Influence of solution treatment on microstructure and properties of in-situ Mg2Si/AZ91D composites

PENG Lei, CHEN Gang, ZHAO Yu-tao, HUANG Kang, SHAO Yang

School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China

Received 26 October 2010; accepted 11 April 2011

Abstract: The influence of solution treatment on the microstructure and properties of Mg2Si/AZ91D composites fabricated from Mg-SiO2 system via in-situ processing method was investigated. The results show that coarse Chinese script shape Mg2Si phases can be formed by adding SiO2 into AZ91D magnesium alloy with Si content up to 1.5% of the alloy melt. During solution treatment, the morphology and distribution of the coarse Chinese script shape Mg2Si phases are modified. Meanwhile, the β-Mg17Al12 phase is dissolved into the magnesium matrix. With increasing holding time, the coarse Mg2Si phases tend to dissolve, break and spheroidize. After solution treatment at 420 °C for 16 h, Mg2Si phases become the finest and relatively well-distributed phase. The tensile strength and elongation are increased by 14.9% and 38.9%, respectively. It is believed that the Mg2Si phases continuously dissolve and break, and finally the spheroidized Mg2Si particles are obtained due to the interface tension of Mg2Si/Mg interface.

Key words: Mg2Si/AZ91D composites; solution treatment; spheroidized Mg2Si particle; interface tension

1 Introduction

Recently, there have been increasing uses of light-weight materials as structural materials in engineering applications such as automobile, aerospace, and electronic industries. Magnesium matrix composites are considered to have great potential in these modern industries due to their low density, high specific strength and stiffness, excellent damping and shock absorption capacity [1]. And magnesium matrix composites reinforced by in situ synthesized Mg2Si particles have been attracting attention as heat resistant light metal materials. Mg2Si have many advantages such as low density, high melting point and elastic modulus, and low thermal expansion coefficient [2-3]. But on the regular founding condition, because of the low cooling rate, the coarse Chinese script shape inhomogeneously distributed and partly agglomerated Mg2Si phases can be formed in the matrix, leading to a decrease of mechanical properties (especially elongation), castabilities and processabilities [4-5]. At the same time, the existing β-Mg17Al12 phase in the as-cast structure is easily brittle fractured and distributed as mesh structure, thus the mechanical properties of the composites would be damaged [6-7]. Therefore, on the regular founding condition, how to modify the morphology of the coarse Mg2Si phases is the key in in-situ synthesis of Mg2Si/Mg composites. Nowadays, the widely used methods are spray forming, hot extrusion, rapid solidification [1], mechanical alloying [8], modification treatment [9-10], and heat treatment [11], etc.

Solution treatment exhibits good characteristics in refining microstructure and improving the properties of composites, with low-cost and convenience to process. However, the investigation about the influence of solution treatment on the microstructure and mechanical properties of the in-situ Mg2Si/AZ91D matrix composites is very scarce. In this work, in order to obtain fine, well-distributed, and spheroidized Mg2Si phase, solution treatment at 420 °C for different holding times and their effects on the microstructure and mechanical properties of the Mg2Si/AZ91D composites are investigated.

2 Experimental

Industrial AZ91D magnesium alloy whose chemical composition is listed in Table 1. Pure magnesium, pure aluminum and pure zinc (purity of 99.9%), and SiO2 powder (analytical reagent) were used as the starting materials. Mg2Si/AZ91D composite was fabricated by adding SiO2 powder into AZ91D magnesium alloy, in which Si took up 1.5% (mass fraction) of the alloy melt. And about 2% (volume fraction) Mg2Si phase was formed.

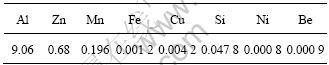

Table 1 Chemical composition of AZ91D alloy (mass fraction, %)

AZ91D alloy was melted in a crucible resistance furnace (power 5 kW, permitted highest temperature 1 000 °C) which was protected under a mixed gas atmosphere of SF6 (0.5%, volume fraction) and CO2. Firstly, the alloy was put into the preheated crucible at 680 °C under the protection gas. Then the SiO2 powder packed by aluminum foil was added into the alloy melt with the bell-jar at 740 °C. In order to avoid the powder floating on the melt surface, the bell-jar must be kept for 30 s. The melt was held at 740 °C for 20 min, and then manually stirred for about 2 min using a coated stainless steel impeller. Finally, the melt was poured into a copper mould (preheating at 200 °C, size of 80 mm×70 mm× 10 mm) to obtain Mg2Si/AZ91D composite casting.

