文章编号:1004-0609(2007)07-1025-09

快速凝固镁合金开发原理及研究进展

余 琨,黎文献,王日初,冯 艳,吴志文

(中南大学 材料科学与工程学院,长沙410083)

摘 要:介绍快速凝固镁合金材料研究与开发的物理冶金原理及发展历程。在开发原理中着重介绍快速凝固镁合金的镁基固溶体扩展、新型弥散合金相的形成、晶粒及显微组织细化以及合金钝化等基础理论。在这些研发理论基础上,进一步阐述镁合金雾化快凝、模冷淬火和表面重熔这3种典型的快速凝固制备技术,举例说明了这3种快速凝固技术制备的多种镁合金的各项性能及显微组织特征。综合评价快速凝固技术制备镁合金材料的优势,说明快速凝固技术是开发新型镁合金材料,扩展镁合金在工程材料中应用的重要且具有发展前途的制备技术。

关键词:镁合金;快速凝固;显微组织;力学性能

中图分类号:TG146.2 文献标识码:A

Research theory and development of rapidly solidified magnesium alloy

YU Kun, LI Wen-xian, WANG Ri-chu, FENG Yan, WU Zhi-wen

(School of Materials Science and Engineering, Central South University, Changsha 410083,China)

Abstract: The research theory and development of rapidly solidified magnesium alloy were reviewed. The extension of solid solubility of α(Mg), the formation of new dispersed phases, the grain refinement and corrosion resistance of rapidly solidified magnesium alloy were explained. Three main categories of rapid solidification techniques, such as gas-blast sputtering, chill-block melt-spinning and laser surface melting, were described. The structures and properties of different alloys produced via such three methods were given examples to explain the effects of rapidly solidified techniques on magnesium. The rapid solidification is an important technique that can produce new and high performance magnesium alloys in industry.

Key words: magnesium alloy; rapid solidification; microstructure; mechanical properties

镁及镁合金在平衡或接近平衡的凝固条件下结晶,即常规的铸锭冶金(Ingot metallurgy)技术,是目前大多数镁合金的生产方法[1-2]。采用这种铸造技术制备的镁合金,在性能和组织结构上存在一些缺点。例如镁具有很弱的电负性,在已知的二元常规镁合金中,有2/3的溶质元素在α(Mg)固溶体中的最大固溶度小于1%(摩尔分数),这使镁合金很难通过合金化来提高合金的强度[3];镁还具有很高的化学活性,不能像铝那样可以在腐蚀气氛中形成表面防护膜,因此镁和镁合金很容易被腐蚀特别是电化学腐蚀[3];此外,镁还有很高的自扩散系数,这使镁合金中的沉淀相很容易粗化[4]。因此,用常规铸锭冶金方法生产的镁合金的压缩强度、高温热稳定性、断裂韧性等性能都比较差。快速凝固技术是改善镁合金组织结构,提高镁合金各项性能的重要制备技术。快速凝固技术制备的镁合金组织结构与常规铸锭冶金技术制备的会有很大的区别,包括固溶度的扩展、非平衡结、微观组织结构细化、形成准晶或非晶。利用快速凝固技术可以生产出目前综合性能最好的镁合金材料[5-6]。

快速凝固技术最早是于1950年代应用在镁及镁合金中,当时考虑采用这一新技术是可以扩展镁合金在工程材料中的应用范围。到1960年代,由美国Dow化学公司采用气体雾化技术和旋转冷却盘雾化技术实现镁合金快速凝固技术的开发和商业生产[3, 7]。1970年代以后,在快速凝固镁合金中开展了更多的试验性工作,主要有Allied Signal公司和Pechiney/ Norsk-Hydro公司等开发的模冷法,包括熔体旋铸技术和双辊淬火技术[3]。近年来,日本东北大学Inoue等[8]采用单辊熔体旋铸技术制备的新型快速凝固镁合金,获得目前世界上报道过的屈服强度大于600 MPa的最高强的镁合金。快速凝固技术在镁合金中的应用受到更加广泛的关注和重视,已经开始在遍布欧美的15个研究机构进行研究开发[9]。

1 快速凝固镁合金开发原理

采用快速凝固技术可以改善镁合金各项性能的基本原理在于以下几个方面。

1.1 扩展α(Mg)基固溶体的固溶度

现有数据表明,镁中平衡固溶度大于1%(摩尔分数)的合金元素共有24种,它们有可能与镁组成工程应用的镁合金。采用快速凝固技术,可以使原子半径在±15%范围内的合金元素在α(Mg)基体中的固溶度增加,与平衡凝固相比较,可以在镁中形成有效固溶体,从而使实现合金化的元素数量可以提高一倍以上,对合金元素溶解度的增加有利[10-11]。α(Mg)基体固溶度的扩展可以丰富镁合金的合金体系。

