高分数GNFs/6061Al基复合材料的放电等离子体烧结制备及其显微组织与性能

来源期刊:中国有色金属学报(英文版)2021年第6期

论文作者:常浩 孙健 陈国宏 汪冰 杨磊 张建华 汤文明

文章页码:1550 - 1560

关键词:电子封装复合材料;放电等离子体烧结(SPS);6061铝合金;纳米石墨片(GNF);显微组织;热学性能;力学性能

Key words:electronic packaging composite; spark plasma sintering (SPS); 6061Al alloy; graphite nanoflake (GNF); microstructure; thermal property; mechanical property

摘 要:采用放电等离子体烧结(SPS)工艺在610°C制备30%~50%(质量分数)纳米石墨片(GNF)/6061Al基复 合材料,研究烧结压力及GNF含量对复合材料显微组织和力学、热学性能的影响。结果表明,SPS有效抑制 GNFs/6061Al基复合材料中Al4C3等界面反应产物的生成。随着GNF含量的增加,GNFs团聚程度增加,取向分布程度降低,复合材料致密度、抗弯强度及热膨胀系数(CTE)下降,X-Y方向热导率(TC)增大。提高烧结压力,有助于降低GNFs团聚程度,GNFs沿X-Y方向择优分布越明显,复合材料致密度、抗弯强度及TC增大,CTE下降。在610 °C、55 MPa下烧结的50%GNFs/6061Al基复合材料的性能最佳,抗弯强度为72 MPa,TC及CTE分别为254 W/(m·K)和8.5×10-6 K-1 (室温~100 °C,X-Y方向),以及55 W/(m·K)和9.7×10-6 K-1 (Z方向)。

Abstract: 30–50 wt.% graphite nanoflakes (GNFs)/6061Al matrix composites were fabricated via spark plasma sintering (SPS) at 610°C. The effects of the sintering pressure and GNF content on the microstructure and properties of the composites were investigated. The results indicated that interfacial reactions were inhibited during SPS because no Al4C3 was detected. Moreover, the agglomeration of the GNFs increased, and the distribution orientation of the GNFs decreased with increasing the GNF content. The relative density, bending strength, and coefficient of thermal expansion (CTE) of the composites decreased, while the thermal conductivity (TC) in the X-Y direction increased. As the sintering pressure increased, the GNFs deagglomerated and were distributed preferentially in the X-Y direction, which increased the relative density, bending strength and TC, and decreased the CTE of the composites. The 50wt.%GNFs/6061Al matrix composite sintered at 610°C under 55 MPa demonstrated the best performance, i.e., bending strength of 72 MPa, TC and CTE (RT-100°C) of 254 W/(m·K) and 8.5×10-6 K-1 in the X-Y direction, and 55 W/(m·K) and 9.7×10-6 K-1 in the Z direction, respectively.

Trans. Nonferrous Met. Soc. China 31(2021) 1550-1560

Hao CHANG1, Jian SUN1, Guo-hong CHEN2, Bing WANG3, Lei YANG4, Jian-hua ZHANG1, Wen-ming TANG1,5

1. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China;

2. Electric Power Research Institute, State Grid Anhui Electric Power Co., Ltd., Hefei 230601, China;

3. Anhui Province Key Laboratory of Microsystem, Hefei 230088, China;

4. Hefei Shengda Electronic Technology Industry Co., Ltd., Hefei 230088, China;

5. Engineering Research Center of High Performance Copper Alloy Materials and Processing, Ministry of Education, Hefei 230009, China

Received 18 June 2020; accepted 24 December 2020

Abstract: 30–50 wt.% graphite nanoflakes (GNFs)/6061Al matrix composites were fabricated via spark plasma sintering (SPS) at 610 °C. The effects of the sintering pressure and GNF content on the microstructure and properties of the composites were investigated. The results indicated that interfacial reactions were inhibited during SPS because no Al4C3 was detected. Moreover, the agglomeration of the GNFs increased, and the distribution orientation of the GNFs decreased with increasing the GNF content. The relative density, bending strength, and coefficient of thermal expansion (CTE) of the composites decreased, while the thermal conductivity (TC) in the X-Y direction increased. As the sintering pressure increased, the GNFs deagglomerated and were distributed preferentially in the X-Y direction, which increased the relative density, bending strength and TC, and decreased the CTE of the composites. The 50wt.%GNFs/6061Al matrix composite sintered at 610 °C under 55 MPa demonstrated the best performance, i.e., bending strength of 72 MPa, TC and CTE (RT-100 °C) of 254 W/(m·K) and 8.5×10-6 K-1 in the X-Y direction, and 55 W/(m·K) and 9.7×10-6 K-1 in the Z direction, respectively.

Key words: electronic packaging composite; spark plasma sintering (SPS); 6061Al alloy; graphite nanoflake (GNF); microstructure; thermal property; mechanical property

1 Introduction

Miniaturization and high-density packaging of microelectronics and power electronic devices require high-performance electronic packaging materials [1]. Carbon materials/Al matrix composites with high thermal conductivities (TCs) and low thermal expansion have been developed as novel electronic packaging materials. Examples of these materials include Al and Al alloy composites reinforced by the natural graphite plates (NGPs), carbon nanotubes (CNTs), carbon fibers, graphene, and diamond [2,3]. However, the fabrication and application of these carbon materials/Al matrix composites still face many challenges. A brittle interfacial phase (Al4C3) may form at high temperatures because C-Al is a binary reaction system. The formation of this phase has negative influences on the microstructure and properties of the composites [4]. Although the formation of Al4C3 can be effectively inhibited by wrapping the carbon reinforcements by Ag, Cu, and Ni films [5,6], this process is complicated.

