High temperature frictional wear behaviors of nano-particle reinforced NiCoCrAlY cladded coatings

来源期刊:中国有色金属学报(英文版)2011年第6期

论文作者:王宏宇 左敦稳 王明娣 孙桂芳 缪宏 孙玉利

文章页码:1322 - 1328

关键词:纳米颗粒增强NiCoCrAlY熔覆涂层的高温摩擦磨损行为

Key words:metal-matrix composite; frictional wear; NiCoCrAlY coating; nano-particles; laser cladding

摘 要:采用激光熔覆技术,在镍基高温合金表面制备相同含量的3种不同纳米颗粒增强的NiCoCrAlY涂层,考察它们在500 °C空气氛围下的干摩擦磨损行为,并与未加纳米颗粒的涂层进行比较。结果表明:纳米颗粒增强涂层的高温摩擦磨损机制与未加纳米颗粒的涂层一致,均为强烈塑性变形引起的剥层磨损和氧化磨损;加入纳米颗粒后,涂层的摩擦因数增大且随滑行距离的增加呈减小趋势,涂层的磨损率仅为未加纳米颗粒涂层的34.0%~64.5%。在3种纳米颗粒中,纳米SiC颗粒对涂层高温耐磨性的改善最为显著。

Abstract:

The NiCoCrAlY coatings strengthened by three nano-particles with the same addition were prepared on a Ni-base super alloy using laser cladding technique. The dry frictional wear behaviors of the coatings at 500 °C in static air were investigated. The comparison was made with the coating without nano-particles. The results show that the wear mechanism of the NiCoCrAlY coatings with nano-particles, like the coating without nano-particles, is the delamination wear due to the strong plastic deformation and oxidative wear. However, the frictional coefficient of the coatings increases and presents the decrease trend with the increase of sliding distance after adding nano-particles. Moreover, the wear rate of the coatings with nano-particles is only 34.0%?64.5% of the coating without nano-particles. Among the three nano-particles, the improvement of nano-SiC on the high temperature wear resistance of the coating is the most significant.

WANG Hong-yu1, 2, ZUO Dun-wen2, WANG Ming-di3, SUN Gui-fang1, MIAO Hong2, SUN Yu-li2

1. School of Mechanical Engineering, Jiangsu University, Zhenjiang 212013, China;

2. College of Mechanical and Electrical Engineering,

Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

3. College of Mechanical and Electrical Engineering, Soochow University, Suzhou 215021, China

Received 28 June 2010; accepted 15 October 2010

Abstract: The NiCoCrAlY coatings strengthened by three nano-particles with the same addition were prepared on a Ni-base super alloy using laser cladding technique. The dry frictional wear behaviors of the coatings at 500 °C in static air were investigated. The comparison was made with the coating without nano-particles. The results show that the wear mechanism of the NiCoCrAlY coatings with nano-particles, like the coating without nano-particles, is the delamination wear due to the strong plastic deformation and oxidative wear. However, the frictional coefficient of the coatings increases and presents the decrease trend with the increase of sliding distance after adding nano-particles. Moreover, the wear rate of the coatings with nano-particles is only 34.0%-64.5% of the coating without nano-particles. Among the three nano-particles, the improvement of nano-SiC on the high temperature wear resistance of the coating is the most significant.

Key words: metal-matrix composite; frictional wear; NiCoCrAlY coating; nano-particles; laser cladding

1 Introduction

NiCoCrAlY coating has been widely used as a protective coating for gas turbine engine components utilized at high temperature [1-3]. As the particulate nature of the exhaust, especially when gas turbine engines serves in the dusty environment like desert region, it often fails due to high temperature wear of NiCoCrAlY coating.

With the widespread use of metal matrix composite coating in the field of high temperature protective coating, the oxide dispersion strengthened NiCoCrAlY coatings were obtained through the introduction of hard oxide particles, which becomes an important trend to improve its high wear resistance [4-9]. ZHAO et al [4] used the high velocity oxy-fuel (HVOF) to prepare micron Al2O3 dispersion strengthened NiCoCrAlY coating. Under the sliding dry friction at 800 °C, the coating has a more stable friction coefficient compared with normal NiCoCrAlY coating, although the wear rate did not obviously decrease. BOBZIN et al [5] prepared micron yttria partially stabilized zirconia (YPSZ) dispersion strengthened NiCoCrAlY coating by using HVOF. Under the sliding dry friction at 700 °C, the high temperature wear resistance of NiCoCrAlY coating with 5% (mass fraction) micron YPSZ was significantly improved, and its wear rate was only half of the unstrengthened coating. SONG et al [6] introduced nano-CeO2 into the NiCrBSiFe coating by laser cladding technology, and the wear rate of the coating at room temperature was only about 15% of that of the coating without nano-particles. It can be expected that a good high temperature wear resistance of NiCoCrAlY coating could be obtained by introducing nano-particles. However, the researches on the high temperature frictional wear behaviors of nano-particle reinforced NiCoCrAlY coating are still rare.