Solution treatment was processed in a heat treatment furnace (with a temperature accuracy of ±1 °C ), and the samples were covered by graphite powder. The solution treatment was carried out at 420 °C for different holding times (4-20 h), then quenched into the cool water at 15 °C (the transit time ≤3 s).

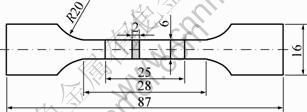

Metallographic samples were prepared in accordance with the standard procedures with a final polishing and then etching with 0.5% HNO3+ethanol at room temperature for about 10 s. The microstructures of metallographic samples were examined by Olympus optical microscope and JEOL JSM-6460LV type scanning electron microscope (SEM) equipped with an energy dispersive spectrometer (EDS). XRD (Japan, SHIMADZU XRD-6000) and SEM-EDS analyses were used to detect the in-situ formed intermetallics of Mg2Si/AZ91D composites. The tensile properties of the composites at room temperature were determined by the CSS-44000 electric universal material testing machine (tensile rate 0.5 mm/min), and the elongation to failure was obtained based on the average of three tests. The size of the tensile specimens is shown in Fig. 1.

Fig. 1 Sketch of tensile specimen (Unit: mm)

3 Results and discussion

3.1 Microstructure and phase analysis of Mg2Si/ AZ91D composites

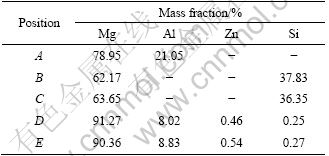

Figure 2 shows the SEM images of the Mg2Si/AZ91D composites as-cast and solution-treated at 420 °C for 16 h, respectively. And the EDS results of the positions A, B, C, D and E in Fig. 2 are listed in Table 2. From Table 2, the discontinuous is β-Mg17Al12 phase (position A) and the Chinese script shape is Mg2Si phase (position B) in Fig. 2(a). Meanwhile, after solution treatment at 420 °C for 16 h, the spheroidized shape appeared which was identified as Mg2Si phase (position C in Fig. 2(b)). The positions D and E are matrixes near Mg2Si phases in the as-cast and solutionized composites. The Si content in the matrix near Mg2Si phases is 0.25% and 0.27% (mass fraction), respectively, indicating that little Si dissolves in the matrix after solution treatment and Si is still in the form of Mg2Si. Therefore, it can be concluded that the volume fraction of Mg2Si phase keeps constant.

Fig. 2 SEM images of Mg2Si/AZ91D composites: (a) As-cast; (b) Solution treated at 420 °C for 16 h

Table 2 EDS results of positions A, B, C, D and E in Fig. 2

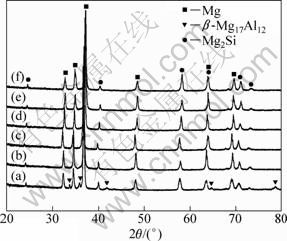

Figure 3 shows the XRD patterns of the Mg2Si/AZ91D composites as-cast and solution-treated at 420 °C for different times. As shown in Fig. 3(a), the as-cast composite, which was fabricated from Mg-SiO2 system via in-situ processing method, is mainly composed of Mg, β-Mg17Al12 phases and Mg2Si phases, which is in consistent with Fig. 2(a). Figures 3(b)-(f) show the diffraction patterns of Mg2Si/AZ91D composites after solution treatment at 420 °C for 4-20 h. It is obviously found that β-Mg17A112 peaks completely disappeared, and only Mg and Mg2Si phases left in the composites. This phenomenon indicates that the β-Mg17Al12 phases in the Mg2Si/AZ91D composite have been dissolved into the matrix after solution treatment.