1.2 形成新型合金相及多相弥散体系

采用快速凝固技术制备镁合金,可以形成新的晶态相、准晶相或非晶。快速凝固形成的新型晶态相有很多,典型的有Mg-Sn和Mg-Pb合金中形成的FCC结构的新相。在快速凝固Mg-Si合金中会形成“反-PbCl2结构”的Mg2Si相。在快速凝固Mg-Al合金中,Al在α(Mg)固溶体中分解成新相的过程包括6个放热或吸热的显微组织演变,当α(Mg)中铝的固溶度扩展到22%时,就可能形成至今尚未鉴定的γ′相。 快速凝固还可以在镁合金中形成准晶相,在镁中加入至少10%~20%(摩尔分数)以上的Zn、Cu和Ni等元素,在快速凝固的条件下就会出现5次对称的准晶相。最近,在Mg-Zn-Y合金中也发现了准晶相,该相有很好的强化效果。在快速凝固Mg-Cu、Mg-Ni合金中容易形成非晶,加入第三组元,如Ca,还可以在形成非晶的同时减小合金的密度[12]。

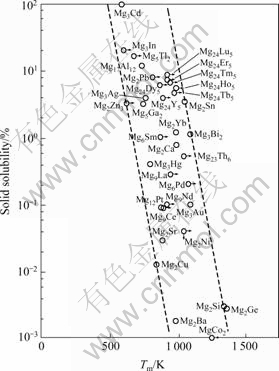

此外,快速凝固的镁合金很容易得到高体积分数的沉淀相或弥散相,这些相多数集中在网胞及晶界或均匀分布在细化的晶粒中。快速凝固镁合金具有尺寸为0.3~0.5 μm的等轴α(Mg)晶粒,并含有尺寸为0.01~0.1 μm的均匀弥散的第二相。小一些的弥散相如Mg2Si、AlxREy等分布在晶内,而较大的如Mg17Al12等相则集中在晶界。这些沉淀相尺寸细小,分布弥散,体积分数高而且热稳定性好,这对提高合金的综合力学性能,尤其是高温下的力学性能十分有利。这些相的热稳定性可以参考图1中第二相熔点及其在镁中固溶度的关系,其中如Mg2Si等相熔点高,在镁中固溶度又低,因此热稳定性高[13]。此外,MgxCe等二元相对控制晶粒长大和提高合金的热稳定性有利,在快速凝固镁合金中都已获得应用。

图1 镁合金中第二相在镁中的固溶度[13]

Fig.1 Solid solution of Mg compounds in matrix[13]

1.3 细化晶粒

常规铸锭冶金工艺生产镁合金的基本目标之一是细化显微组织,以便提高相应镁合金的强度、热稳定性、变形能力及减少显微缩孔。快速凝固技术可以有效细化镁合金的晶粒,减小枝晶网胞尺寸,同时使分布在晶界或网胞上的第二相尺寸一起细化,从而可以减小或消除合金成分偏析。双辊淬火快速凝固技术可以使Mg-Li合金薄片晶粒细化30倍。熔体旋铸法制备的快速凝固Mg-Mn合金网胞的尺寸只有0.4 μm,Mg-Al合金的只有0.1~0.3 μm,Mg-Zn-Al合金的为0.4~1.5 μm[2, 14]。快速凝固细化镁合金晶粒对镁合金综合力学性能的提高十分有利,尤其是在提高镁合金强度的同时可以显著提高合金的塑性和断裂韧性。

根据Hall-Petch关系,晶粒细化后镁合金的屈服强度提高的幅度比铝合金的要大得多。Allied Signal开发的含硅及含稀土的快速凝固Mg-Al-Zn合金的屈服强度数据比Hall-Petch公式计算和测量的数据还要 高[2](见图2),这是因为在这种合金中的硅及稀土形成了钉扎位错及晶界运动的温度稳定的弥散相的缘故。晶粒细化在提高镁合金强度的同时也显著提高了合金的塑性,如具有约1 μm晶粒尺寸的快速凝固AZ91合金在室温下就有超塑性,伸长率超过1 000%[15]。而对于其它的镁合金,其快速凝固后获得细小晶粒的合金的塑性提高幅度都在2倍以上。因此快速凝固是提高镁合金综合力学性能的有效方法。