Compared with the one-dimensional carbon materials, e.g., CNTs and carbon fibers, the two-dimensional carbon materials such as NGPs and graphene are superior for reducing the anisotropic structures and properties in composites. However, NGPs/Al matrix composites still have low strengths and considerably anisotropic TCs and coefficients of thermal expansion (CTEs) due to the dramatic segmentation of large NGPs from Al matrix [7,8]. For example, 50wt.%NGPs/Al matrix composites prepared via SPS have a TC of 375 W/(m·K) in the direction parallel to the graphite basal plane (the X-Y direction), whereas their TC in the direction perpendicular to the graphite basal plane (Z direction) is as low as 40 W/(m·K) [9]. Although a small amount of graphene (<1 wt.%) can be uniformly distributed in the metal matrix by ultrasonic stirring [10], ball milling [11], and electrostatic adsorption [12], graphene undergoes severe agglomeration at high fractions [13]. This problem limits the development and application of the graphene/metal matrix composites used as the electronic packaging materials [14].

CHEN et al [15] and NIE et al [16] have achieved good results in obtaining uniformly-dispersed reinforcements. 5-15wt.%GNFs/6061Al matrix composites fabricated by spark plasma sintering (SPS) showed satisfactory mechanical and thermal properties, and the anisotropies of TCs and CTEs of the composites were greatly reduced [15]. As an example, the relative density and bending strength of a 10wt.%GNFs/6061Al matrix composite were 98.5% and 120 MPa, respectively. Meanwhile, the TCs and CTEs (RT-100 °C) of the composite were 155 W/(m·K) and 14.2×10-6 K-1 in the X-Y direction, and 61 W/(m·K) and 12.1×10-6 K-1 in the Z direction; however, the TC of composites is not high enough. As reported by ESMATI et al [17], the TC/CTE of the graphite/6061Al matrix composites can be further increased/reduced with increasing the graphite fraction of the composites, because the composites have a high relative density and an excellent microstructure.

As for the SPS process, extra Joule heat can be used to rapidly heat the interior of sintered bodies, and the heating rate can reach 400 °C/min, which allows sintered bodies to be densified quickly [18]. In addition, the sintering pressure is a vital factor for improving the microstructure and properties of composites [19]. In this work, 30-50wt.%GNFs/ 6061Al matrix composites were fabricated via SPS process. The effects of the sintering pressure and the GNF fraction on the microstructure, mechanical properties, and thermal properties of the high- fraction GNFs/6061Al matrix composites were systematically investigated. The TC and CTE of the composites meet the installation requirement of electronic devices (≥30 MPa) [20].

2 Experimental

2.1 Raw materials

Nitrogen atomized 6061Al alloy powder (average diameter: 15 μm) provided by Tianjiu Metal Co., Ltd., Changsha, China, and GNFs (purity 99 wt.%, average diameter 80 μm and thickness less than 100 nm) supplied by Q-CARBON Carbon Materials Co., Ltd., Shanghai, China, were used as raw materials to prepare the GNFs/6061Al matrix composites. The spherical or quasi-spherical 6061Al alloy powders have a chemical composition of 0.975 wt.% Mg, 0.59 wt.% Si, 0.092 wt.% Fe, 0.289 wt.% Cu, 0.08 wt.% Mn, 0.031 wt.% Zn, and Al balance. The characteristics of the 6061Al alloy powders and the GNFs are available in Ref. [15].

2.2 Processing

The GNFs varying from 30 to 50 wt.% were first dispersed in the absolute ethanol and then ultrasonically stirred for 60 min. After that, 6061Al powders were placed into the GNFs-ethanol suspension and mechanically stirred for 8 h with ultrasonic stirring. A viscous slurry gradually formed, and it was dried at 60 °C for 3 h. Finally, the dried product was ground lightly in an agate mortar to obtain the GNFs/6061Al powder mixture.

The powder mixtures with GNF fractions of 30, 40, and 50 wt.% were filled into a graphite mold and then sintered through SPS process at 610 °C for 10 min under pressures of 35, 45, and 55 MPa. The maximum loading of 55 MPa was limited by the strength of the graphite die. The other parameters used in the SPS procedure were the same as those in our previous work [15].

2.3 Characterization

The microstructures and fracture morphologies of the sintered specimens were investigated using an MR-3000 optical microscope (OM) and an SU8020 field emission scanning electron microscope (SEM). Energy-dispersive spectroscopy (EDS) was conducted using an Oxford INCA instrument. The phases of the composites were detected through X-ray diffraction (XRD) with Cu Kα radiation.

The density of the specimens was measured by the Archimedes’ method. The three-point bending strength was tested on an AG-X PLUS microcomputer-controlled electronic universal testing machine, and the specimen dimensions were 50 mm × 4 mm × 3 mm with a span of 32 mm. The coefficient of thermal diffusivity (a) of the composites was tested on an LFA457 laser thermal conductivity meter. The TC (K) was then calculated as

K=aρcp (1)

where ρ is the density of the composites, and cp is the constant pressure heat capacity of the composites calculated by the rule of mixtures [21]:

cp=cmmm+crmr (2)

where cm and cr are the constant heat capacities of 6061Al and GNFs, which were 0.896 and 0.71 J/(g·K), respectively; mm and mr refer to the mass fractions of 6061Al and GNFs in the composites. The CTEs of the composites (10 mm × 5 mm × 3 mm) were measured by a TMA402F3 thermal mechanical analyzer with a test temperature ranging from RT to 500 °C at a heating rate of 5 °C/min.