In this work, on the basis of the previous [10] successful preparation of nano-Al2O3 particles dispersion strengthened NiCoCrAlY coating, three NiCoCrAlY coatings reinforced by different kinds of nano-particles with the same addition were prepared on a Ni-base super alloy using laser cladding technique. The dry frictional wear behaviors of the coatings at 500 °C in static air are investigated. The comparison is made with the coating without nano-particles.

2 Experimental

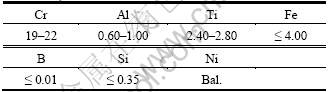

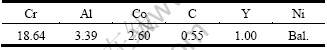

The substrate material was Ni-base super alloy GH4033. Its nominal chemical composition is listed in Table 1. The coating material NiCoCrAlY powders were provided by Beijing General Research Institute of Mining & Metallurgy, China, with an average particle size of 75 μm. Its chemical composition is listed in Table 2. The nano sized Al2O3, SiC, and CeO2 powders with an average particle size of 20 nm were provided by High Technology Nanometer Company, China.

Table 1 Chemical compositions of GH4033 alloy (mass fraction, %)

Table 2 Chemical compositions of NiCoCrAlY powders (mass fraction, %)

Micro-nanometer composite powders were made with content of 1% (mass fraction) nano-particles using a self-developed method [11]. The powders for cladding were preset on the substrate surface using a self-developed method (the squash presetting method). The preset layer thickness was 0.4 mm. The multi-channel laser cladding was performed using a crosscurrent CO2 laser with the optimized process parameters: laser power 1 kW, spot diameter 2 mm, scanning speed 5 mm/s, overlap ratio 50%, as well as a nitrogen gas environment [12].

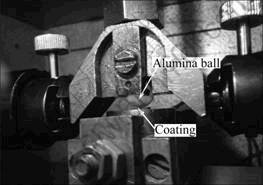

The SRV high frequency reciprocating wear tester was employed to investigate high temperature frictional wear characteristics of the coatings. First, the central part of the coatings polished with 400# sandpaper was cut into sample with dimensions of 6 mm × 4 mm × 3.75 mm. The sample was inlaid in a quenching 45# steel disk with 24 mm in diameter for making the lower specimen. As counter part (the upper specimen), an Al2O3 ball with 10 mm in diameter was used. Then, the pin-on block tests were performed at 500 °C in static air, as shown in Fig. 1. Prior to the testing, the Al2O3 ball and experimental samples were cleaned with acetone. The load force was 20 N and the total sliding distance was 120 m. The sliding speed was adjusted to 0.1 m/s. In the frictional wear test, three parallel samples were made for the each coating.

Fig. 1 Experimental setup of high temperature frictional wear

Before the testing, a micro-hardness tester (HXS-1000A) was used for measuring coating hardness, with a load of 0.98 N.

After frictional wear test, the surface profile of the wear scar was analyzed by a Micro-XAMTM non-contact 3-dimensional topography instrument and the scan length was 2.07 mm. Three cross-sections were intercepted in the marks of each sample to obtain the wear scar line profile. The wear area was calculated using self-developed software. Based on the nine measurements of three parallel samples, the mean of wear area was obtained. The wear rate (Ws), used as a wear resistance index, was calculated by the formula as

![]()

where Ws is the wear rate, mm3/(N?m); C is the wear scar length, mm; A is the mean of wear area, mm2; F is normal load, N; L is sliding distance, m.

Morphology of the wear scar was characterized using a JSM-7001F scanning electron microscope (SEM) equipped with an IE-350 energy dispersive spectrometer (EDS).

3 Results and discussion

3.1 Surface hardness of coatings

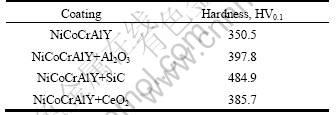

The surface hardness of four coatings is shown in Table 3. As can be seen from Table 3, by adding nano-particles, the hardness of the coatings is increased. Among them, the hardness of the coating with nano-SiC particles is 38.3% higher than that without nano-particles. The hardness of the coatings with Al2O3 or CeO2 nano-particles is about 10% higher than that without nano-particles, wherein the hardness of the coating with nano-Al2O3 particles is slightly higher than that with nano-CeO2 particles.