图2 铸锭冶金及快速凝固镁合金屈服强度与晶粒直径d-1/2的关系[2]

Fig.2 Relationship between yield strength and grain diameter in Mg alloy[2]

1.4 钝化合金

采用快速凝固使镁合金的端际固溶度扩展可以钝化镁合金,提高镁合金的耐腐蚀性能。镁合金中有许多微量杂质,这些杂质元素可能生成微电池性质的活化第二相,是导致镁合金耐蚀性差的主要原因[16]。快速凝固使显微组织细化,也提高了合金的化学均匀性,因此可避免杂质可能带来的有害的以及无法预测的微电池现象。例如,快速凝固Mg-15%Al薄片与铸锭冶金的AZ91合金比较,前者腐蚀速率较后者低1~2个数量级。这种改善是因为快速凝固使镁合金的固溶度提高,α(Mg)基体因含铝而惰性化以及快速凝固使含铁夹杂物细化而使其周围的质子放电速率降低。在应用最广泛的Mg-Al合金中,铸锭冶金工艺制备的Mg-16Al合金的氧化物厚度为100~200 nm,而相应 合金的快速凝固薄片的产物的氧化物厚度仅为 10~50 nm,后者中的铝保留在表层下的α(Mg)固溶体中[17-18]。固溶体的阳极极化效应增加,有更好的耐 蚀性。

2 镁合金快速凝固技术

镁及镁合金快速凝固技术主要可以分为3种,第一种是采用雾化喷射获得快速凝固合金粉末或薄片技术,也包括喷射成形技术;第二种是采用连续急冷模冷铸造技术,如熔体旋铸技术或将熔体细流通过旋转的急冷盘上甩出获得连续薄带的平面流技术;第三种是在已有的镁合金材料表面进行的原位快凝技术,如采用激光重熔技术获得快速凝固组织的表面层。这3种技术中前两种是镁合金快速凝固技术发展的重点,第三种是针对镁合金表面的处理技术,对改变镁合金材料的表面性质及提高抗腐蚀能力十分有效[9, 19-20]。

2.1 镁合金雾化快速凝固技术

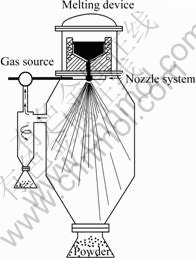

镁合金快速凝固雾化技术采用加速的惰性气体(氩气、氦气或其混合气体)从喷嘴中喷出破碎金属液流,使金属液流破碎成细小的粉末颗粒从而获得很快的冷却速度而凝固。雾化后的金属粉末可以在随后的工序中进行回收。雾化技术制备快速凝固镁合金的关键在于气体的喷嘴及其喷射控制装置来控制冷却速度。一般雾化技术的冷却速度介于铸锭冶金(IM)工艺和熔体旋铸技术之间。目前雾化技术主要采用Laval喷嘴来获得超音速的高压气流,实现对液流的破碎从而提高冷却速度。该工艺的示意图见图3,获得快速凝固镁合金粉末后再采用粉末冶金的工艺来进一步加工。

喷射成形技术是从雾化快冷技术中发展出来的。将熔化的镁合金液流在惰性气体中雾化形成颗粒,然后喷射到较冷的基体上形成沉积物。在这种工艺条件下,可以制备板、管、圆锭等旋转对称形状的产品。

图3 雾化快速凝固技术示意图[9]

Fig.3 Schematic view of gas sputtering Mg alloy[9]

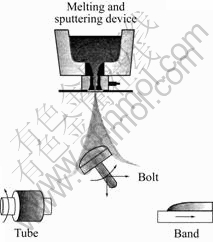

图4所示为该工艺的示意图。喷射成形工艺可以获得103~104 K/s的冷却速度,是一种介于铸锭冶金和粉末冶金之间的工艺技术。喷射成形技术比其它快速凝固技术制备镁合金所需要的生产周期短,生产工序简单,生产效率高。与普通铸锭冶金工艺比较,喷射成形镁合金的冷却速度高,晶粒细小,力学性能显著提高,同时兼备铸锭冶金和粉末冶金两种工艺的优点并且克服了各自的主要缺点。采用雾化快冷技术提高镁合金的冷却速度,如可以使Al在Mg中的平衡溶解度从11.8%提高到22%,使Mn在Mg中的溶解度提高2.5倍达到2.5%(摩尔分数),可以在Mg-Sn合金中形成亚稳的FCC结构相,在Mg-Ni和Mg-Cu合金中形成金属玻璃。雾化快冷技术制备的镁合金的断裂韧性可以

