快速连续加热过程中剧烈冷变形亚稳β钛合金 显微组织、相组成和拉伸性能的演变

来源期刊:中国有色金属学报(英文版)2014年第5期

论文作者:P. E. MARKOVSKY V. I. BONDARCHUK YU. V. MATVIYCHUK O. P. KARASEVSKA

文章页码:1365 - 1371

关键词:钛合金;剧烈冷变形;快速加热;回复和再结晶;相组成;显微组织;力学性能

Key words:titanium alloy; severe cold deformation; rapid heating; recovery and recrystallization; phase composition; microstructure; mechanical properties

摘 要:研究连续快速加热条件下亚稳β Ti-1.5%Al-6.8%Mo-4.5%Fe钛合金剧烈冷变形对其显微组织、相组成和拉伸性能演变的影响。轧制态合金具有准非晶单相β结构,其电阻率与温度的关系呈现异常;将轧制态合金在室温下冷却暴露48 h,由于等温ω相的析出,电阻率与温度的关系恢复正常。随后,将合金以加热速率为5 °C/s进行快速热处理,导致回复和再结晶发生。测定和讨论了不同处理后合金的拉伸性能。

Abstract: Influence of severe cold deformation of titanium alloy Ti-1.5%Al-6.8%Mo-4.5%Fe in metastable β condition on the evolution of phase composition, microstructure, and tensile properties during continuous rapid heating was studied. As-deformed alloy was characterized by quasi-amorphous single-phase β condition with an abnormal temperature dependence of electric resistance that was normalized after 48 h exposure at room temperature as a result of isothermal ω phase precipitation. Subsequent rapid heating with a rate of 5 °C/s caused recovery and recrystallization. Tensile properties of the alloy after different treatments were determined and discussed.

Trans. Nonferrous Met. Soc. China 24(2014) 1365-1371

P. E. MARKOVSKY, V. I. BONDARCHUK, YU. V. MATVIYCHUK, O. P. KARASEVSKA

G. V. Kurdyumov Institute for Metal Physics, National Academy of Sciences of Ukraine, 36, Vernadsky Blvd., 03142, Kiev, Ukraine

Received 9 August 2013; accepted 9 October 2013

Abstract: Influence of severe cold deformation of titanium alloy Ti-1.5%Al-6.8%Mo-4.5%Fe in metastable β condition on the evolution of phase composition, microstructure, and tensile properties during continuous rapid heating was studied. As-deformed alloy was characterized by quasi-amorphous single-phase β condition with an abnormal temperature dependence of electric resistance that was normalized after 48 h exposure at room temperature as a result of isothermal ω phase precipitation. Subsequent rapid heating with a rate of 5 °C/s caused recovery and recrystallization. Tensile properties of the alloy after different treatments were determined and discussed.

Key words: titanium alloy; severe cold deformation; rapid heating; recovery and recrystallization; phase composition; microstructure; mechanical properties

1 Introduction

Titanium alloys comprise a unique group of structural materials for many applications due to their high specific strength, good hardenability, excellent fatigue/crack-propagation and corrosion resistance [1,2]. The best combination of high strength with other important properties can be achieved in metastable β titanium alloys of which superiority over other titanium base structural materials is most pronounced in the solid solution treated and aged (STA) conditions with a fully β-transformed, fine-grained and precipitation-hardened microstructure [3,4]. After STA, the ductility of these alloys is essentially determined by β grain size, so that for the same strength finer grains result in higher tensile elongation and reduction of area [5]. As the size of β grains in titanium alloys can be reduced only by deformation and recrystallization processes due to comparatively low volume changes at  phase transformation [1], plastic deformation is a technologically inevitable stage for grain refinement. Therefore, the ability of metastable β alloys to undergo cold deformation (CD) with high reductions in metastable single-phase β condition is of great importance [2,6]. Severe CD (with up to 90% reduction in cross section) combined with subsequent recrystallization upon continuous rapid heating (RH) allowed to form a unique fine-grained microstructure, with an excellent balance of extremely high strength, acceptable ductility and fatigue strength [7-9]. IVASISHIN et al [7,8] reported that higher CD reductions led to the formation of finer β grains after recrystallization. This was attributed to the decrease in distance between primary β grain boundaries at which new grains nucleated during recrystallization. Some metastable β alloys, including Ti-1.5%Al-6.8%Mo-4.5%Fe (TIMETAL-LCB), can be subjected to severe CD due to their high ability to accommodate plastic deformation via the development of subgrain/cell substructure [6], so, very fine grains (about 2 m in diameter [10]) can be formed upon recrystallization. At the same time, when grain size in titanium alloys is below 1 μm (sub-micron scale microstructure), various physical and mechanical properties are significantly improved [11,12]. The present work concerned the possibility to employ cold deformation with reduction over 90%, followed by recovery/recrystallization induced with rapid continuous heating, aiming at the formation of a fine β-grain microstructure in TIMETAL-LCB alloy. Tensile properties of the material with such microstructure are assessed.

