Preparation of semi-solid slurry containing fine and globular particles for wrought aluminum alloy 2024

GUO Hong-min(郭洪民)1, YANG Xiang-jie(杨湘杰)2

1. School of Materials Science and Engineering, Nanchang University, Nanchang 330047, China;

2. School of Mechanical and Electronic Engineering, Nanchang University, Nanchang 330047, China

Received 9 November 2006; accepted 8 May 2007

Abstract: The semi-solid slurry of wrought aluminum alloy 2024 was prepared by a well developed rheocasting process, low superheat pouring with shearing field(LSPSF). The appreciate combination of pouring temperature and rotation speed of barrel, can give rise to a transition of the growth morphology of primary α(Al) from coarse-dendritic to coarse-particle-like and further to fine-globular. The combined effects of both localized rapid cooling and vigorous mixing during the initial stage of solidification can enhance wall nucleation and nuclei survival, which leads to the formation of fine-globular primary α(Al). By using semi-solid slurry prepared by LSPSF, direct squeeze cast cup-shaped component with improved mechanical properties such as yield strength of 198 MPa, ultimate tensile strength of 306 MPa and elongation of 10.4%, can be obtained.

Key words: semi-solid metal processing; wrought aluminum alloy; solidification; microstructure; mechanical property

1 Introduction

Wrought aluminum alloys have wide variety applications in aerospace and automobile industries, due to their superior properties compared with casting aluminum alloys[1]. Up to now, the most popular processes used to manufacture wrought aluminum alloys are methods that introduce plastic deformation, such as forging, extrusion or rolling, which significantly add the cost of manufactured components. Invariably, it has economical advantage to cast wrought aluminum alloys directly into components. The biggest problems in casting these alloys are their high tendency to form hot tearing and worse fluidity in the conventional casting processes[1]. One approach for the near-net- shape casting of wrought aluminum alloys is the application of semi-solid metal processing such as thixoforming and rheoforming[2]. The focus of current investigations on wrought aluminum alloys is mainly given to thixoforming[2-9]. However, the rheoforming technique principally has a greater potential concerning energy consumption and cost reduction compared with the thixoforming technique due to the shorter process chain, in which a liquid alloy is transformed into semi-solid slurry and followed directly by component shaping and eliminating the high cost of special produced feedstock [10-12]. During rheoforming technique, the preparation of semi-solid slurry with spherical primary grains plays a very important role, because it is the most important factor to achieve the cost effectively and make rheoforming commercialized in industry application. At present, there are many rheocasting methods for preparing semi-solid slurry, such as electromagnetic stirring, new rheocasting (NRCTM) process, twin-screw process, semi-solid rheocasting(SSRTM) process, continuous rheoconvection process(RCP), the sub- liquidus casting(SLC) and near liquidus casting process. However, only the electromagnetic stirring and NRCTM processes have successfully been used for exploiting the potential of rheoforming, other processes are still in development now[11-16]. As a result, creating simpler and more economical methods for preparing sound semi-solid slurry should be solved. Moreover, the focus of current researches on rheoforming is mainly on casting alloys such as A356, A357 and AZ91D, but wrought aluminum alloys have not yet been applied to the process.

In the present study, sound semi-solid slurry of wrought aluminum alloy 2024 was prepared using a well developed rheocasting process, termed low superheat pouring with shear field(LSPSF). The microstructure evolution under different processing parameters was investigated. Moreover, some primary results of rheoforming with the combination of LSPSF and direct squeeze casting were also presented.

2 Experimental

The experimental alloy used is a commercial wrought aluminum alloy 2024, which has a wide solidification range with solidus and liquidus from 503 to 638 ℃. Its nominal chemical compositions are Cu 4.4, Mg 1.6, Si 0.3, Fe 0.4, Mn 0.6, Cr 0.1, Zn 0.2 (mass fraction, %), and balance Al. The material is supplied in the form of extruded rods of 69 mm in diameter.

Fig.1 shows a schematic diagram of the LSPSF process. The LSPSF machine consists of a rotational barrel, a cooling-heating element and a slurry holder. The barrel made of stainless steel, the core of the equipment, is specially designed with the characteristics of adjustable rotation speed, which provides localized rapid cooling and forced mixing during the initial stage of solidification. The slurry holder, a graphite mold with an inner diameter of 80 mm and a height of 225 mm, sitting just below the outlet of the rotational barrel, can be preheated to the suitable temperature for adjusting the cooling rate and the solid fraction of semi-solid slurry. In LSPSF process, the molten alloy with a predetermined superheat was poured into the rotational barrel through the feeder attached to the inlet of the rotational barrel. The fed liquid alloy was rapidly cooled and mixed through the rotation of barrel, decreasing the melt temperature slightly below its liquidus. Then the melt with numerous nuclei flowed into the slurry holder in which the melt was cooled slowly (in a quiescent state) to achieve the required solid fraction.