图4 喷射成形镁合金工艺示意图[9]

Fig.4 Schematic view of spray-forming Mg alloy[9]

得到大幅度改善,综合力学性能得到提高,而且材料的耐腐蚀性能提高。因此,该技术是镁合金快速凝固技术中重要的一种制备技术。

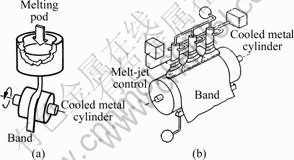

2.2 镁合金模冷快速凝固技术

镁合金模冷快速凝固技术是在镁合金雾化技术之后开发的另一类镁合金快速凝固技术。将熔融的镁合金液流引导到不断被冷却的金属表面上,从而导致镁合金的快速凝固(见图5)。该方法可以生产宽度达50 mm的薄带,冷却速度可以达到约106 K/s。这种工艺最常见的是熔体旋铸技术(Melt-spinning)(图5(a))。根据这一技术发展起来的平面流(Planar flow cast- process)工艺中(图5(b)),采用一矩形状孔作为紧靠快速旋转冷却辊正上方的铸造喷嘴。在保护罩下,用惰性气流使旋转冷却轮上的金属熔池形状稳定,从而获得宽度比熔体旋铸方法的产品更宽的薄片,这种技术可以获得长达数米,宽度为300 mm,厚度为30 μm的薄带[9]。

图5 熔体旋铸和平面流快速凝固技术示意图[9]

Fig.5 Schematic view of melt-spin process(a) and planar flow cast process(b)

大量的研究工作表明,采用熔体旋铸技术或平面流技术可以开发许多新型快速凝固镁合金。如新型的“简单”的Mg-Zn金属玻璃和具有独特原子、电子结构和物理性质的Mg-Cu金属玻璃。而且,该方法还可以生产出具有优异性能的镁合金工程用结构材料,如日本报道的目前工程上屈服强度最高的镁合金结构材料就是采用单辊的熔体旋铸技术制备的[21-24]。

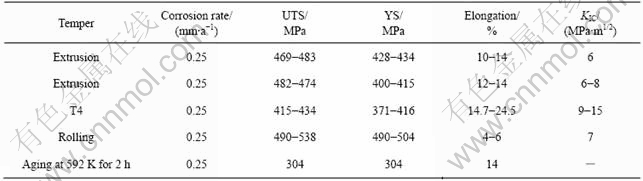

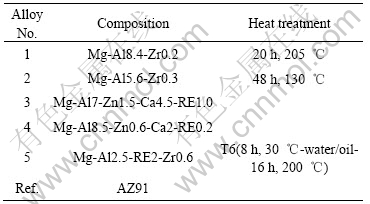

Allied Signal公司开发的专利平面流铸造工艺制备的EA55RS合金的性能见表1[25-26]。

2.3 镁合金表面重熔快速凝固技术

镁合金重熔快凝技术是从1980年代新发展起来的镁合金快凝技术,它主要采用激光等大能量输入技术使镁合金表面层迅速熔化,然后又由于金属基底的传热使其迅速凝固,获得表面层很薄的一层快速凝固组织,该层可以对镁合金起到表面改性的作用。如Kattamis采用激光和电子束表面熔化技术改变了高强变形镁合金ZK60的表面从而提高其抗磨损能力和抗腐蚀性能。Kalimullin等采用激光熔覆技术对Mg-Li合金进行表面改性,提高了Mg-Li合金的耐腐蚀性能[27]。

3 快速凝固镁合金的性能

与常规铸锭冶金工艺制备的镁合金及现有的铝合金相比较,快速凝固镁合金性能的提高主要包括[2, 15]如下几个方面。

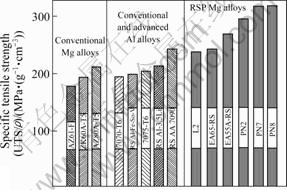

1) 快速凝固镁合金的室温极限抗拉强度超过常规铸锭工艺镁合金及最强铝合金之比极限抗拉强度40%~60%,压缩屈服强度-拉伸屈服强度比值(CYS/TYS)由0.7增加到1.1以上。