phase transformation [1], plastic deformation is a technologically inevitable stage for grain refinement. Therefore, the ability of metastable β alloys to undergo cold deformation (CD) with high reductions in metastable single-phase β condition is of great importance [2,6]. Severe CD (with up to 90% reduction in cross section) combined with subsequent recrystallization upon continuous rapid heating (RH) allowed to form a unique fine-grained microstructure, with an excellent balance of extremely high strength, acceptable ductility and fatigue strength [7-9]. IVASISHIN et al [7,8] reported that higher CD reductions led to the formation of finer β grains after recrystallization. This was attributed to the decrease in distance between primary β grain boundaries at which new grains nucleated during recrystallization. Some metastable β alloys, including Ti-1.5%Al-6.8%Mo-4.5%Fe (TIMETAL-LCB), can be subjected to severe CD due to their high ability to accommodate plastic deformation via the development of subgrain/cell substructure [6], so, very fine grains (about 2 m in diameter [10]) can be formed upon recrystallization. At the same time, when grain size in titanium alloys is below 1 μm (sub-micron scale microstructure), various physical and mechanical properties are significantly improved [11,12]. The present work concerned the possibility to employ cold deformation with reduction over 90%, followed by recovery/recrystallization induced with rapid continuous heating, aiming at the formation of a fine β-grain microstructure in TIMETAL-LCB alloy. Tensile properties of the material with such microstructure are assessed.

2 Experimental

Ti-1.5%Al-6.8%Mo-4.5%Fe (TIMETAL-LCB) alloy was received as a hot-rolled d25 mm rod from Perryman Company (USA). A 250 mm-long piece was cut out of the rod, solid solutionized at 900 °C for 1 h and water quenched in order to eliminate any impact of previous processing history and to form a single β-phase state with average grain diameter of about 200 μm [6,7]. The first CD step consisted of multi-pass rolling from d25.0 mm to d8.0 mm at room temperature using industrial-scale rolling mills, as it was done in Refs. [6-8]. The second CD step comprised rolling from d8.0 mm to d1.3 mm with fine-scaled “jewelry mills” application. So, at the first stage the reduction of cross-section area was about 90% (true deformation |ε|=2.28), and after the second stage it equaled 97% (|ε|=3.63). Thus, the total reduction from the initial diameter (25.0 mm) to the final one (1.3 mm) was about 99.9% (|ε|=5.91), which is even higher than the reductions typical for various techniques of severe plastic deformation [11,13]. After CD, 300 mm-long wire samples were rapidly heated at a rate of 5 °C/s by resistance heating (50 Hz, air cooling) at various peak temperatures, with parallel in situ measurements of electric resistance [14]. After reaching peak temperatures, the samples were immediately water quenched in order to fix actual phase and microstructural state. Then some of the samples were subjected to aging either at 538 °C or 520 °C, in order to achieve the highest strengthening effect [15]. Also a part of aged specimens were polished with a diamond paste to enhance the surface smoothness. In this case, final wire diameter was 1.1 mm. The alloy microstructures at different treatment stages were examined by light microscopy (LM) and transmission electron microscopy (TEM). Phase composition of the samples was determined by standard X-ray diffraction (XRD) technique, and special orientation XRD analysis was employed to detect phases with low volume fractions [6]. Tensile tests of d1.3 mm and d1.1 mm wire specimens were conducted in accordance with ASTM E8M standard using an INSTRON 3376 machine with a tension rate of 8×10-4 s-1.