Fig.1 Schematic illustration of laboratory scale LSPSF slurry maker

The alloy 2024 was first melted in an electric furnace and then fined. The liquid alloy was eventually poured at 660-700 ℃ into the feeder. During pouring, the rotation speed of barrel was set as 0-120 r/min. The temperature of rotational barrel inclined at 20? to the horizontal was balanced at 450 ℃ by the heating-cooling element, and the temperature of slurry holder was kept at (620±1) ℃ to utilize a slower cooling. After filling, the slurry holder was cooled with air. As the temperature of slurry held in the slurry holder reached 628 ℃, the metallographic samples were taken by sucking a small amount of semi-solid slurry each time into a quartz tube and then quenched in a water pool. Generally, a total cycle time for producing 1.5 kg semi- solid slurry is around 25 s, including about 3-4 s for the melt to flow through the barrel, and about 22 s for microstructure evolution in the slurry holder.

In order to demonstrate advantages of LSPSF process, the direct squeeze casting test for cup-shaped part of wrought aluminum alloy 2024 was carried out to compare the differences of microstructures and mechanical properties with semi-solid slurry and full liquid alloy. During direct squeeze casting, the pouring temperature in semi-solid slurry-making stage is 670 ℃, the processing temperature of full liquid alloy is 700 ℃, the lower die and the plunger are both preheated to about 300 ℃, a typical hot forging lubricant is used on the tool surfaces to facilitate the ejection of the part, the applied pressure is 90 MPa and the compression holding time is about 20 s, the punching speed is 200 mm/s.

The samples for microstructure observation were taken from the water-quenched and squeeze cast materials. A closer description of microstructure can be given by the grain diameter D=2(A/π)1/2 and shape factor F=4πA/P2, where A and P are average area and average perimeter of primary phase, respectively.

3 Results and discussion 3.1 Microstructures of rheocast wrought alloy 2024 by LSPSF

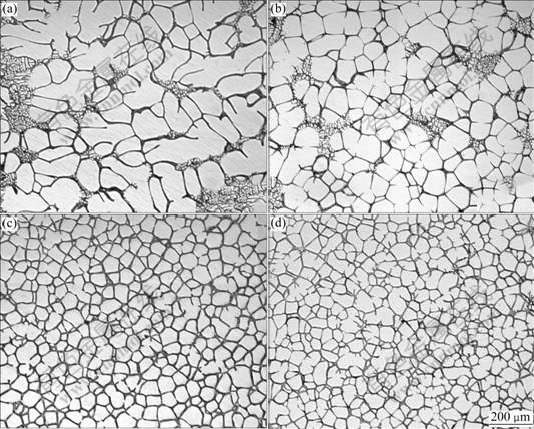

Fig.2 shows the semi-solid microstructures of alloy 2024 rheocast under the same rotation speed of barrel (90 r/min) but the different pouring temperatures. When the pouring temperature is or over 700 ℃, the primary α(Al) presents an appearance of well-developed dendrite with strong secondary arms, as shown in Fig.2(a). When the pouring temperature is 690 ℃, the microstructure consists of coarse particle shaped α(Al) with an average equivalent diameter of 118 μm, as shown in Fig.2(b). With performing the process with lower pouring temperature of 680 ℃, the microstructure takes a further improvement. The primary α(Al) grains are mainly globular, refined obviously and distributed homogeneously, as shown in Fig.2(c). With further decreasing pouring temperature, it is interesting to note that the grain size and morphology of primary α(Al) rheocast at a pouring temperature of 660 ℃, appear to be almost similar to those poured at 680 ℃, as shown in Figs.2(c) and (d). The primary α(Al) has an equivalent diameter of 73 μm and a mean shape factor of 0.79 in pouring temperature range of 660-680 ℃. Under the current experimental conditions as shown in Fig.2, it is found that the primary α(Al) rheocast by LSPSF tends to be fine, globular and distributed homogenously, while the superheat of poured melt alloy is decreased, and that the optimum pouring temperature range is 660-680 ℃.