2) 快速凝固镁合金的比屈服强度(TYS/ρ)超过铸锭工艺镁及铝合金的相应值,拉伸时超过52%~98%,压缩时则超过45%~230%。

3) 快速凝固镁合金的断裂伸长率在5%~15%之间,随后的变形热处理可使其达到22%,高于铸锭工艺镁合金。在100 ℃以上的温度下具有优良的塑性变形行为或超塑性,并且由于明显的晶粒细化,其疲劳抗力为铸锭冶金镁合金的两倍。

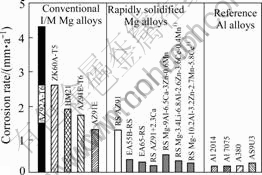

4) 快速凝固镁合金的大气腐蚀行为处于新型高纯常规铸锭镁合金AZ91E及WE43和抗蚀铝合金2014-T6的范围,相应的腐蚀速率比一般的镁合金小两个数量级。

5) 快速凝固镁合金与SiCp等增强剂的相容性已得到验证,因而快速凝固镁合金可作为镁基复合材料的基体。

3.1 雾化技术制备的快速凝固镁合金的主要性能

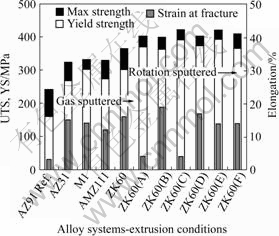

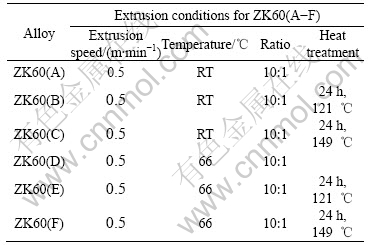

Issrrow和Rizzitano针对ZK60合金采用旋转圆盘制粉快凝技术研究了不同挤压条件和热处理工艺的影响,和铸锭冶金法生产的合金比较,其强度提高了50%(见图6)[28]。Kainer对QE22、ZC63和AZ91合金快凝粉末进行了研究,与铸锭冶金同类合金比较,这些合金气体雾化挤压态强度提高40%~300%。快凝AZ91合金的主要改善表现在时效效应上,该合金经175 ℃、3 h时效后,挤压态最大UTS值为400 MPa,而最大TYS值为350 MPa。这些合金性能的提高是因为细小弥散的金属间化合物及氧化物阻碍了合金在350℃等高温下挤压时的再结晶[29]。

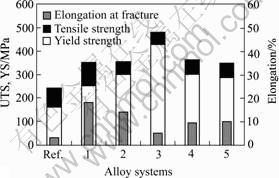

喷射成形技术是雾化法制备快速凝固镁合金的新型工艺技术及最有前途的新技术,它不仅可以用来制备镁合金,还可以用来制备镁基复合材料。与常规铸锭工艺比较,喷射成形镁合金材料的断裂韧性KIC有较大改善,同时其它力学性能(强度、塑性)和电化学性能亦有相当大的提高。研究表明(见图7),与压铸的AZ91合金比较,喷射成形镁合金的力学性能有显著的改善[2, 30]。而喷射成形的镁合金QE22与相应的铸锭冶金镁合金比较,强度提高40%,延展性从3%增加到10%,耐蚀性提高1/3[2]。

Faure等[31]研究了新型的喷射沉积Mg-7Al-4.5Ca- 1.5Zn-1.0RE合金,其抗拉强度和屈服强度分别为480和435MPa,伸长率为5%;另一种Mg-8.5Al-2Ca- 0.6Zn-0.2Mn合金,其抗拉强度和屈服强度分别为365和305 MPa,伸长率为9.5%。这两种合金的断裂韧性分别为30 MPa?m1/2及35 MPa?m1/2,均优于铸锭冶金工艺生产的AZ80及由熔体旋铸薄带制得的RSAZ91+2Ca。相应的显微组织由尺寸为3~25 μm的晶粒及优先于晶界沉淀的Mg17Al12、Al2Ca、MgRE及AlRE相组成。

表1 EA55RS合金产品及其力学性能

Table 1 Mechanical properties of EA55RS alloy

图6 快速凝固挤压态镁合金的室温力学性能[9]

Fig.6 Room temperature properties of RS Mg after extrusion[9]

图7 喷射成形镁合金与压铸AZ91合金力学性能的比较[9]

Fig.7 Mechanical property comparison of spray formed Mg alloy with AZ91 Mg alloy[9]