3 Results and discussion

3.1 Sintering pressure

3.1.1 Microstructures

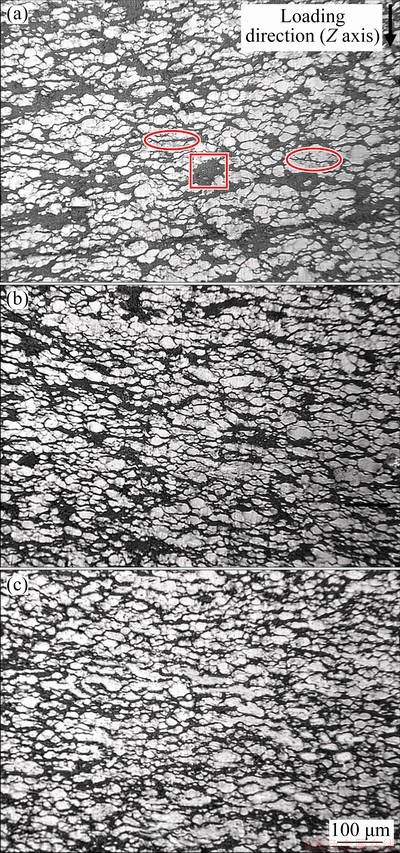

Figure 1 illustrates the microstructures of the 30wt.%GNFs/6061Al matrix composite sintered at 610 °C under different pressures. The gray zones are the 6061Al alloy matrix, and the black zones are mostly the GNFs, besides very few pores. The composites were compressed axially with a large displacement. The GNFs deflect accordingly along with the plastic deformation of the 6061Al alloys and were preferentially distributed in the X-Y direction, as shown by the ellipse in Fig. 1(a). The agglomeration of the GNFs was observed due to the high GNF fraction in the composites, as shown in the box in Fig. 1(a). The agglomeration of the GNFs was the severest, and the greatest number of pores was obtained in the composite sintered under 35 MPa (Fig. 1(a)). Moreover, discontinuously- distributed spherical aluminum alloy particles were observed, indicating poor sintering densification of the composites [22]. With increasing the sintering pressure, the relative density of the composites, and the orientation degree of the GNFs increased, but the GNF agglomeration decreased (Figs. 1(b, c)). This was attributed to the tendency of GNFs to move axially and orient radially along the Al alloy matrix, resulting in the deagglomeration and preferential distribution of GNFs in the X-Y direction via an interlayer slipping mechanism. After significant plastic deformation, the Al alloy matrix originally wrapped or segmented by the GNFs was connected to form continuous long stripes, which appeared to improve the densification of the composites.

Fig. 1 OM images of 30wt.%GNFs/6061Al matrix composites sintered under 35 MPa (a), 45 MPa (b) and 55 MPa (c)

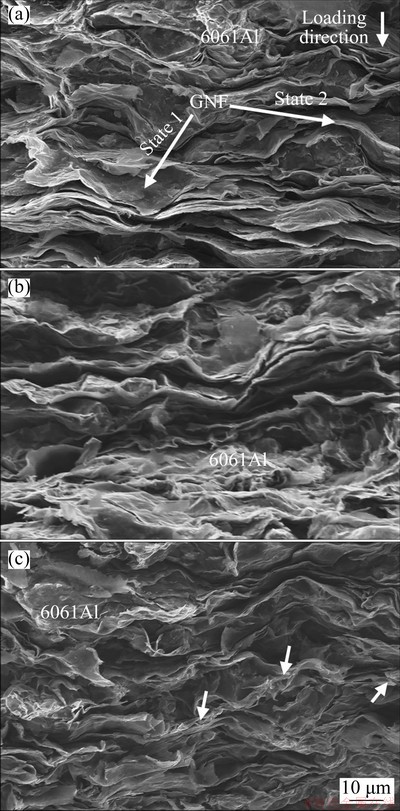

Two states of the GNFs on the bending fracture surfaces of the 30wt.%GNFs/6061Al matrix composites are presented in Fig. 2(a). One is the GNFs tile on the fracture surfaces, where the fracture cracks extend along the GNF layers. The other is that the GNFs are perpendicular to the fracture surface, and thus they are torn or pulled out along the basal plane under the applied load. The carbon atoms between the two GNF layers were connected by extremely weak π-bonding, preventing the GNFs from dissipating the fracture energy. Conversely, the carbon atoms in the same GNF basal plane were connected by strong σ bonding [23]; therefore, the tearing of the GNFs across the basal plane must consume large amounts of energy. Moreover, incommensurable plastic deformation between the GNFs and the 6061Al alloy matrix led to the debonding of the GNF/6061Al interfaces [24], and the GNFs were completely pulled out from the matrix under the fracture stress to form severe deep flat secondary cracks perpendicular to the fracture surface.

Fig. 2 SEM images of 30wt.%GNFs/6061Al composites sintered under 35 MPa (a), 45 MPa (b) and 55 MPa (c)

The Al alloy matrix in Fig. 2(a) was segmented by the GNFs. Both the densification and the plastic deformation of the Al alloy matrix were low at such a low sintering pressure. As the sintering pressure increased, the preferential orientation of the GNFs tended to be more distinct, and more GNFs were oriented perpendicularly to the fracture surface. The plastic fracture of the Al alloy matrix also indicates a high densification of composites (Figs. 2(b, c)). In addition, the GNFs in the composites experienced compressive stress, which improved the GNFs/Al alloy interfacial bonding strength. More GNFs torn across their basal plane appeared on the fracture surface, as shown by the arrows in Fig. 2(c). This huge energy absorption significantly improved the strength and toughness of the GNFs/6061Al matrix composites.

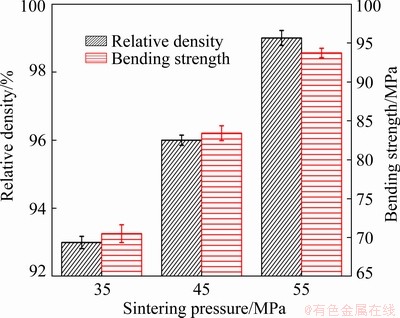

3.1.2 Relative density and bending strength

As shown in Fig. 3, the relative density and bending strength of the 30wt.%GNFs/6061Al matrix composites increased almost simultaneously with the sintering pressure. This indicated that the relative density was the key factor for improving the strength of the GNFs/6061Al matrix composites. First, the bridging effect between Al alloy particles was eliminated under a high sintering pressure, which was conducive to the pulse discharge and a steady-state current flow in the sintered bodies during SPS procedure [25]. Secondly, the compression yield strength of the 6061Al was 55.2 MPa at RT, and it decreased as the temperature increased. Therefore, the Al alloy matrix underwent plastic deformation in the 30wt.%GNFs/6061Al matrix composites during sintering at 610 °C under pressures varying from 35 to 55 MPa. This is the same as Cu in the diamond/Cu matrix composites during SPS procedure [26]. In this way, the pores were further filled, which densified the composites. Finally, as mentioned in Section 3.1.1, the deagglomeration and orientation distribution in the X-Y direction of the GNFs were promoted. In summary, the continuously-distributed Al alloy matrix and the well-combined GNFs/Al alloy interface simultaneously increased the relative density and strength of the composites.