Table 3 Surface hardness of coatings

According to the previous results [13], the refinement of the coating with different nano-particles is directly related with the size of nano-particles in micro-nanometer composite powders and their stability under the action of the laser beam. In the micro-nanometer composite powders, nano-Al2O3 particles mainly exist in the form of micro aggregates of about 100 nm, while nano-SiC particles mainly exist in the form of single dispersed particles. Meanwhile, the nano-Al2O3 and nano-SiC particles have good stability under the action of the laser beam. However, nano-CeO2 particles has both single dispersed particles and micro-aggregates (100 nm or so), and the majority will be decomposed under the laser beam [13].

3.2 Friction behavior of coatings

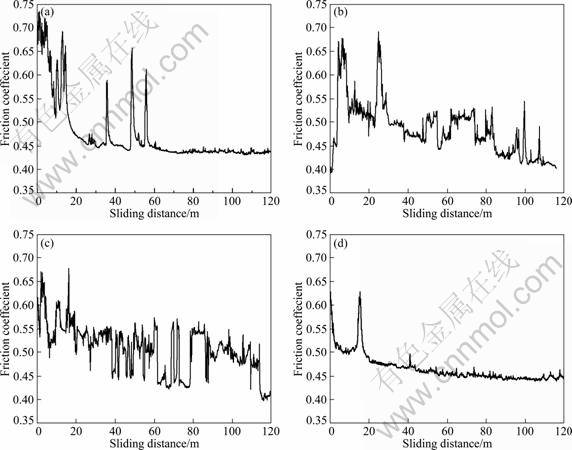

The friction coefficients of the four coatings changing with the sliding distance are shown in Fig. 2. It can be seen from Fig. 2 that the coating without nano-particles enters into the stable period after sliding about 60 m (Fig. 2(a)), while the one with nano-CeO2 particles enters into the stable period after sliding about 20 m (Fig. 2(d)); for the ones with nano-Al2O3 or nano-SiC particles, their friction coefficients fluctuate greatly throughout the test, which is unable to obtain a stable value (Figs. 2(b) and (c)). Meanwhile, during the grinding with the Al2O3 ball, their friction coefficients all present the friction behavior like “the fast rise-the rapid decline–remaining relatively stable”, which is consistent with the friction behavior that the metal transfers and adheres to the ceramic surface, forming a transfer layer due to the great difference between their hardness during the grinding of metal matrix composites with ceramics [14].

The friction coefficients of the coatings with nano-Al2O3 and nano-SiC particles fluctuate greatly during the whole test, mainly because there are more nano-particles in the transfer layer, and these nano-particles are brittle phase, thus leading to the easy damage of the transfer layer. The continuous formation and destruction of transfer layer resulted in the fluctuation of the friction coefficients. Further comparison between Figs. 2(c) and 2(b) shows that the fluctuation frequency of friction coefficient of the nano-SiC-added coating is higher than that of the nano-Al2O3-added coating. This may be related to the size of different nano-particles in the coatings. The size of nano-SiC particles distributed in the coating is small and the dispersion degree is high, these brittle particles are more apt to the destruction of the transfer layer.

Fig. 2 Friction coefficients of four coatings changing with sliding distance: (a) Without nano-particles; (b) With nano-Al2O3 particles; (c) With nano-SiC particles; (d) With nano-CeO2 particles

The friction coefficient of the coating with nano-CeO2 particles shows different law from the other two nano-particles, but it is similar to that without nano-particles, mainly due to the fact that the majority of nano-CeO2 particles has been decomposed under the action of the laser beam [13]. In other words, the effects of nano-CeO2 particles on the friction behavior of the coating are not significant in this respect. Meanwhile, the time required for the coating with nano-CeO2 particles entering into the stable period is only 1/3 of that required by the coating without particles. The reason may be that the hardness of the coating with nano-CeO2 particles is improved, which results in the decrease of changing frequency of friction coefficient [15].