Fig.2 Optical microstructures rheocast under different pouring temperatures (rotation speed of barrel is 90 r/min): (a) 700 ℃; (b) 690 ℃; (c) 680 ℃; (d) 660 ℃

Rotation speed of barrel is another very important parameter in LSPSF process. The typical microstructures of alloy 2024 produced at a pouring temperature of 660 ℃ for various rotation speeds of barrel, are presented in Figs.3(a) and (c). As expected, with increasing the rotation speed of barrel, fine and globular shaped primary α(Al) grains are formed. With decreasing the rotation speed of barrel, however, the morphology of grains change from fine-globular to coarse-particle-like and further to coarse-dendritic. It also reveals that the characteristics of microstructure rheocast at rotation speeds within 90-120 r/min are almost the same as shown in Fig.2(d) and Fig.3(c), in which the primary α(Al) presents in equivalent diameter of 70 μm and shape factor of 0.80. Moreover the effect of rotation speed of barrel on the microstructure poured at 680 ℃ is also similar to the above as shown in Fig.2(c) and Fig.3(d). Therefore, at the given pouring temperatures of 660-680 ℃, it dose not need to further increase the rotation speed of barrel and 90 r/min is enough to obtain the spherical primary α(Al) grains in the semi-solid slurry of alloy 2024.

Fig.3 Optical microstructures rheocast: (a) Pouring temperature 660 ℃ and rotation speed 0 r/min; (b) Pouring temperature 660 ℃ and rotation speed 60 r/min; (c) Pouring temperature 660 ℃ and rotation speed 120 r/min; (d) Pouring temperature 680 ℃ and rotation speed 120 r/min

The experimental results show that the appreciable combination of pouring temperature and rotation speed of barrel can result in substantial grain refinement, indicating that an increase in the nucleation rate, consequently, can improve the grain morphology. The essential metallurgical feature of LSPSF process is to control solidification conditions to maximize grain density in the melt and promote grain growth in a spherical type. The rotation of barrel can result in a large and ever-renewing surface area between the melt and the barrel wall, which, together with a lower pouring temperature is ideal for enhancing nucleation and nuclei survival. According to the wall mechanisms[17-18], when the liquid flows over the barrel, the nucleation takes place on or near the barrel wall. Under the vigorous mixing action offered by the barrel rotation, which exerts ![]()

![]() a great force on the nuclei growing along the barrel wall, the nuclei can be easily separated from the barrel wall and dispersed. New nuclei can form on the new surfaces of the barrel wall and go through the same cycle so that the melt will contain a larger number of smaller nuclei. Besides the forced nucleation, the dendrite multiplication may be another nucleation source that can be exploited in LSPSF process. It is evident that vigorous mixing and localized rapid cooling can provide significant temperature disturbance in a melt. This is helpful for the remelting and separation of a dendrite arm from a “mother” dendrite, leading to grain multiplication[10, 18]. At the same time, the melt is still being poured, the later poured melt continuously exerts an impact effect on the melt poured earlier, so the separated small primary α(Al) grains are strongly mixed and distributed more evenly in the melt. The mixing action caused by the circle flow of the melt can promote the heat of the melt to give off. Sequentially, the temperature of the whole melt from the rotational barrel can be decreased below its liquidus temperature within 3-4 s. Those are typical phenomena, when the pouring temperature is 660-680 ℃ and rotation speed of barrel is 90-120 r/min as shown in Fig.4. Thus numerous nuclei formed can survive and be carried into the slurry holder by fluid flow. As a result, they can grow into individual grains, resulting in significant grain refinement. With the pouring temperature increasing to 690 or 700 ℃, the liquid alloy 2024 carries more physical heat and needs to be transferred more heat to the rotational barrel. Moreover, if the rotation speed of barrel is 0-60 r/min, the heat extraction ability of barrel becomes weaker compared with a higher rotation speed such as 90 r/min. As a result, the temperature of the melt from the rotational barrel is above its liquidus temperature as shown in Fig.4. In this case, the melt dose not start to solidification or there is a limited amount of primary α(Al) grains separated and survived.