3 Results and discussion

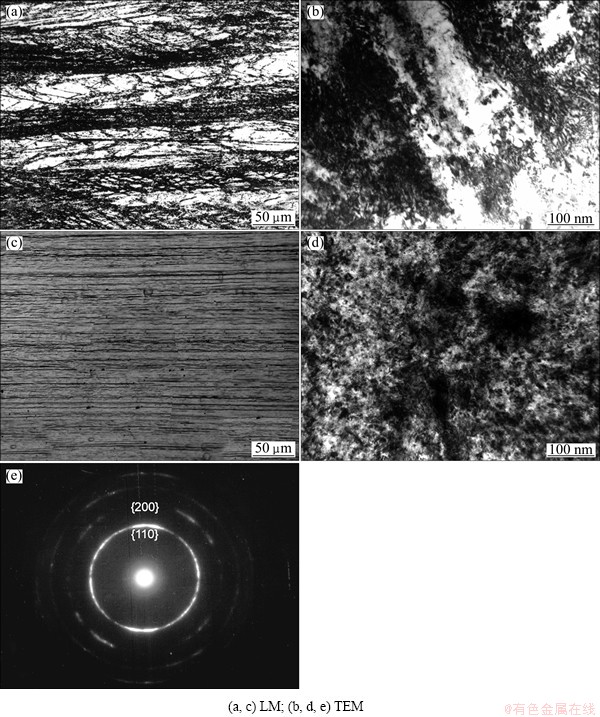

The microstructure of TIMETAL-LCB after the first CD step is shown in Figs. 1(a) and (b). The β grains of 40-80 μm in diameter with a well-developed substructure inside, elongated in the rolling direction, were observed (Fig. 1(a)). High-density dislocations assembled in elongated cells were detected inside these grains (Fig. 1(b)). XRD analysis revealed the β phase with a small amount (about 3% in volume fraction) of athermal ω phase, which is consistent with earlier obtained data [6,7]. Subsequently, the second CD step caused the formation of much finer (thickness below a couple of micrometers) elongated β grains (Fig. 1(c)). Dislocations density inside these β grains also increased, and their distribution became random (Fig. 1(d)). Ring smearing of BCC lattice reflections on SAD patterns (Fig. 1(e)) was observed, indicating the formation of nanocrystalline or even quasi-amorphous condition. The XRD pattern of as-rolled material indicated completely single-phase β state (Fig. 2, curve a), whereas 48 h keeping of the same sample at room temperature resulted in the appearance of ω-phase reflections and an increase in relative intensity of the b-phase reflections (Fig. 2, curve b). Therefore, severe plastic CD (|ε|=5.91) at room temperature led to the dissolution of athermal w phase formed in the quenching and remained during the first CD step. This is consistent with the results in Ref. [16] where volume fraction of the w phase in solution treated TIMETAL-LCB and b21s alloys reduced after room temperature deformation under compression, reaching zero at high strains. The disappearance of w phase at true strains e>0.04 was also reported for a metastable b Ti-12% Mo alloy in Ref. [17], and it was explained by the destruction of w-phase particles by shear bands.

Fig. 1 Microstructures of TIMETAL-LCB after CD 90% (|ε|=2.28) (a, b), and 99.9% (|ε|=5.91) (c, d, e)

Fig. 2 XRD patterns of TIMETAL-LCB under different conditions

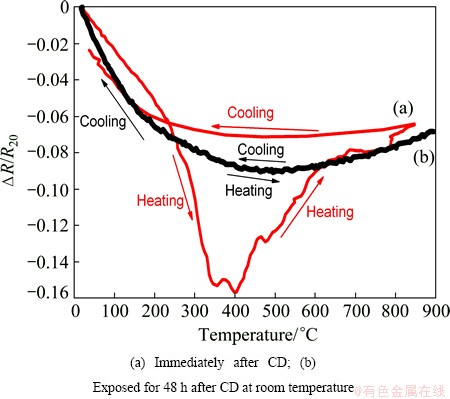

Fig. 3 Temperature dependency of relative electric resistance (RH at 5 °C/s followed by air cooling) of TIMETAL-LCB under different conditions