Elias等[32]采用原位喷射沉积合金化工艺将铝粉、Al-40%Si合金粉加入到两种含Mn的镁合金中,光学显微镜和电子显微镜下都发现有Mg17Al12或Mg2Si相沉淀相。这些金属间化合物是在喷射成形固结过程中加入的颗粒溶解到基体中然后再析出的。DSC检测发现还有Mg-Al-Si共晶存在,这为喷射成形制备沉淀强化镁合金提供了思路,并可以在其它合金系中进一步开发沉淀强化镁合金。

Kainer等[9]研究了WE54、AS21、AS21Ca等一系列喷射成形镁合金。其中喷射成形WE54合金的最小晶粒尺寸约10 μm,最大仅30 μm,平均晶粒尺寸20 μm。在喷射成形镁合金中有非常细小的析出相,如Mg-Al-Ca合金中有MgO、Al2Ca、Mg17Al12等相存在,在含Nd镁合金中有Mg12Nd相存在。在含Si的镁合金中,经过喷射成形后,汉字状的粗大Mg2Si相完全消失,成为细小弥散相,起到变质效果,这有利于提高合金的性能(见图8)。

3.2 模冷淬火技术制备的快速凝固镁合金的主要性能

熔体旋铸法是制备快速凝固金属材料的重要制备技术,在镁合金中应用可以提高镁合金的室温和高温力学性能,提高镁合金的耐腐蚀能力。该工艺生产的快速凝固镁合金强化机制主要包括晶粒细化、锌在α(Mg)固溶体中的强化以及一种Mg-Zn基弥散相的强

图8 铸锭冶金法(a)和喷射成形法(b)制备的AS21合金显微组织比较

Fig.8 Microstructure comparison of IM(a) and spray formed(b) AS21 alloy

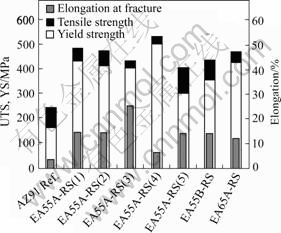

化,其中在室温下主要是Mg17Al12、Mg2Zn在α(Mg)固溶体中的固溶强化。根据添加的第四或第五组元的不同,如添加Si或是稀土元素,该EA/RS系列合金的性质也会不同,添加Si主要形成如Mg2Si等弥散相,添加稀土Y或Nd后会有Al2Y、Al2Nd等弥散相导致附加的弥散硬化,对合金的室温强度和高温强度都有好处。添加稀土元素后的腐蚀速率仅为0.2~0.4 mm/a。图9给出了Allied Signal公司开发的EA系列快速凝固镁合金的主要力学性能[33-34]。

与铝合金相比较,这些快速凝固EA系列镁合金具有更高的比强度(图10),并且它们强度和延展性的综合性能优于最好的铸锭冶金镁合金。其中EA55A合金的力学性能有大幅度的提高,成为已报道的性能最佳的镁合金型材。室温下EA55RS挤压制品的代表性强度值处于343 MPa(拉伸屈服强度)、384 MPa(压缩屈服强度)及423 MPa(极限抗拉强度)之间,此时伸长率为13%。而腐蚀速率大约为0.25 mm/a,与Al合金2024-T6相当,次于A1合金7075[35]。

图9 EA系列合金的力学性能

Fig.9 Mechanical properties of EA alloy

图10 快速凝固EA系列镁合金的比强度[2]

Fig.10 Specific strength of RS EA alloy[2]

Pechiney及Norsk Hydro的European Collaboration采用熔体旋铸和平面流铸造法也制备出了快速凝固镁合金。与Allied的快速凝固镁合金比较,该工艺用AZ91合金为基体,加入硅和混合稀土(MM)、钙和锶,但铝含量较高,为5%~9%,而锌含量降低至0~3%。将快速凝固技术用于制备AZ91合金时,新合金具有1.5~5 μm的细晶粒,并且可以生成温度稳定的AlaXb弥散相(X=RE,Ca,Sr)。不添加Ca时,已细化的多相显微组织在200℃的温度下暴露24 h不出现粗化;加入Ca后可在350 ℃温度下暴露24 h[36]。