In addition, the average friction coefficients of the coatings with nano-Al2O3, nano-SiC and nano-CeO2 particles are 0.485, 0.508 and 0.466, respectively, which are higher than that of the coating without nano-particles (its average friction coefficient is 0.445). The effect of three kinds of nano-particles is the same as that on the coating surface hardness (Table 3). It is suggested that the coating surface hardness is improved after adding nano-particles, which increases the friction surface deformation resistance. Therefore, the friction coefficient increases. This has some similarities with the research reported by CHEN et al [16]. It can also be seen from Fig. 2 that the friction coefficient of three nano-particle reinforced coatings presents decreasing trend with the increase of sliding distance, while the friction coefficient of the coating without nano-particles basically remains unchanged.

3.3 Wear behavior of coatings

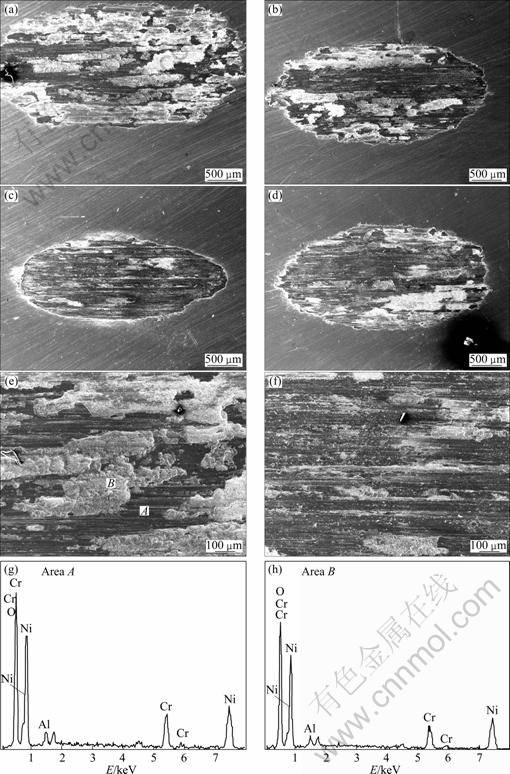

The SEM morphologies of wear scar of four coatings are shown in Fig. 3. As can be seen from Fig. 3, there is a lot of spallations (Fig. 3(a)) on the wear scar surface of the coating without nano-particles, while the amounts of spallations on the wear scar surface of the coatings with nano-particles decrease significantly, especially the spallations are very small on the wear scar surface of the coating with nano-SiC particles (Figs. 3(c) and (f)). The high magnification morphology of the spalling area on the wear scar surface shows the zone experienced a strong plastic deformation; at the same time, whether the coatings without nano-particles or with nano-particles such as nano-SiC particles, the EDS analysis of the spalling area and non-spalling area shows that the compositions between the two are consistent (Figs. 3(g) and 3(h)). So it can be believed that the spallation on the wear scar surface is formed due to the strong plastic deformation of the coating surface of the friction zone. After adding nano-particles, the coating hardness is improved, and the deformation resistance of the friction surface increases, thereby the spallations on the surface of the wear scar decrease. It can also be seen from Fig. 3, as for the wear scar of the coating without nano-particles, both the width and length are greater than that of the coatings with nano-particles. In the three nano-particle reinforced coatings, the length of the wear scar is basically the same but their width is significantly different (Figs. 3(b)-(d)). Among them, the wear scar width of the coating with nano-SiC particles is the smallest, followed by the coating with nano-Al2O3 particles and nano-CeO2 particles. Moreover, according to the EDS analysis of the wear scar surface, the wear scar surface contains O, indicating that there is some of oxidation wear during the frictional wear process, but there is no significant difference in oxygen content between the coating without nano-particles and the coatings with nano-particles.

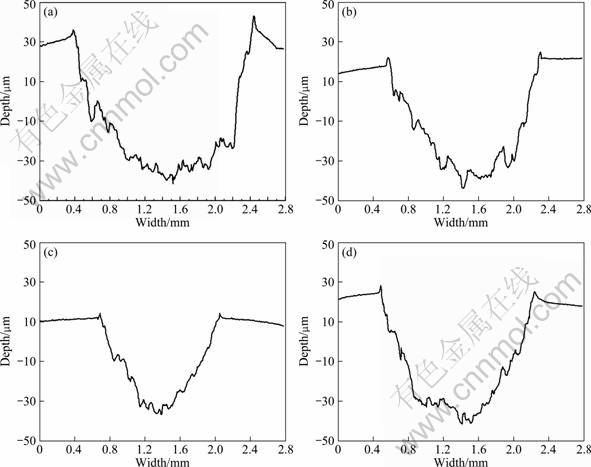

The cross-sectional profile of wear scar of the four coatings is shown in Fig. 4. As can be seen from Fig. 4, the wear scar of the coating without nano-particles is broad and deep, which is in the inverted trapezoidal shape, indicating that the bottom of the wear scar is relatively wide. Both the width and depth of the wear scar of the coatings with nano-particles are smaller than those of the coating without nano-particles, which is in the inverted triangle shape, and that is narrow at the bottom of the wear scar. In the three nano-particle reinforced coatings, the effect on the depth is the same with that on the width, that is, the depth of the wear scar on the coating with nano-SiC particles is the shallowest, followed by the coating with nano-Al2O3 particles. For the coating with nano-CeO2 particles, the depth is the deepest.