a great force on the nuclei growing along the barrel wall, the nuclei can be easily separated from the barrel wall and dispersed. New nuclei can form on the new surfaces of the barrel wall and go through the same cycle so that the melt will contain a larger number of smaller nuclei. Besides the forced nucleation, the dendrite multiplication may be another nucleation source that can be exploited in LSPSF process. It is evident that vigorous mixing and localized rapid cooling can provide significant temperature disturbance in a melt. This is helpful for the remelting and separation of a dendrite arm from a “mother” dendrite, leading to grain multiplication[10, 18]. At the same time, the melt is still being poured, the later poured melt continuously exerts an impact effect on the melt poured earlier, so the separated small primary α(Al) grains are strongly mixed and distributed more evenly in the melt. The mixing action caused by the circle flow of the melt can promote the heat of the melt to give off. Sequentially, the temperature of the whole melt from the rotational barrel can be decreased below its liquidus temperature within 3-4 s. Those are typical phenomena, when the pouring temperature is 660-680 ℃ and rotation speed of barrel is 90-120 r/min as shown in Fig.4. Thus numerous nuclei formed can survive and be carried into the slurry holder by fluid flow. As a result, they can grow into individual grains, resulting in significant grain refinement. With the pouring temperature increasing to 690 or 700 ℃, the liquid alloy 2024 carries more physical heat and needs to be transferred more heat to the rotational barrel. Moreover, if the rotation speed of barrel is 0-60 r/min, the heat extraction ability of barrel becomes weaker compared with a higher rotation speed such as 90 r/min. As a result, the temperature of the melt from the rotational barrel is above its liquidus temperature as shown in Fig.4. In this case, the melt dose not start to solidification or there is a limited amount of primary α(Al) grains separated and survived.

Fig.4 Exiting temperature of semi-solid slurry under combination of pouring temperature and rotation speed of barrel

In LSPSF process, the melt flowing into the slurry holder is cooled slowly in a quiescent state. Considering that the initial grain density is large, the melt is thermal undercooled and primary α(Al) grains disperse everywhere, so the coincident solidification phenomenon is greatly strengthened. Because of coincident solidification, latent heat released in a short time and a slowly cooling condition, a uniform temperature field in the semi-solid slurry can be obtained. Moreover, under slowly cooling and high grain density, the gradient of solute concentration in the liquid drops very rapidly due to the overlapping of the diffusion layers around grains [19-20]. These conditions are not favorable to the preferred growth of the grain and the grains are forced to grow uniformly at each direction. So the evolution of the grain into a spherical occurs rapidly. In the case of a much smaller number of initial grains, the conditions for uniform growth of grain at each direction are greatly discounted. For a given increase in solid fraction during cooling, each grain will grow more significantly. As a result, the grain will ripen into a “deformed dendrite” that is unacceptable for semi-solid forming.

3.2 Direct squeeze casting of 2024 wrought alloy cup- shaped component

Fig.5 shows the cup-shaped components of alloy 2024 by direct squeeze casting of the semi-solid slurry prepared by LSPSF process and full liquid metal. The difference among them is not evident in macroscopic view, due to the simple geometry of the die, virtually, no porosity occurred in all the castings. However, as shown in Fig.6, the difference among their microstructures is very significant. The grains of squeeze casting using full liquid alloy are coarse and dendritic. Moreover its microstructure is inhomogeneous and there is an obvious segregation. Compared with common squeeze casting, there are fine spherical grains with grain size of about 72 μm in the microstructure of squeeze cast cup-shaped part using semi-solid slurry containing solid fraction of 55%. Some plastic deformation has occurred along the flow direction due to the higher solid fraction in semi-solid slurry.

Fig.5 Squeeze cast cup-shaped components: (a)-(d) Semi-solid slurry; (e) Full liquid metal

Fig.6 Typical microstructures of squeeze cast cup-shaped components using full liquid metal (a) and semi-solid slurry containing solid fraction of 55% (b)

Table 1 lists the mechanical properties of direct squeeze cast cup-shaped part using above two different precursor metals. It can be seen that the mechanical properties of squeeze cast part using semi-solid slurry are enhanced greatly: yield strength of 198 MPa, ultimate tensile strength of 306 MPa and elongation of 10.4%. It is obviously demonstrated that LSPSF process is a novel technique to prepare semi-solid slurry for wrought aluminum alloy 2024. Moreover it is found that applying LSPSF process into squeeze casting is a desirable application to the rheoforming of wrought aluminum alloy.

![]() Table 1 Mechanical properties of squeeze cast components using full liquid metal and semi-solid slurry

Table 1 Mechanical properties of squeeze cast components using full liquid metal and semi-solid slurry

4 Conclusions

1) LSPSF is a novel rheocasting process. If wrought aluminum alloy 2024 is poured at 660-680 ℃ and meanwhile mixed by a rotational barrel at rotation speed of 90-120 r/min for 3-4 s, the pouring process is easily controlled and the sound semi-solid slurry containing fine-globular primary α(Al) grains can be prepared.

2) Low superheat pouring combined with localized rapid cooling and vigorous mixing during the initial stage of solidification can enhance the wall nucleation, grain multiplication and nuclei survival, which gives rise to a significant grain refinement and the spherical microstructure of primary α(Al) grains.

3) The direct squeeze casting of LSPSF alloy 2024 is very easy and powerful. The yield strength, ultimate tensile strength and elongation of the squeeze cast products are 198 MPa, 306 MPa and 10.4%, respectively.