Fig. 4 Microstructures of TIMETAL-LCB after CD 99.9% (|ε|=5.91) and 48 h exposure at room temperature followed by RH at 5 °C/s to 400 °C (a, b), 500 °C (c), 600 °C (d), 700 °C (e), 800 °C (f), and RH at 5 °C/s to 800 °C + aging 538 °C, 6 h, TEM (g)

Subsequent continuous RH of as-rolled material became abnormal for this alloy (as well as for all metastable β alloys quenched from the β field [7]) changes in electric resistivity within the temperature range of 200-600 °C (Fig. 3, curve a). After reaching 820 °C, which temperature corresponded recrystallization completion in this alloy cold-rolled with 90% reduction (|ε|=2.28) [7], on further cooling the resistometric curves were typical for the smooth shape of β alloys with the minimum about 500 °C. Unlike as-rolled material, the resistivity curves of the samples held after CD for 48 h at room temperature changed during both continuous heating and cooling in a way typical for the metastable β alloys [7], namely the abrupt drop at 200-400 °C upon heating was absent (curve b in Fig. 3).

Continuous RH of rolled material led to considerable changes in its microstructure. In the samples heated up to 400 °C a tendency toward the formation of cellular dislocation substructure was observed (Fig. 4(a)), which was accompanied by transformation of diffraction rings (Fig. 1(e)) into separate slightly smeared reflections on the SAD patterns (Fig. 4(b)). After RH up to 500 °C, substructure further evolved towards the formation of cells (about 100 nm in diameter), but the cell boundaries were still rather diffused (Fig. 4(c)). The samples quenched after RH up to 600 °C consisted of a complex microstructure that comprised several components: subgrains with residual dislocations of relatively high density, fine recrystallized (about 100 nm) β grains with low defect density, and few rather coarse β grains formed, obviously, by the coalescence of subgrains (Fig. 4(d)).

Extension of RH up to 700 °C led to the completion of recrystallization (Fig. 4(e)) with β grain diameter of 200-300 nm, whereas after RH up to 800 °C β grain size increased up to 400-500 nm (Fig. 4(f)). It is worth mentioning that for the TIMETAL-LCB cold-rolled with 90% reduction (|ε|=2.28) and then rapidly heated at 5 °C/s the temperature of recrystallization finish was 815 °C [7], so the increase of true deformation from 2.3 to 5.9 reduced this temperature by about 100 °C. XRD of the samples heated up to various temperatures (Fig. 2) revealed gradual dissolution of the ω phase and α phase precipitation that appeared after 48 h holding at room temperature. The latter was not observed unequivocally in a conventional TEM study, presumably because during the heating nanosized α precipitates nucleated heterogeneously at ω particles [7,18,19]. It should be also noted that increasing the RH peak temperature above 400 °C was accompanied by an increase in the intensity of β phase peaks (curves d and e in Fig. 2). This may be explained by the reduction of average crystalline size, occurred at initial stages of recovery and recrystallization according to Ref. [20].

The data depicted above can be rationalized as follows. While the as-quenched material contained athermal w phase inside coarse b grains, intense cold deformation led to the shearing of w particles by gliding dislocations up to their complete breakdown/dissolution. Reappearance of the w phase reflections after 48 h exposure at ambient temperature looks somewhat astonishing, because isothermal w phase usually precipitates in the metastable b alloys at higher temperatures (250-400 °C) [7,21]. Nonetheless, extremely high density of defects after severe cold deformation, probably, could enhance diffusion processes even at room temperature, similarly to that in Ref. [20], where isothermal β→ω transformation at ambient temperature has been observed in-situ under electron irradiation in a TEM column. The abnormal drop in relative resistance of as-rolled samples upon subsequent RH can be attributed to extensive recovery, while after preliminary room-temperature exposure for 48 h the w precipitation led to stress relaxation and pinning up of dislocations. Eventually the phase composition and substructure of unexposed and exposed at room temperature samples equalized upon further heating, and their resistivity again coincided above 600 °C.