Fig. 3 Changes in relative density and bending strength of 30wt.%GNFs/6061Al matrix composites with sintering pressure

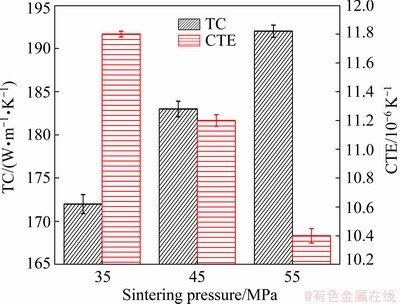

3.1.3 Thermal conductivity and coefficient of thermal expansion

As shown in Fig. 4, the TC/CTE of the 30wt.%GNFs/6061Al matrix composites in the X-Y direction increased/decreased monotonically with the increase of the sintering pressure. The increased pressure improved the GNF/6061Al interfacial bonding, which led to better coupling between the electrons in the Al alloy and the phonons in the GNFs [8]. Furthermore, the increase in the relative density of the composites indicates a decrease in the porosity. As reported by WANG et al [27], taking the influence of the pores into account, the TC of the composites can be described as

Kc-p=KcVc+KpVp (3)

where V is the volume fraction, and the subscripts c-p, c, and p refer to the composites with/without pores and the pores, respectively. The TC of air is only 0.026 W/(m·K), and hence fewer pores cause a lower thermal resistance; thus, the TC of the composites can be improved by reducing the pores as much as possible [28]. Besides, the well- combined GNF/6061Al interface also improves the ability of the GNFs to inhibit the thermal expansion of the 6061Al alloy matrix [29].

Fig. 4 TC and CTE of 30wt.%GNFs/6061Al matrix composites in X-Y direction with sintering pressure

More importantly, the deagglomeration and preferential orientation of the GNFs caused an apparent increase/decrease in the TC/CTE of the composites in the X-Y direction, since the TC of the GNFs along the basal plane was extremely higher than that of the GNFs perpendicular to the basal plane, whereas the CTE of the composites displayed the opposite trend [30]. Thus, the preferentially-distributed GNFs had a greater impact on both improving the TC in the X-Y direction and reducing the thermal expansion of the 30wt.%GNFs/6061Al matrix composites. Compared with the 10wt.%GNFs/6061Al matrix composites subjected to SPS process (relative density: 98.5%, TC: 155 W/(m·K), CTE: 14.2× 10-6 K-1 (RT-100 °C)) [15], the 30wt.%GNFs/ 6061Al matrix composites in this work showed much higher TCs and lower CTEs.

In summary, both the mechanical and thermal properties of the GNFs/6061Al matrix composites were improved by increasing the sintering pressure. Therefore, the largest sintering pressure (55 MPa) was used in subsequent studies to probe the effect of the GNF fraction on the microstructure and properties of the GNFs/6061Al matrix composites.

3.2 GNF fraction

3.2.1 Microstructures

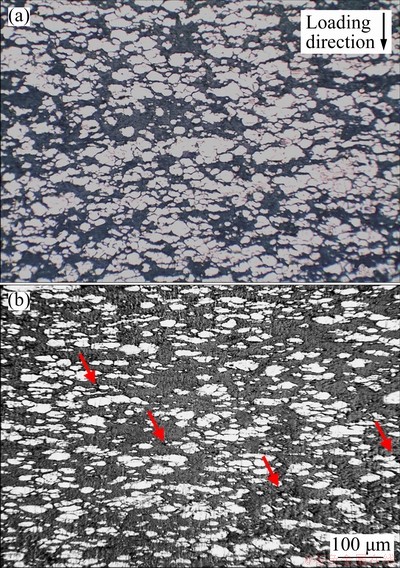

Microstructures of the GNFs/6061Al matrix composites with GNF fractions varying from 30 to 50 wt.% fabricated by SPS process at 610 °C under 55 MPa are shown in Figs. 1(c) and 5, respectively. With increasing the GNF fraction, severe aggregation of the GNFs was observed in the composites, and the Al alloy particles were distributed more discontinuously in the GNFs matrix. Besides, more micropores were present in the GNFs and at the GNF/6061Al interfaces, as shown by the arrows in Fig. 5(b). More detailed microstructural information is available in Ref. [15]. Accordingly, the relative densities of the composites decreased gradually.

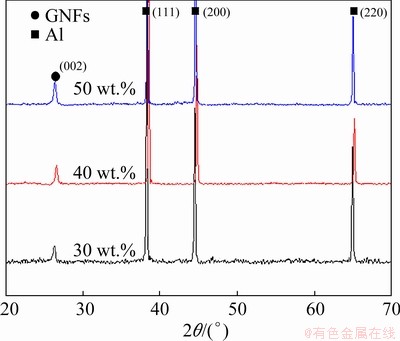

In the previous work, the interface characteristic of the 5wt.%GNFs/6061Al matrix composite fabricated by SPS process at 610 °C was investigated [15]. A 15-18 nm interfacial transition layer connected the GNFs and the 6061Al matrix tightly. No Al4C3 was observed at the GNF/6061Al interface. In this work, only diffraction peaks of graphite and Al in the 30-50wt.%GNFs/6061Al matrix composites were detected by XRD (Fig. 6), and the three strongest diffraction peaks of Al4C3 (101), (012), and (107) were not found in the 2θ range of 30.5°-41.0° [31]. Thus, it was concluded that no Al4C3 was formed, even in the high-fraction GNFs/6061Al matrix composites, because the interfacial reactions were prohibited in the composites.

