑飞

哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001

摘 要:采用泰勒法制备了直径范围在30~100 μm之间的玻璃包裹Ni-Mn-In-Co合金纤维。利用综合物性测量系统(PPMS)研究了磁场对制备态和退火态纤维马氏体相变温度的影响,并且从M-B曲线中分别计算得出了制备态和退火态纤维的磁热效应。研究结果表明:制备态纤维在室温下为7M马氏体结构。在制备态和退火态纤维中,奥氏体相变开始温度随外加磁场变化速率(ΔAs/ΔB)分别为-1.6和-4 K/T。退火态纤维在As点附近发生磁场诱发马氏体向奥氏体逆相变。退火态纤维最大磁熵变为3.0 J/(kg·K),远大于制备态纤维的0.5 J/(kg·K)。Ni-Mn-In-Co合金纤维的大磁熵变和低成本使其成为最具潜力的磁制冷材料之一。

关键词:铁磁形状记忆合金;纤维;马氏体相变;磁热效应;磁化曲线

(Edited by Yun-bin HE)

Foundation item: Project (51001038) supported by the National Natural Science Foundation of China

Corresponding author: Xue-xi ZHANG; Tel: +86-451-86415894; Fax: +86-451-86413921; E-mail: xxzhang@hit.edu.cn

DOI: 10.1016/S1003-6326(14)63454-3