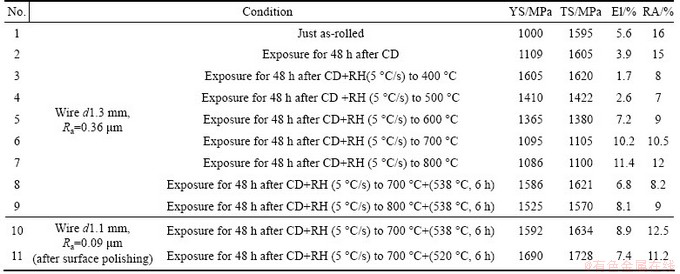

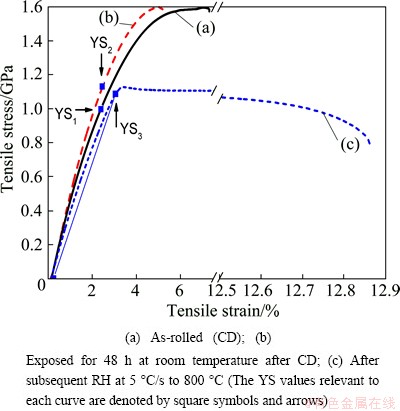

The results of tensile tests (Table 1) are consistent with the data and considerations stated above. Both specimens as-rolled and exposed for 48 h at room temperature had a relatively low yield strength (YS in Table 1, and curves a and b in Fig. 5), which can be attributed to easy initiation of plastic flow due to a high density of dislocations, including glissile ones. At the same time, tensile strength (TS) was rather high because of a significant cold-work strengthening, and the gap between YS and TS was unusually wide, being an evidence of residual potential of this material to subject further plastic deformation [6]. While 48 h pause between CD and tensile tests caused a negligible increase in TS, it was accompanied by an essential raise of YS (more than 100 MPa) and drop in ductility, which can be again explained by the ω phase precipitation that impeded dislocation motion. The specimens after CD held for 48 h at room temperature also had somewhat higher elastic modulus compared with as-rolled ones, which had been caused supposedly by isothermal w-phase precipitation. The w-phase elastic modulus was found to be approximately 4 times higher compared with the β-phase [22].

Table 1 Tensile properties of TIMETAL-LCB specimens under different conditions

Upon the RH to 400 °C the difference between YS and TS decreased (Table 1), while both strengths slightly increased, and the ductility dropped dramatically. Presumably, this is a result of formation of a specific metastable condition, characterized by a superposition of two parallel processes: ω particles dissolution, and dislocation structure transformation from a chaotic to cellular one (Fig. 4(c), and curve c in Fig. 2). Further heating resulted in a gradual reduction of strength and increase in ductility (Table 1). For instance, the specimens rapidly heated up to 800 °C, where recrystallization had competed and the β grains slightly had grown (Fig. 4(f)), had TS above 1000 MPa and elongation over 11% (Table 1 and curve 3 in Fig. 5). These changes in tensile properties after RH can be attributed to the processes mentioned above. Dissolution of isothermal ω phase precipitated at room temperature, recovery and cell substructure formation in the β phase, followed by recrystallization and grain growth. It is notable that tensile properties of recrystallized material with 100 nm (RH to 700 °C) and with 300 nm (RH to 800 °C) β-grain size were quite similar to those determined earlier for the same alloy cold-rolled (with |ε|=2.28) and then rapidly recrystallized (final β grain size below 10 μm), but measured on standard specimens with a gage of d4 mm [15].

Fig. 5 Engineering tensile stress-strain curves of TIMETAL-LCB under different conditions