Fig. 5 OM images showing microstructures of 40 wt.% (a) and 50 wt.% (b) GNFs/6061Al matrix composites

Fig. 6 XRD patterns of GNFs/6061Al matrix composites with different GNF fractions

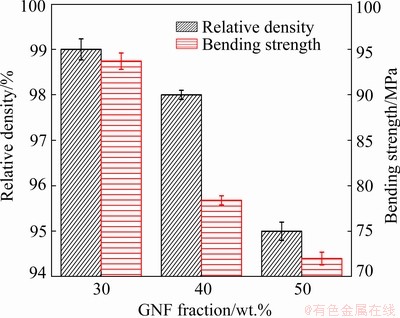

3.2.2 Relative density and bending strength

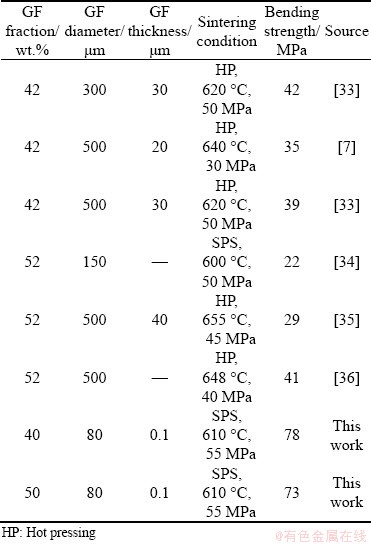

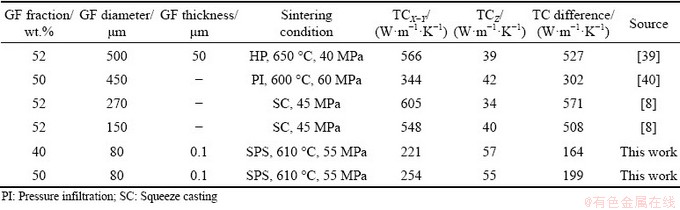

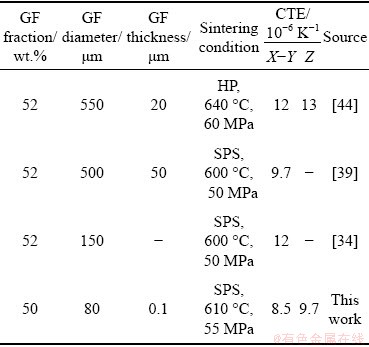

As shown in Fig. 7, the relative densities and bending strengths of the GNFs/6061Al matrix composites decreased monotonically with increasing the GNF fraction. As the GNF fraction increased, the GNFs aggregated more severely (Fig. 1(c) and Fig. 5), and the pores were difficult to be welded or filled with the Al alloy [13]. On the other hand, the Al alloy matrix was separated by the GNFs to form more GNF/Al alloy interfaces and interfacial pores, which caused the relative densities to decrease. In this situation, microcracks in the composites preferentially propagated both in the GNF agglomerates and GNF/Al alloy interfaces due to the low microcrack propagation resistance. The bending strengths of the composites therefore considerably decreased. The 50wt.%GNFs/6061Al matrix composite showed a bending strength of 72 MPa, which was much higher than that of the NGPs/2014Al matrix composites (23 MPa) [32]. Compared with other graphite flakes (GFs)/Al matrix composites with similar GF fractions, the GNFs/6061Al matrix composites have a higher bending strength (Table 1). Despite the different methods and conditions used to prepare these composites, the main results in this work demonstrated that the factors affecting the strength of the composites were mainly their relative density and microstructure. The orientation distribution of the GNFs and the segmentation of the Al alloy matrix by the GNFs were greatly reduced in the GNFs/6061Al matrix composites due to the much smaller diameter and thickness of the GNFs. As a result, the bending strengths of the composites considerably increased.

Fig. 7 Relative density and bending strength of GNFs/6061Al matrix composites with different GNF fractions

Table 1 Bending strengths of GFs/Al matrix composites

3.2.3 Thermal conductivity and coefficient of thermal expansion

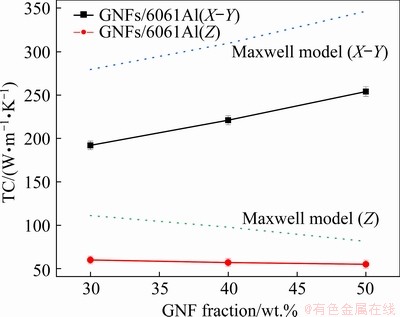

As shown in Fig. 8, with increasing the GNF fraction, the TCs of the GNFs/6061Al matrix composites in the X-Y direction increased, while those of the composites in the Z direction decreased slightly. Since the TC of the GNFs in the basal plane (600 W/(m·K)) [15] was much higher than that of the 6061Al alloy (163.6 W/(m·K), heat conduction in the composites along the X-Y direction was mainly implemented by the basal plane of the GNFs. Since the GNF fraction was higher than 30 wt.%, the GNFs in the composites tended to be continuous (Figs. 1(c) and 5); therefore, the TCs of the high-fraction GNFs/ 6061Al matrix composites in the X-Y direction increased greatly. The continuously-distributed GNFs separated in the Al alloy matrix; thus, the contribution of the Al alloy matrix to the TCs of the composites in the Z direction gradually decreased. The TC of the composites in the Z direction mainly depended on that of the GNFs perpendicular to the basal plane (15 W/(m·K)) [37]. Therefore, the TCs in the Z direction were much lower than those in the X-Y direction in the high-fraction GNFs/6061Al matrix composites. As the GNF fraction increased from 30 to 50 wt.%, the TCs of the composites in the Z direction decreased slightly. Compared with the low-fraction GNFs/6061Al matrix composites, the high-fraction composites had much higher TCs in the X-Y direction and approximately equaled TCs in the Z direction. Thus, the composites generally exhibited a remarkable improvement in thermal conductivity.

Fig. 8 Measured (solid lines) and model-predicted (dashed lines) TCs of GNFs/6061Al matrix composites as function of GNF fraction

The TCs of the GNFs/6061Al matrix composites were predicted via a modified Maxwell model [38]:

(4)

(4)

where Kc, Km, and Kr are the TCs of the composites, the 6061Al matrix, and the GNFs, respectively; n is the shape factor of the GNFs. All of them are available in Ref. [15]. As shown in Fig. 8, the measured (solid lines) TCs of the composites in both the X-Y and Z directions followed the same trend as the calculated ones (dashed lines) as the GNF fraction increased. However, the measured TCs were always low due to the high thermal resistance of the pores and the GNF/6061Al interfaces in the composites.