快速凝固技术可使AZ91合金的屈服强度由226 MPa增至475 MPa,提高106%;抗拉强度由313 MPa增至517 MPa,提高65%,伸长率为8.7%~20.1%。挤压后的新型快速凝固Mg-9Al-6.5Ca-3Zn-0.6Mn合金具有特别高的强度值,抗拉强度为575 MPa,拉伸屈服强度为542 MPa,伸长率为4.6%。挤压的快速凝固Mg-5Al-2.5Ca-3Sr合金棒,抗拉强度为562 MPa,拉伸屈服强度为545 MPa,伸长率3.3%。这些新型快速凝固镁合金的腐蚀速率为0.2~0.6 mm/a,而快速凝固AZ91合金则为0.8 mm/a,可以认为与A380铝合金的耐蚀性相近(图11)[37]。加入2%Ca使快速凝固AZ91E合金T6状态的腐蚀速率由0.8降低到0.2 mm/a,是已报道的工程镁合金之最低腐蚀速率,合金的延展性为9.6%。

图11 快速凝固镁合金的耐腐蚀性能[2]

Fig.11 Corrosion resistance of RS Mg alloy[2]

快速凝固Mg-Al-Zn基合金具有的显微组织使得其超塑成形速率可明显高于其它轻合金。例如,挤压态的EA55B-RS及EA65A-RS合金在150 ℃、应变速率大于1×10-3 s-1时,断裂伸长率在190%~220%,因而有可能锻造极为复杂的零件而不发生裂纹。在高于100 ℃温度下,EA55B-RS的应变速率敏感性急剧增加,在275~300℃间,采用的应变速率不小于0.1s-1时,断裂伸长率为376%~436%。EA55B-RS板材超塑成形的理想温度是300℃,用EA55B-RS板的超塑成形可制造复杂形状零件,在加工时,未发现晶粒粗化现象[38]。

4 结论

快速凝固镁合金的研究只是刚刚起步,显现出其它工艺制备的材料所无法替代的许多优良性能,是未来轻质高强镁合金材料发展的重要方向。但要使快速凝固镁合金真正成为一种结构材料投入实际的应用,还有很多重要的理论和实验工作要做,特别是在不明显增加合金密度的条件下通过合金化进一步提高合金的室温和高温下的强度、耐疲劳性能和耐腐蚀性能。可以认为,快速凝固技术是开发新型镁合金材料,扩展镁合金在工程材料中应用的重要且具有发展前途的制备技术。

REFERENCES

[1] ASM International. Magnesium and magnesium alloy[M]. Ohio: Metal Park, 1999: 1-130.

[2] Cahn R W. Microstructures and properties of non-ferrous alloy [M]. Beijing: Science Press, 1999: 460-480.

[3] Polmear I J. Magnesium alloys and applications[J]. Mater Sci Technol, 1994, 10: 1-16.

[4] Polmear I J. Light alloy: Metallurgy of light metals[M]. London: Edward Arnold, 1989: 340-467.

[5] 吉泽升. 日本镁合金研究进展及新技术[J]. 中国有色金属学报,2004,14(12):1977-1984.

JI Ze-sheng. Research process and new technology of magnesium alloy in Japan[J]. The Chinese Journal of Nonferrous Metals, 2004,14(2): 1977-1984.

[6] Ashbrook R L. Rapid solidification technology[M]. Ohio: Metal Park, 1983: 28-134.

[7] Chisholm D S, Dow Chemical Co. Atomozing magnesium and its alloy: US, 2676359[P]. 1954.

[8] Kawamara Y, Hayashi K, Inoue A. Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa[J]. Mater Trans JIM, 2001, 42(7): 1172-1176.

[9] Kainer K U. Magnesium alloys and technology[M]. Weinheim: GKSS Research Center Geesthacht GmbH, 2003: 164-183.

[10] Michael M A, Baker H. Magnesium and magnesium alloys[M]. Ohio: Metal Park, 1999: 8-11.

[11] Okamoto H. Phase diagrams for binary alloys[M]. Ohio: ASM International Metal Park, 2000: 79-134.

[12] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2005: 174-215.

LI Wen-xian. Magnesium and magnesium alloy[M]. Changsha: Central South University Press, 2005: 174-215.

[13] Hehmann F, Jones H. Rapidly solidified alloys and their mechanical and magnetic properties[M]. Pittsburgh, 1986: 259-275.

[14] Burke J, Weiss W. 超细晶粒金属[M]. 北京: 国防工业出版社, 1982: 112-116.

Burke J, Weiss W. Ultrafine grain metals[M]. Beijing: National Defense Industry Press, 1982: 112-116.

[15] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金研究、进展及应用[J]. 中国有色金属学报, 2003, 13(2); 277-287.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-287.

[16] 余 刚, 刘跃龙, 李 瑛, 叶立元, 郭小华, 赵 亮. 镁合金的腐蚀与防护[J]. 中国有色金属学报, 2002, 12(6): 1087-1098.