Fig. 3 XRD patterns of Mg2Si/AZ91D composites: (a) As-cast; (b) 420 °C, 4 h; (c) 420 °C, 8 h; (d) 420 °C, 12 h; (e) 420 °C, 16 h; (f) 420 °C, 20 h

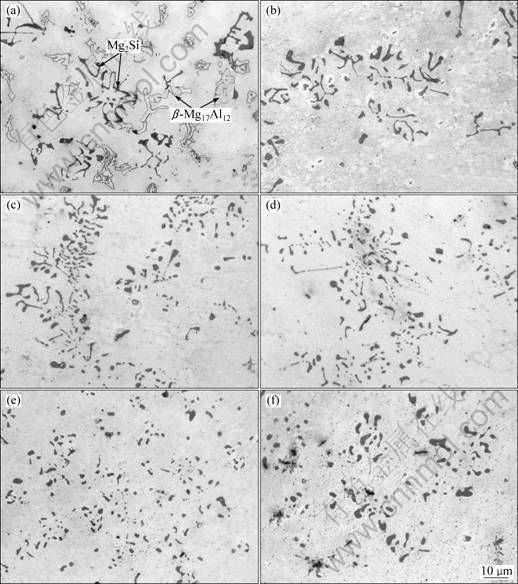

Figure 4 shows the microstructures of the as-cast and solution-treated Mg2Si/AZ91D composites. In Fig. 4(a), it can be observed that the as-cast Mg2Si/AZ91D composite is mainly composed of Mg, grey β-Mg17Al12 phase, and Mg2Si phases with Chinese script shape, which is in accordance with Fig. 2(a) and Fig. 3(a). Figures 4(b)-(f) show the microstructures of the composites solutionized at 420 °C for 4, 8, 12, 16 and 20 h, respectively. After being solutionized for 4 h, the Chinese script shape Mg2Si phases began to dissolve and break, and the sharp tip of Mg2Si phases tended to be obtuse. The grey β-Mg17Al12 phase is hardly found (Fig. 4(b)). The reason is that the β-Mg17Al12 phase can easily dissolve into the matrix to form supersaturated α-Mg solid solution at 420 °C [12-13]. It is proved from Fig. 4(c) that the Chinese script shape Mg2Si phases partly dissolved and broke, and parts of Mg2Si phases spheroidized. Further increasing the holding time to 12 h, the Mg2Si phase was further broken and spheroidized, and the size also became finer, but the distribution of Mg2Si phase was not uniform (Fig. 4(d)). With the holding time increasing to 16 h, Mg2Si phase turned to be the finest and best relatively distributed as well as mostly spheroidized (Fig. 4(e)), with the size in 0.5-5 μm. After being solutionized for 20 h, the Mg2Si phases were still distributed uniformly but the size tended to increase.

3.2 Room temperature mechanical properties of Mg2Si/AZ91D composites

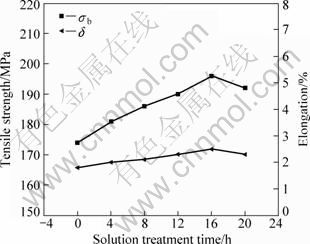

The room temperature mechanical properties of as-cast and solution treated Mg2Si/AZ91D composites at 420 °C for different holding times are presented in Fig. 5. It can be seen that both the tensile strength σb and the elongation δ of the solutionized composites are increased with the extending of holding time, which indicates that solution treatment can greatly improve the mechanical properties of the Mg2Si/AZ91D composites. More specifically, the composites solution-treated for 16 h exhibit the best tensile strength and elongation, as well as the finest size spheroidization of Mg2Si particles and distribution (Fig. 4(e)). Compared with the as-cast composite, the tensile strength of the composite solution treated for 16 h is increased by 14.9% and the elongation is increased by 38.9%. After being solutionized for 20 h, the mechanical properties of the composites have a slightly decline due to the size increasing. Overall, the mechanical properties of Mg2Si/AZ91D composites experienced an earlier raising and later decreasing with the prolonging holding time. This interesting phenomenon must be related to the modification of the Mg2Si phases during the solution treatment course.