The GNFs/6061Al matrix composites in this work possessed the highest TC in the Z direction and the smallest TC difference between the X-Y and Z directions (Table 2) among the GFs/Al composites. This confirmed that the GNFs with a small diameter and thickness greatly alleviated the anisotropy of the GNFs/6061Al matrix composites.

Table 2 TCs in X-Y and Z directions and their differences in GFs/Al matrix composites

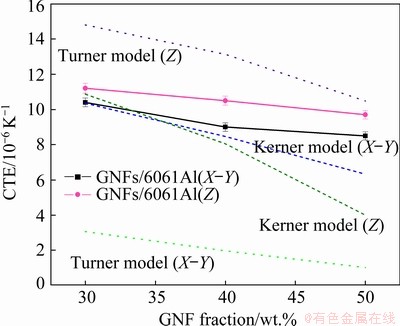

As shown in Fig. 9, the CTEs (RT-100 °C) in the X-Y and Z directions of the GNFs/6061Al matrix composites decreased as the GNF fraction increased [41]. Once the GNF fraction reached 50 wt.%, the CTEs of the composites in the X-Y and Z directions were 8.5 and 9.7×10-6 K-1, respectively. They are also much lower than those of the 10wt.%GNFs/6061Al matrix composites (14.2×10-6 and 12.1×10-6 K-1, respectively) [15]. In general, the high-fraction GNFs/6061Al matrix composites exhibited low CTEs in the two directions, similar to the CTEs of the chips and ceramic substrates used in electronic devices [40]. This should effectively eliminate the thermal stress and improve the durability and operational reliability of the electronic devices.

Fig. 9 Measured (solid lines) and model-predicted (dashed lines) CTEs of GNFs/6061Al matrix composites as function of GNF fraction

Here, TURNER and KERNER models [42,43] (Eqs. (5) and (6)) were used to predict the CTEs of the high-fraction GNFs/6061Al matrix composites:

(5)

(5)

(6)

(6)

where α is the CTE of the GNFs; K is the bulk modulus, K=E/[3(1-2v)]; G is the shear modulus, G=E/[2(1+v)]; E is the elastic modulus; v is Poisson ratio; the subscripts c, m, and r represent the composites, the 6061Al alloy, and the GNF reinforcements, respectively. All are available in Ref. [15]. The calculated CTEs of the high-fraction GNFs/6061Al matrix composites were superimposed in Fig. 9. The Kerner model is more suitable for predicting the CTEs of the composites because the Turner model only assumes a uniform static stress, as two phases in the composites deform harmoniously. Furthermore, shear stress also exists between the reinforcements and the matrix of the composites in the Kerner model. Thus, the Kerner model is more suitable for the high-fraction GNFs/6061Al matrix composites. Furthermore, the relative density has a great influence on the thermal expansion of the composites. Since the 30wt.%GNFs/6061Al matrix composite is nearly completely dense (99%), the tested CTE is very close to the value predicted by the Kerner model. As the GNF fraction increased, the relative densities of the composites gradually decreased, and the restraining effect of the GNFs on the thermal expansion of the Al alloy matrix became increasingly weaker. As a result, the deviation between the measured and predicted CTEs of the composites increased.

A comparison of the CTEs of several GFs/Al matrix composites of similar GF fractions is listed in Table 3. The 50wt.%GNFs/6061Al matrix composites have the lowest CTEs in both X-Y and Z directions, indicating the strongest restraint effect of the GNFs on thermal expansion of the Al alloy matrix. This is also attributed to the small diameter and thickness of the GNFs.

Table 3 Comparison of CTEs of GFs/Al matrix composites

4 Conclusions

(1) Low-temperature, rapid sintering of the 30-50wt.%GNFs/6061Al matrix composites via SPS process were achieved, and the obtained composites have a high relative density and clean interface without any Al4C3 interfacial reaction product.

(2) The preferential orientation of the GNFs in the X-Y direction became more apparent as the sintering pressure increased. The bending strength of the composites increased as the relative density increased. Moreover, as the GNF fraction increased, the GNFs aggregated, and the GNF/Al alloy interface degraded, which led to a decrease in the relative density and bending strength.

(3) With increasing the GNF fraction and/or the sintering pressure, the TCs in the X-Y direction of the GNFs/6061Al matrix composites increased, while the CTEs of the composites decreased. These are in accordance with the results predicted by the modified Maxwell model and the Kerner model, respectively.

(4) The bending strength of the 50wt.%GNFs/ 6061Al matrix composite fabricated by the SPS process at 610 °C and 55 MPa was 72 MPa. The TC and CTE of the composite were 254 W/(m·K), 8.5×10-6 K-1 in the X-Y direction, and 55 W/(m·K), 9.7×10-6 K-1 in the Z direction, respectively. Compared with the GFs/Al matrix composites fabricated using large GFs, the GNFs/6061Al matrix composites possessed better properties. Additionally, the TC of the composite in the Z direction was significantly improved, and the anisotropy of the composites was therefore effectively reduced.

Acknowledgments

The authors are grateful for the financial support from the International Science & Technology Cooperation Program of China (No. 2014DFA50860).

References

[1] TENG Fei, YU Kun, LUO Jie, FANG Hong-jie, SHI Chun-li, DAI Yi-long, XIONG Han-qing. Microstructures and properties of Al-50%SiC composites for electronic packaging applications [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(10): 2649-2651.

[2] LIU T T, HE X B, ZHANG L. Fabrication and thermal conductivity of short graphite fiber/Al composites by vacuum pressure infiltration [J]. Journal of Composite Materials, 2014, 48(18): 2207-2214.

[3] YANG Bo, YU Jia-kang, CHEN Chuang. Microstructure and thermal expansion of Ti coated diamond/Al composites [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1167-1173.

[4] WANG J, GUO L N, LIN W M, CHEN J, LIU C L, CHEN S D, ZHANG S, ZHEN T T. Effect of the graphene content on the microstructures and properties of graphene/aluminum composites [J]. Carbon, 2019, 34(3): 275-285.

