Isothermal forging of γ-TiAl based alloys

来源期刊:中国有色金属学报(英文版)2003年第6期

论文作者:黄朝晖

文章页码:1325 - 1328

Key words:TiAl alloy; isothermal forging; microstructure

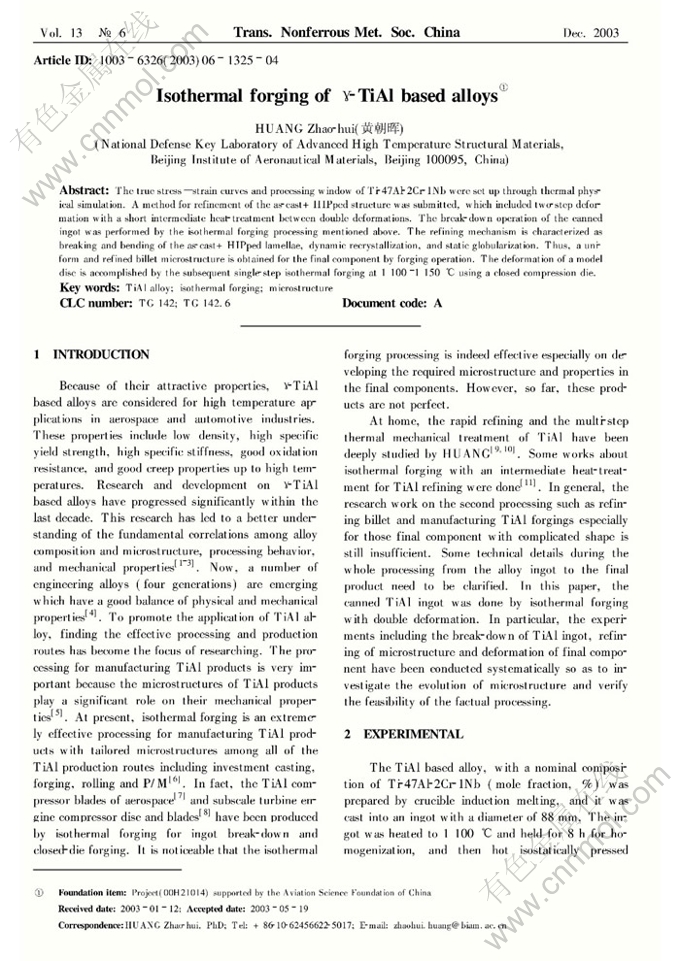

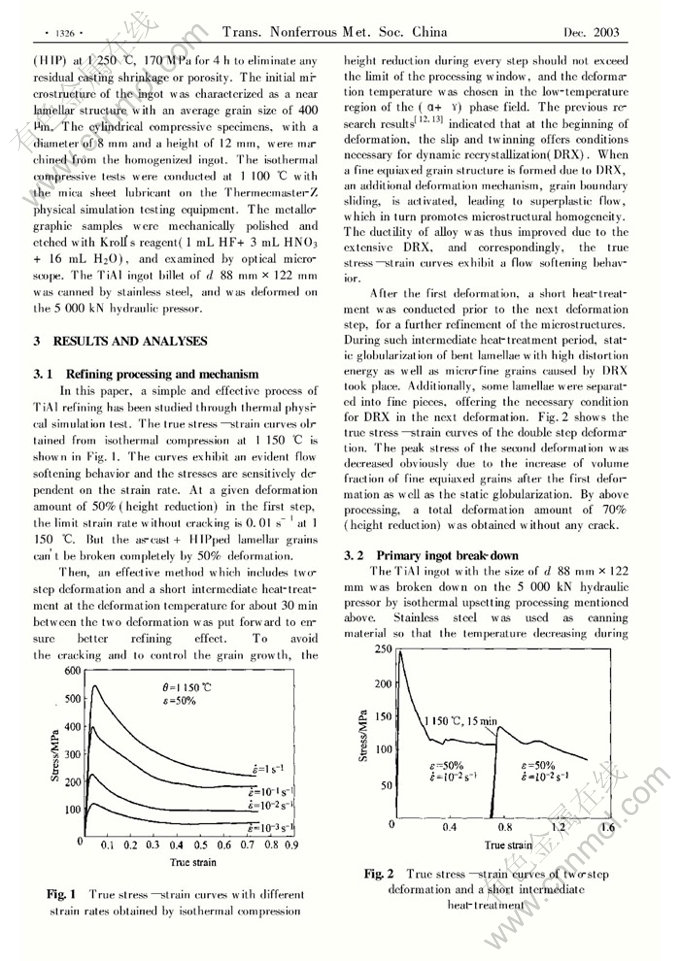

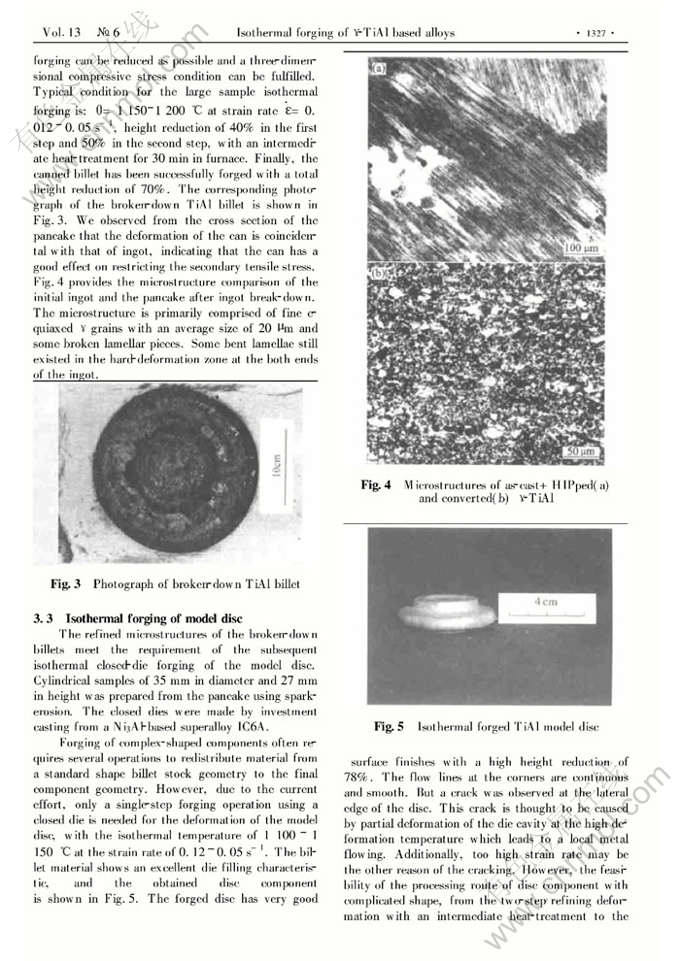

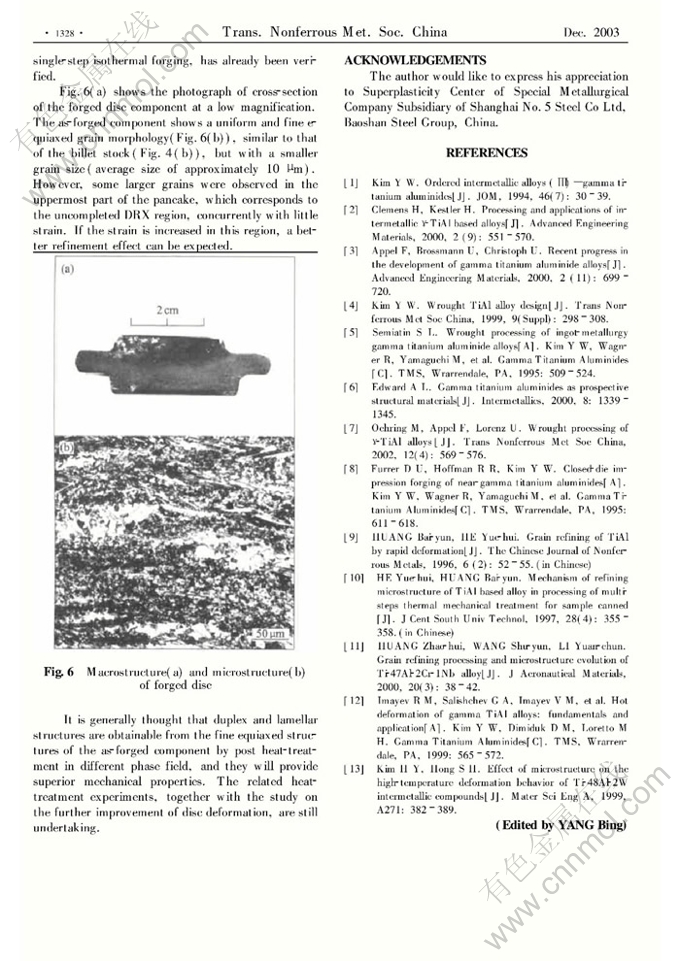

Abstract: The true stress—strain curves and processing window of Ti-47Al-2Cr-1Nb were set up through thermal physical simulation. A method for refinement of the as-cast+HIPped structure was submitted, which included two-step deformation with a short intermediate heat-treatment between double deformations. The break-down operation of the canned ingot was performed by the isothermal forging processing mentioned above. The refining mechanism is characterized as breaking and bending of the as-cast+HIPped lamellae, dynamic recrystallization, and static globularization. Thus, a uniform and refined billet microstructure is obtained for the final component by forging operation. The deformation of a model disc is accomplished by the subsequent single-step isothermal forging at 1100-1150℃ using a closed compression die.