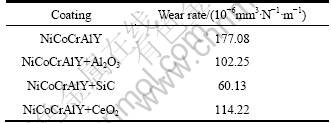

According the wear rate of four coatings listed in Table 4 and the wear scar morphologies mentioned above, it can be concluded that the high temperature wear resistance of coating is improved significantly after adding nano-particles, especially for the nano-SiC-added coating, and the wear rate is only 34.0% of that of the coating without nano-particles.

Based on these results, we can see that the effects of three nano-particles on high temperature wear resistance of the coatings are the same with that on the hardness of the coating surface. This indicates that the coating hardness is the decisive factor in its high temperature wear resistance. In addition, when these hard nano- particles exist in the coating in the form of hard particles, the protruding hard particles of the coating surface in the friction zone also play a good anti-wear role. In this work, the hardness of coating with nano-Al2O3 particles is 3.5% higher than that of the coating with nano-CeO2 particles, but the wear rate reduces by 6.8% compared with the coating with nano-CeO2 particles.

Fig. 3 SEM morphologies of wear scar of four coatings: (a) Without nano-particles; (b) With nano-Al2O3 particles; (c) With nano-SiC particles; (d) With nano-CeO2 particles; (e) Local amplification of Fig. 3(a); (f) Local amplification of Fig. 3(c); (g) EDS pattern of area A in Fig. 3(e); (h) EDS pattern of area B in Fig3.(e)

Fig. 4 Cross-sectional profiles of wear scar of four coatings: (a) Without nano-particles; (b) With nano-Al2O3 particles; (c) With nano-SiC particles; (d) With nano-CeO2 particles

Table 4 Wear rate of coatings

4 Conclusions

1) The wear mechanism of the nano-particle reinforced NiCoCrAlY cladded coatings and the coating without nano-particles coupled with Al2O3 ball at 500 °C in static air, is the delamination wear due to the strong plastic deformation and oxidative wear.

2) After adding nano-particles, the frictional coefficient of the coatings with nano-particles increases compared with the coating without nano-particles and presents the trend of decrease with the increase of sliding distance. Meanwhile, the time required by the coating with nano-CeO2 particles entering into the stable period is only 1/3 of that required by the coating without nano-particles, while the friction coefficients of the coatings with nano-Al2O3 and nano-SiC particles fluctuate greatly during the whole test.

3) After adding nano-particles, the coating wear scar becomes smaller and shallower, the spallations on the wear scar surface become smaller and the wear rate decreases. The wear rate of the nano-SiC-added coating is 34.0% of that of the coating without nano-particles.

4) The effects of three kinds of nano-particles on high temperature wear resistance of the coating are the same with that on the hardness of the coating surface. This indicates that the coating hardness is the decisive factor in its high temperature wear resistance.

References

[1] GURRAPPA I, SAMBASIVA BAO A. Thermal barrier coatings for enhanced efficiency of gas turbine engines [J]. Surface & Coatings Technology, 2006, 201: 3016-3029.

[2] UWE S, CHRISTOPH L, KLAUS F. Some recent trends in research and technology of advanced thermal barrier coatings [J]. Aerospace Science Technology, 2003(7): 73-78.

[3] LIU Chun-bo, LIN Feng, JIANG Xian-liang. Current state and future development of thermal barrier coating [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 1-13. (in Chinese)

[4] ZHAO L D, PARCO M, LUGSCHEIDER E. Wear behavior of Al2O3 dispersion strengthened MCrAlY coating [J]. Surface & Coatings Technology, 2004, 184: 298-306.

[5] BOBZIN K, SCHL?FER T, RICHARDT K, BR?HL M. Development of oxide dispersion strengthened MCrAlY coatings [J]. Journal of Thermal Spray Technology, 2008, 17: 853-857.