[5] HAN X P, HUANG Y, DING L, GAO X G, XU Z P. High thermal conductivity of GF@Cu@Ni/Si/Al composites reinforced with Cu and Ni co-deposited graphite flakes [J]. Ceramics International, 2020, 46(11): 19191-19197.

[6] HAN X P, HUANG Y, GAO Q, FAN R, PENG X Y. Effects of nanotube content on thermal and mechanical properties of NT@Cu/Ag@GF/Al composites [J]. Journal of Alloys and Compounds, 2018, 766: 594-600.

[7] XUE C, BAI H, TAO P F, WANG J W, JIANG N, WANG S L. Thermal conductivity and mechanical properties of flake graphite/Al composite with a SiC nano-layer on graphite surface [J]. Materials and Design, 2016, 108: 250-258.

[8] LI W J, LIU Y. Preparation of graphite flakes/Al with preferred orientation and high thermal conductivity by squeeze casting [J]. Carbon, 2015, 95: 545-551.

[9] ODDONE V, BOERNER B, REICH R. Composites of aluminum alloy and magnesium alloy with graphite showing low thermal expansion and high specific thermal conductivity [J]. Science and Technology of Advanced Materials, 2017, 8: 180-186.

[10] ANKITA B, MUKUL S, MANOJ K, INDRANIL L, DEBRUPA L. Strengthening mechanism in graphene nanoplatelets reinforced aluminum composite fabricated through spark plasma sintering [J]. Materials Science and Engineering A, 2017, 695: 20-28.

[11] LI Z, FAN G, GUO Q, LI Z, SU Y, ZHANG D. Synergistic strengthening effect of graphene carbon nanotube hybrid structure in aluminum matrix composites [J]. Carbon, 2015, 95: 419-427.

[12] ZHAO Wen-min, BAO Rui, YI Jian-hong, HOU Xiang-hui, FANG Dong, LIU Chun-xuan. Fabrication of RGO/Cu composites based on electrostatic adsorption [J]. Transactions of Nonferrous Metals Society of China, 2020, 30(4): 982-991.

[13] LI J L, XIONG Y C, WANG X D, YANG S J, YANG C, HE W W, CHEN J Z, WANG S Q, ZHANG X Y, DAI S L. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling [J]. Materials Science and Engineering A, 2015, 626: 400-405.

[14] SABOORI A, PAVESE M, BADINI C. Development of Al- and Cu-based reinforced by graphene nanoplatelets: Fabrication and characterization [J]. Frontiers of Materials Science, 2017, 11(2): 171-181.

[15] CHEN G D, CHANG H, SUN J, WANG B, YANG L, ZHANG J H, TANG W M. Microstructures and properties of graphite nanoflake/6061Al matrix composites fabricated via spark plasma sintering [J]. Journal of Materials Engineering and Performance, 2020, 29(2): 1235-1244.

[16] NIE Q Q, WEI X, QIN X L, HUANG Y Q, CHEN G H, YANG L, WANG B, TANG W M. Microstructure and properties of graphite nanoflakes/Cu matrix composites fabricated by pressureless sintering and subsequent thermo- mechanical treatment [J]. Diamond and Related Materials, 2020, 108: 594-600.

[17] ESMATI M, SHARIFI H, RAESI M. ATRIANB A, RAJAEE A. Investigation into thermal expansion coefficient, thermal conductivity and thermal stability of Al-graphite composite prepared by powder metallurgy [J]. Journal of Alloys and Compounds, 2019, 773(1): 503-510.

[18] HAMID G A, IMAN E, MORTEZA H, MORTEZA T. The effect of alumina nanoparticles addition on high-temperature wear behavior of intermetallic iron aluminide produced by the spark plasma sintering process [J]. Surface Review and Letters, https://doi.org/10.1142/S0218625X20500043.

[19] MARCELO B, IZABEL F M, DANIEL R. Analysis of sintering parameters by SPS on cemented carbide [J]. Advanced Materials Research, 2011, 223(4): 579-587.

[20] XU Yao. Research on preparation and properties of graphite/copper composites with high thermal conductivity [D]. Wuhan: Huazhong University of Science and Technology, 2013. (in Chinese)

[21] MAO X Z, HUANG Y Q, WANG B H, LIU J W, ZHANG Y J, FENG D, YANG L, SHI C D, WU Y C, TANG W M. Fabrication, microstructures and properties of 50vol.%/ SiCp/6061Al composites via a pressureless sintering technique [J]. Powder Metallurgy, 2018, 61(1): 1-9.

[22] SABOORI A, PAVESE M, BADINI C. Microstructure and thermal conductivity of Al-graphene composites fabricated by powder metallurgy and hot rolling techniques [J]. Acta Metallurgica Sinica (English Letters), 2017, 30(7): 675-687.

[23] LIN D, RICHARD L C, CHENG G J. Single-layer graphene oxide reinforced metal matrix composites by laser sintering: Microstructure and mechanical property enhancement [J]. Acta Materialia, 2014, 80(11): 183-193.

[24] BO K, FAN T X, RU J M. Improved wetting and thermal properties of graphite-Cu composite by Cr-solution immersion method [J]. Diamond and Related Materials, 2016, 65(1): 191-197.

[25] LIU Yi-zhuo-zi, GUO Hong, HAN Yuan-yuan, ZHANG Xi-min, FAN Ye-ming. Preparation of high thermal conductivity flake graphite/aluminum composites by spark plasma sintering [J]. Rare Metals, 2008, 2(3): 259-264. (in Chinese)

[26] TAO Jing-mei, ZHU Xin-kun, TIAN Wei-wei, YANG Peng, YANG Hao. Properties and microstructure of Cu/diamond composites prepared by spark plasma sintering method [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3210-3214.

[27] WANG Y L, DUAN K Y, WANG K K, DAI Z G, XUE Z H. Structure and thermal properties of layered Ti-clad diamond/Cu composites prepared by SPS and HP [J]. Rare Metal Materials and Engineering, 2018, 47(7): 2011-2016.