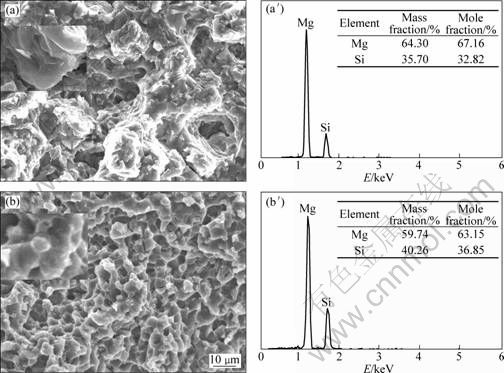

Figure 6 shows the SEM images and EDS spectra of the tensile fracture surface of as-cast and solution treated composites at 420 °C for 16 h. From Fig. 6(a), it can be found that the Chinese script shape Mg2Si phases are assumed to be the layer flake shape distributed in the composites. Moreover, the tensile fracture of the composites is cleaved as shown in Fig. 6(a). After solution treatment at 420 °C for 16 h, the number of dimples increased evidently and became deeper and smaller (Fig. 6(b)). Tear ridges also appeared in this process, leading to the coexistence of dimple and tear ridges in the tensile fracture of solutionized composites. Therefore, it is reasonable to conclude that the fracture mode of Mg2Si/AZ91D composite changed from cleavage pattern to quasi-cleavage fracture after the solution treatment. These results agree well with the microstructures of Mg2Si/AZ91D composites displayed in Fig. 4.

Fig. 4 OM microstructures of as-cast and solution-treated Mg2Si/AZ91D composites: (a) As-cast; (b) 420 °C, 4 h; (c) 420 °C, 8 h; (d) 420 °C, 12 h; (e) 420 °C, 16 h; (f) 420 °C, 20 h

Fig. 5 Room temperature mechanical properties of Mg2Si/ AZ91D composites

3.3 Discussion

It is well known that when SiO2 powder is added into AZ91D magnesium alloy melts, an exothermic reaction will happen and Si can be produced by this reaction. Furthermore, the solubility of Si in Mg is very limited, only about 0.003% (mole fraction) [4, 14]. This means that the diffusion of Si atoms into Mg matrix composites is difficult and it is easy for them to react with Mg atoms to form Mg2Si. This can be explained by the fact that the vibration energy and the diffusion coefficient of the atoms are improved in the solution treatment process. In addition, the defects such as vacancy, dislocation and subboundary will be also increased in the alloys. All these factors lead to an accelerated diffusion of Si atoms into the composites, as well as an easier diffusion along the grain boundaries and interfaces. Therefore, the Mg2Si/Mg interface is the possible and only diffusion way for Si atoms. These results are in accordance with that of LU et al [11].

Fig. 6 SEM images and EDS spectra of tensile fracture surface of as-cast and solution-treated composites: (a) As-cast; (b) Solution treated at 420 °C for 16 h

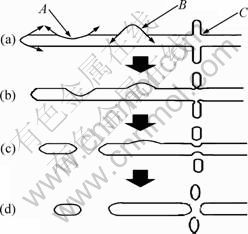

Figure 7 shows the sketch of the spheroidization process of the Chinese script shape Mg2Si phase. Actually, the Chinese script shape Mg2Si phase takes a dendrite character. From the microcosmic view, there always exist concaves and convexities on the straight long branches of Mg2Si dendrite along the interface between Mg2Si phase and Mg matrix [12], as shown in points A and B in Fig. 7(a). Considering the different curvatures of these positions, the concentration gradient of Si is formed. During solution-treatment at 420 °C, the activity of Si is enhanced with increasing temperature. Owing to the effect of surface tension of Mg2Si/Mg interface, the Si atoms would diffuse continuously from the position with large curvature and high Si concentration to around interface with lower Si concentration, indicating a downhill diffusion occurs. The Si atoms enter the magnesium matrix in a plane position to form Mg2Si again, resulting in the local decomposition and morphology changing of the Mg2Si particles. As a result, the concaves will become more sunken while the convexities become smoother. Finally, the concaves of the straight long branches of Mg2Si dendrite will be broken and the spheroidization of the sub-particles continues.

In addition, the secondary and tertiary dendrites are also observed on the Chinese script shape Mg2Si phases. A concave pit with large curvature and high Si concentration is presented on the bottom of the dendrite arms [15], as the position C shown in Fig. 7(a). Therefore, the Si atoms would diffuse from this position to flat interface with lower Si concentration during the solution treatment, leading to the breaking of local Si concentration balance. In order to keep the balance of Si concentration, the Mg2Si phase in these positions would dissolve gradually to supply the shortage of Si concentration. Thus, the curvature radii would be increased and the balance of interface tension of Mg2Si/Mg interface in these positions is damaged. Consequently, under the effect of interface tension, the concave pit with larger curvature at the dendrite arm bottom is dissolved and finally broken. At the same time, in the Mg matrix with flat interface, the Mg2Si phases would form due to the supersaturation of Si concentration. After the secondary dendrite and/or tertiary dendrite being dissolved and broken, there must be concaves on the trunk of Mg2Si dendrite, and then the Mg2Si would transform to spheroidization particles as position A shown in Fig. 7(a). With prolonging the treatment time, the granule Mg2Si phases continuously dissolve, diffuse, and precipitate, and the spheroidized and uniformly distributed Mg2Si phases are formed finally.