[6] SONG Chuan-wang, LI Ming-xi. Effect of nano-CeO2 on the microstructure and properties of laser clad nickel-based alloy coating [J]. Laser Technology, 2006, 30(3): 228-231. (in Chinese)

[7] WU Bin, XU Bin-shi, ZHANG Bin, L? Yao-hui. Preparation and properties of Ni/nano-Al2O3 composite coatings by automatic brush plating [J]. Surface & Coatings Technology, 2007, 201: 6933-6939.

[8] ZHANG Hui, HE Yi-zhu. Research progress on nano-particle reinforced metal matrix composite coatings [J]. Journal of Anhui University of Technology, 2006, 23(1): 21-25. (in Chinese)

[9] LI M X, ZHANG S H, LI H S, YOON J H. Effect of nano-CeO2 on cobalt based alloy laser coatings [J]. Journal of Materials Processing Technology, 2008, 202(1-3): 107-111.

[10] WANG Hong-yu, ZUO Dun-wen, SUN Yu-li, XU Feng, ZHANG Dan. Microstructure of nanometer Al2O3 dispersion strengthened ni-based high-temperature protective coatings by laser cladding [J].Transactions of Nonferrous Metals Society of China, 2009, 19(3): 586-591.

[11] WANG Hong-yu, ZUO Dun-wen, YU Shou-xin, ZHANG Dan. Preparation process of metal matrix micro/nano-powders reinforced by nanometer particles [J]. Advanced Materials Research, 2009, 60-61: 155-159.

[12] WANG Hong-yu, ZUO Dun-wen, MA Hao, WANG Ming-di, LU Ying-yan. Effects of process parameters on microscopic qualities of coatings formed by squash presetting type laser cladding [J]. Journal of Materials Engineering, 2009, 43(3): 80-83, 88. (in Chinese)

[13] WANG Hong-yu, ZUO Dun-wen, CHEN Xing-feng, YU Shou-xin, GU Yuan-zhi. Microstructure and oxidation behaviors of nano-particles strengthened NiCoCrAlY cladded coatings on superalloys [J]. Chinese Journal of Mechanical Engineering, 2010, 23(3): 297-304.

[14] ZHANG Yong-zhen. Materials dry tribology [M]. Beijing: Science Press, 2007. (in Chinese)

[15] WANG Yuan, ZHOU Fei, ZHANG Qin-wen. Tribological properties of duplex Al2O3 / CrNx coatings [J]. Journal of Materials Engineering, 2010, 44(2): 42-46. (in Chinese)

[16] CHEN Hui, GOU Guo-qing, LIU Yan, TU Ming-jing. Wear behavior of plasma sprayed nanostructured WC-17Co coatings at elevated temperature [J]. Transactions of the China Welding Institution, 2008, 29(12): 53-55, 60. (in Chinese)

王宏宇1, 2, 左敦稳2, 王明娣3, 孙桂芳1, 缪 宏2, 孙玉利2

1. 江苏大学 机械工程学院,镇江 212013;2. 南京航空航天大学 机电学院,南京 210016;

3. 苏州大学 机电学院,苏州 215021

摘 要:采用激光熔覆技术,在镍基高温合金表面制备相同含量的3种不同纳米颗粒增强的NiCoCrAlY涂层,考察它们在500 °C空气氛围下的干摩擦磨损行为,并与未加纳米颗粒的涂层进行比较。结果表明:纳米颗粒增强涂层的高温摩擦磨损机制与未加纳米颗粒的涂层一致,均为强烈塑性变形引起的剥层磨损和氧化磨损;加入纳米颗粒后,涂层的摩擦因数增大且随滑行距离的增加呈减小趋势,涂层的磨损率仅为未加纳米颗粒涂层的34.0%~64.5%。在3种纳米颗粒中,纳米SiC颗粒对涂层高温耐磨性的改善最为显著。

关键词:金属基复合材料;高温摩擦磨损;NiCoCrAlY涂层;纳米颗粒;激光熔覆

(Edited by LI Xiang-qun)

Foundation item: Project (20060287019) supported by the Research Fund for Doctoral Program of Higher Education of China; Project (kjsmcx07001) supported by the Opening Research Fund of Jiangsu Key Laboratory of Tribology, China; Project (BK2010267) supported by the Jiangsu Provincial Natural Science Foundation of Jiangsu Province, China

Corresponding author: ZUO Dun-wen; Tel: +86-25-84890249; E-mail: imit505@nuaa.edu.cn

DOI: 10.1016/S1003-6326(11)60860-1