[28] HONG Yu, WANG Wu-jie, LIU Jia-qin, TANG Wen-ming, WU Yu-cheng. Effect of porosity and interface structures on thermal and mechanical properties of SiCp/6061Al composites with high volume fraction of SiC [J]. Transactions of Nonferrous Metals Society of China, 2019, 29(5): 941-949.

[29] ZENG Cong-yuan. Fabrication and property study of diamond/Al composites used for electronic packaging [D]. Nanjing: Southeast University, 2016. (in Chinese)

[30] NELSON J B, RILEY D P. The thermal expansion of graphite from 15 to 800 °C: Part I. Experimental [J]. Poceedings of the Physical Society, 1945, 57(6): 477-486.

[31] ZHOU C, JI G, CHEN Z, WANG M, ADDAD A, SCHRYVERS D, WANG H. Fabrication, interface characterization and modeling of oriented graphite flakes/Si/Al composites for thermal management applications [J]. Materials and Design, 2014, 63(11): 719-728.

[32] AKHLAGHI F, ZARE B A. Influence of graphite content on the dry sliding and oil impregnated sliding wear behavior of Al 2024-graphite composites produced by in situ powder metallurgy method [J]. Wear, 2009, 266(1-2): 37-45.

[33] LIU Xiao-yun, WANG Weng-guang, WANG Dong, XIAO Bo-lv, NI Ding-rui, MA Zong-yi. Effect of sheet graphite size on the strength and thermal conductivity of sheet graphite/Al composites [J]. Acta Metallurgica Sinica, 2017, 53(7): 869-878. (in Chinese)

[34] LIU Yi-zhuo-zi. Preparation of high thermal-conductivity flake graphite/Al composites [D]. Beijing: Beijing General Research Institute for Nonferrous Metals, 2016. (in Chinese)

[35] HUANG Kai, BAI Hua, ZHU Ying-bin, XUE Chen, JIANG Nan, TONG Xing-sheng. Effect of Cu electroless plating on the surface of graphite on thermal and physical properties of natural flake graphite/Al composites [J]. Acta Materiae Compositae Sinica, 2018, 35(4): 920-926. (in Chinese)

[36] WANG Jun-wei, ZHANG Xian-zhou, XUE Chen, BAI Hua, JIANG Nan, ZHU Ying-bin, WANG Chen, MA Hong-bing. Effect of Si on the surface of graphite on thermal and physical properties of graphite/Al composites [J]. Acta Materiae Compositae Sinica, 2017, 34(4): 608-615. (in Chinese)

[37] LIN W, ZHANG R W, WONG C P. Modeling of thermal conductivity of graphite nanosheet composites [J]. Journal of Electronic Materials, 2010, 39(3): 268-272.

[38] XU J Z, GAO B Z, KANG F Y. A reconstruction of Maxwell model for effective thermal conductivity of composite materials [J]. Applied Thermal Engineering, 2016, 102(6): 972-979.

[39] ZENG Fan-kun. Study on preparation and strengthening methods of flake graphite/Al composites with high thermal conductivity [D]. Wuhan: Jianghan University, 2019: 24. (in Chinese)

[40] TONG Wei, PEI Jiu-yang, CHEN Ming-hai, LIU Ning, XU Wen-lei. Preparation and its thermal properties of graphite flakes/Al composites by pressure infiltration method [J]. Journal of Functional Materials, 2016, 47(S2): s120-s124. (in Chinese)

[41] FENG Hao, YU Jia-kang, XUE Chen, MA Ming-hui. Microstructure and thermal expansion of diamond/Al composites used for electronic packaging [J]. Hot Working Technology, 2010, 39(14): 59-62. (in Chinese)

[42] TURNER P S. Thermal expansion stresses in reinforced plastics [J]. Journal of Research of the National Bureau of Standards, 1946, 37: 239-250.

[43] KERNER E H. The elastic and thermo-elastic properties of composite media [J]. Proceedings of the Physical Society: Section B, 1956, 69(8): 808-813.

[44] CHEN J K. Thermal properties of aluminum–graphite composites by powder metallurgy [J]. Composites B, 2013, 44(1): 698-703.

常 浩 1,孙 健1,陈国宏2,汪 冰3,杨 磊4,张建华1,汤文明1,5

1. 合肥工业大学 材料科学与工程学院,合肥 230009;

2. 国网安徽省电力有限公司 电力科学研究院,合肥 230601;

3. 微系统安徽省重点实验室,合肥 230088;

4. 合肥圣达电子科技实业有限公司,合肥 230088;

5. 高性能铜合金材料及成形加工教育部工程研究中心,合肥 230009

摘 要:采用放电等离子体烧结(SPS)工艺在610 °C制备30%~50%(质量分数)纳米石墨片(GNF)/6061Al基复 合材料,研究烧结压力及GNF含量对复合材料显微组织和力学、热学性能的影响。结果表明,SPS有效抑制 GNFs/6061Al基复合材料中Al4C3等界面反应产物的生成。随着GNF含量的增加,GNFs团聚程度增加,取向分布程度降低,复合材料致密度、抗弯强度及热膨胀系数(CTE)下降,X-Y方向热导率(TC)增大。提高烧结压力,有助于降低GNFs团聚程度,GNFs沿X-Y方向择优分布越明显,复合材料致密度、抗弯强度及TC增大,CTE下降。在610 °C、55 MPa下烧结的50%GNFs/6061Al基复合材料的性能最佳,抗弯强度为72 MPa,TC及CTE分别为254 W/(m·K)和8.5×10-6 K-1 (室温~100 °C,X-Y方向),以及55 W/(m·K)和9.7×10-6 K-1 (Z方向)。

关键词:电子封装复合材料;放电等离子体烧结(SPS);6061铝合金;纳米石墨片(GNF);显微组织;热学性能;力学性能

(Edited by Xiang-qun LI)

Corresponding author: Wen-ming TANG, Tel: +86-551-62901362, E-mail: wmtang@hfut.edu.cn

DOI: 10.1016/S1003-6326(21)65597-8

1003-6326/ 2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press

2021 The Nonferrous Metals Society of China. Published by Elsevier Ltd & Science Press