Fig. 7 Sketch of spheroidization process of Chinese script shape Mg2Si phase

As we all know that the presence of fine and uniformly dispersed phases along the grain boundaries can act as an effective pinning to the dislocation motion, thus improving the properties of the alloys [3-9]. Apparently, the brittle Mg2Si phases in coarse Chinese script shape in the as-cast Mg2Si/AZ91D composite would give a detrimental effect on the mechanical properties of the composite since the long cracks can easily nucleate along the interface between Chinese script shape Mg2Si particles and Mg matrix [14, 16-17]. Whereas, with extending the holding time of solution treatment, the morphology of the Mg2Si phase changes from the initial Chinese script shape to spheroidized particles and the distribution is relatively uniform. Therefore, the interface combination between Mg2Si and Mg matrix can be enhanced and the extending trend of microcracks would decrease. As a result, the mechanical properties of the Mg2Si/AZ91D composite are remarkably improved (Fig. 5).

According to the previous investigations, the hard and brittle phase of reticular β-Mg17Al12 discontinuously distributes along the grain boundary, which is easy to generate microcrack and deteriorate the performance of the alloy [18]. However, the discontinuous and brittle β-Mg17Al12 phase is dissolved into the Mg matrix after solution treatment, resulting in the microcracks being difficult to nucleate and extend [13]. Consequently, the mechanical properties of the Mg2Si/AZ91D composites are improved after solution treatment.

As mentioned above, both the morphology and distribution of the Mg2Si phases and β-Mg17Al12 phases in the matrix greatly affect the mechanical properties of composites. In addition, the spheroidization process of Mg2Si may be influenced by the dissolving of β-Mg17Al12 phases during solution treatment, but more investigations are needed in the future.

4 Conclusions

1) The solution treatment can evidently modify the morphologies and the distribution of the coarse Chinese script shape Mg2Si phases in the Mg2Si/AZ91D composites. With increasing the holding time, the Si atoms at different curvature positions on Mg2Si phases diffuse due to the effects of interface tension of Mg2Si/Mg interface during the solution treatment process, and the coarse Chinese script shape Mg2Si phases tend to dissolve, break, and spheroidize. Meanwhile, the β-Mg17Al12 phase completely dissolves into the matrix to form supersaturated α-Mg solid solution. After solution treatment at 420 °C for 16 h, Mg2Si phase becomes the finest and relatively well-distributed one.

2) With prolonging the treatment time, both the tensile strength and elongation are improved. After holding for 16 h, the solution treated composite exhibits higher tensile strength and elongation than others. It is found that the fracture mode of Mg2Si/AZ91D composite changes from cleavage patterns into quasi-cleavage fracture.

References

[1] CHEN Zhen-hua. Magnesium alloy [M]. Beijing: Chemical Industry Press, 2004: 20-89. (In Chinese)

[2] ZHANG Song-li, ZHAO Yu-tao, CHEN Gang. In-situ (Mg2Si+MgO)/Mg composites fabricated from AZ91-Al2(SiO3)3 with assistance of high-energy ultrasonic field [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 2096-2099.

[3] CHEN K, LI Z Q, LIU J S, YANG N J, SUN Y D, BIAN S G. The effect of Ba addition on microstructure of in situ synthesized Mg2Si/Mg-Zn-Si composites [J]. Journal of Alloys and Compounds, 2009, 487: 293-297.

[4] CHEN Xiao, FU Gao-sheng, QIAN Kuang-wu, WANG Lian-deng. Thermodynamics and kinetics of in-situ MgO/Mg2Si reinforced magnesium matrix composite [J]. Foundry Technology, 2003, 24(4): 321-323. (in Chinese)

[5] YUAN G Y, LIU Z Y, WANG Q D, DING W J. Microstructure refinement of Mg-Al-Zn-Si alloys [J]. Materials Letters, 2002, 56: 53-58.

[6] KAVEH M A, ALIREZA T, FARZAD K. The effect of different content of Al, RE and Si element on the microstructure, mechanical and creep properties of Mg-Al alloys [J]. Materials Science and Engineering A, 2009, 532(1-2): 1-6.