As the metastable b titanium alloys are employed predominantly in an aged condition (Fig. 4(g)), the tensile properties of the samples after ageing were assessed. The aging of recrystallized samples at 538 °C for 8 h led to an attractive combination of strength and ductility. Again, the properties of aged material did not change significantly with more than a tenfold β-grain size reduction (Table 1). For instance, the samples after RH up to 700 °C and ageing had TS=1621 MPa, which is higher only by 110 MPa than that at the same alloy with a grain size of about 8 mm, but with a noticeable worsening of ductility [15]. Taking into account that titanium alloys in highly strengthened condition are very sensitive to stress concentrators [2], we assumed that in the present case, tensile properties could be underestimated because of relatively rough (Ra=0.36 μm) surface of the d1.3 mm wire obtained by rolling. From our point of view, such relatively strong roughness for this small wire diameter plays the role of a stiff enough surface stress concentrator, causing early failure of the material. Our attempts to improve the surface quality via electropolishing were unsuccessful, whereas mechanical polishing of the wire with a diamond paste allowing to reduce the surface roughness to 0.09 μm. As a result, both strength and ductility of the alloy aged at 538 °C were noticeably improved (Table 1), i.e., surface polishing allowed to reveal the real balance of mechanical properties of the alloy after this treatment. This effect allowed us to apply more “stiff” regime of aging at a lower temperature of 520 °C. The balance of tensile properties (TS=1728 MPa, and El=7.4% in Table 1) is prominent for this alloy, and may find a practical use, e.g. for the alloy used as a material reinforcing fibers for composites or in the wire ropes production.

4 Conclusions

Severe cold deformation applied to titanium TIMETAL-LCB alloy in metastable β condition led to the formation of a specific phase (because of athermal ω phase dissolution) and microstructural (extremely high density of dislocations) state, unstable to β→ω transformation even at room temperature. Subsequent rapid continuous heating allowed to control recovery and recrystallization processes at relatively low temperatures, and to form submicron microstructures with average β grain size of about 100 nm. As a result, an attractive combination of high strength and acceptable ductility was attained after aging; however, special attention should be paid to the surface conditions from the viewpoint of stress concentration mitigation. A wire with such a combination of high strength and acceptable ductility is promising for certain practical applications.

References

[1] ZWIKKER U. Titan und titanlegierungen [M]. Germany: Springer Verlag, 1974.

[2] LUTJERING G, WILLIAMS J C. Titanium [M]. Germany: Springer Verlag, 2003.

[3] BANIA P J. Beta titanium alloys and their role in the titanium industry [C]//Beta Titanium Alloys in the 1990’s. Warrendale, PA: The Three M’s Society, 1993: 3-14.

[4] EYLON D. Beta-titanium alloys—An overview [C]//3rd Japan International SAMPE Symposium. Tokyo: Society for the Advancement of Materials and Process Engineering, 1993: 1588-1595.

[5] IVASISHIN O M, TELIOVICH R V. Potential of rapid heat treatment of steels and titanium alloys [J]. Materials Science and Engineering A, 1999, 263: 142-154.

[6] KARASEVSKA O P, IVASISHIN O M, SEMIATIN S L, MATVIYCHUK YU V. Deformation behavior of beta-titanium alloys [J]. Materials Science and Engineering A, 2003, 354: 121-132.

[7] IVASISHIN O M, MARKOVSKY P E, SEMIATIN S L, MATVIYCHUK YU V. Precipitation and recrystallization behavior of beta titanium alloys during continuous heat treatment [J]. Metallurgical and Materials Transactions A, 2003, 34: 147-158.

[8] IVASISHIN O M, MARKOVSKY P E, SEMIATIN S L, WARD C H. Aging response of coarse- and fine-grained beta-titanium alloys [J]. Materials Science and Engineering A, 2005, 405: 296-305.

[9] GERASIMCHUK O M, NALIMOV YU S, MARKOVSKY P E, TERUKOV A V, BONDARCHUK V I. Microstructure influence on fatigue resistance characteristics of commercial titanium alloys [J]. Strength of Materials, 2011, 43: 282-297.

[10] GAZDER A A, VIET Q V, SALEH A A, MARKOVSKY P E, IVASISHIN O M, DAVIES C H J, PERELOMA E V. Recrystallization in a cold drawn low cost beta titanium alloy during rapid resistant heating [J]. Journal of Alloys and Compounds, 2013.

[11] SEMENOVA I P, RAAB G I, SAITOVA L R, VALIEV R Z. The effect of equal-channel angular pressing on the structure and mechanical behavior of Ti–6Al–4V alloy [J]. Materials Science and Engineering A, 2004, 378-389: 805-808.