References

[1] ESKIN D G, KATGERMAN S L. Mechanical properties in the semi-solid state and hot tearing of aluminum alloys [J]. Progress in Materials Science, 2004(49): 629-711.

[2] ATKINSON H V, KAPRANOS P, KIRKWOOD D H. Alloy development for thixoforming [C]// Proceedings of the Sixth International Conference on Semi-Solid Processing of Alloys and Composites. Turin, Italy, 2000: 443-450.

[3] LIU D, ATKINSON H V, KAPRANOS P, JIRATTITICHAROEAN W, JONES H. Microstructure evolution and tensile mechanical properties of thixoformed high performance aluminum alloys [J]. Mater Sci Eng A, 2003, A361: 213-224.

[4] TZIMAS E, ZAVALIANGOS A. A comparative characterization of near-equiaxed microstructures as produced by spray casting, magnetohydrodynamic casting and the stress induced, melt activated process [J]. Mater Sci Eng A, 2000, A289: 217-227.

[5] KANG C G, SEO P K, JEON Y P. Thixo diecasting process for fabrication of thin-type component with wrought aluminum alloys and its formability limitation [J]. Journal of Materials Processing Technology, 2005, 160: 59-69.

[6] CHOI J C, PARK H J. Microstructure characteristics of aluminum 2024 by cold working in the SIMA process [J]. Journal of Materials Technology, 1998, 82: 107-116.

[7] RACHMAT R S, TAKANO H, IKEYA N, KAMADO S, KOJIMA Y, RO?SZ A, RETTENMAYR M, WATRING D. Application of semi-solid forming to 2024 and 7075 wrought aluminum billets fabrication by the EMC process [J]. Materials Science Forum, 2000, 329/330: 487-492.

[8] DONG J, CUI J Z, LE Q C, LU G M. Liquidus semi-continuous casting, reheating and thixoforming of a wrought aluminum alloy 7075 [J]. Mater Sci Eng A, 2003, A345: 234-242.

[9] XIA K, TAUSIG G. Liquidus casting of a wrought aluminum alloy 2618 for thixoforming [J]. Mater Sci Eng A, 1998, A246: 1-10.

[10] FLEMINGS M C. Behavior of metal alloys in the semi-solid state [J]. Metall Trans, 1991, A22(4): 957-981.

[11] FAN Z. Semisolid metal processing [J]. Int Mater Rev, 2002, 47(2): 1-37.

[12] DASGUPTA R. Industrial application—the present status and challenges we face [C]// Proceedings of the 8th International Conference on Semi-Solid processing of Alloys and Composites. Limassol, Cyprus, 2004: 1-14.

[13] KAUHANN H, WABUSSEG H, UGGOWITZER P J. Metallurgical and processing aspects of the NRC semi-solid casting technology [J]. Aluminum, 2000, 76(1/2): 70-75.

[14] JI S, FAN Z, BEVIS M J. Semi-solid processing of engineering alloys by a twin-screw rheomoulding process [J]. Mater Sci Eng A, 2001, A299: 210-217.

[15] MARTINEZ R A, FLEMINGS M C. Evolution of particle morphology in semisolid processing [J]. Metall Mater Trans, 2005, A36: 2205-2210.

[16] APELIAN D, PAN Q Y, FINDON M. Low cost and energy efficient methods for the manufacture of semi-solid(SSM) feedstock [J]. Die Casting Engineer, 2004, 48(1): 22-28.

[17] CHALMERS B. The structure of ingots [J]. J Aust Inst of Metals, 1963, 8: 255-270.

[18] OHNO A. Solidification—The separation theory and its particle applications [M]. Germany: Springer-Verlag, 1987.

[19] GUO Hong-min YANG Xiang-jie. Morphology evolution of primary alpha phase in rotated duct process [C]// Proceedings of the 8th International Conference on Semi-Solid processing of Alloys and Composites. Limassol, Cyprus, 2004: 695-703.

[20] JACOT A, RAPPAZ M. A pseudo-front tracking technique for the modeling of solidification microstructures in multi-component alloys [J]. Acta Materialia, 2002, 50: 1909-1926.

Foundation item: Project(50474007) supported by the National Natural Science Foundation of China; Project(0450050) supported by the Natural Science Foundation of Jiangxi Province, China; Projects(GanJiaoZi[2005]2, 24) supported by the Science and Technology Program of Education Department of Jiangxi Province, China

Corresponding author: GUO Hong-min; Tel: +86-791-3969611; E-mail: hmguo_email@163.com

(Edited by HE Xue-feng)