[7] BRONFIN B, KATSIR M, AGHION E. Preparation and solidification features of AS21 magnesium alloy [J]. Materials Science and Engineering A, 2001, 302: 46-50.

[8] LU L, THONG K K, GUPTA M. Mg-based composite reinforced by Mg2Si [J]. Composites Science and Technology, 2003, 63: 627-632.

[9] SRINIVASAN A, PILLAI U T S, PAI B C. Effects of elemental additions (Si and Sb) on the ageing behavior of AZ91 magnesium alloy [J]. Materials Science and Engineering A, 2010, 527(24-25): 6543-6550.

[10] GARIBOLDI E, SPIGARELLI S. An analysis of strain–time relationships for creep in an as-cast Mg-Al-Si alloy [J]. Materials and Design, 2003, 24: 445-453.

[11] LU Y Z, WANG Q D, ZENG X Q. Behavior of Mg-6Al-xSi alloys during solution heat treatment at 420 °C [J]. Materials Science and Engineering A, 2001, 301: 255-2581.

[12] JIA S Z, XU C J, GUO X F. Influence of solution heat treatment and ageing on microstructure and properties of in-situ Mg2Si/Mg-Al matrix composite [J]. Transactions of Materials and Heat Treatment, 2006, 27(6): 25-28.

[13] YANG You, WU Yao-da. Influences of heat treatment on fatigue properties of AZ91D cast magnesium alloys [J]. Foundry, 2009, 58(4): 383-386. (in Chinese)

[14] WANG Jun. Study on the in-situ fabrication and properties of AZ91 composites reinforced by Mg2Si particles [D]. Zhenjiang: Jiangsu University, 2010: 7-16. (in Chinese)

[15] JIN Yun-xue, ZHANG Er-lin, ZENG Song-yan, ZHU Zhao-jun. Effect of heat treatment on morphology of TiC in Ti-6Al-2C alloy [J]. Materials Engineering, 2001, 8: 18-21. (in Chinese)

[16] MA G R, LI X L, XIAO L, LI Q F. Effect of holding temperature on microstructure of an AS91 alloy during semisolid isothermal heat treatment [J]. Journal of Alloys and Compounds, 2010, 496: 577-581.

[17] PEKGULERYUZ M O, AVEKSIAN M M. Magnesium alloying, some potentials for alloy development [J]. Light Metal, 1992, 42(12): 679-686.

[18] GUTMAN I, GOTMAN I, SHAPIRO M. Kinetics and mechanism of periodic structure formation at SiO2/Mg interface [J]. Acta Materialia, 2006, 54: 4677-4684.

固溶处理对原位合成Mg2Si/AZ91D复合材料组织及性能的影响

彭 蕾,陈 刚,赵玉涛,黄 康,邵 阳

江苏大学 材料科学与工程学院,镇江 212013

摘 要:研究固溶处理对Mg-SiO2体系原位合成制备的Mg2Si/AZ91D复合材料的组织和性能的影响。结果表明:AZ91D镁合金在加入SiO2(其中Si占合金质量的1.5%)后,出现了粗大的汉字状Mg2Si相,固溶处理改变了Mg2Si相的形貌与分布,并使β-Mg17Al12相溶入到基体中;随着固溶时间的增加,汉字状的Mg2Si相熔断、球化,在420 °C保温16 h时Mg2Si相最为细小、弥散;固溶处理后复合材料的抗拉强度增加了14.9%,伸长率增加了38.9%。固溶处理时在Mg2Si/Mg界面间的界面张力作用下,Mg2Si相不断熔断、聚集、扩散,最终获得球化的Mg2Si相。

关键词:Mg2Si/AZ91D复合材料;固溶处理;Mg2Si颗粒球化;界面张力

(Edited by YUAN Sai-qian)

Foundation item: Project (BG2007030) supported by High-tech Research Program of Jiangsu Province, China; Project (07KJA43008) supported by the Natural Science Foundation of Jiangsu Province, China; Project (20070299004) supported by the Specialized Research Fund for the Doctoral Program of Higher Education of China

Corresponding author: ZHAO Yu-tao; Tel: +86-511-88797658; E-mail: zhaoyt@ujs.edu.cn

DOI: 10.1016/S1003-6326(11)61021-2