[12] GUO Q, WANG Q, SUN D L, HAN X L, WU G H. Formation of nanostructure and mechanical properties of cold-rolled Ti-15V-3Sn-3Al-3Cr alloy [J]. Materials Science and Engineering A, 2010, 527: 4229-4232.

[13] ZHANG Z Q, DONG L M, YANG Y, GUAN S X, LIU Y Y, YANG R. Microstructure refinement of a dual phase titanium alloy by severe room temperature compression [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2604-2608.

[14] GRIDNEV V N, IVASISHIN O M, MARKOVSKY P E. Influence of heating rate on the temperature of the α+β→β transformation of titanium alloys [J]. Met Sci and Heat Treatment, 1985, 25: 43-47.

[15] IVASISHIN O M, MARKOVSKY P E, MATVIYCHUK YU V, SEMIATIN S L, WARD C H, FOX S. A comparative study of the mechanical properties of high-strength beta-titanium alloys [J]. Journal of Alloys and Compounds, 2008, 457: 296-309.

[16] WEISS L, SRINIVASAN R, SAGIB M, STEFANSSON N, JACKSON A G, LeCLAIR S R. Bulk deformation of Ti-6.8Mo-4.5Fe-1.5Al (Timetal LCB) alloy [J]. Journal of Material Engineering and Performance, 1996, 5: 335-352.

[17] SUN F, ZHANG J Y, MARTELEUR M, GLORIANT T, VERMAUT P, LAILLE D, CASTANY P, CURFS C, JACQUES P J, PRIMA F. Investigation of early stage deformation mechanisms in a metastable b titanium alloy showing combined twinning-induced plasticity and transformation-induced plasticity effects [J]. Acta Materialia, 2013, 61: 6406-6417.

[18] PRIMA F, VERMAUT P, TEXIER G, ANASEL D, GLORIANT T. Evidence of a-nanophase heterogeneous nucleation from w particles in a b-metastable Ti-based alloy by high-resolution electron microscopy [J]. Scripta Materialia, 2006, 54: 645-648.

[19] NAG S, BANERJEE R, SRIVASAN R, HWANG J Y, HARPER M, FRASER H L. w-assisted nucleation and growth of a precipitates in the Ti-5Al-5Mo-5V-3Cr-0.5Fe b titanium alloy [J]. Acta Materialia, 2009, 57: 2136-2147.

[20] BANERJEE S, MUKHOPADHYAY P. Phase transformations: examples from titanium and zirconium alloys [M]. USA: Elsevier, 2007.

[21] KRIVOGLAZ M A. Theory of X-ray and thermal-neutron scattering by real crystals [M]. USA: Plenum Press, 1969.

[22] NAKAI M, NIINOMI M, AKAHORI T, TSUTSUMI H, OGAWA M. Improvement in fatigue strength of Ti-29Nb-13Ta-4.6Zr alloy by optimizing omega phase precipitation [C]//Processing and Fabrication of Advanced Materials XVIII, Proceedings of International Symposium. Sendai, Japan: Tohoku University, 2009: 787-794.

P. E. MARKOVSKY, V. I. BONDARCHUK, YU. V. MATVIYCHUK, O. P. KARASEVSKA

G. V. Kurdyumov Institute for Metal Physics, National Academy of Sciences of Ukraine, 36, Vernadsky Blvd., 03142, Kiev, Ukraine

摘 要:研究连续快速加热条件下亚稳β Ti-1.5%Al-6.8%Mo-4.5%Fe钛合金剧烈冷变形对其显微组织、相组成和拉伸性能演变的影响。轧制态合金具有准非晶单相β结构,其电阻率与温度的关系呈现异常;将轧制态合金在室温下冷却暴露48 h,由于等温ω相的析出,电阻率与温度的关系恢复正常。随后,将合金以加热速率为5 °C/s进行快速热处理,导致回复和再结晶发生。测定和讨论了不同处理后合金的拉伸性能。

关键词:钛合金;剧烈冷变形;快速加热;回复和再结晶;相组成;显微组织;力学性能

(Edited by Xiang-qun LI)

Corresponding author: P. E. MARKOVSKY; Tel/Fax: +380-44-4243374; E-mail: pmark@imp.kiev.ua

DOI: 10.1016/S1003-6326(14)63200-3