YU Gang, LIU Yue-long, LI Yin, YE Li-yuan, GUO Xiao-hua, ZHAO Liang. Corrosion and protection of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1087-1098.

[17] Song G, Atrens A. Corrosion mechanisms of magnesium alloys[J]. Advanced Engineering Materials, 1999, 1(1): 11-33.

[18] Rudd A L, Breslin C B, Mansfeld F. The corrosion protection afforded by rare earth conversion coatings applied to magnesium[J]. Corr Sci, 2000, 42(2): 275-288.

[19] Sugamata M, Hanawa S, Kaneko J. Structures and mechanical properties of rapidly solidified Mg-Y based alloys[J]. Mater Sci Eng A, 1997, 226/228: 861-866.

[20] Yamamoto A, Watanabe A, Sugahara K. In situ laser microscopy on corrosion in deposition coated magnesium alloy[J]. Mater Tran JIM, 2001, 42(7): 1243-1248.

[21] Inoue A, Nakamura T, Nishiyama N. Mg-Cu-Y bulk amorphous-alloys with high-tensile strength produced by a high-pressure die-casting method[J]. Mater Trans JIM, 1992, 33(10): 937-945.

[22] Amiya K, Inoue A. Thermal stability and mechanical properties of Mg-Y-Cu-M bulk amorphous alloys[J]. Mater Tran JIM, 2000, 41(11): 1460-1462.

[23] Kojima Y. Project of platform science and technology for advanced magnesium alloys[J]. Mater Trans JIM, 2001, 42(7): 1154-1159.

[24] Jung H C, Shin K S. Processing and characterization of magnesium alloy[J]. Mater Sci Forum, 2005, 488/489: 401-404.

[25] Spigarelli S, Cerri E, Evangelista E. Interpretation of constant-load and constant-stress creep behavior of a magnesium alloy produced by rapid solidification[J]. Mater Sci Eng A, 1998, A254: 90-98.

[26] Govind G, Suseelan N K, Mittal M C. Development of rapidly solidified (RS) magnesium aluminium zinc alloy[J]. Mater Sci Eng A, 2001, A304/306: 520-523.

[27] Haferkamp H, Boehm R, Holzkamp U. Alloy development, processing and applications in magnesium lithium alloys[J]. Mater Trans JIM, 2001, 42(7): 1160-1166.

[28] Isserow S, Rizzitano F J. Investigation of microquenched Mg ZK60A alloy[J]. Int J Powder Metallurgy, 1974, 19: 217-227.

[29] Kainer K U. Properties of consolidated magnesium alloy powder[J]. Metall Powder Report, 1990, 45: 684-687.

[30] Laverina E J, Grant N J. Spray deposition of metals: A review[J]. Mate Sci Eng A, 1988, A98: 381-390.

[31] Faure J F, Nussbaum G. Process for obtaining magnesium alloys by Spray deposition: US, 5073207 [P]. 1991.

[32] Elias L G, Duszczyk J. In-situ alloying of high temperature Mg alloys by spray forming technology[C]//Magnesium alloy and their application. Sgesellschaft: DGM Information, 1992: 343-349.

[33] Das S K, Chang C F. High strength magnesium alloys by rapid solidification processing[C]//Rapidly solidified crystalline alloys. Warrendale: The Metallurgy Society, 1985: 137-156.

[34] Das S K, Chang C F. Rapidly solidified Mg-Al-Zn-Rare earth alloys[C]//Rapidly Solidified Materials. Ohio: ASM Metal Park, 1986: 129-135.

[35] Das S K, Chang C F. Rapidly solidified high strength corrosion resistant magnesium base metal alloys: US, 4765954[P]. 1988.

[36] Das S K, Davis L A. High performance aerospace alloys via rapid solidification processing[J]. Mater Sci Eng, 1988, 98: 8-12.

[37] Krishnamurthy S. Development of light alloys by rapid solidification processing[J]. Int J Powder Metallurgy, 1990, 26: 117-129.

[38] Li Y, Jones H. Structure and mechanical properties of rapidly solidified magnesium based Mg-Al-Zn-RE alloys consolidated by extrusion[J]. Mater Sci Technol, 1996, 12: 981-989.

(编辑 袁赛前)

收稿日期:2006-04-24;修订日期:2006-06-07

通讯作者:余 琨,副教授,博士;电话:0731-8879341;传真:0731-8876692; E-mail: kunyu2001@163.com